A lining scraping coating equipment and scraping coating method thereof

A kind of equipment and lining technology, which is applied in the direction of coating, liquid coating device on the surface, etc., can solve problems such as thickness out of control, achieve the effects of improving precision and efficiency, reducing occupational hazards, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

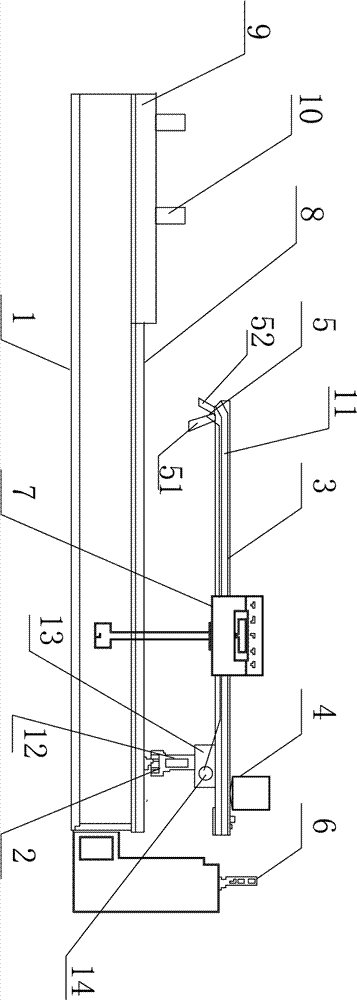

[0026] Such as figure 1 As shown, a liner scraping equipment includes a base 1, a feeding system 2 is installed on the base 1, a lifting mechanism 13 is installed on the feeding system 2, a supporting plate 3 is installed on the lifting mechanism 13, and a supporting plate 3 is installed on the supporting plate 3. There is a hopper 4, and a scraper coating assembly 5 is installed at one end of the supporting plate 3;

[0027] In a further solution, the base 1 is provided with a bracket 9 for supporting the equipment to be scraped, and a pulley 10 is installed on the bracket 9 .

[0028] In a further solution, the base 1 is provided with a guide rail 8 , and the feeding system 2 is installed on the guide rail 8 .

[0029] In a further solution, the feed system 2 is connected with a servo motor 12 .

[0030] In a further solution, the lifting mechanism 13 is also connected with a motor.

[0031] In a further solution, the master mold 51 is connected with the cylinder 14 .

...

Embodiment 2

[0035] The method for scraping the lining of the engine by using the above-mentioned equipment comprises the following steps:

[0036] 1) Install the engine on the pulley 10, adjust its installation height and ensure horizontal installation, and then adjust the height of the supporting plate 3 through the lifting mechanism, so that the part of the engine to be scraped is in contact with the master model 51, and then the scraped Slurry is added in the hopper 4;

[0037] 2) Control the engine to rotate on the pulley 10, the slurry in the hopper 4 reaches the scraper 52 through the screw extrusion device, and the slurry is scraped onto the engine through the scraper 52, and the thickness and trajectory of the scraper are based on the model The position and trajectory of 51 are determined. During the scraping process, the feed system 2 and the lifting mechanism 13 drive the pallet 3, the former 51 and the scraper 52 to move;

[0038] Through the rotation of the engine itself and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com