Patents

Literature

76results about How to "Fit compact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

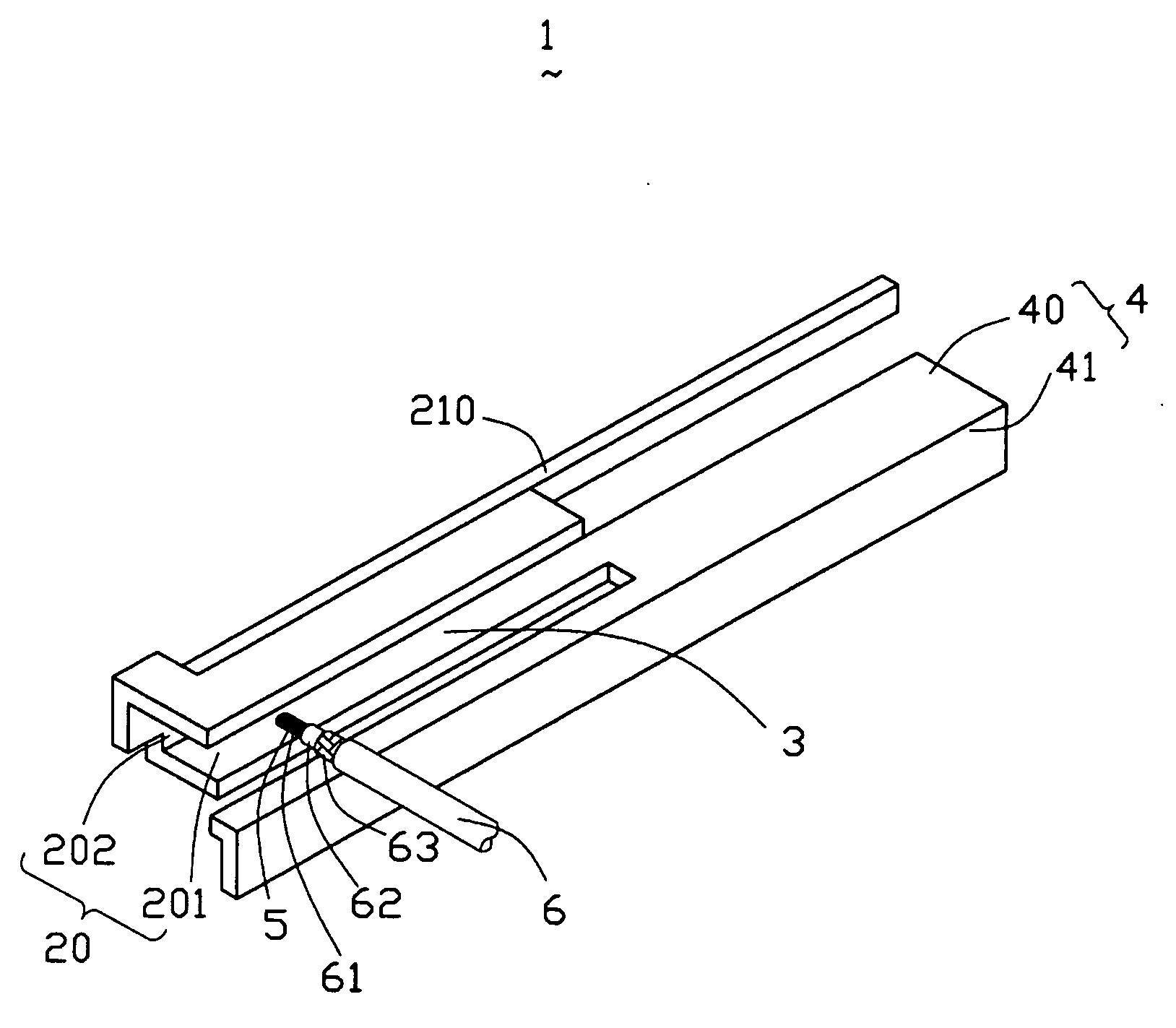

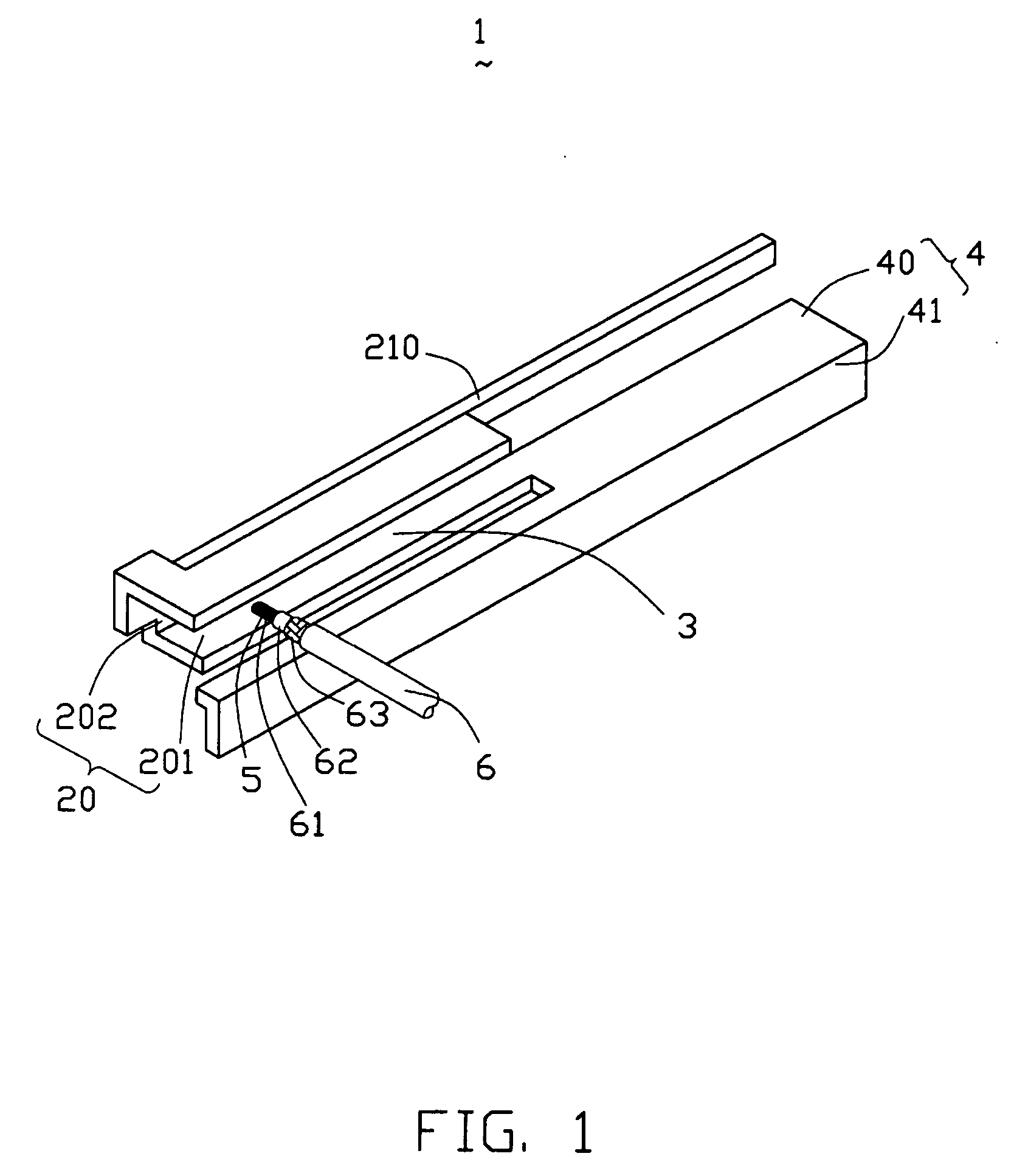

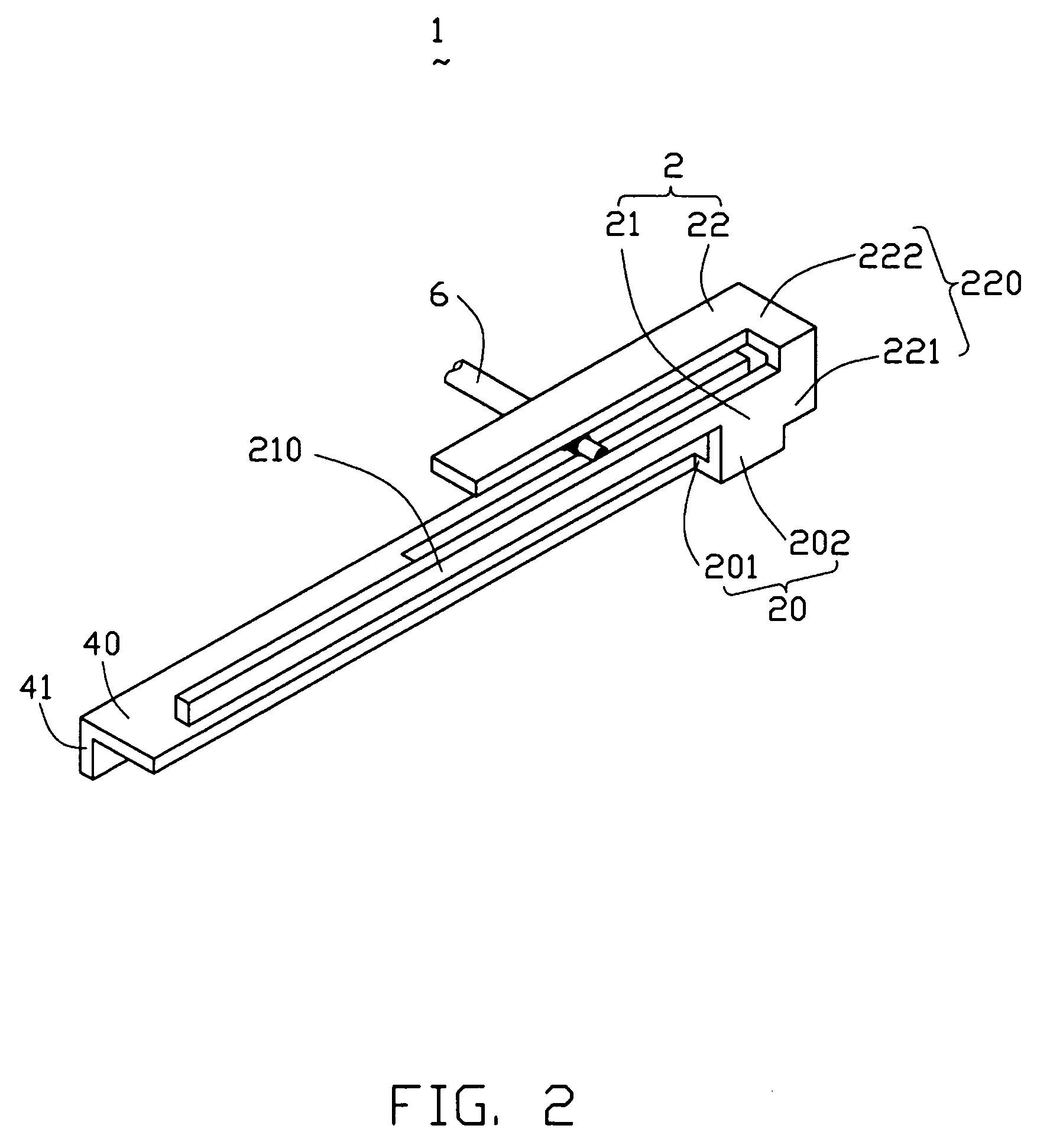

Multi-band antenna

InactiveUS20070040750A1Compact structureFit compactSimultaneous aerial operationsAntenna supports/mountingsMulti bandElectrical devices

A multi-band antenna used in an electronic device, comprising: a grounding element; a radiating element comprises a first radiating section operating at 900 MHz frequency band and a second radiating section operating at 1800 MHz frequency band; and a connecting section connecting the radiating element and the grounding element. The grounding element, the radiating element, and the connecting element locate respectively in the different plane. The whole structure of the multi-band antenna of the present invention designed combining the inner structure of the notebook or other portable electrical device. The multi-band antenna is suit to be installed in a notebook or other portable electrical device because the multi-band antenna occupies small space.

Owner:HON HAI PRECISION IND CO LTD

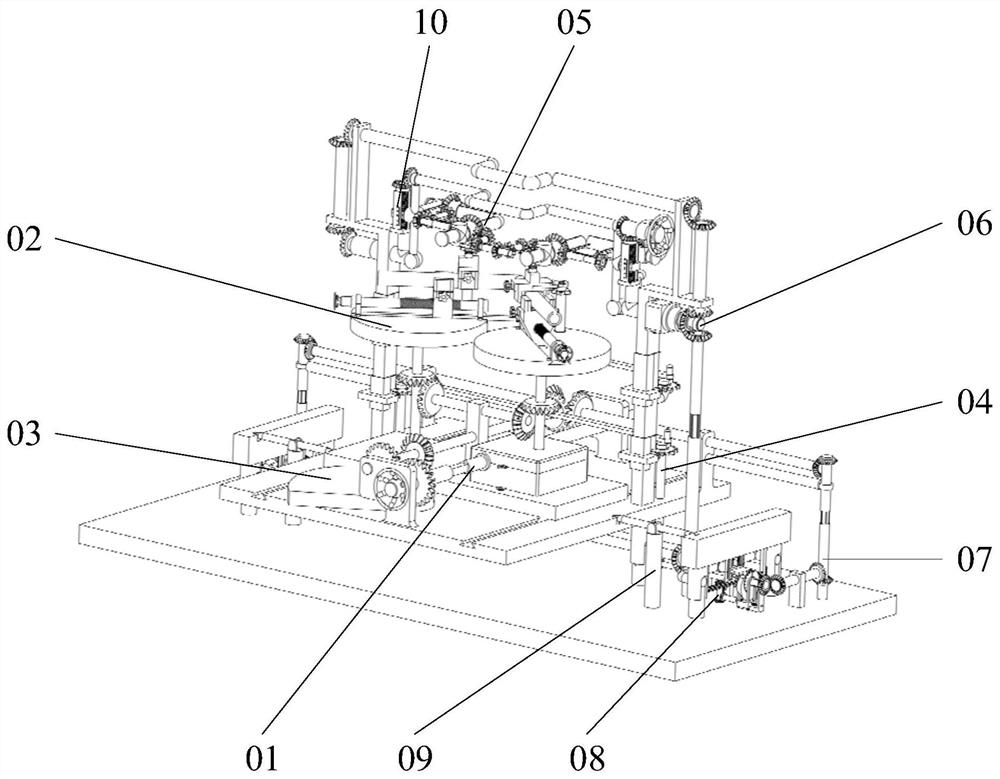

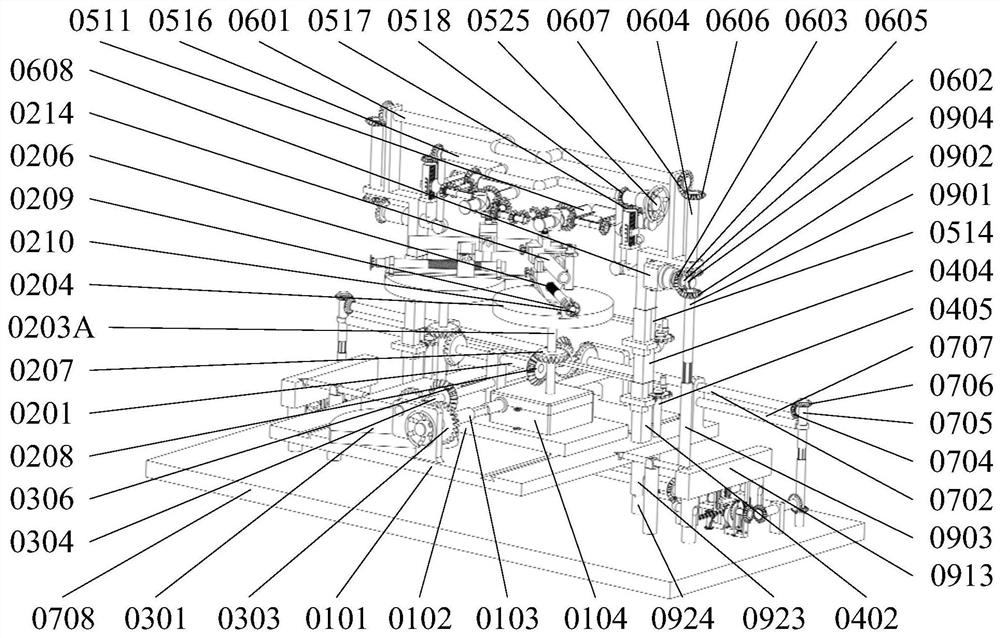

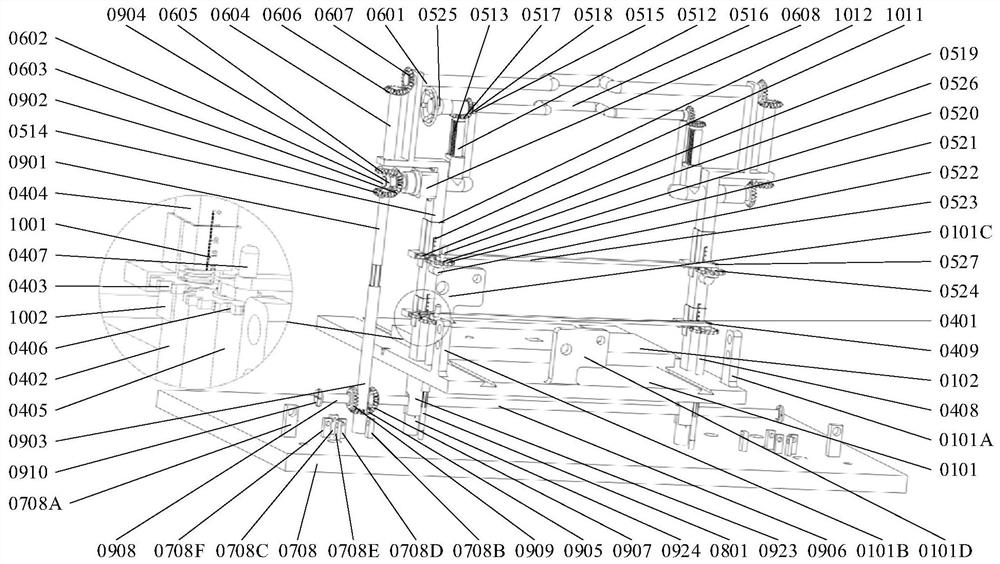

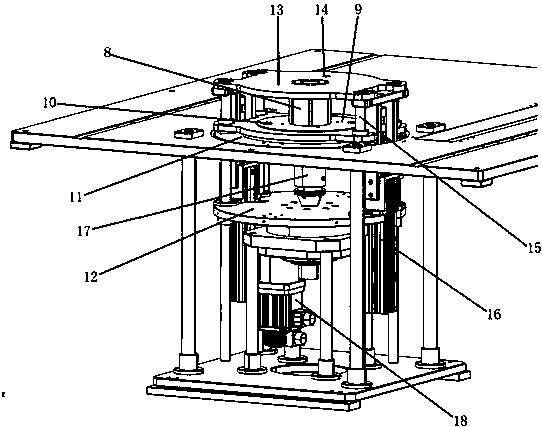

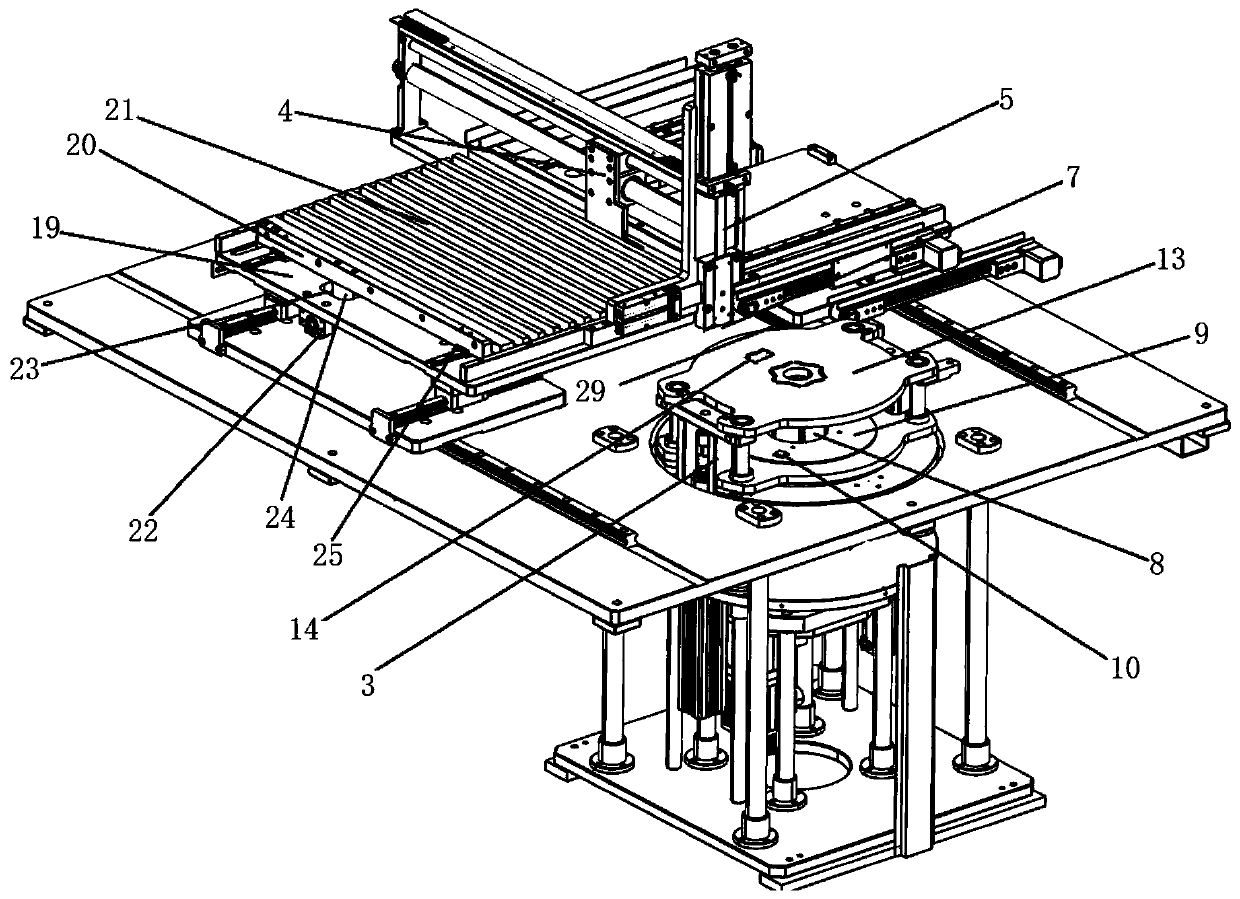

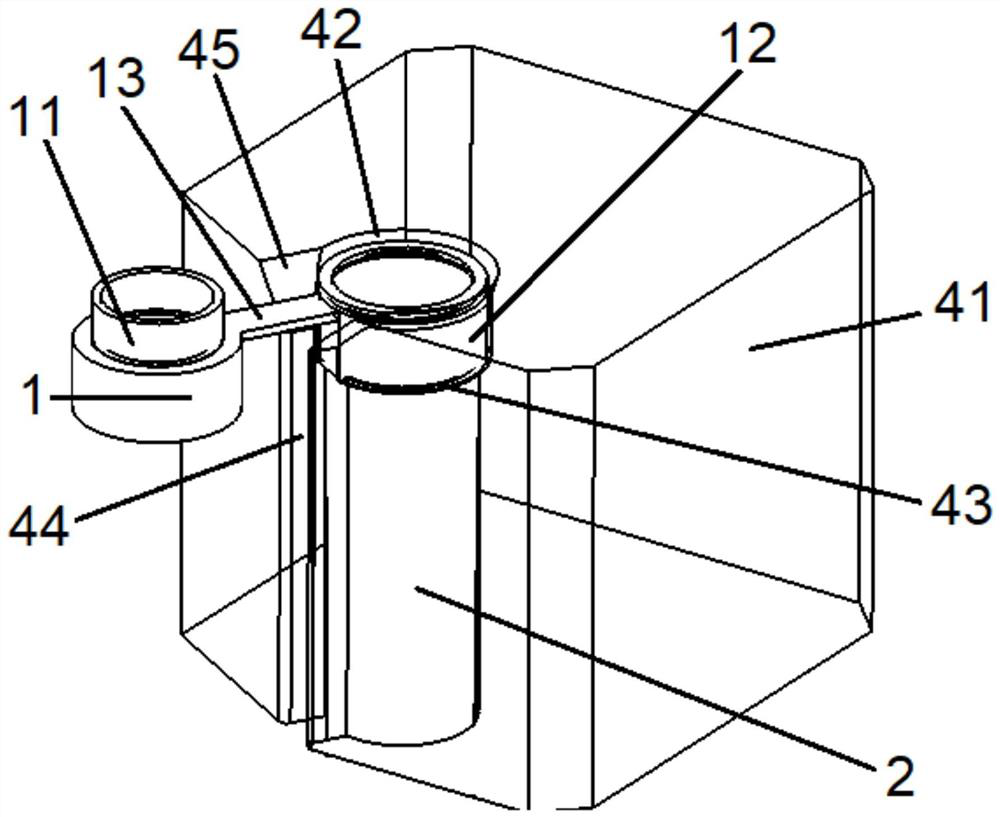

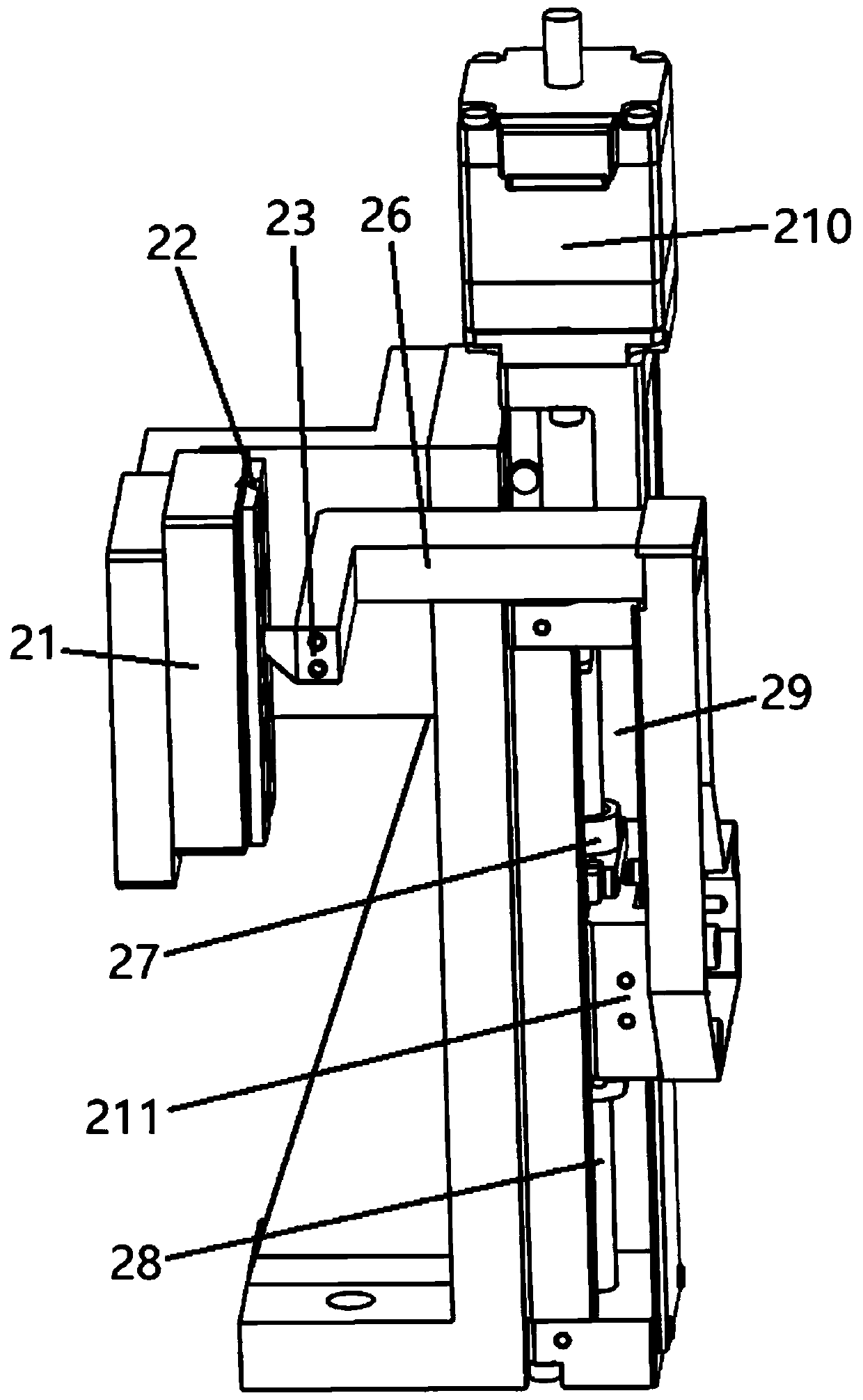

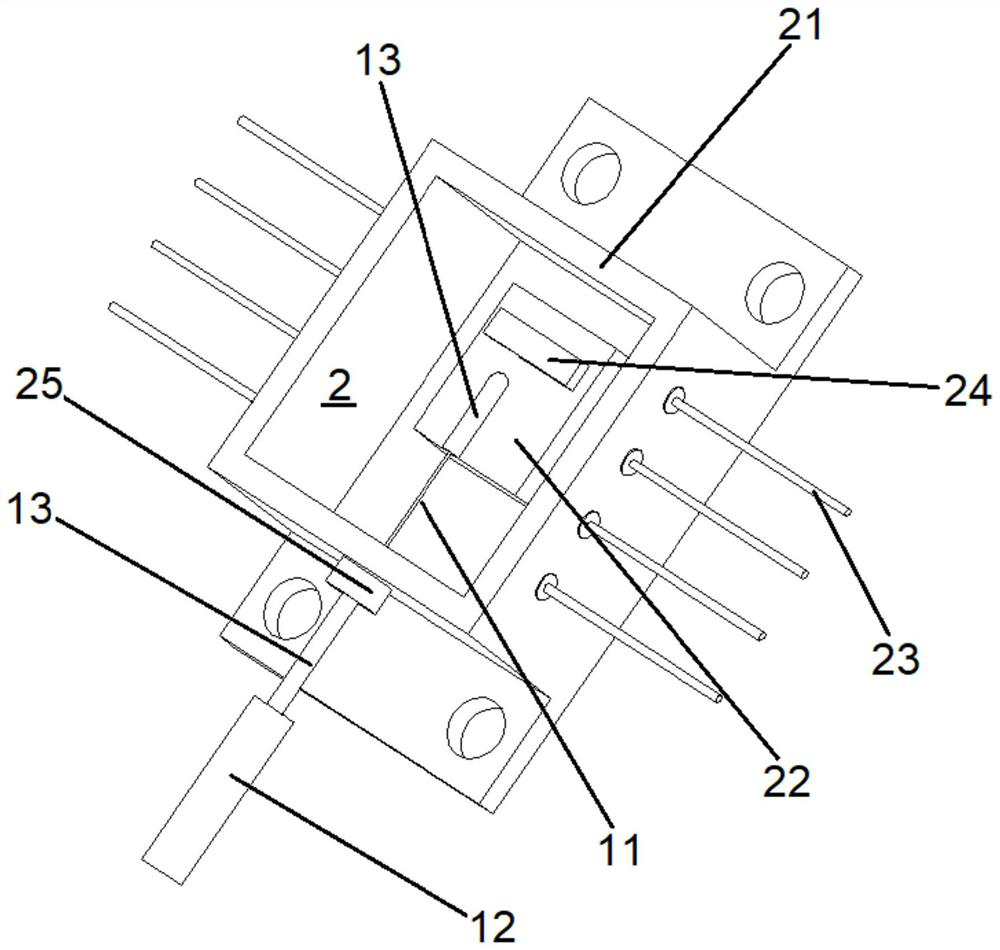

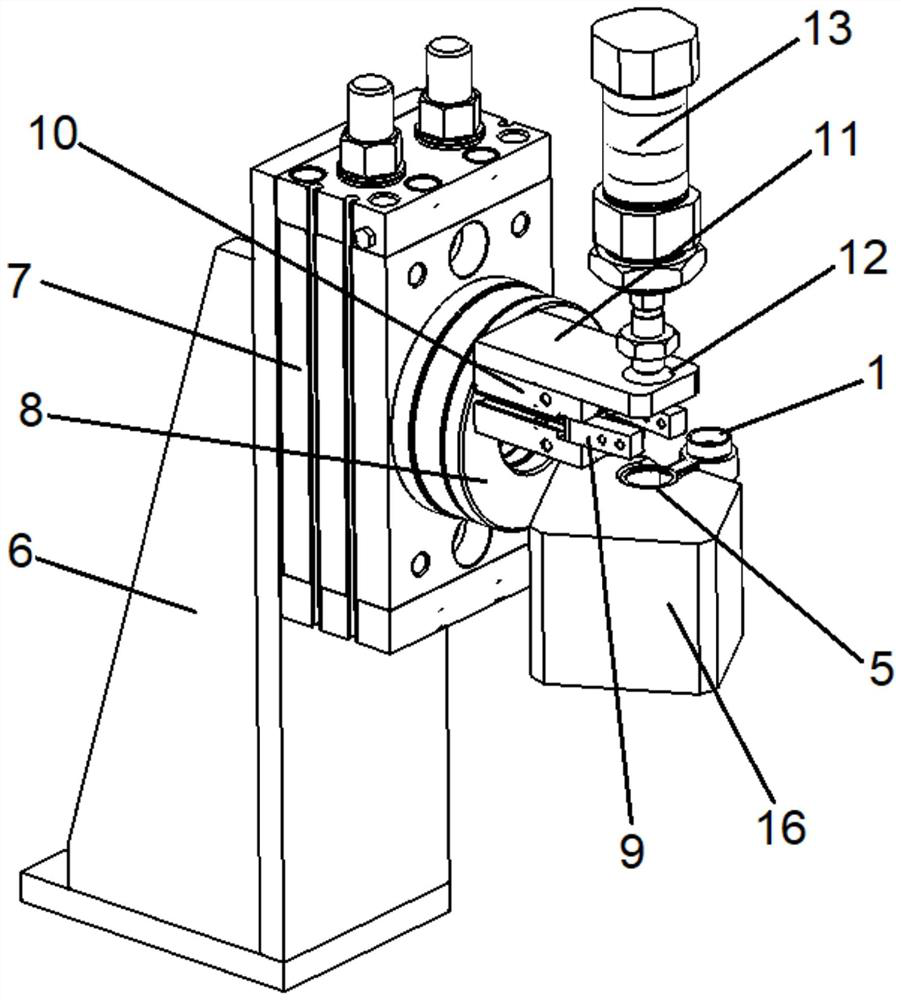

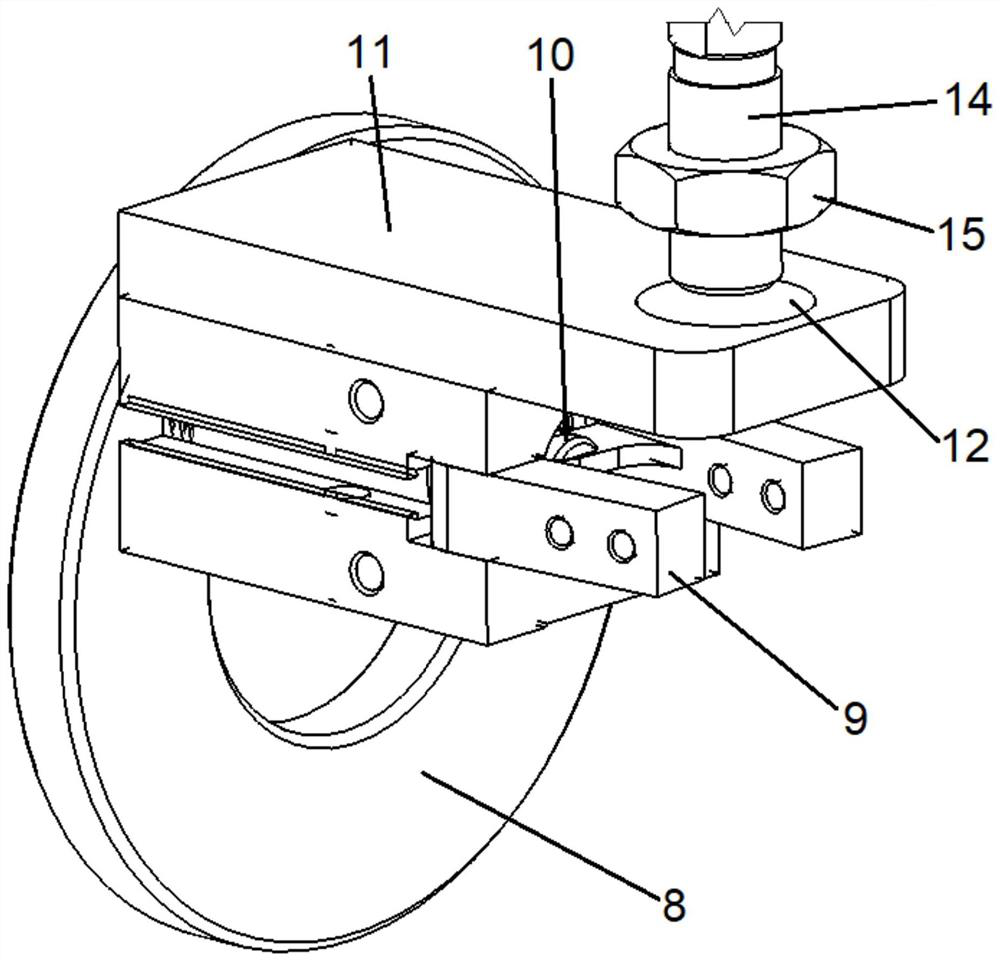

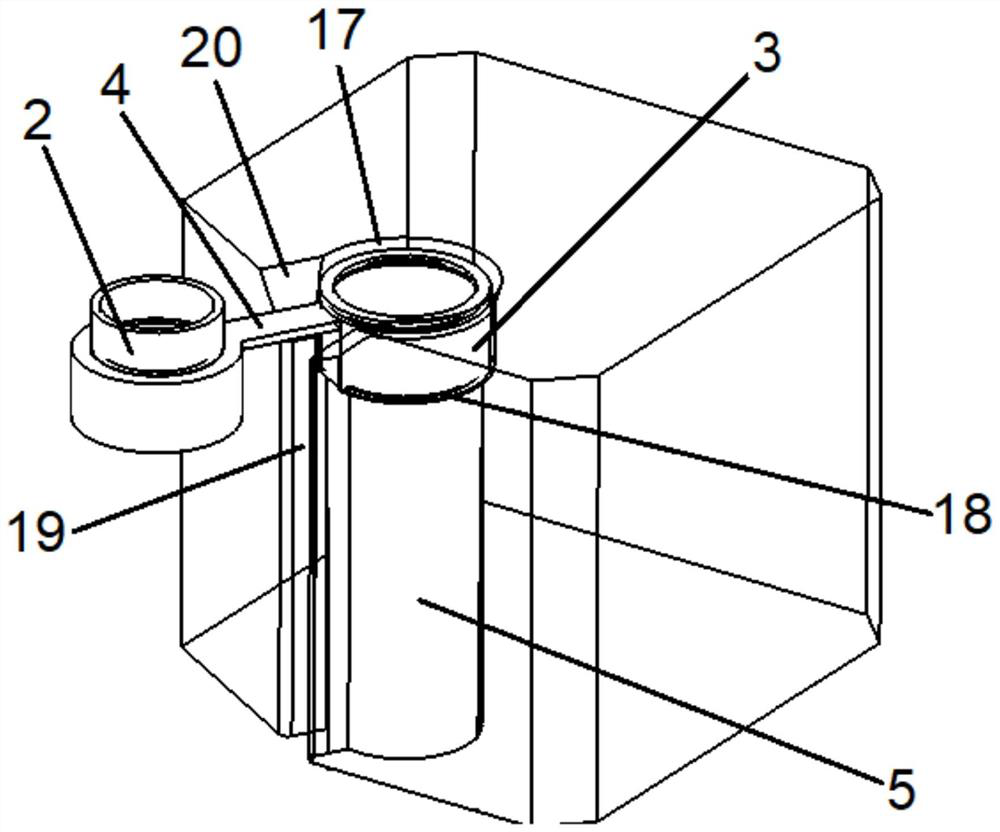

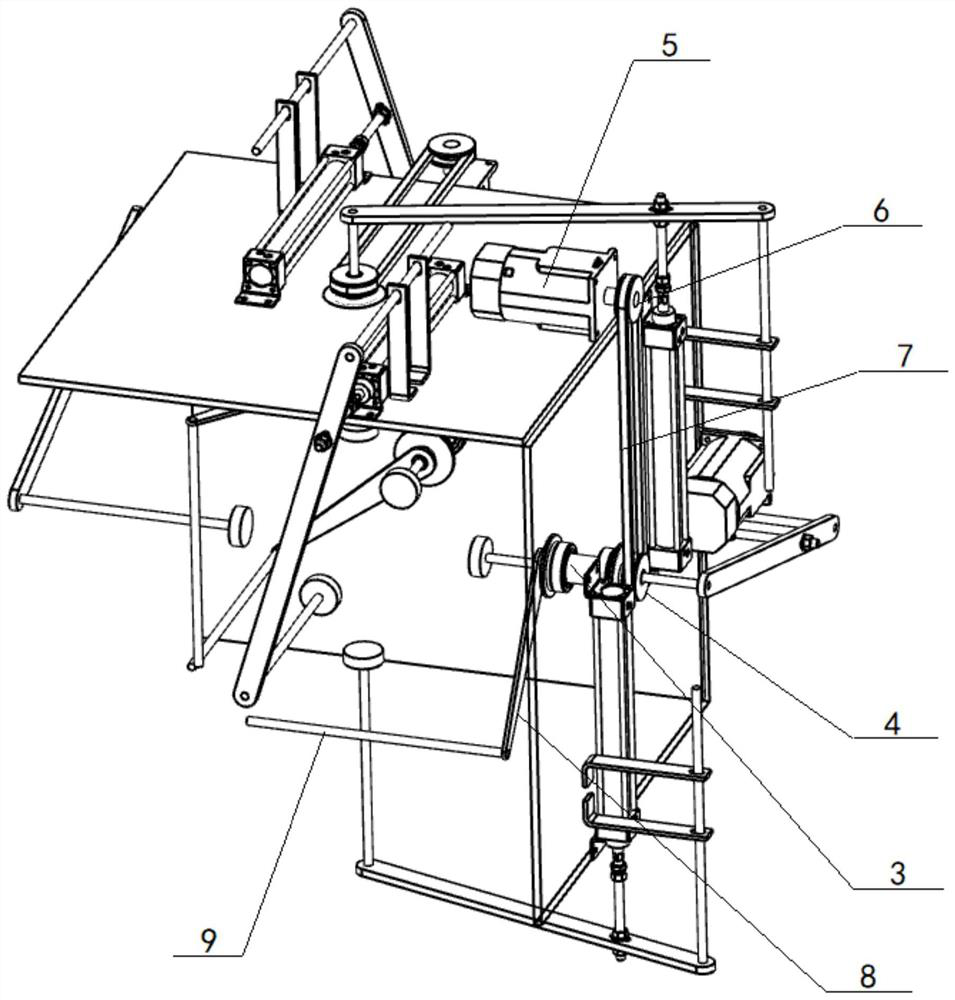

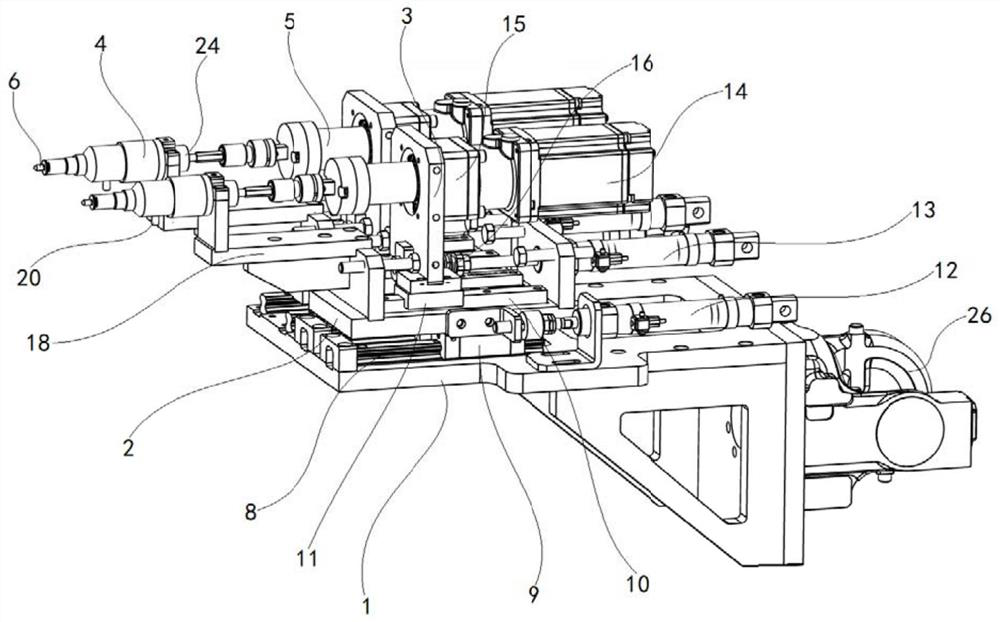

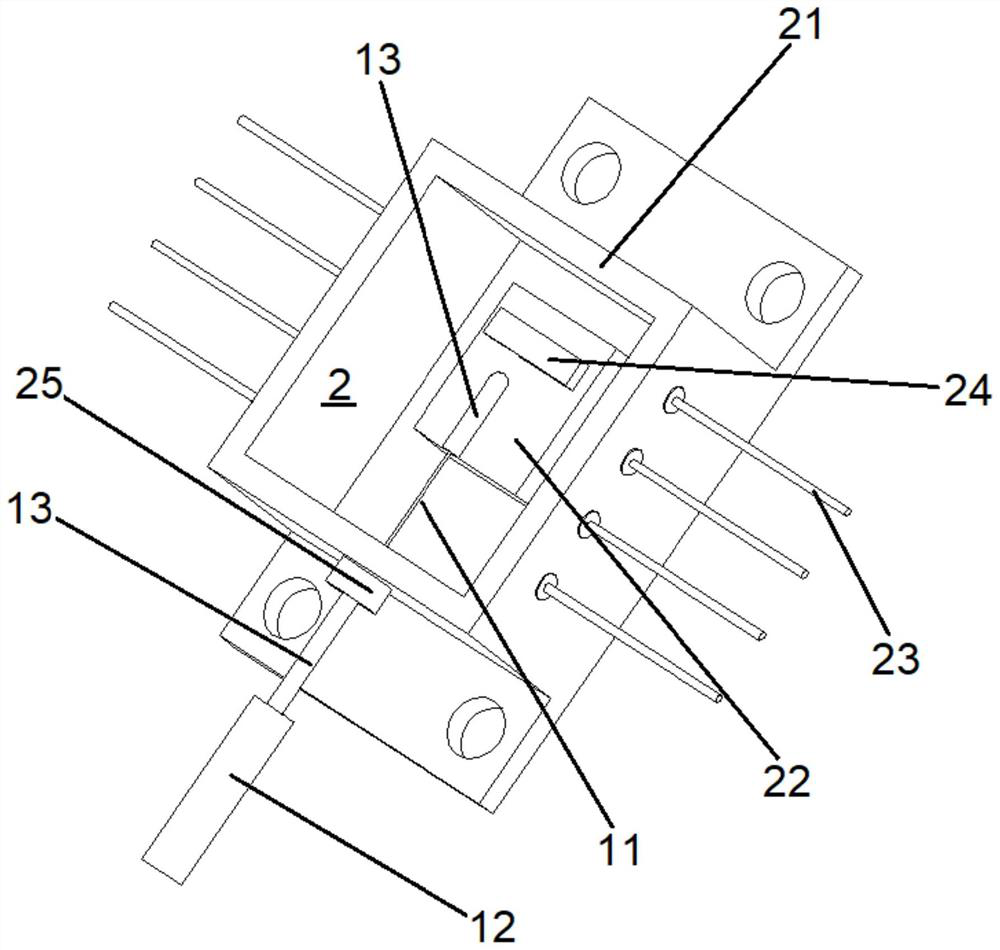

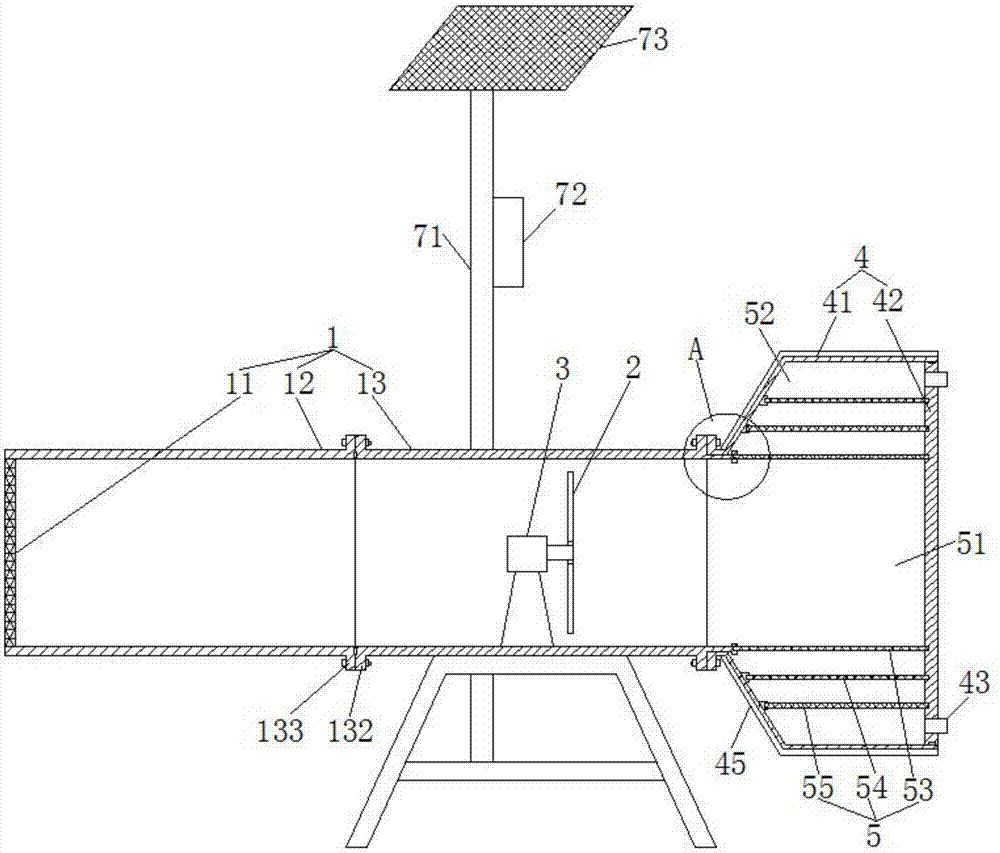

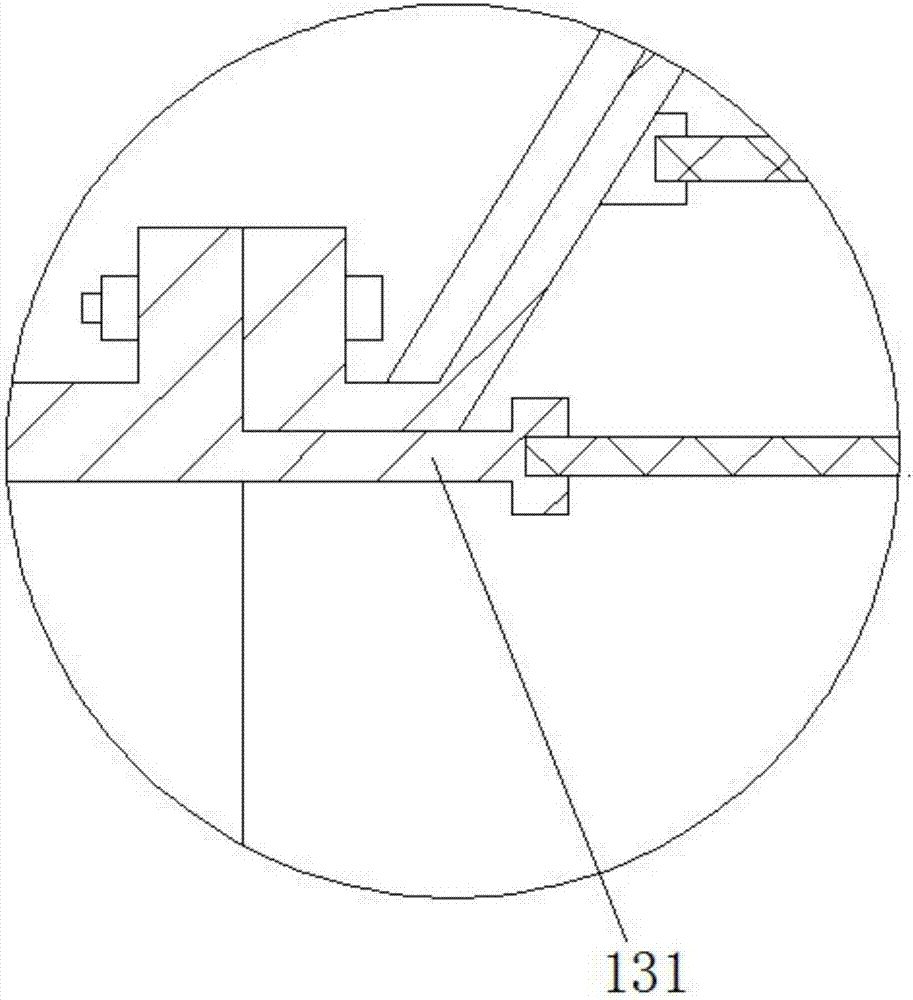

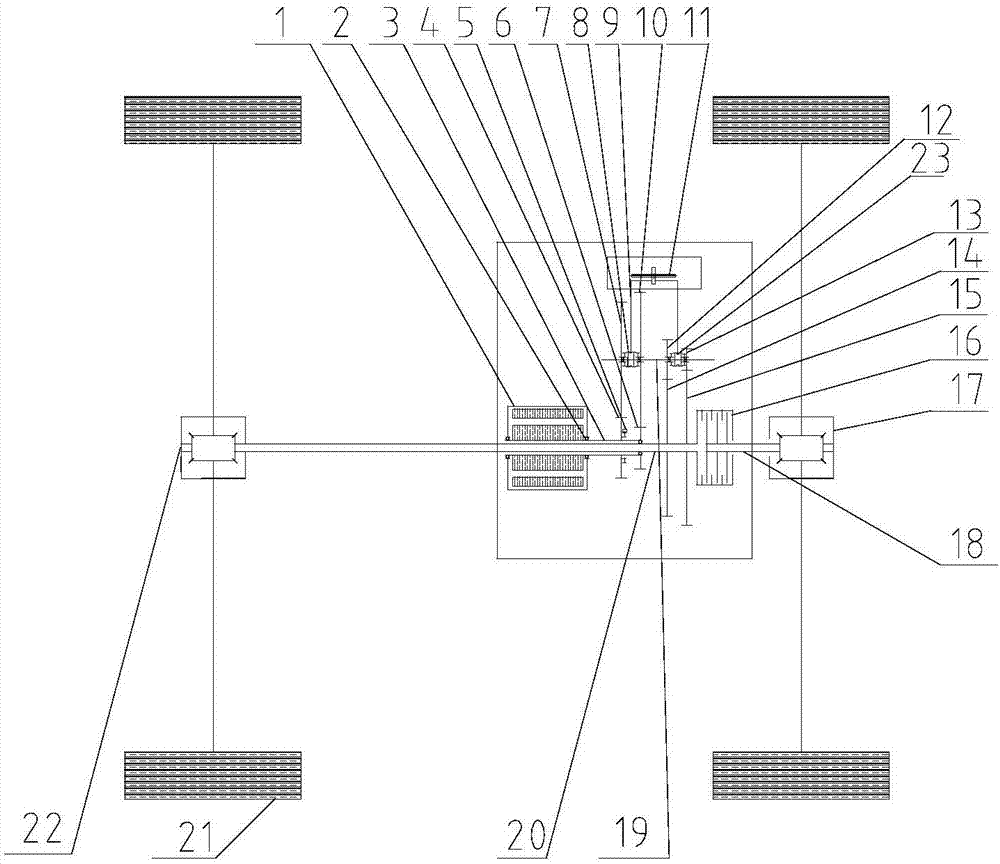

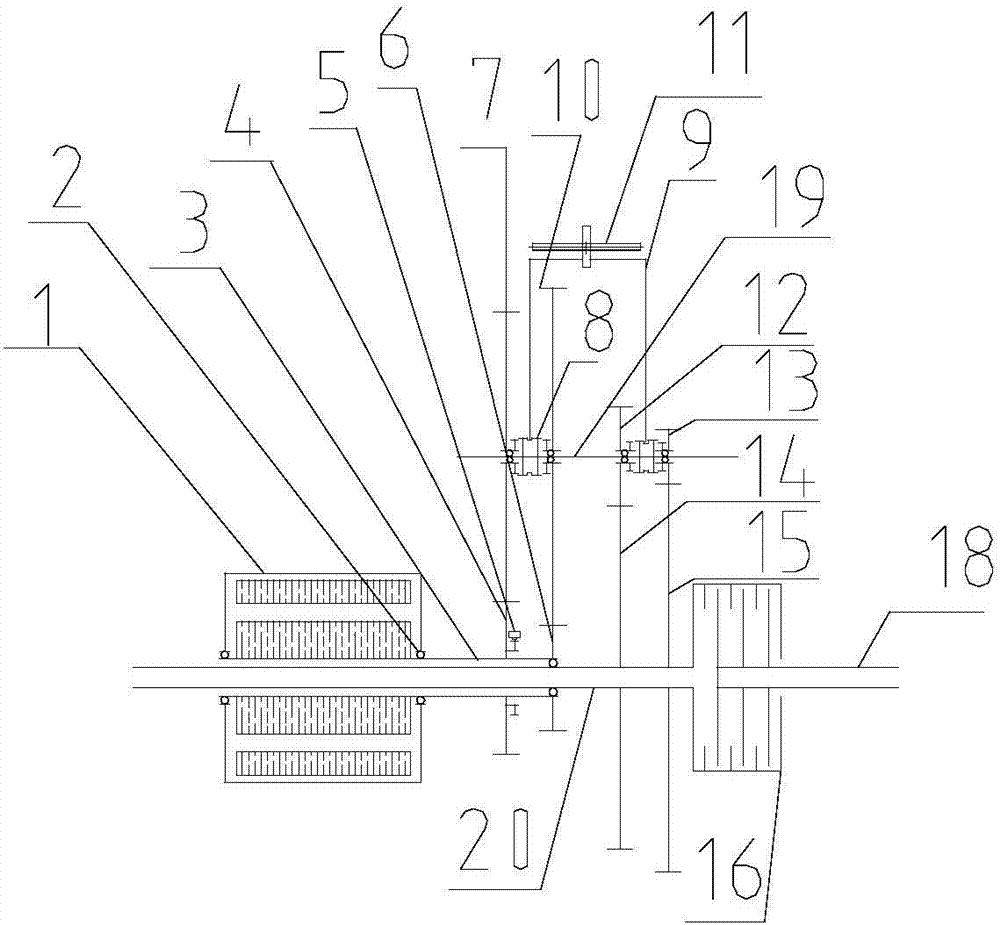

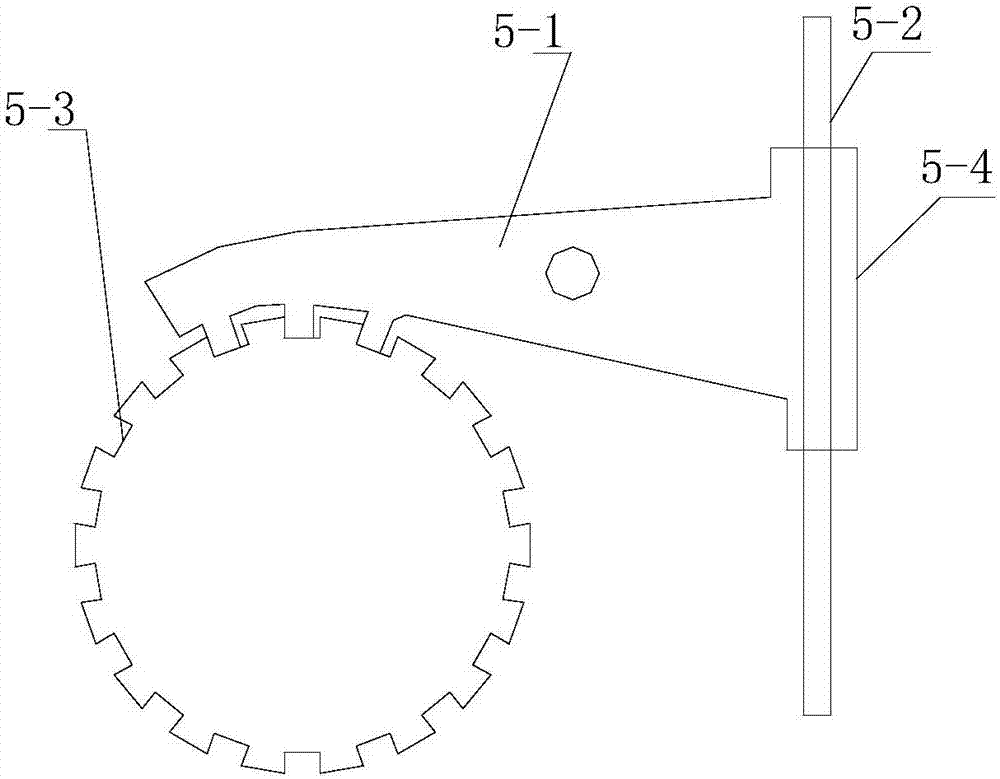

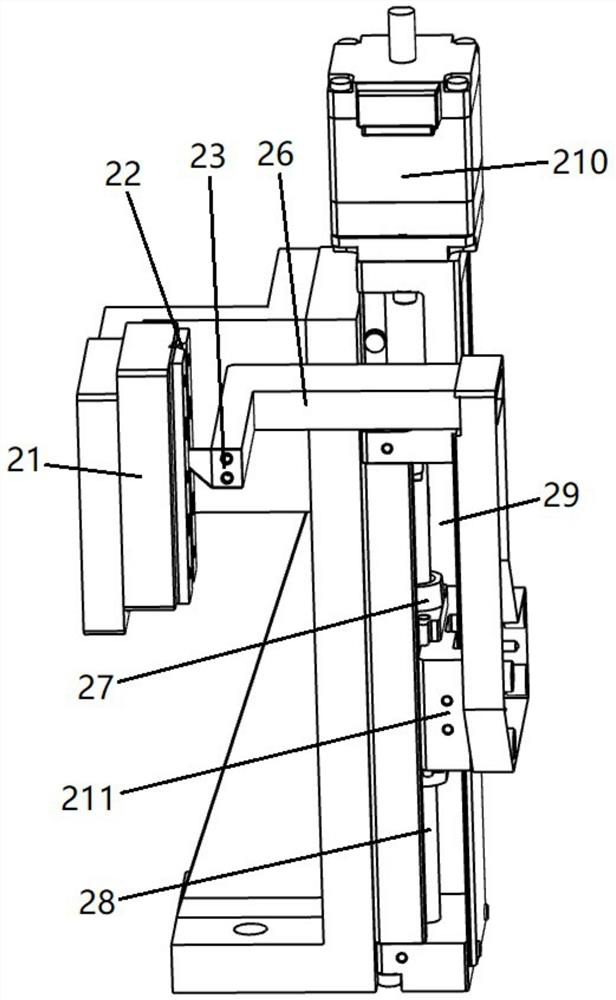

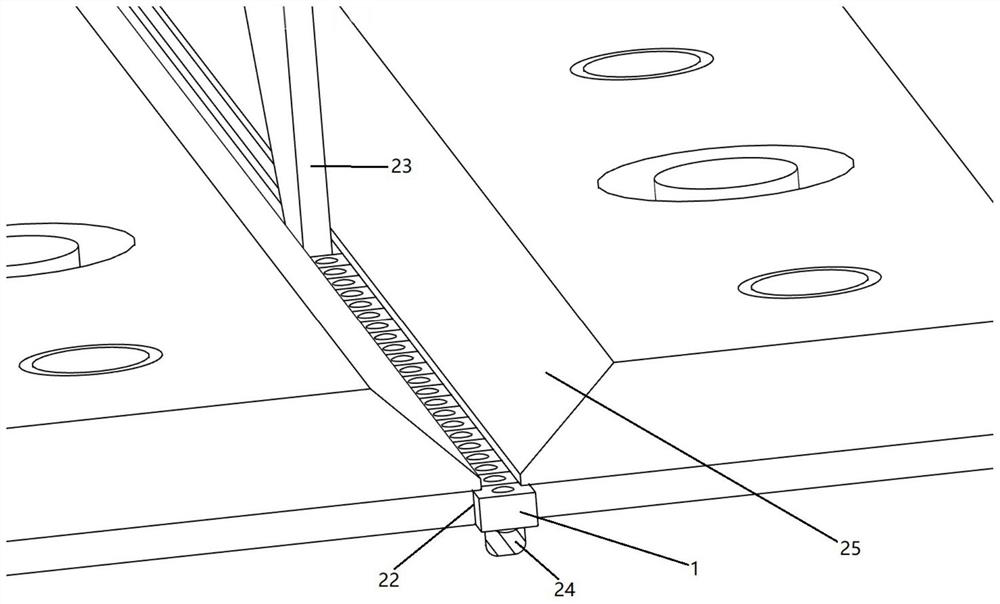

Adjusting device for welding round pipes at different angles

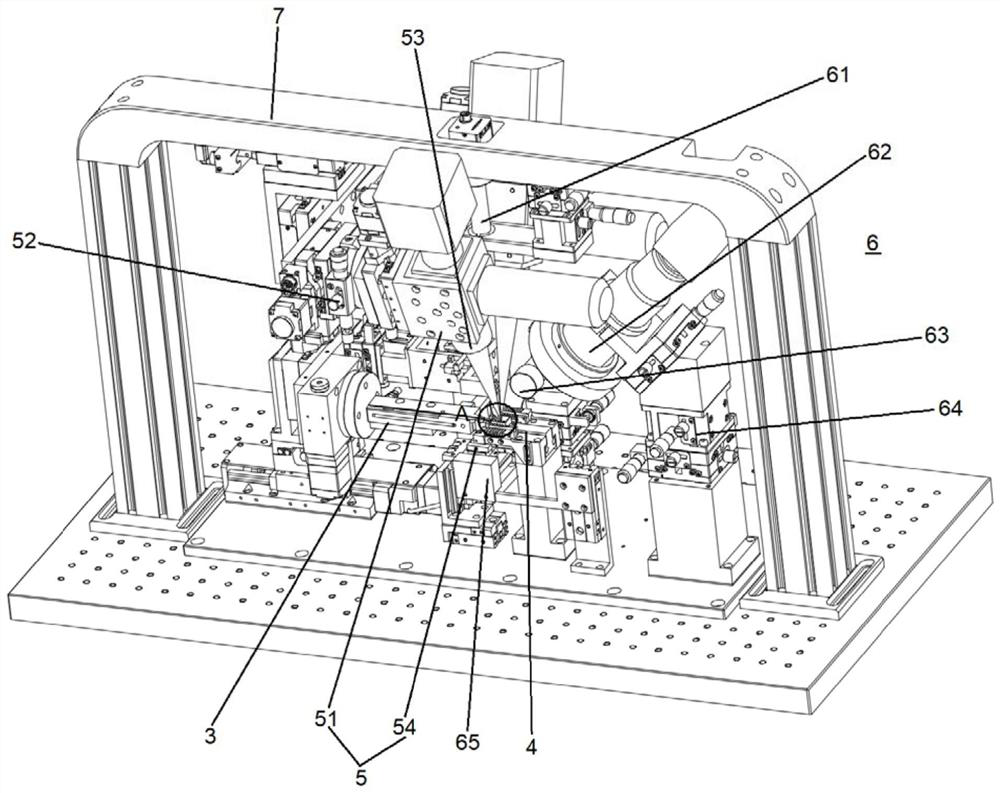

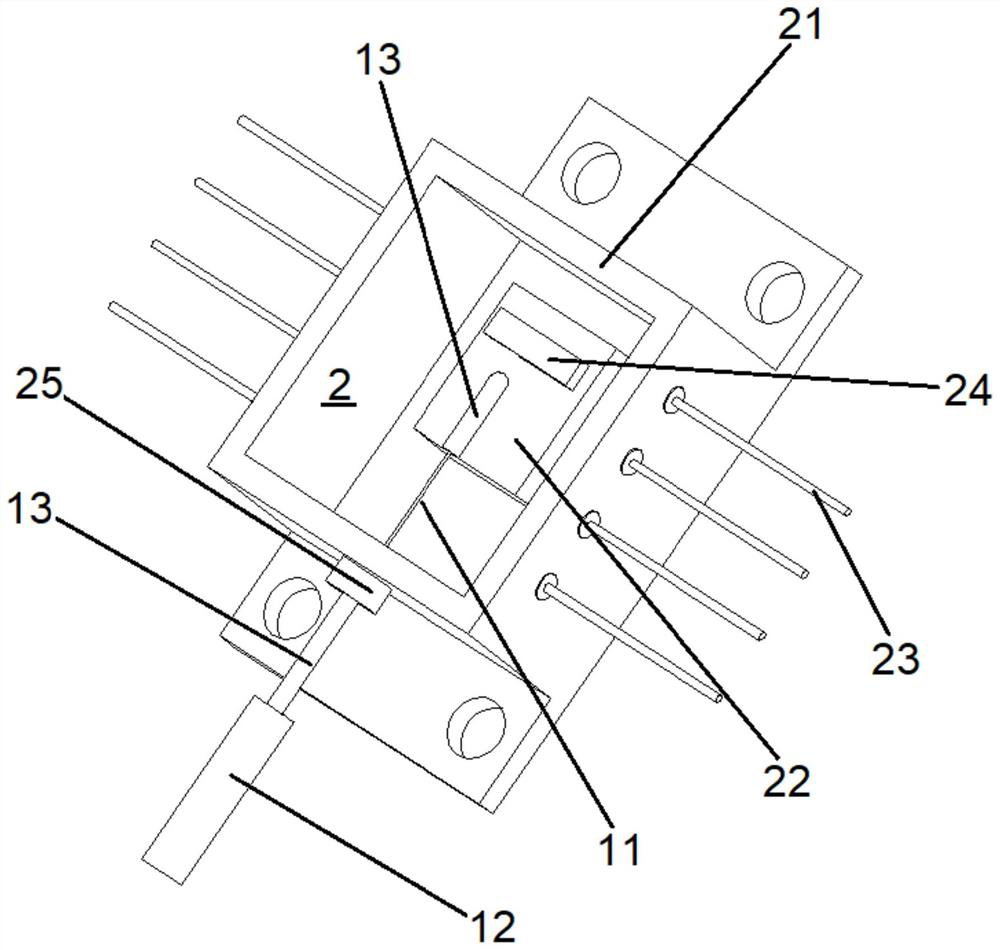

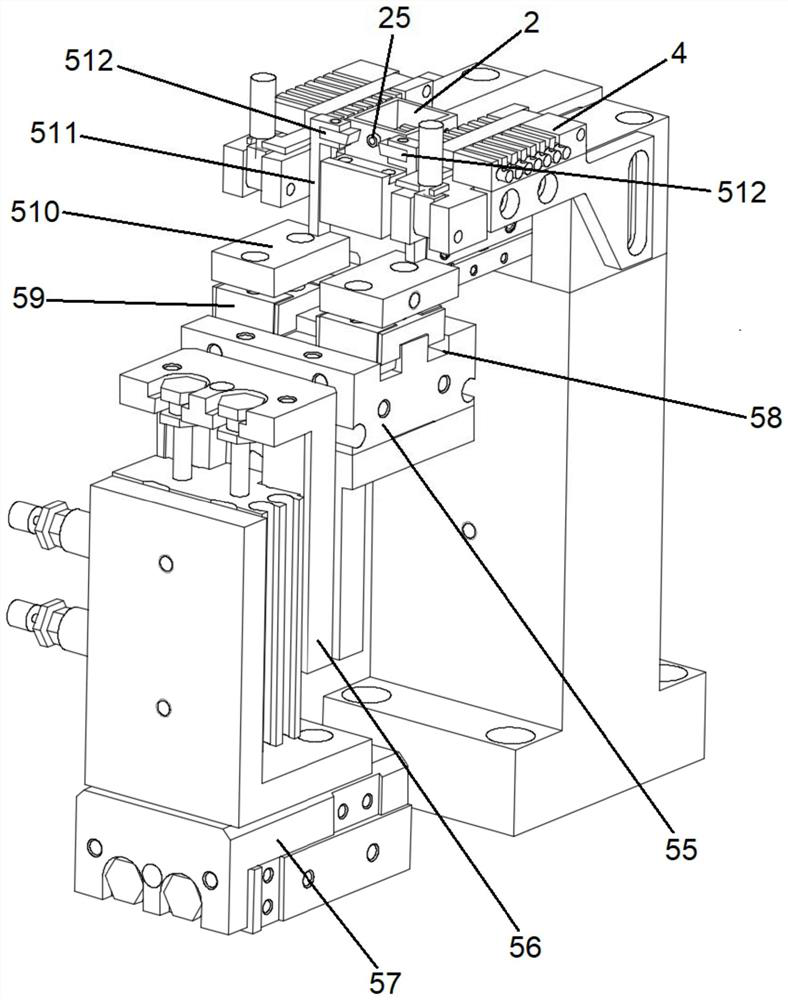

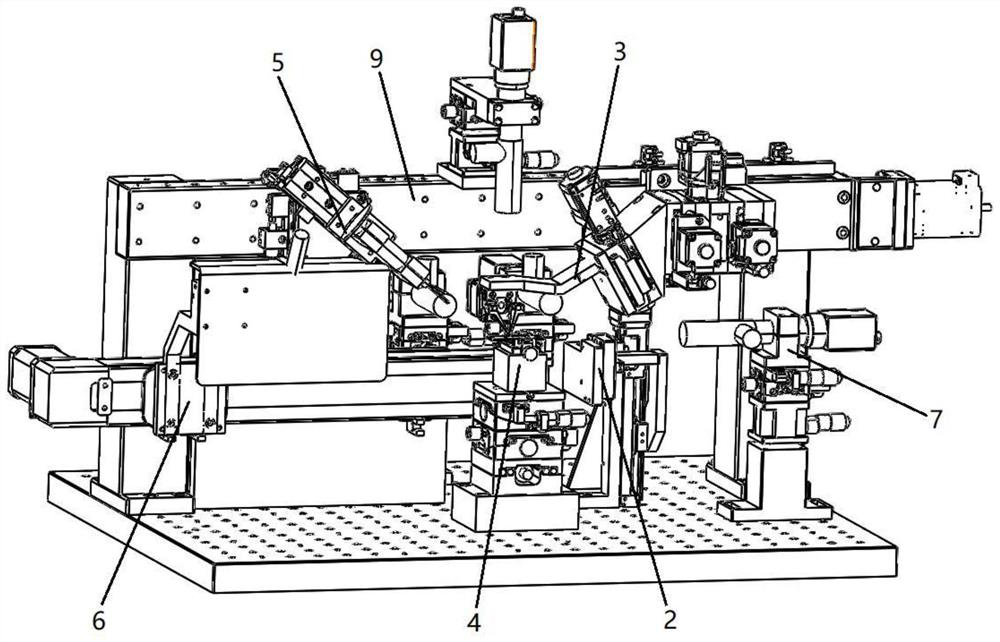

PendingCN112809179APrecise position controlButt weldingWelding/cutting auxillary devicesAuxillary welding devicesButt weldingCentre of rotation

The invention provides an adjusting device for welding round pipes at different angles. The adjusting device comprises an angle adjusting power input assembly, an angle adjusting rotating assembly, a rotating center front-back adjusting assembly, a rotating center up-down adjusting assembly, a clamping and separating assembly, a rotary welding assembly, an angle change compensation adjusting assembly, a size change compensation adjusting assembly, a lifting compensation implementing assembly and an indicating assembly. When the outer diameters of the round pipes are changed or the rotating angle is adjusted, butt welding between the round pipes can be achieved under the condition that the position of a welding laser head is not adjusted, and the problems that the rotating angle is difficult to accurately adjust in the process of welding the round pipes at a certain angle, and the welding process is unstable since the movement track of the round pipes is difficult to control accurately and the distance between welding spots of the round pipes and the laser focus position is changed are solved; and the time for adjusting the welding angle and controlling the welding movement track of the round pipes is saved, and the welding efficiency and quality are improved.

Owner:CENT SOUTH UNIV

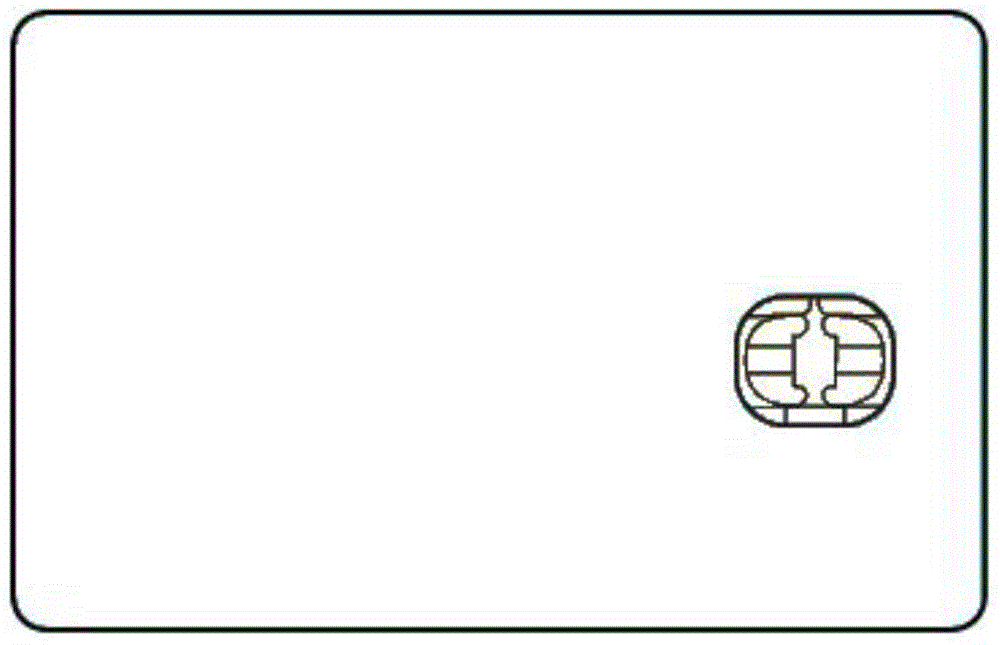

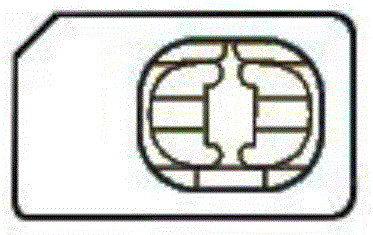

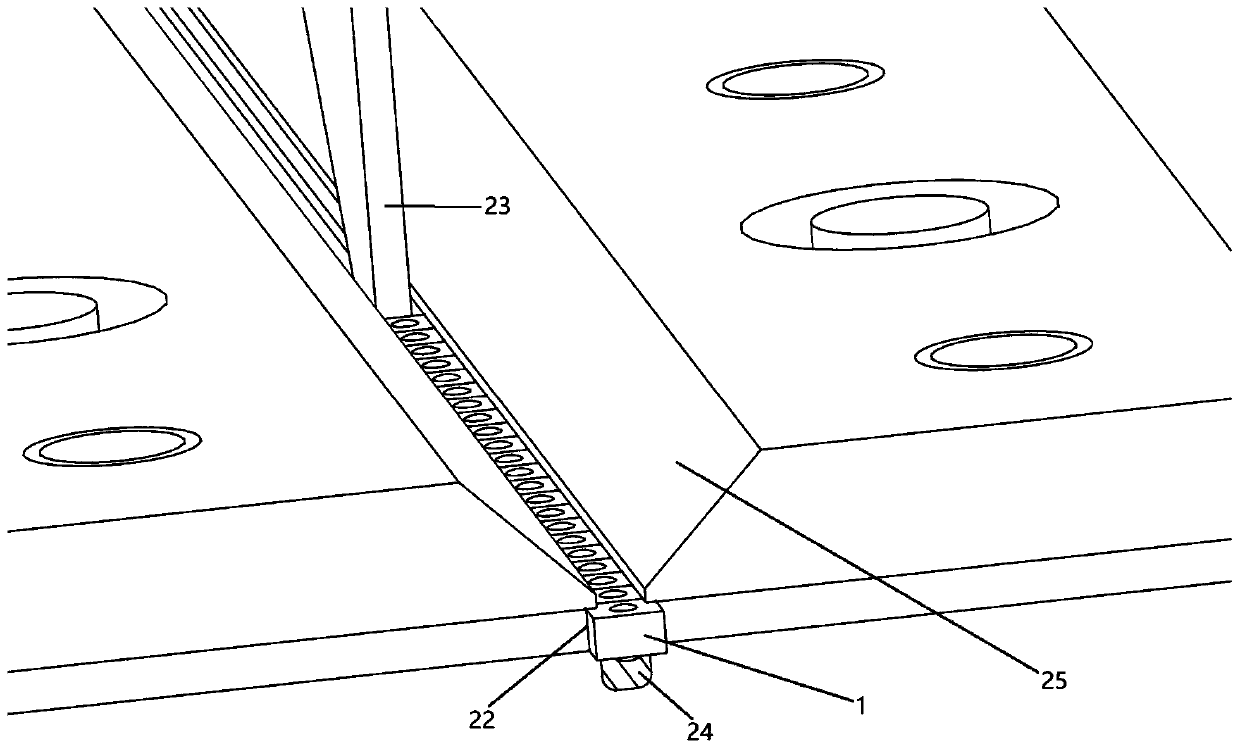

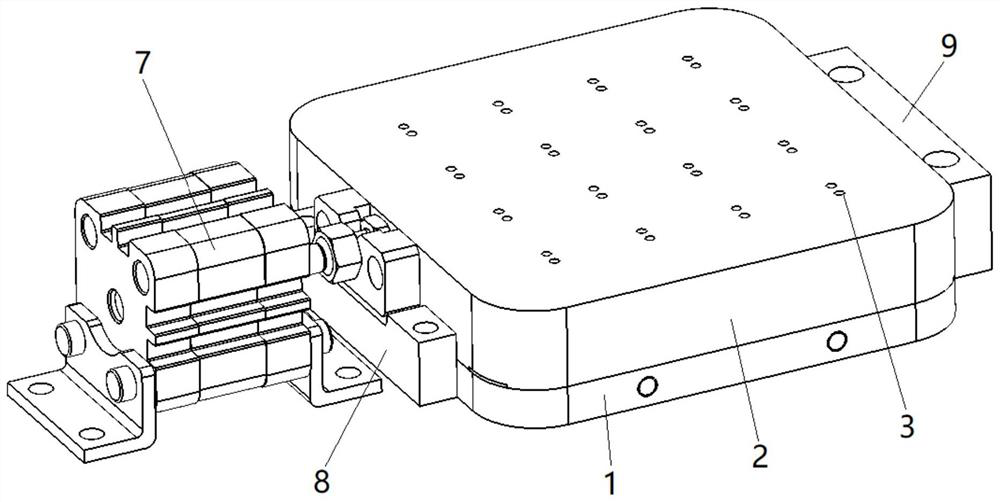

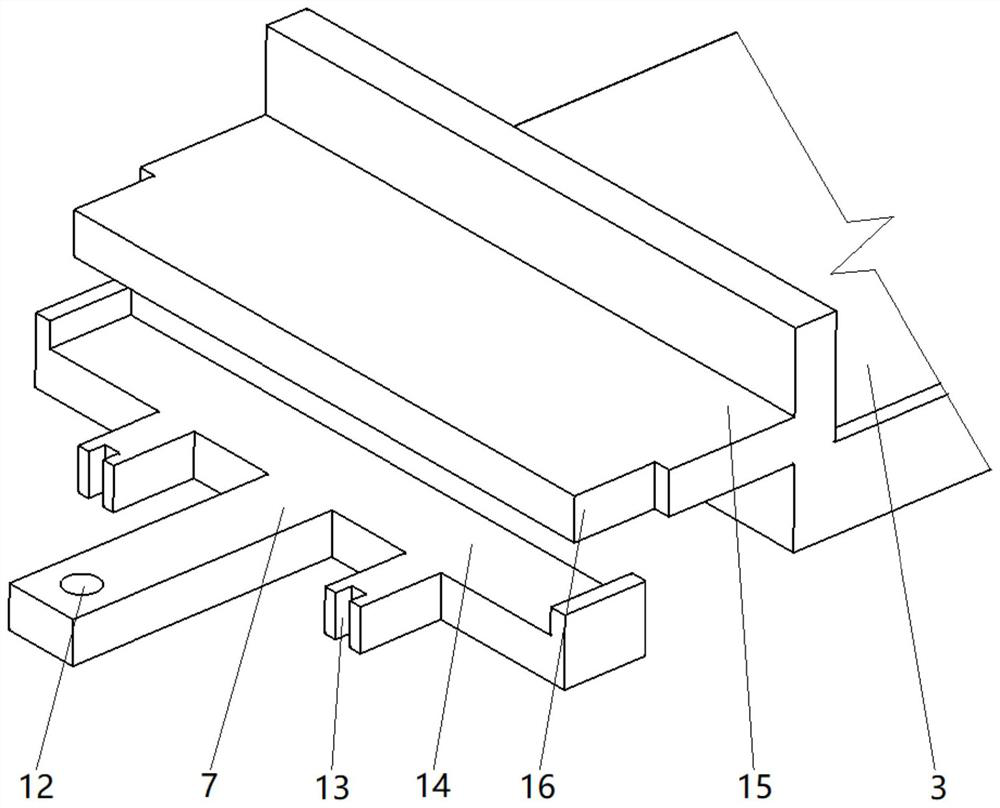

Memory card and card slot device

InactiveCN104485548AFit compactImprove portabilityCoupling device detailsTelephone set constructionsDesign spaceMemory cards

The invention discloses a memory card and a card slot device. The memory card is provided with a gap portion, of which the shape and size are matched with those of an SIM card. The card slot device comprises a base. The base comprises a bottom plate. The bottom plate is provided with SIM card spring pieces and memory card spring pieces. The memory card and the card slot device can enable the SIM card to be placed to the gap portion and enable the SIM card and the memory card to be placed to a card slot jointly, and the SIM card and the memory card can be cooperated more tightly in shape and structure, thereby helping to save design space, improving portability and light and thin design of a mobile terminal, and meanwhile, solving the problem that an "Micro SIM" card and a "Nano SIM" card cannot be compatible with a "Mini SIM" card slot.

Owner:HUAQIN TECH CO LTD

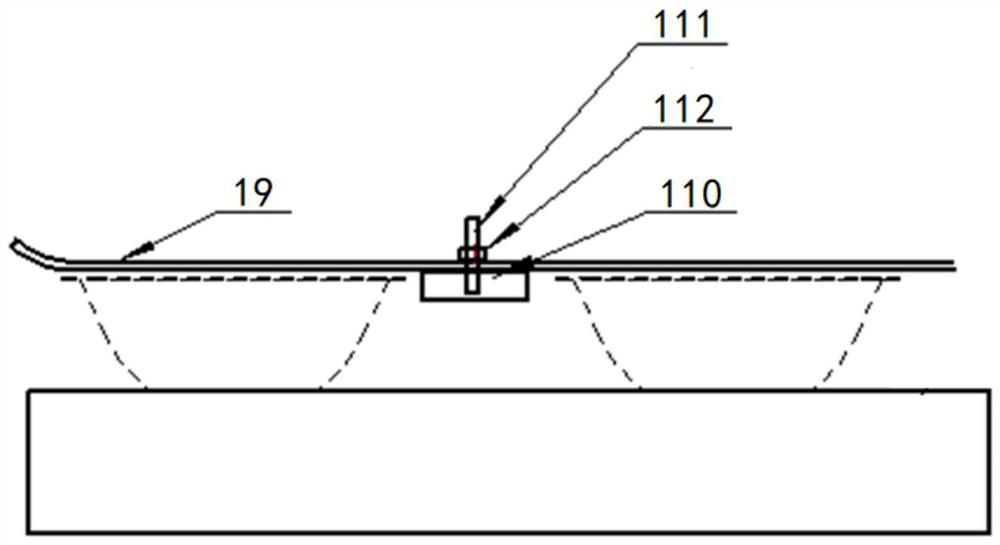

Multi-band antenna

InactiveUS7429955B2Compact structureFit compactSimultaneous aerial operationsAntenna supports/mountingsMulti bandEngineering

A multi-band antenna used in an electronic device, comprising: a grounding element; a radiating element comprises a first radiating section operating at 900 MHz frequency band and a second radiating section operating at 1800 MHz frequency band; and a connecting section connecting the radiating element and the grounding element. The grounding element, the radiating element, and the connecting element locate respectively in the different plane. The whole structure of the multi-band antenna of the present invention designed combining the inner structure of the notebook or other portable electrical device. The multi-band antenna is suit to be installed in a notebook or other portable electrical device because the multi-band antenna occupies small space.

Owner:HON HAI PRECISION IND CO LTD

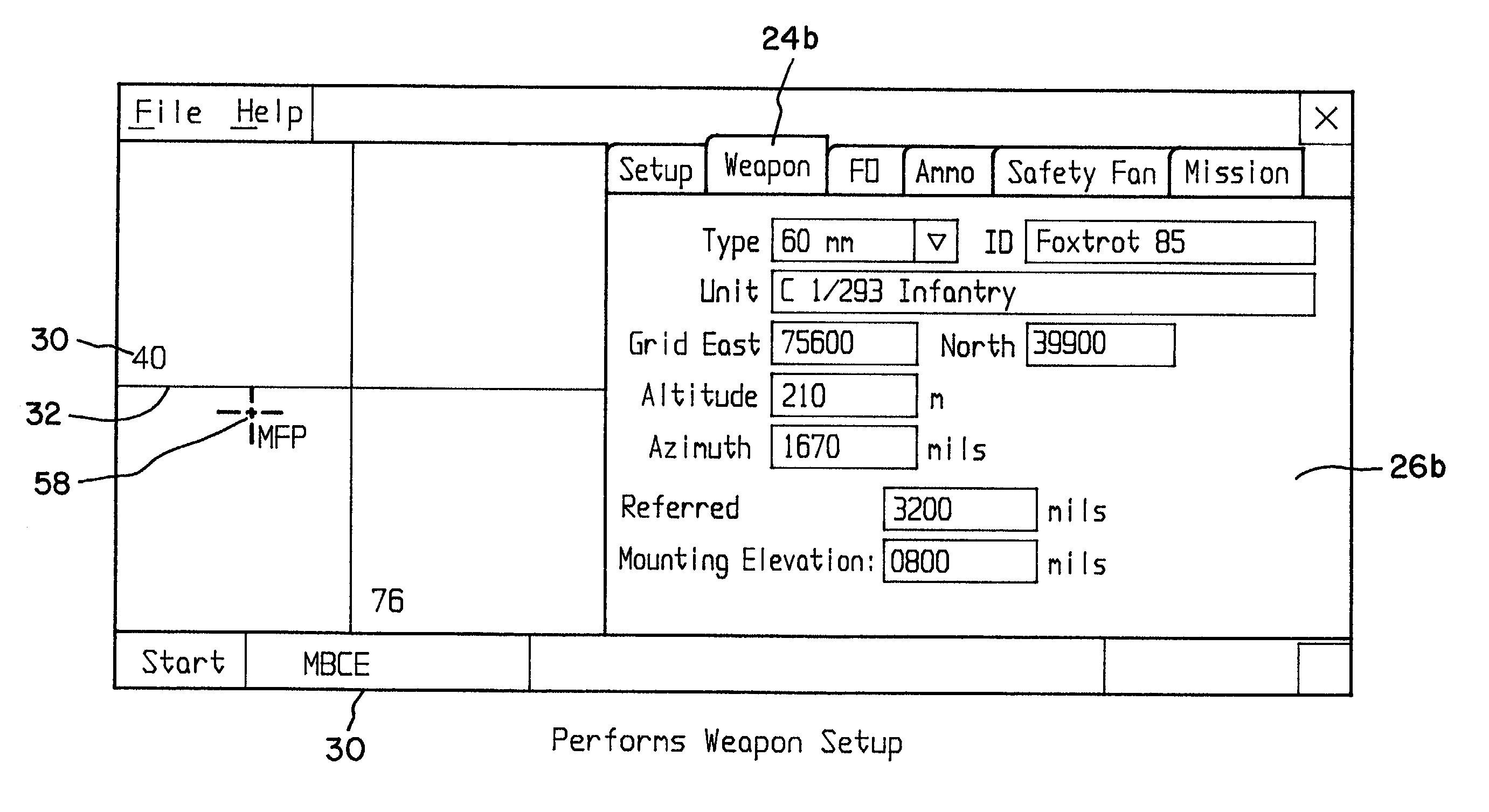

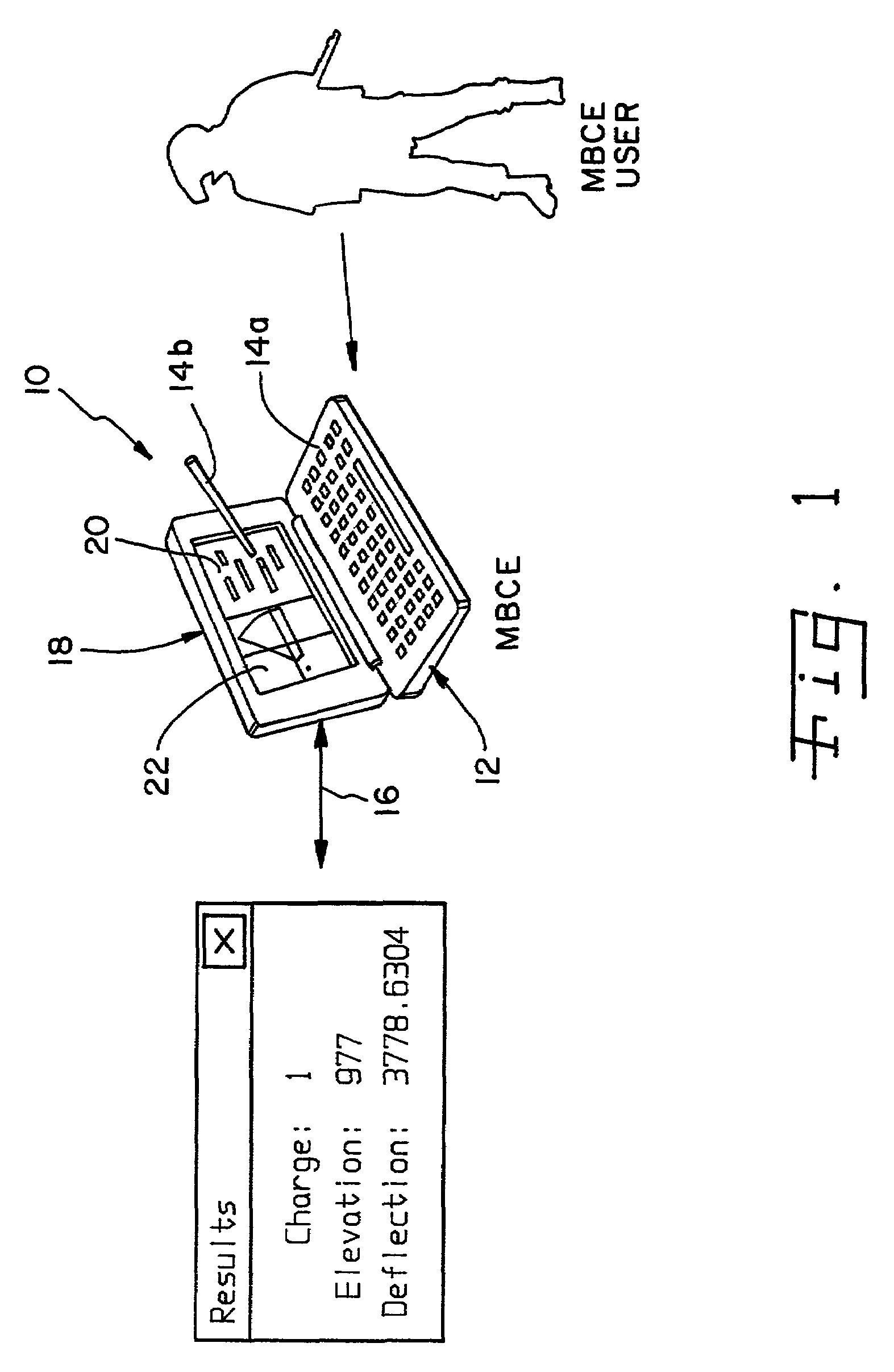

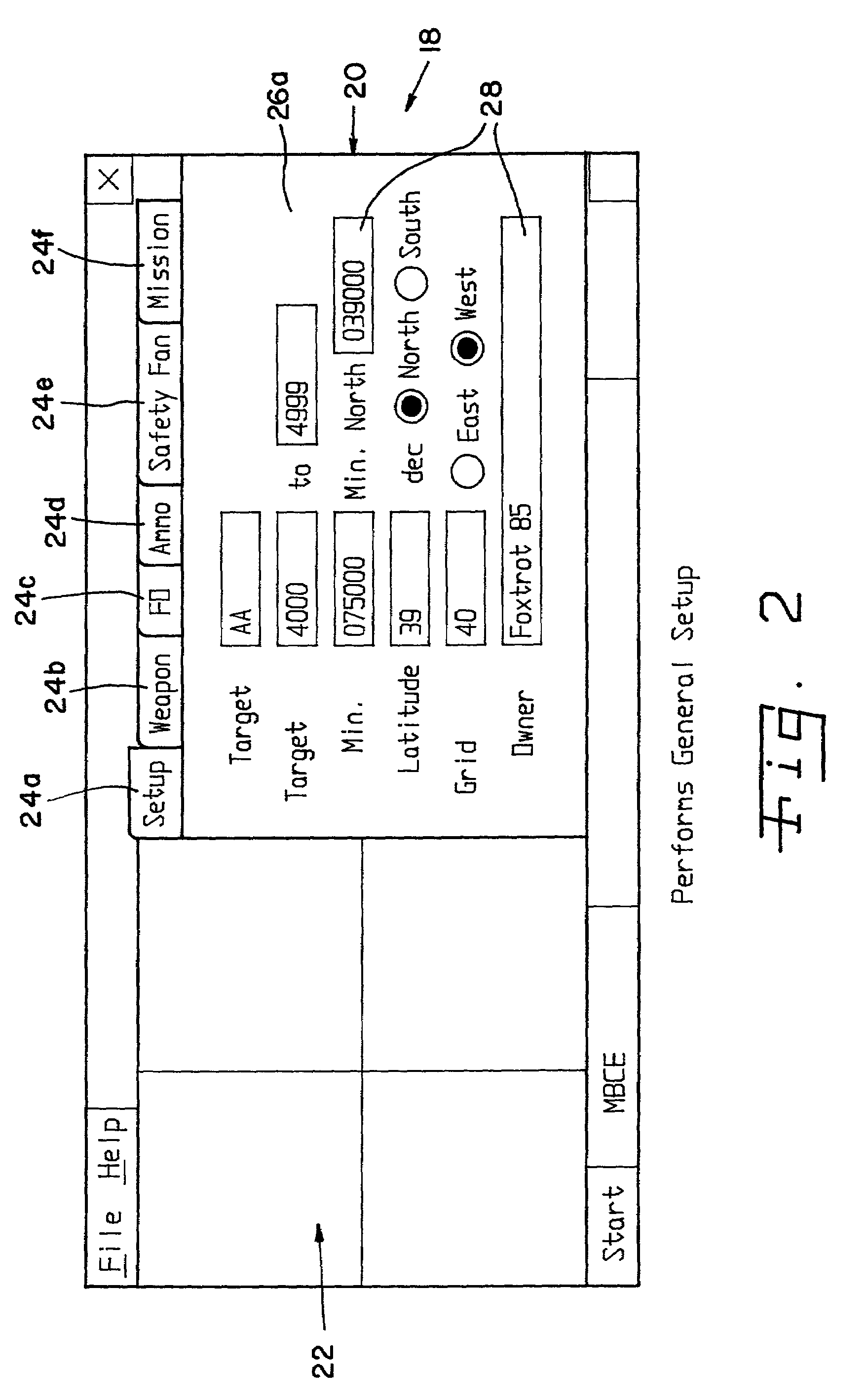

Mortar ballistic computer and system

InactiveUS7526403B2Easy inputEasy to calculate2D-image generationIncline measurementOff the shelfData entry

A software and related software operational system has both military and civilian uses and that can be operated as a light weight, hand-held, commercial, off-the-shelf computer device. The ballistic computer utilizes a display format that permits entry and display of both graphical and alphanumeric data simultaneously. This display and data entry format is especially applicable to the firing of mortars, allowing a representation of both where the mortar currently is and where it is projected to land.

Owner:DAHLGREN

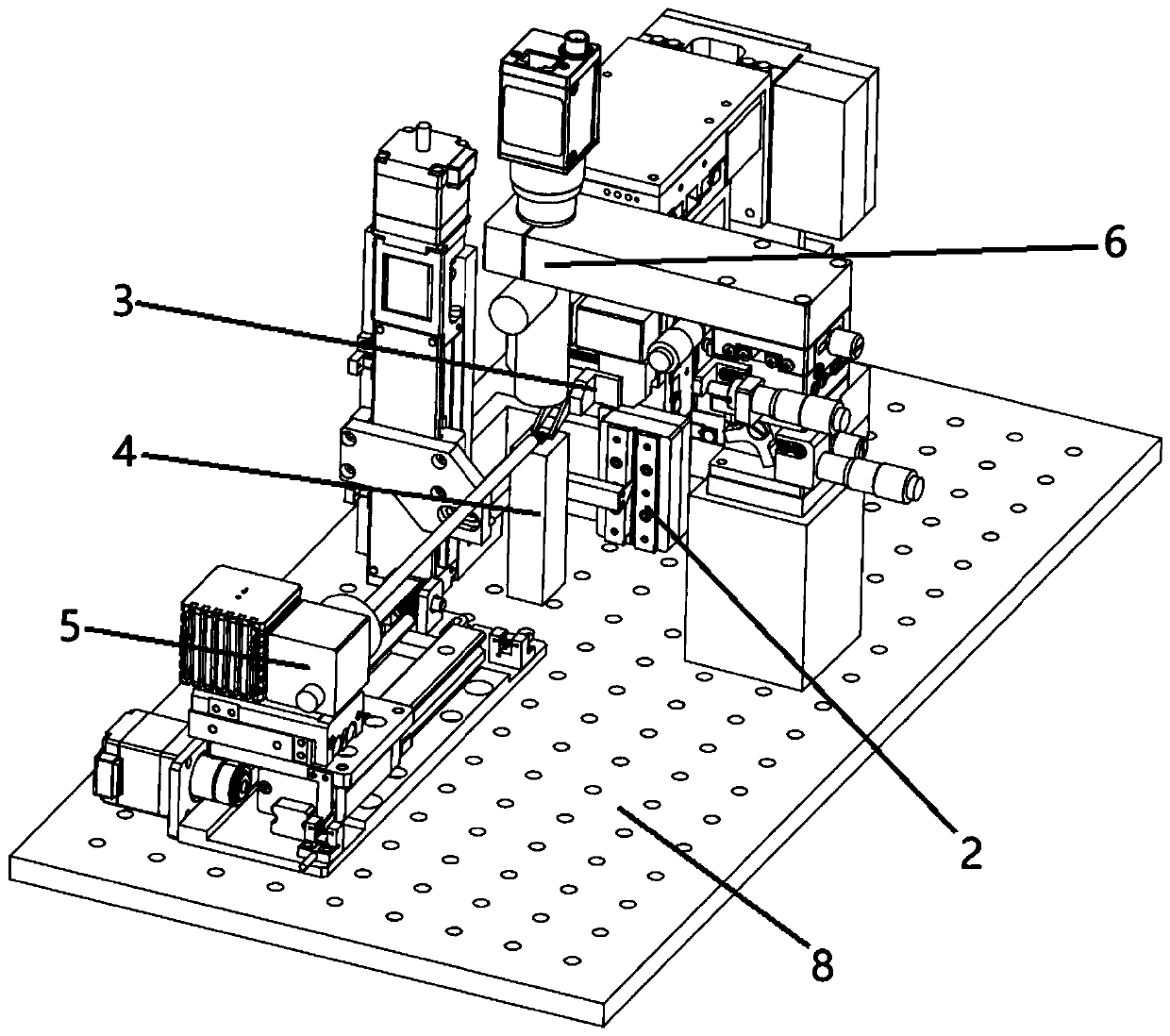

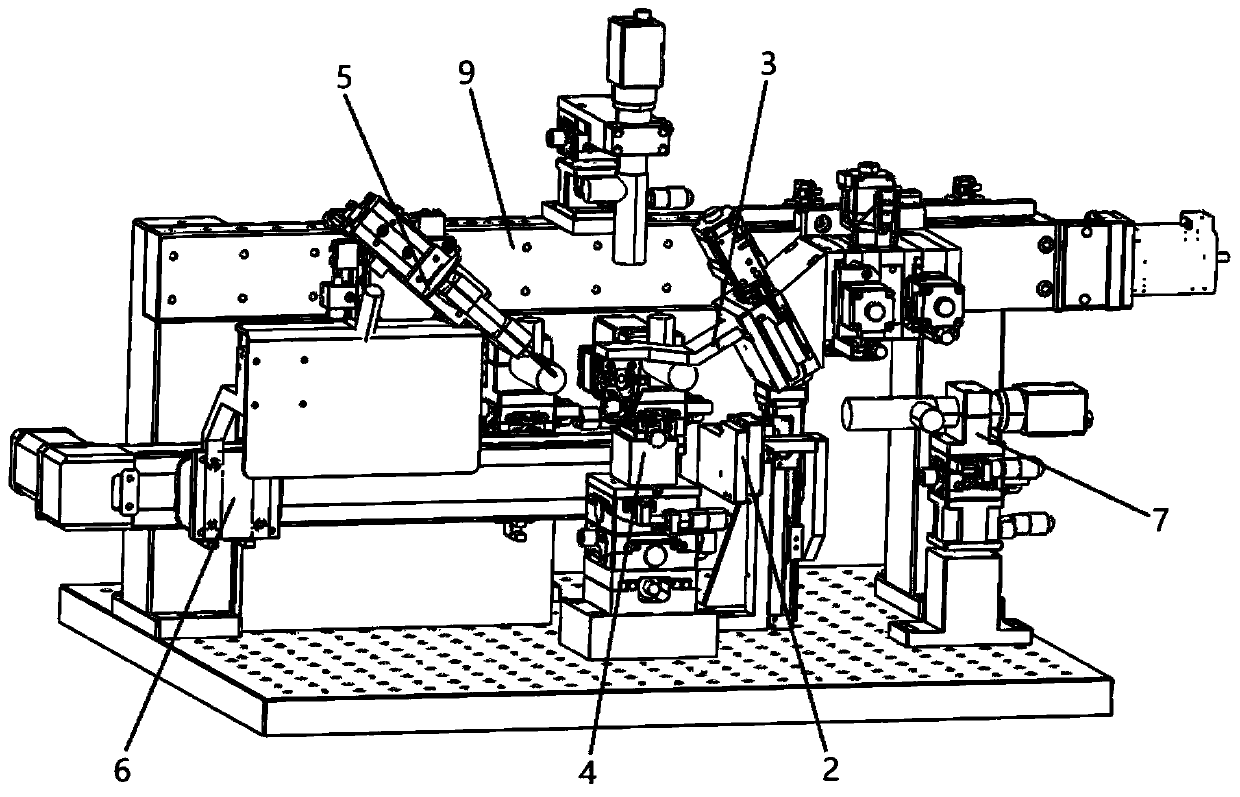

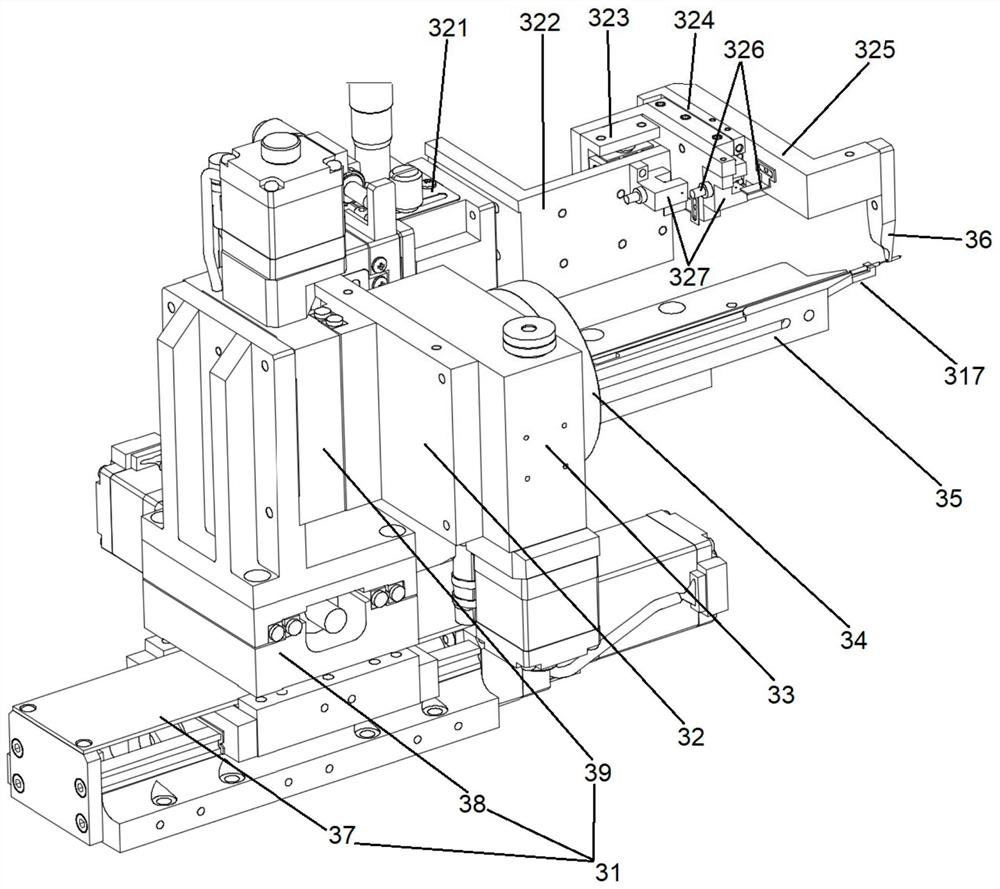

Lens coupling equipment driven by voice coil motor

ActiveCN111443438AReasonable designFit compactCoupling light guidesGeometric properties/aberration measurementEngineeringMechanical engineering

The invention provides lens coupling equipment driven by a voice coil motor. The lens coupling equipment comprises a lens feeding assembly, a lens clamping assembly, an optical device fixing table, acoupling detection assembly and a visual detection assembly, wherein a plurality of lenses are pre-installed in the lens feeding assembly, and are fed in sequence; the lens clamping assembly is used for clamping and moving the lenses fed by the lens feeding assembly to a corresponding packaging position on the optical device fixing table to be coupled with a light-emitting chip of a light-emittingelement fixed to the optical device fixing table; and the coupling detection assembly is used for confirming the coupling precision of the lenses and the light-emitting chip through light spot detection. A lens clamp of the lens clamping assembly is driven by the voice coil motor, has the characteristics of being simple in structure, small in size and fast in response, is suitable for a clamp ofminiaturized lenses, can control clamping force with high precision, and improves clamping and coupling precision of the lenses.

Owner:CENT SOUTH UNIV

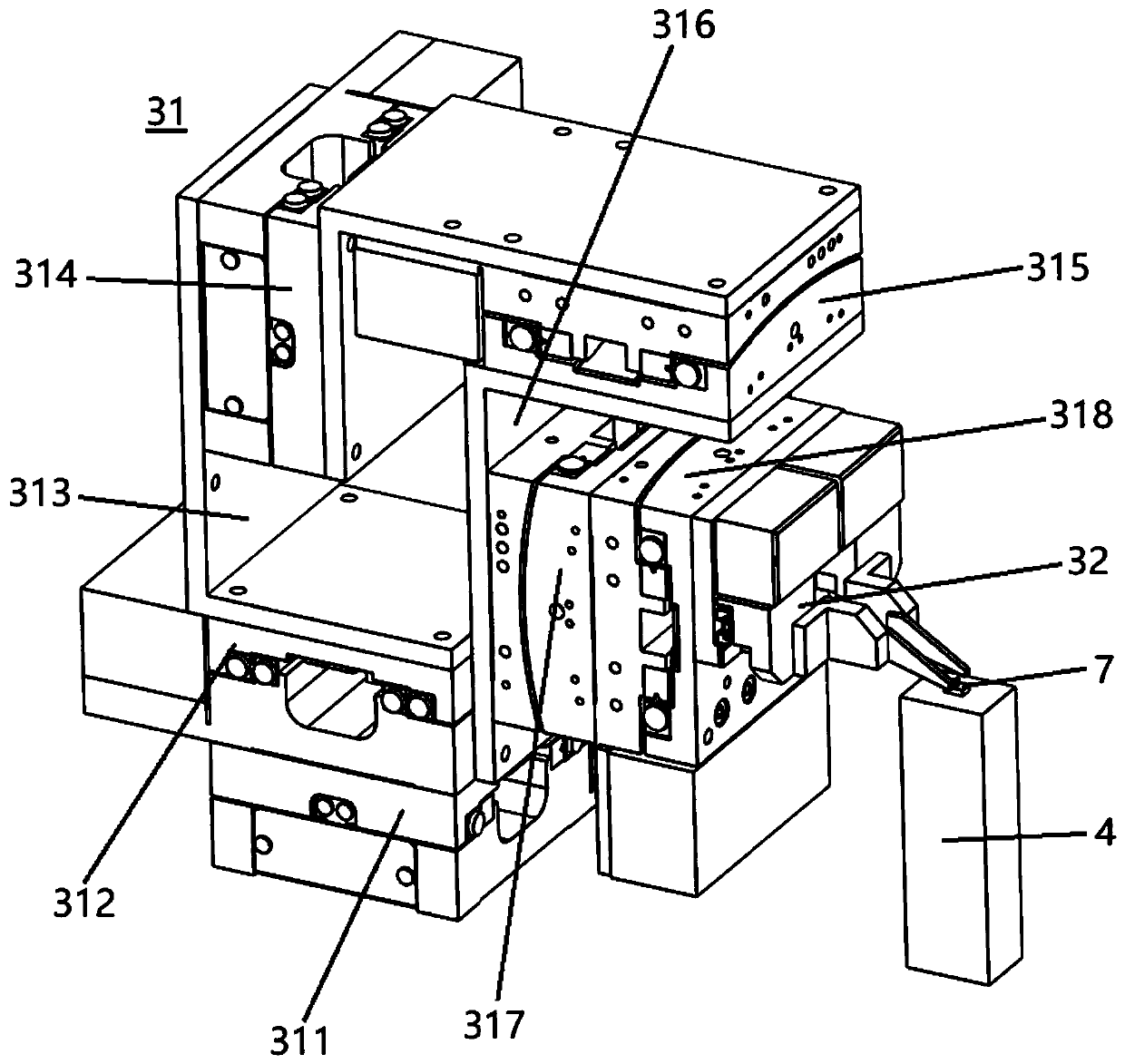

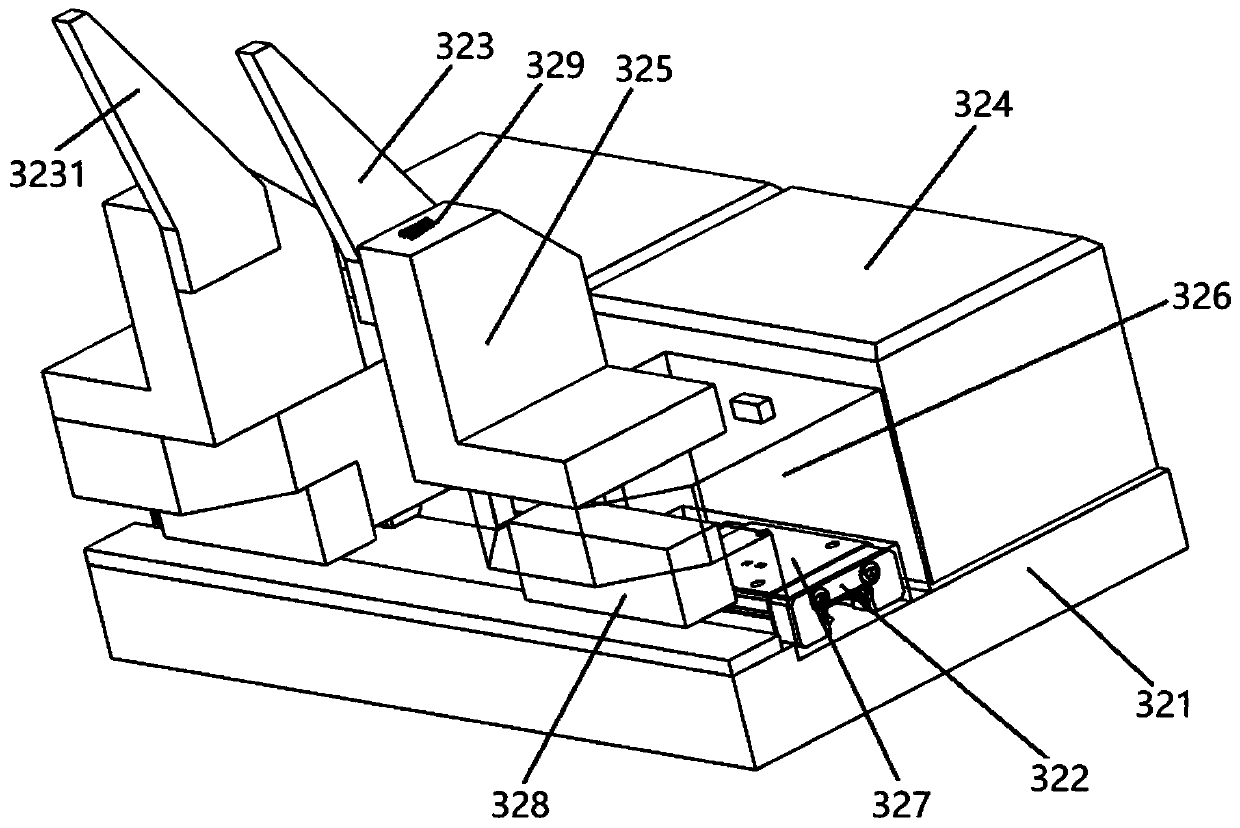

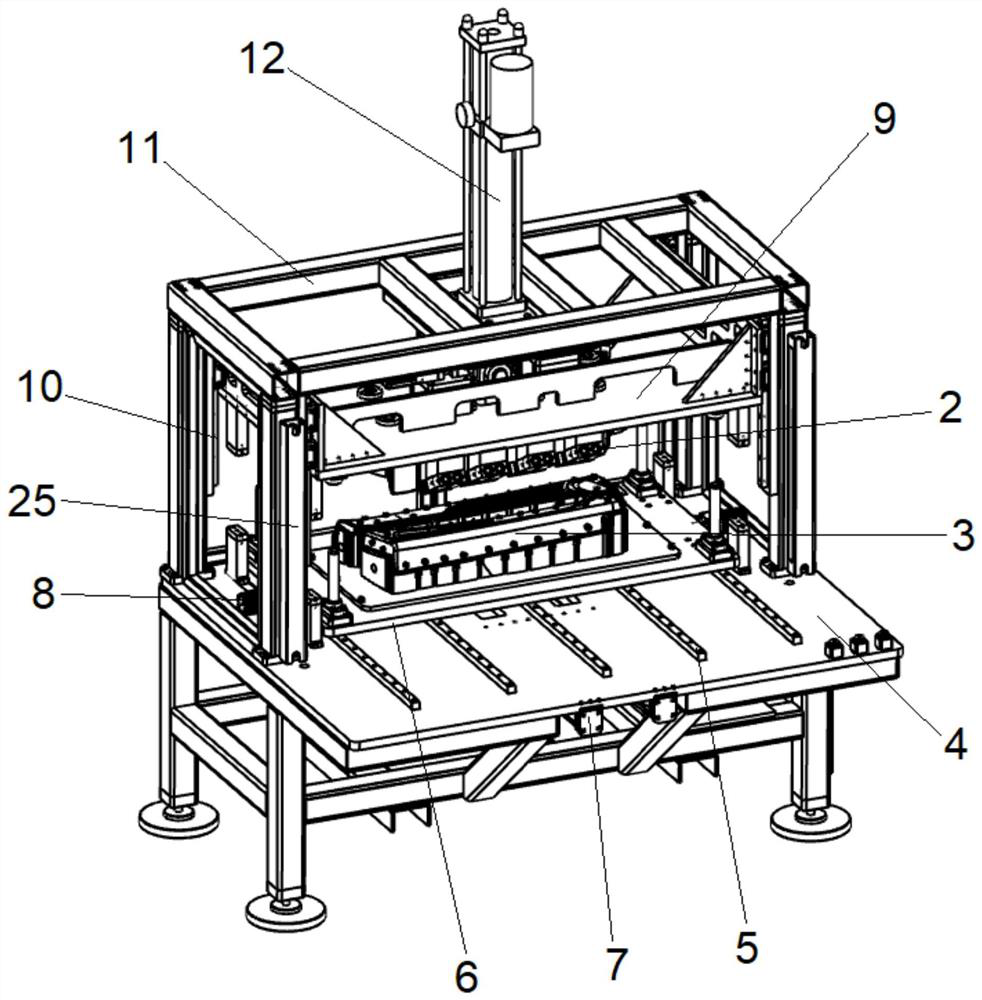

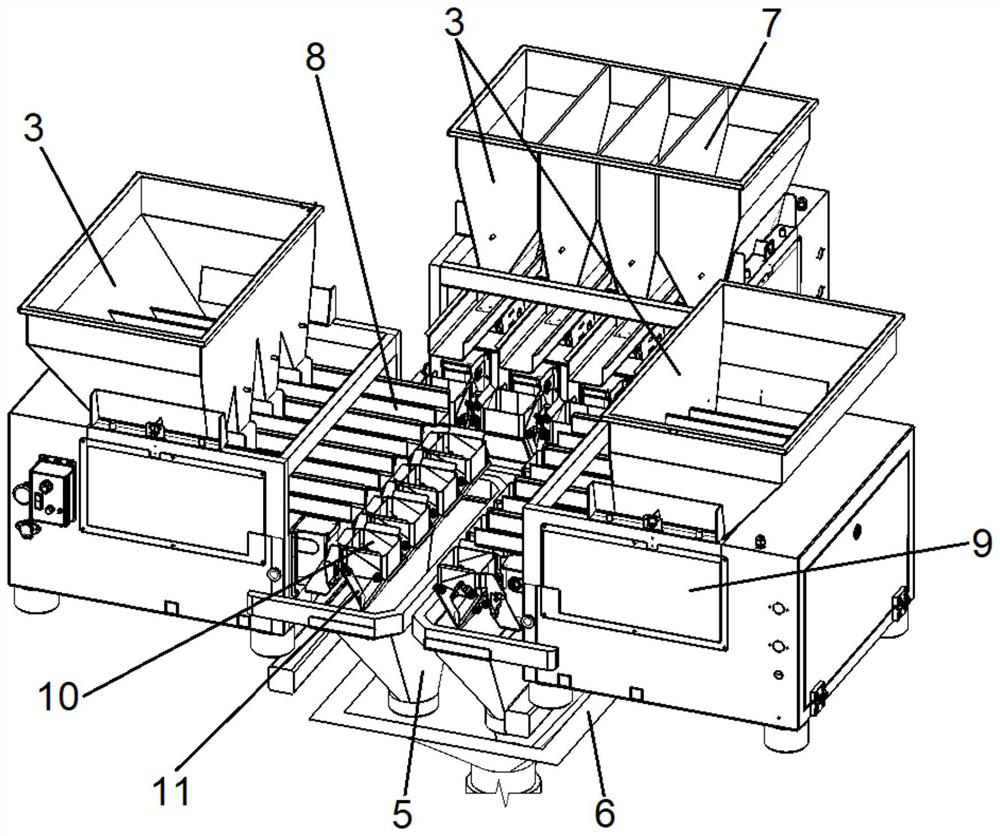

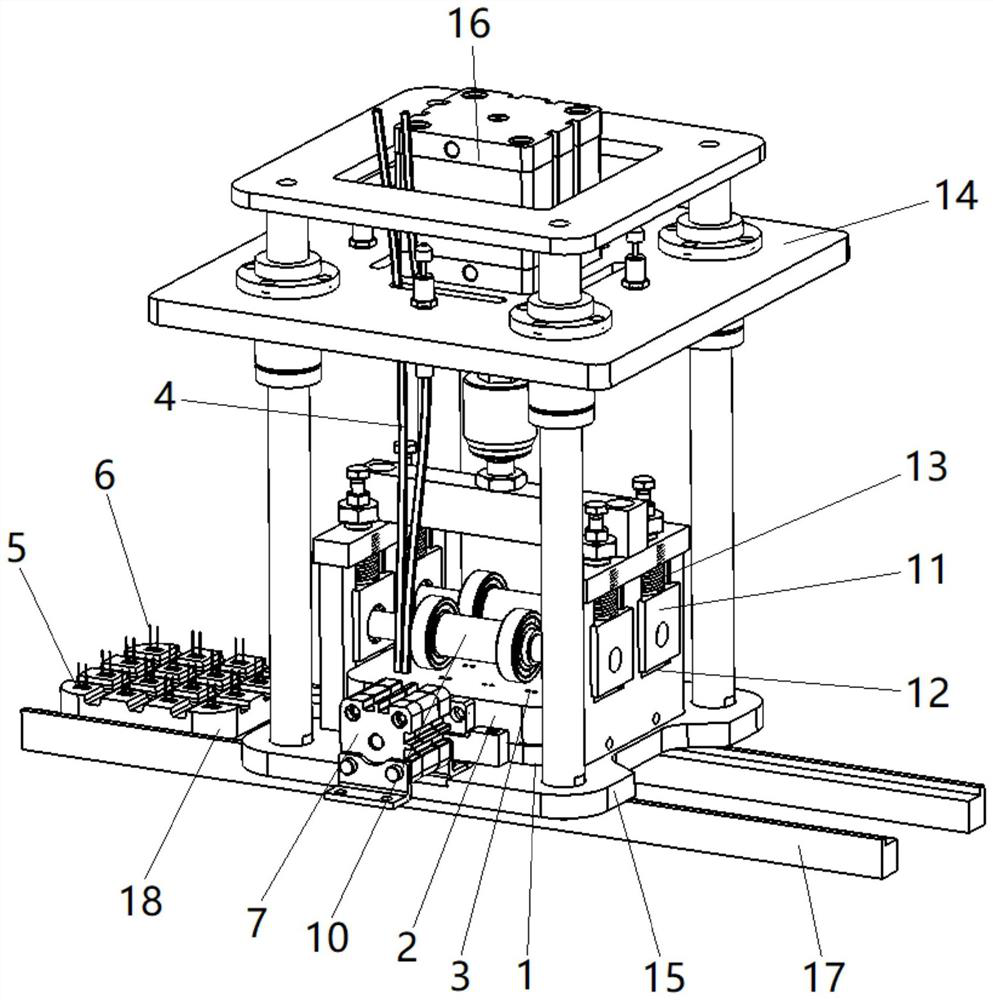

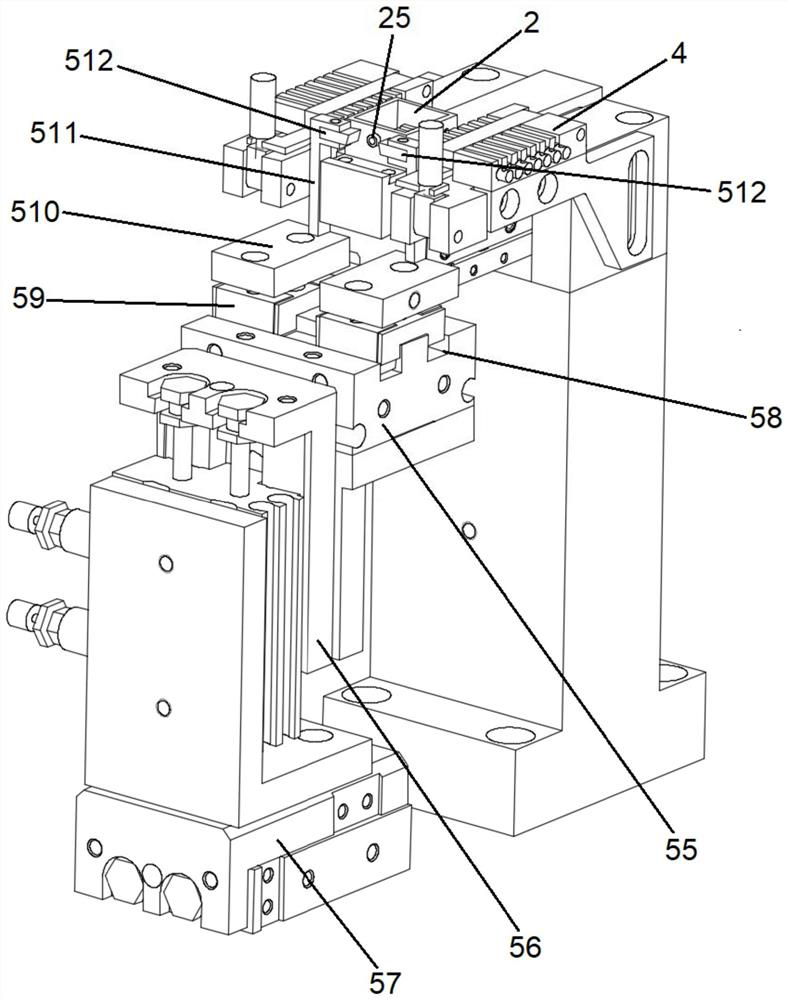

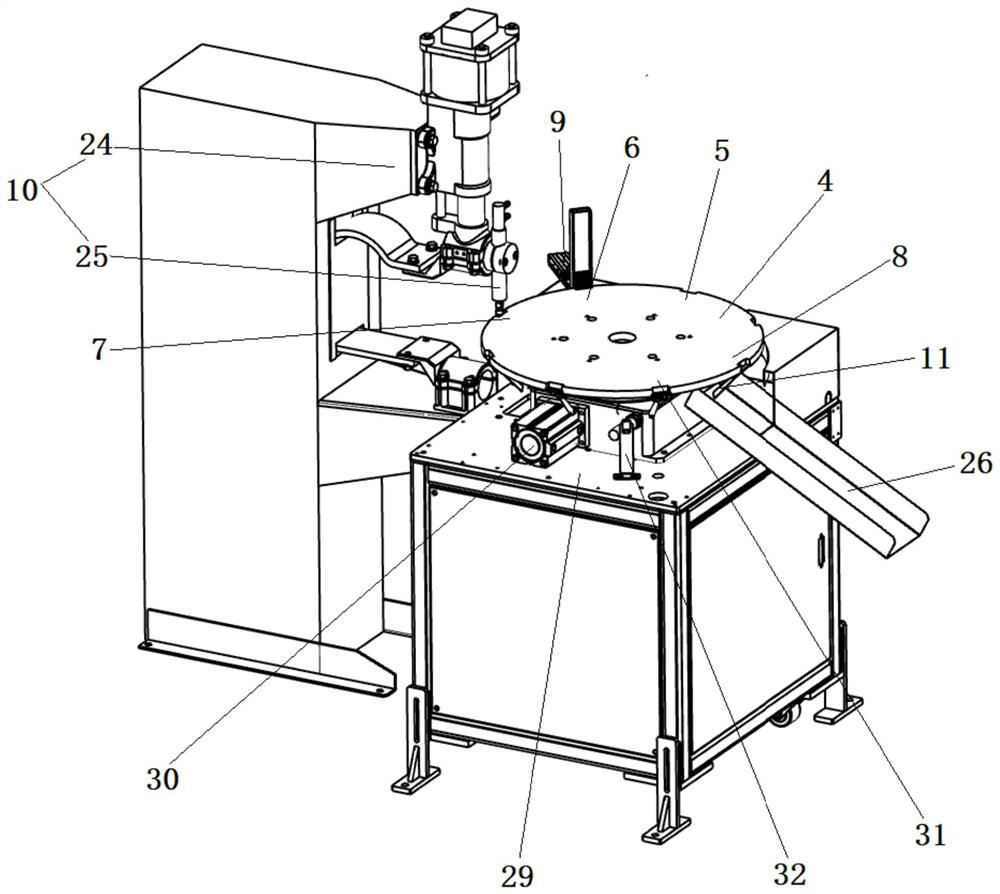

Motor rotor iron core magnetic steel inserting device

InactiveCN111211653AReasonable institutional designFit compactManufacturing stator/rotor bodiesStructural engineeringMechanical engineering

The invention provides a motor rotor iron core magnetic steel inserting device. The device comprises a clamping platform of an iron core and a magnetic steel block assembling assembly. The magnetic steel block assembling assembly is mainly composed of a magnetic steel block feeding mechanism and a magnetic steel block inserting mechanism. The magnetic steel block feeding mechanism sequentially feeds magnetic steel blocks to a discharge port, the clamping platform drives the iron core to rotate so that each slot of the iron core sequentially reaches the discharge port, and the magnetic steel block inserting mechanism inserts the magnetic steel blocks at the discharge port into the iron core. In the invention, the slots on the iron core sequentially reach and are aligned with the discharge port in a rotating manner, and the magnetic steel block assembling assembly automatically feeds the magnetic steel blocks and accurately inserts the magnetic steel blocks into the slots so that magnetic steel inserting operation of the rotor iron core can be completed in a high-automation manner, assembling efficiency and quality are effectively improved, and production cost is reduced.

Owner:SHAODONG INTELLIGENT MFG INNOVATIVE INST

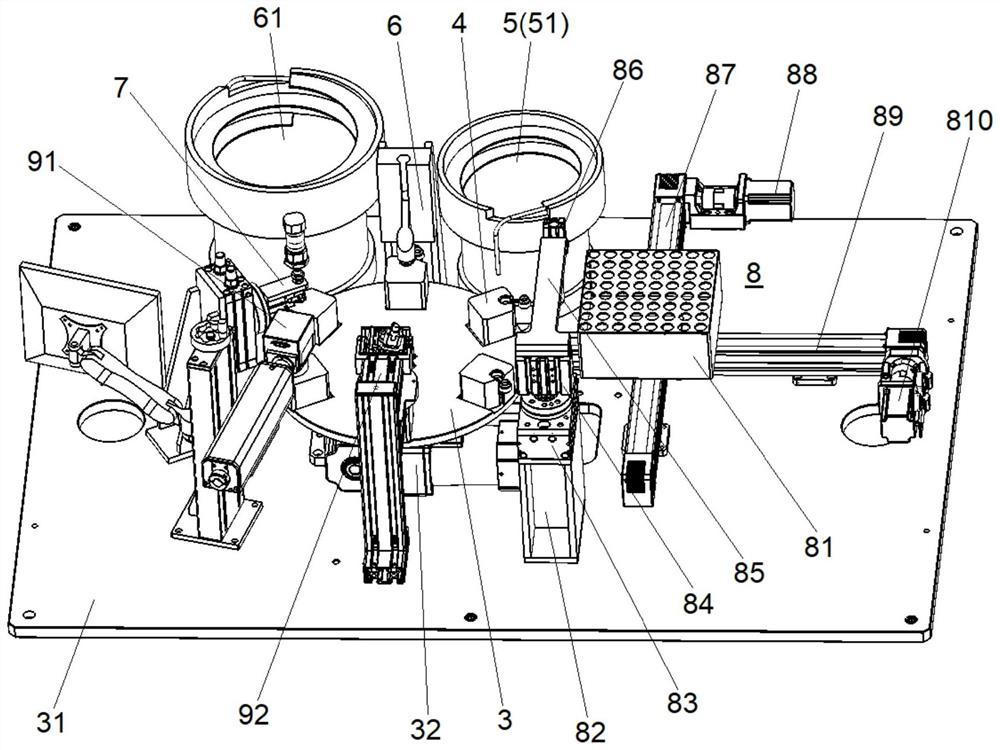

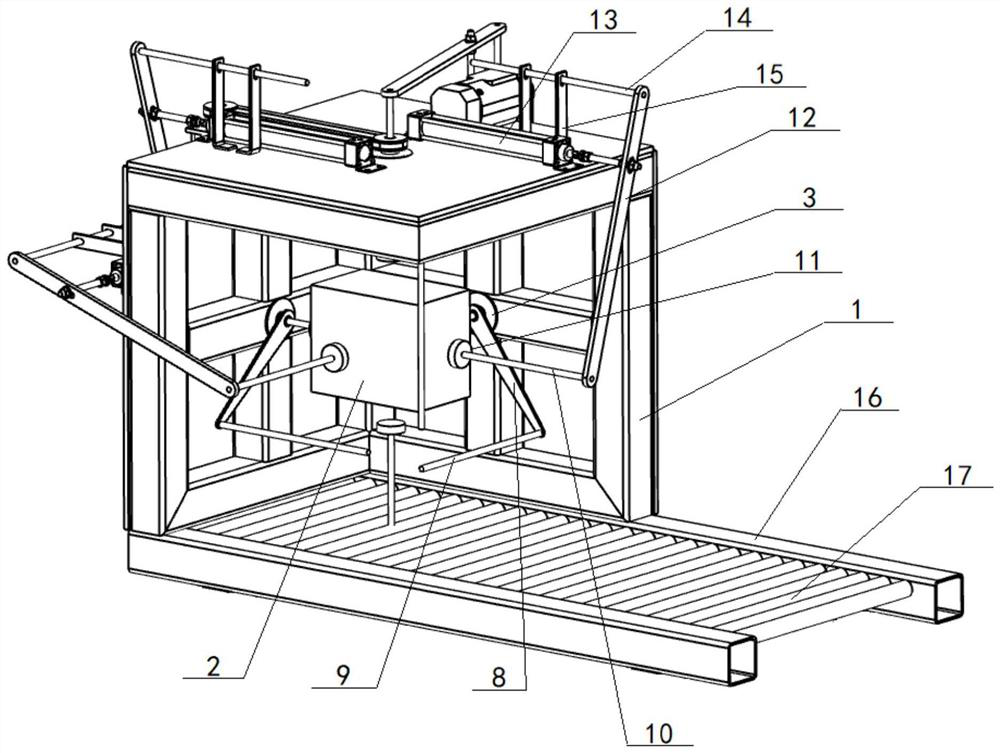

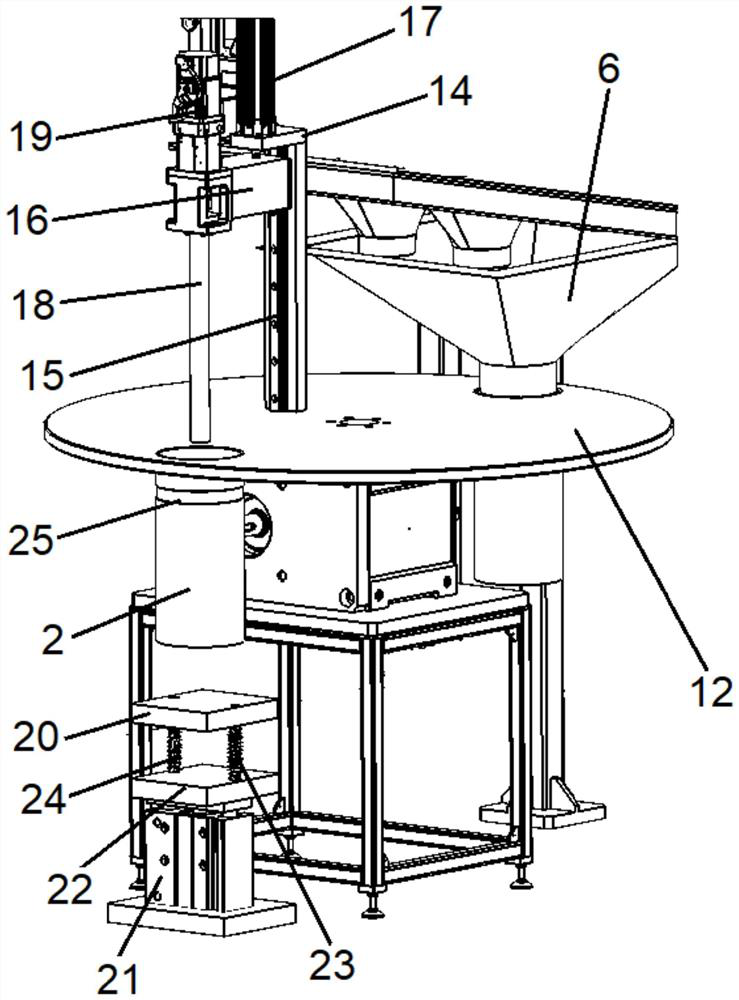

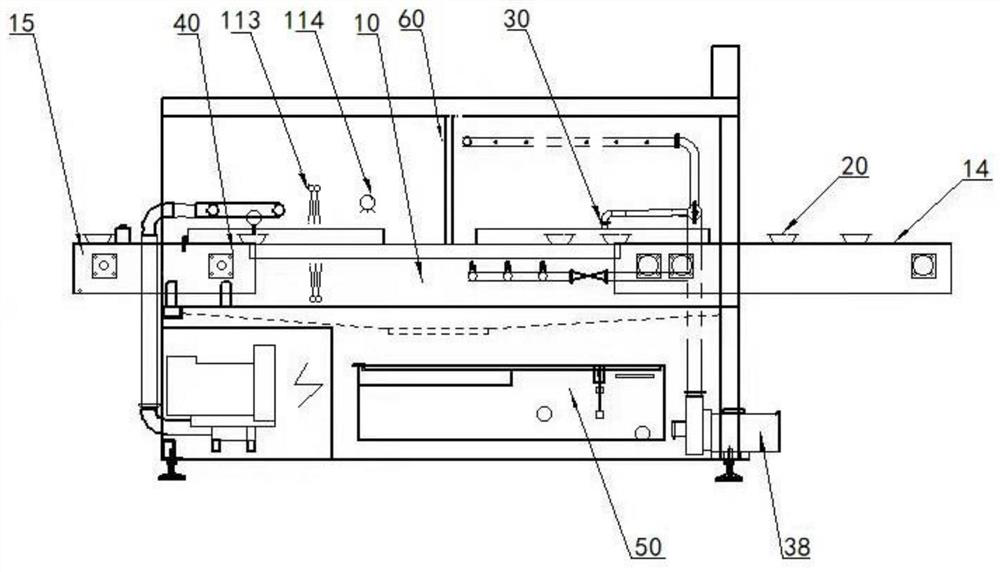

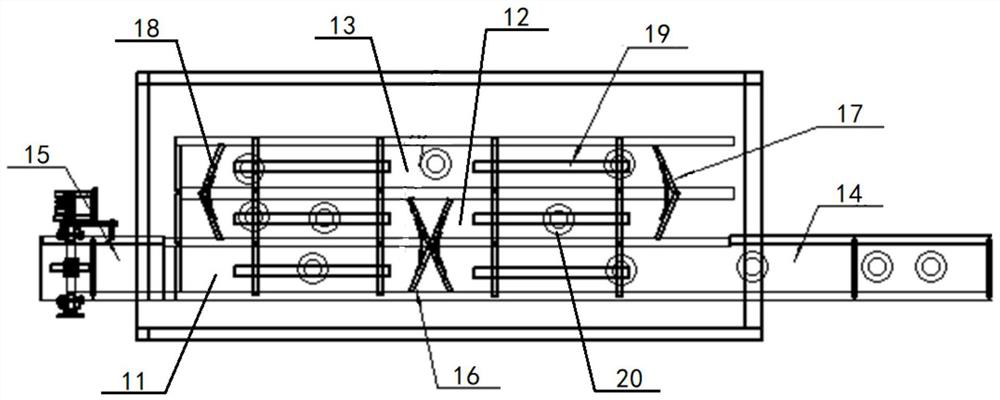

Test tube sealing cover assembling equipment and sealing cover assembling method

ActiveCN111792597AReasonable designFit compactCapsClosure using stoppersStructural engineeringIndustrial engineering

The invention discloses test tube sealing cover assembling equipment. The equipment comprises a conveying table, wherein a plurality of test tube clamps for clamping test tubes are arranged on the conveying table, and the conveying table sequentially conveys the test tube clamps to a plug cover feeding station, a test tube feeding station, a plug cover overturning station and a discharging station; the plug cover feeding station is provided with a plug cover feeding assembly, and plug covers are fed to the test tube clamps; the test tube feeding assembly is provided with a test tube feeding assembly, and test tubes are fed to the test tube clamps and inserted into collars; the plug cover overturning station is provided with a plug cover overturning assembly, and plug heads are overturned and then inserted into test tube openings; and the discharging station is provided with a discharging assembly, and the test tubes are clamped and discharged from the test tube clamps. According to theequipment, all the components are reasonable in design and compact in connection fit, the whole process is controlled in a full-automatic manner, the sealing cover assembly of test tubes is completedin a pipelined manner, the assembly efficiency and quality are improved, and the labor intensity and the production cost are reduced.

Owner:SHAODONG INTELLIGENT MFG INNOVATIVE INST

Lens coupling equipment for multi-path single-mode COB module

ActiveCN111367029AReasonable designFit compactCoupling light guidesMountingsEngineeringMechanical engineering

The invention provides lens coupling equipment for a multi-path single-mode COB module. The lens coupling equipment comprises a lens feeding assembly, a lens clamp assembly, a PCB clamping assembly, adispensing module, a curing module and a visual detection module, wherein a plurality of lenses are pre-installed in the lens feeding assembly, the lenses are fed in sequence, the lens clamp assemblyclamps the lens fed by the lens feeding assembly and moves the lens to a corresponding packaging position on a PCB so as to be coupled with a light-emitting element and a receiving element on the PCB, the PCB is clamped and fixed by the PCB clamping assembly, the dispensing module dispenses glue to the coupled lens, the curing module cures the dispensed lens, and the visual detection module is used for visually detecting the lens feeding and coupling process. The lens is sequentially clamped to the surface of the PCB through the lens clamping assembly in an automatic feeding mode, automatic coupling, dispensing and curing are carried out one by one, the structural design is reasonable, the connection and cooperation are compact, and the lens coupling efficiency, precision and packaging quality are effectively improved.

Owner:CENT SOUTH UNIV

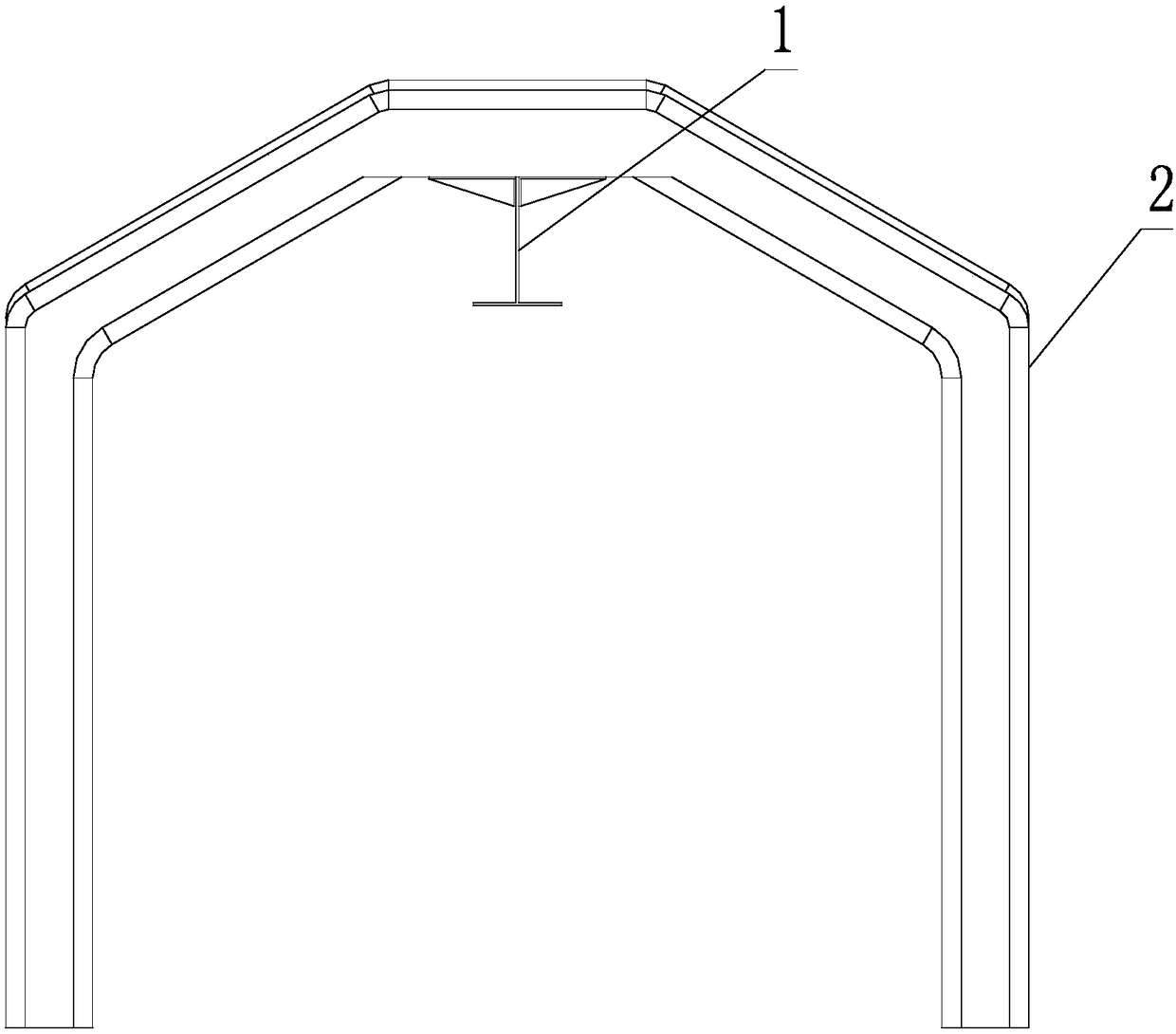

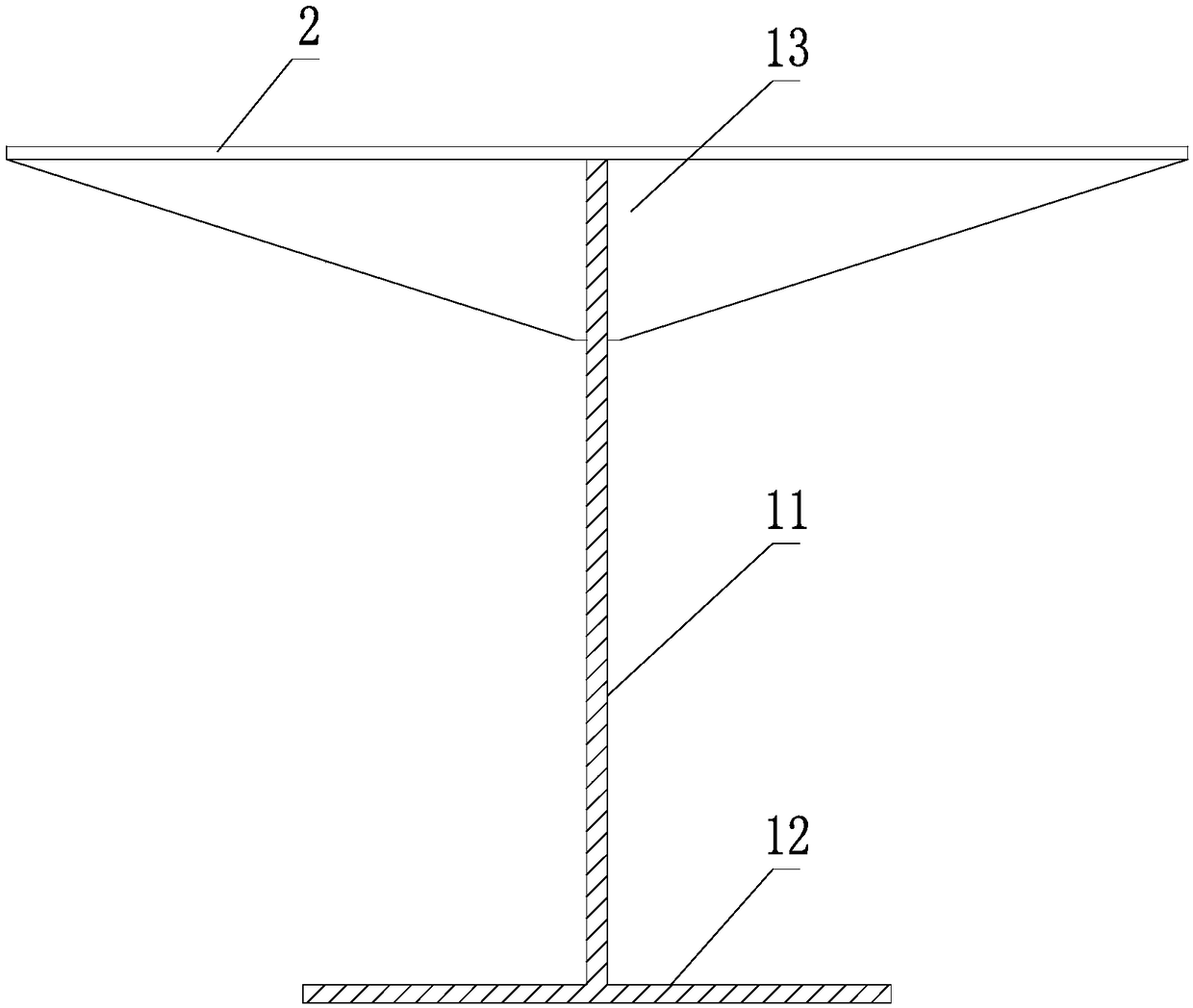

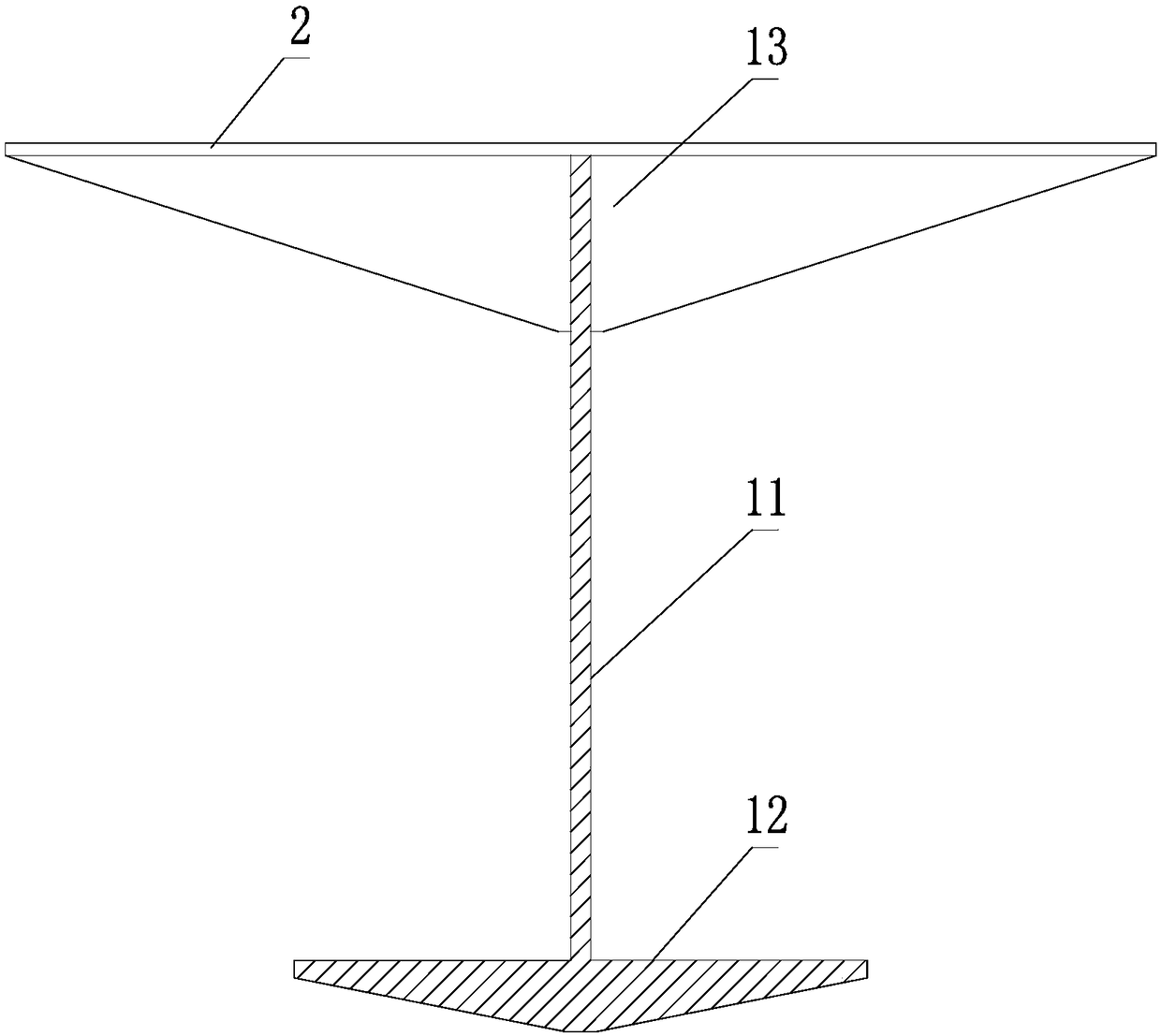

Suspended traffic running system

PendingCN108340926AAchieve horizontal suspensionRealize inclined suspensionRailway tracksElevated railway with suspended vehicleEngineering

The invention discloses a suspended traffic running system. The suspended traffic running system comprises a track frame and a track beam which is mounted on the track frame. In the extension direction of the track beam, the track beam comprises a straight section and a turning section, on the straight section, any points on the track beam which are used for supporting a running surface of a running wheel of a train are located on the same horizontal plane; and on the turning section, any points on the track beam which are used for supporting the running surface of the running wheel of the train are arranged in an inclined mode, and the height of the running surface on the outer side of the turning section is higher than that on the inner side of the turning section. The running system isbeneficial to improving the comfort of passengers when the train turns.

Owner:ZHONGTANG SKY RAILWAY GRP CO CO LTD

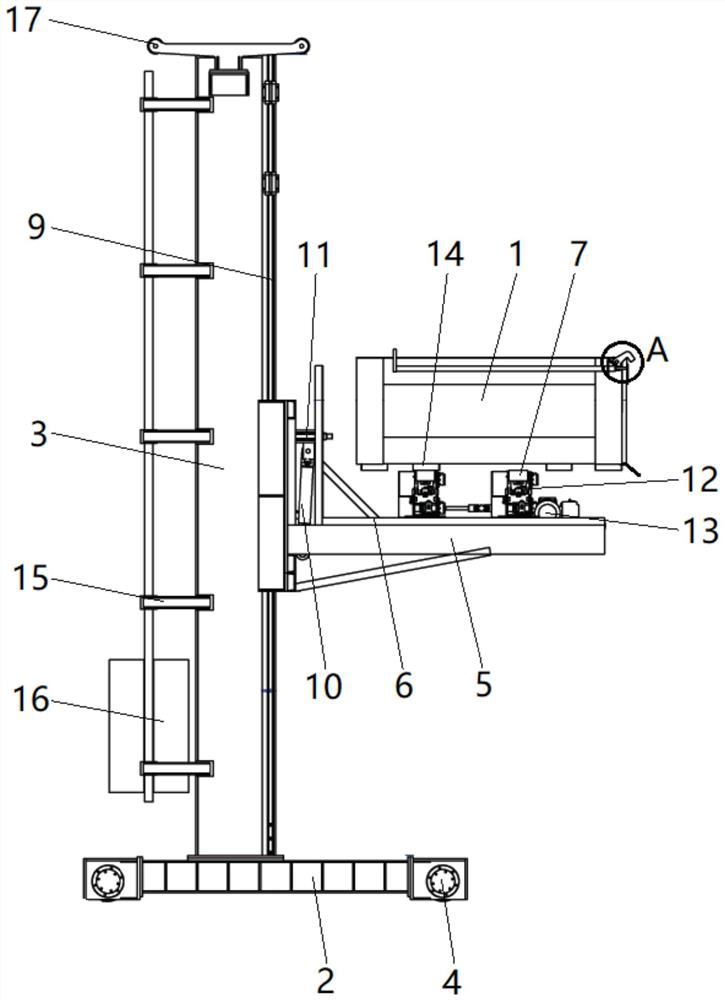

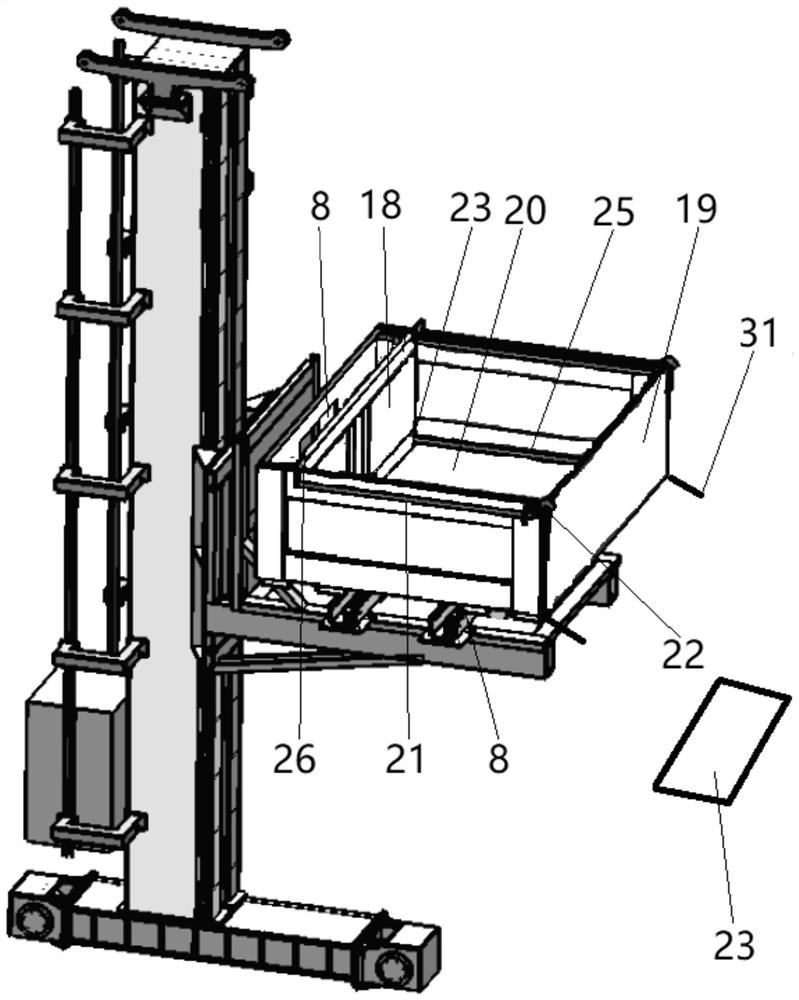

Stacking equipment of refrigerator for storing carcasses of animals dead of illness

ActiveCN112429512AAccurate placementEasy to placeStacking articlesSupporting framesAnimal scienceStructural engineering

The invention provides stacking equipment of a refrigerator for storing carcasses of animals dead of illness. The stacking equipment of the refrigerator for storing the carcasses of the animals dead of illness comprises a main body substrate, wherein driving wheels are arranged at the bottom end of the main body substrate, a lifting mechanism is arranged on the main body substrate, the lifting mechanism is connected with a lifting platform, an overturning platform is arranged on the lifting platform, the outer side of the overturning platform is hinged to the lifting platform, the inner side of the overturning platform is connected with the lifting platform though a first linear driving mechanism, telescopic arms are arranged on the overturning platform, the telescopic arms are magnetically connected with the bottom end of a collection box, a second linear driving mechanism is arranged on the overturning platform, and the second linear driving mechanism corresponds to a pushing openingof the collection box. By means of the stacking equipment of the refrigerator for storing the carcasses of the animals dead of illness, the collection box can be accurately and conveniently placed ina corresponding position of the refrigerator, opening and closing of an unloading board of the collection box are convenient to control, unloading is convenient to operate, and no electric control devices are arranged in the box, so that the box is still reliable to use when stored in the refrigerator environment for a long term.

Owner:HUNAN XIANGBO COMML GREASE CO LTD

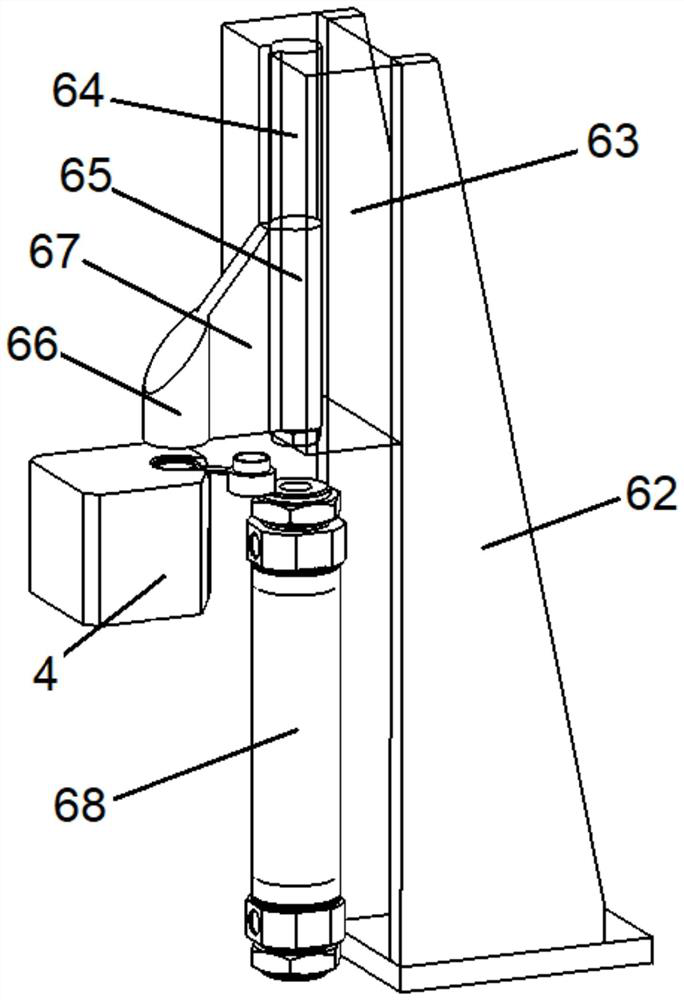

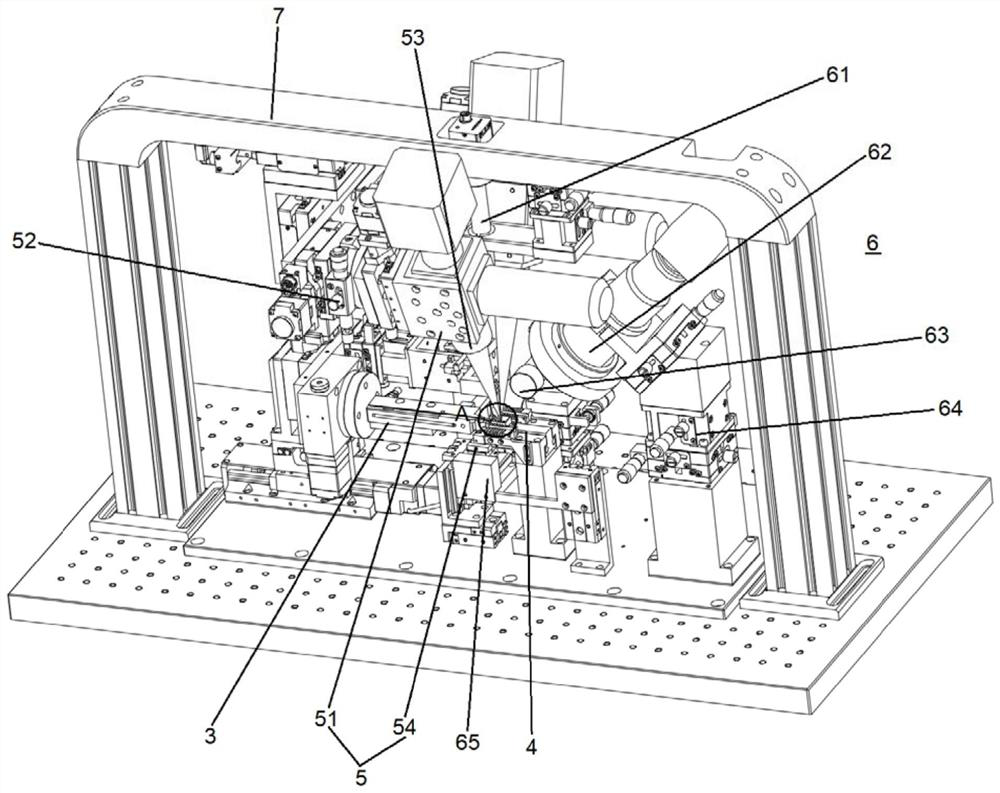

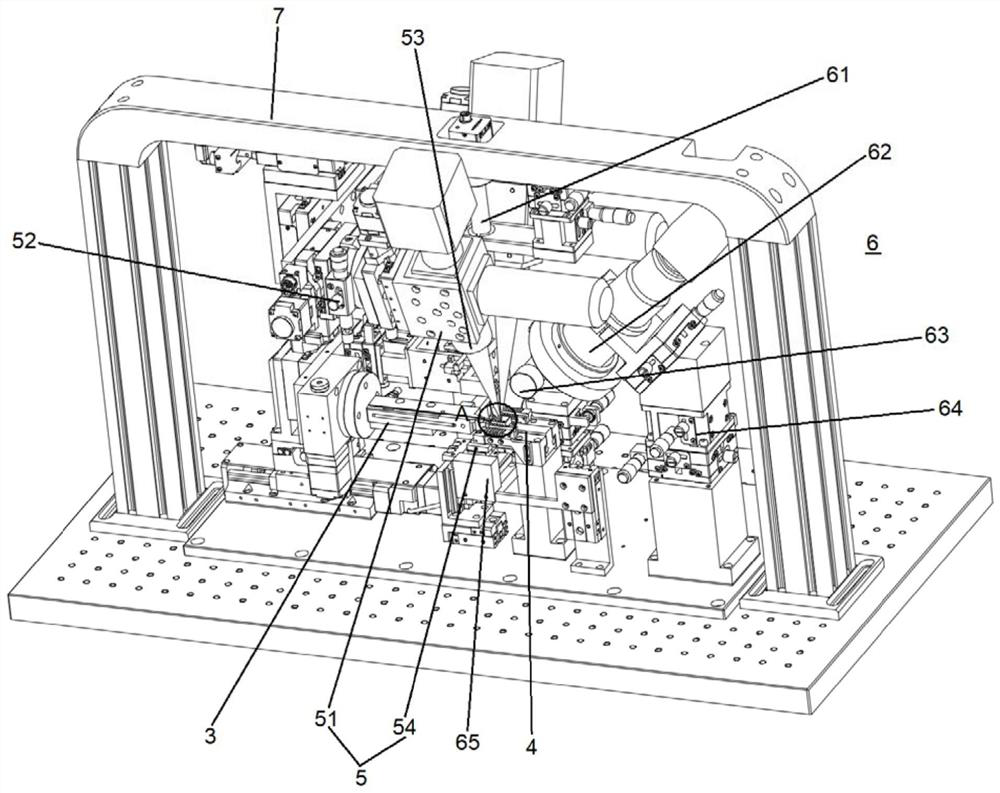

Butterfly laser coupling and welding equipment with polarization-maintaining fiber

ActiveCN111922520AReasonable structural designFit compactLaser beam welding apparatusErbium lasersEngineering

The invention provides butterfly laser coupling and welding equipment with a polarization-maintaining fiber. The butterfly laser coupling and welding equipment comprises an optical fiber clamp module,a pipe shell clamp module, a welding module and a visual monitoring module; the optical fiber clamp module clamps an optical fiber to feed the optical fiber in a pipe shell and adjusts the position and angle of the optical fiber for coupling; the pipe shell clamp module clamps and positions the pipe shell and electrifies the pipe shell; the welding module welds a metal sleeve on a coupled opticalfiber in the pipe shell; the visual monitoring module is used for monitoring the position and angle of the optical fiber; the optical fiber clamp module comprises a mounting plate arranged on a coupling displacement table, an optical fiber rotary support table arranged at one end of the mounting plate, and a front end chuck component arranged at the other end of the mounting plate. According to the butterfly laser coupling and welding equipment, all modules are reasonable in structural design and compact in joining and matching, so that the packaging process is simplified, and the productionefficiency is improved; and when a front end chuck moves, and adsorbs and fixes the metal sleeve at the front end of the optical fiber, the front end chuck does not generate obvious mutual interference with the optical fiber rotary support table, so that the coupling precision is improved.

Owner:CENT SOUTH UNIV

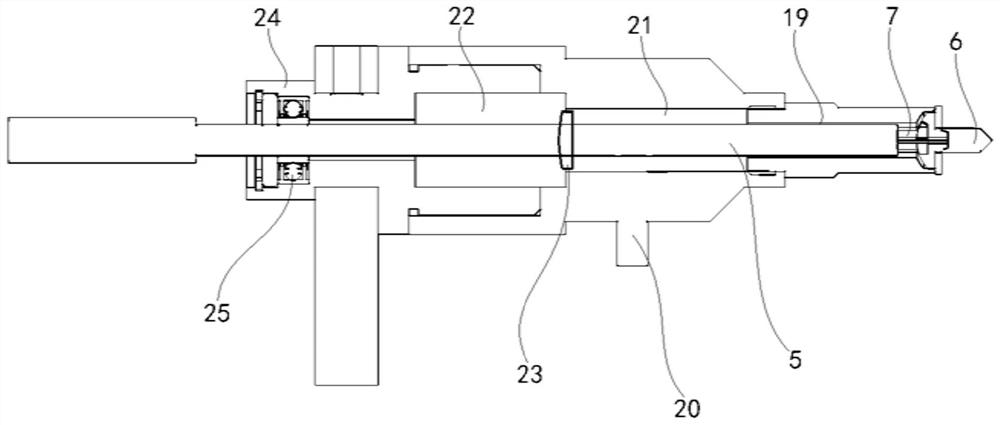

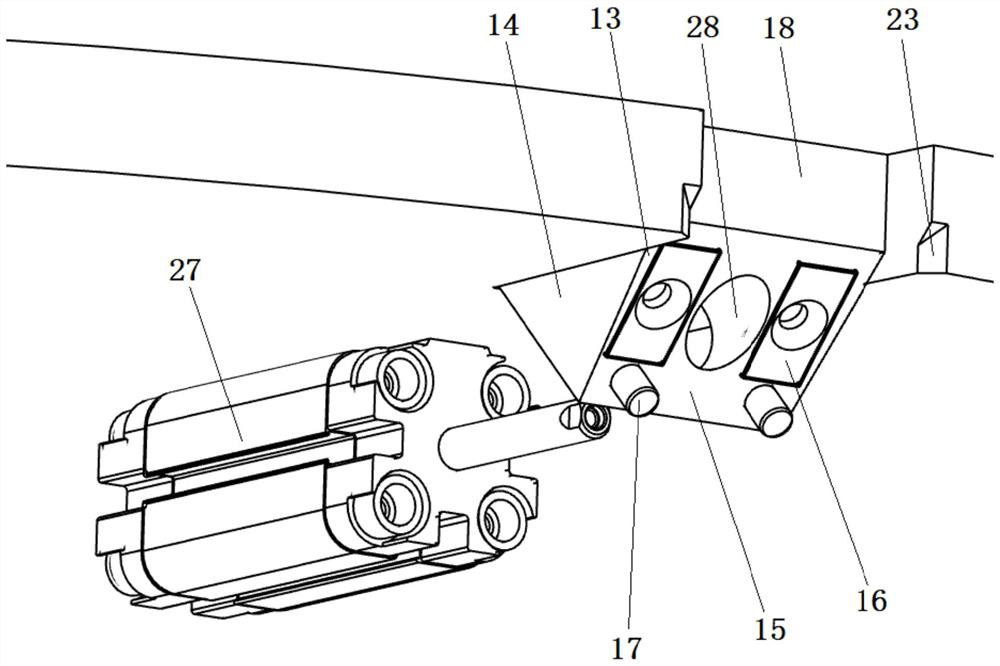

Test tube flipping device

ActiveCN111847342AImprove efficiencyQuality improvementStopper feedingThreadless stopper insertionProduction lineEngineering

The invention relates to the technical field of test tube assembly, in particular to a test tube flipping device comprising a base and a rotary driving part arranged on the base. A flipping table is arranged at the output end of the rotary driving part; the flipping table is provided with a clamping mechanism; after the clamping mechanism clamps the outer lateral wall of a plug head, the flippingtable drives the clamping mechanism to rotate by a preset angle, so that a connecting part is bent, the bottom end of the plug head is aligned with a test tube opening; the test tube flipping device also comprises a plug pressing mechanism, and the plug pressing mechanism drives the flipped plug head to be inserted into the test tube opening. The mechanism has reasonable design and compact linkageand matching, the test tube opening can be automatically sealed with a plug lid, the test tube flipping device is suitable for production line type assembly, and the efficiency and quality of test tube sealing are effectively improved.

Owner:SHAODONG INTELLIGENT MFG INNOVATIVE INST

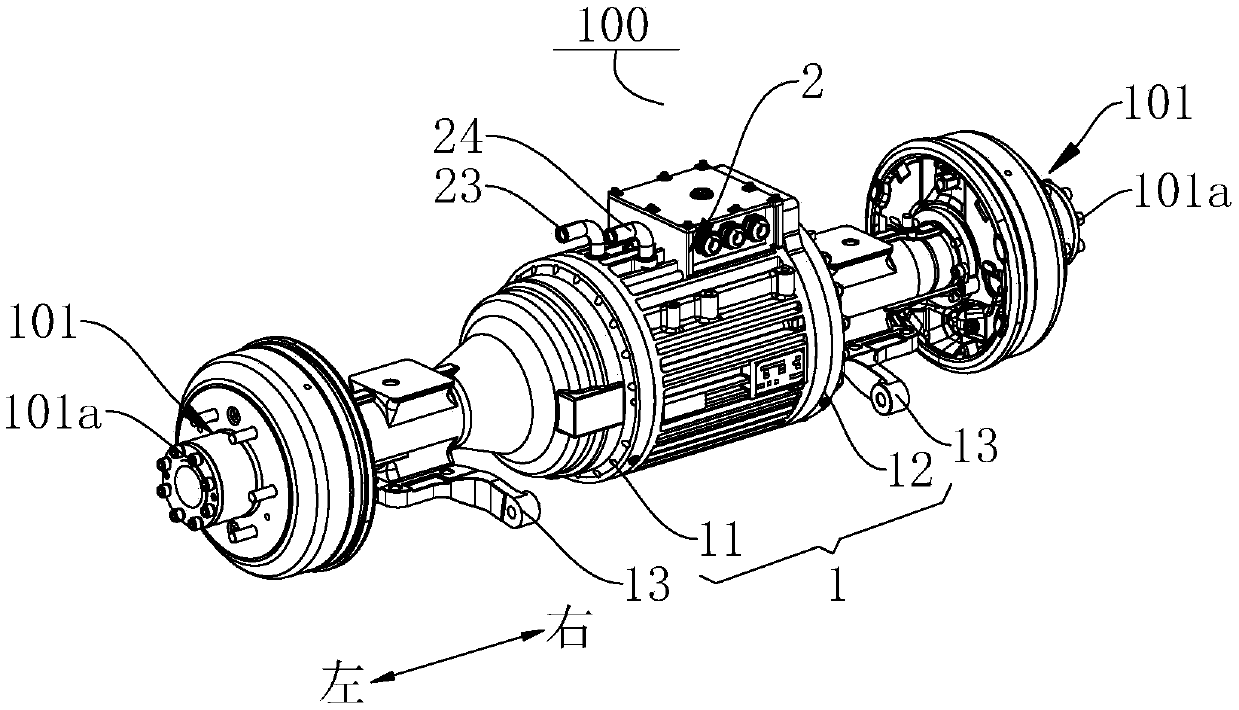

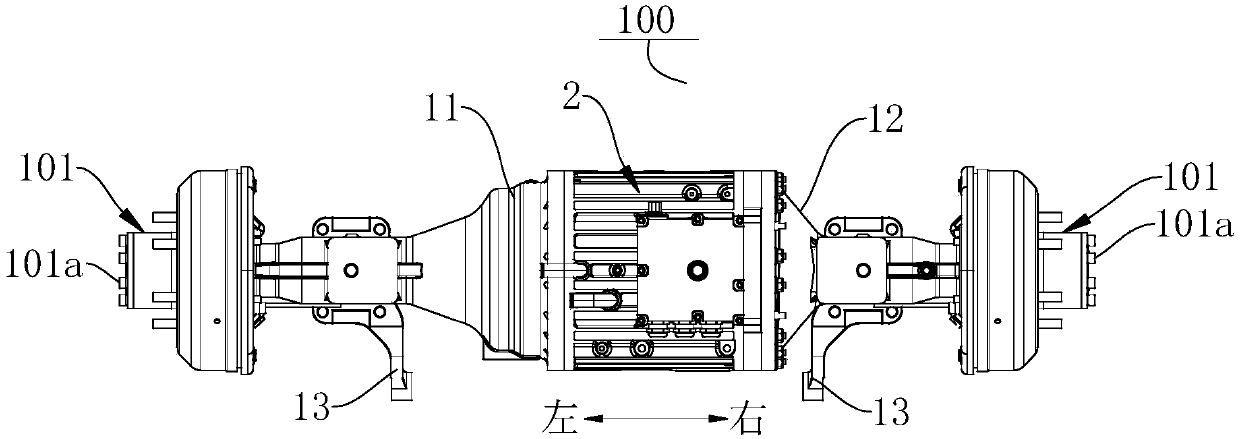

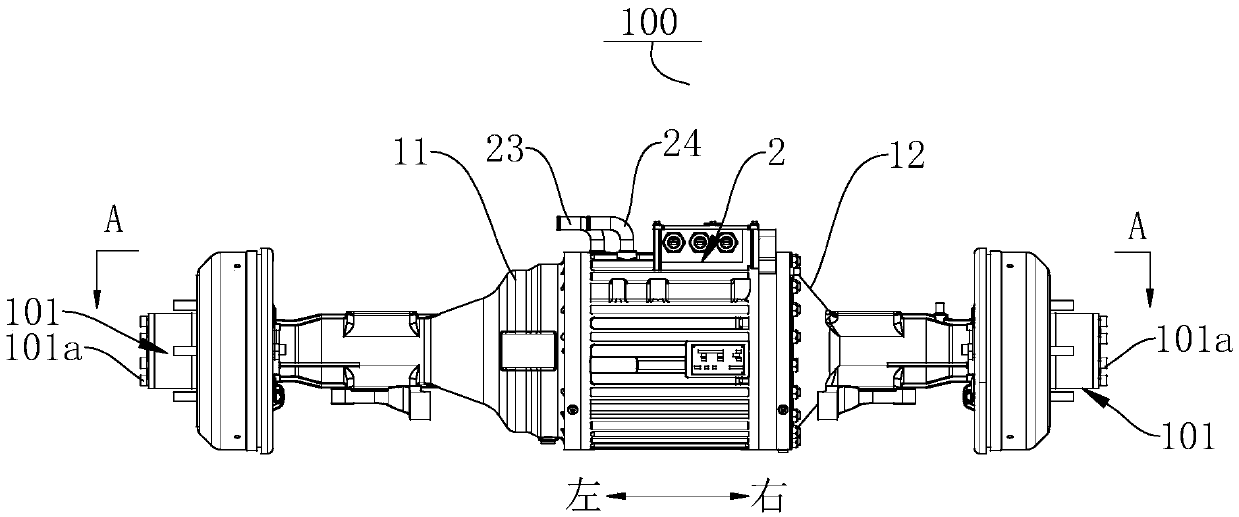

Drive axle and vehicle with same

ActiveCN110962506ACompact structureAchieve lightweightElectric propulsion mountingAxle unitsGear wheelElectric machinery

The invention discloses a drive axle and a vehicle with the drive axle. The drive axle comprises an axle housing assembly, a motor, a planetary reduction gear and a differential mechanism. The motor comprises a motor shaft and a motor shell, the motor shaft is a hollow shaft, and the motor shell is fixed to the axle housing assembly. The planetary reduction gear comprises an input sun gear, an inner gear ring and an output planet carrier, wherein the input sun gear is connected with the motor shaft, the inner gear ring is fixed to the axle housing assembly, and the output planet carrier is theoutput end of the planetary reduction gear. The differential mechanism is arranged on the axle housing assembly and comprises a differential mechanism shell and two half axle gears, wherein the differential mechanism shell and the output planet carrier are integrally formed, the two half axle gears are connected with two wheel end half axles respectively, and one wheel end half axle penetrates through the motor shaft. According to the drive axle, the output planet carrier in the planetary reduction gear and the differential mechanism shell of the differential mechanism are arranged to be an integrally-formed part, such that the light weight and function centralized integrated design of the drive axle can be achieved, and the assembly space of a chassis is greatly saved.

Owner:BYD CO LTD

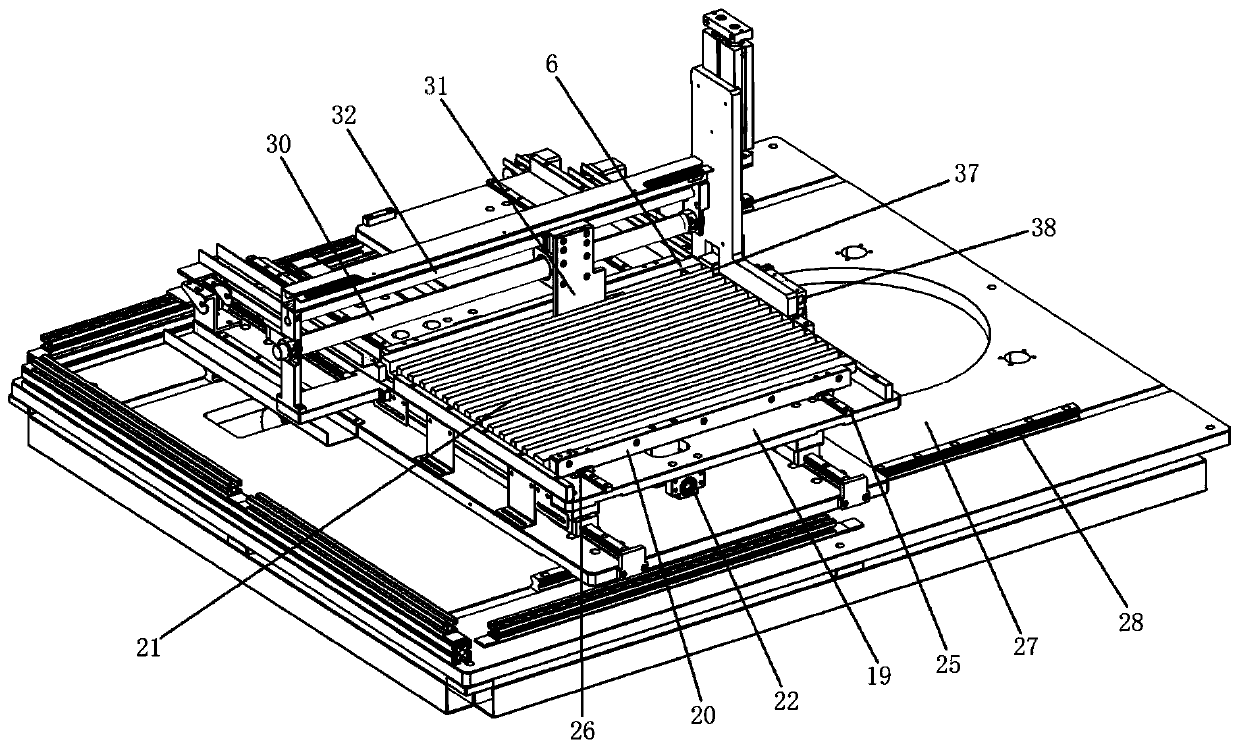

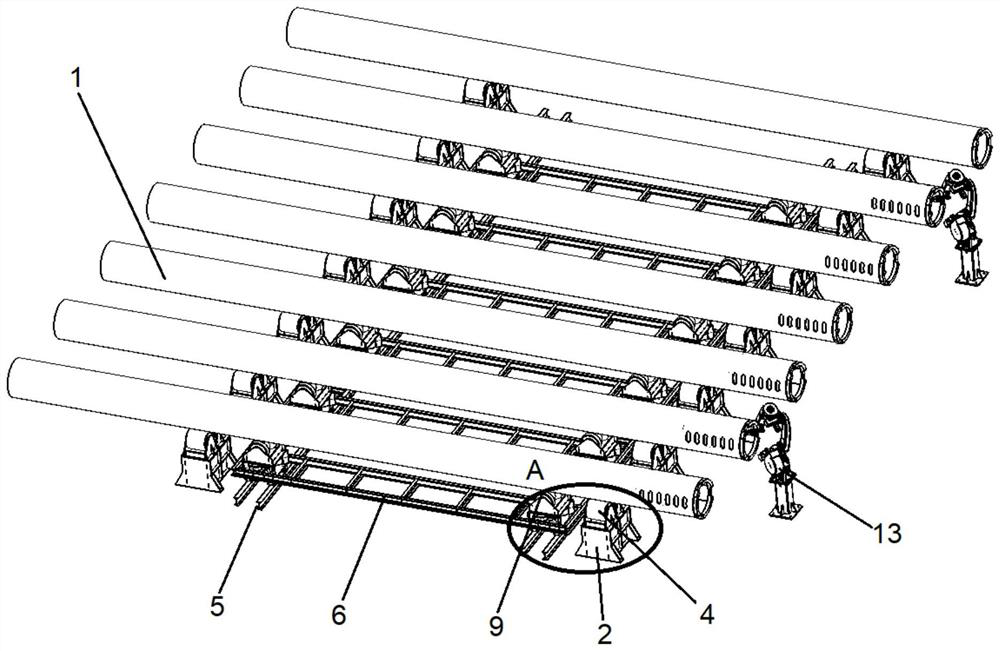

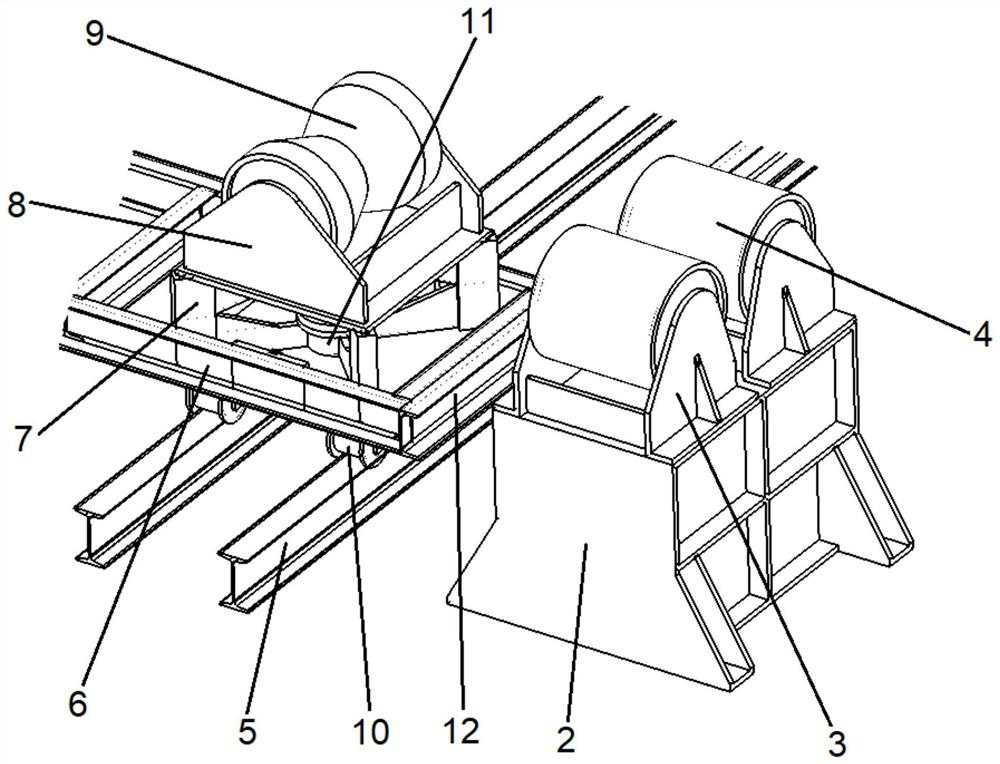

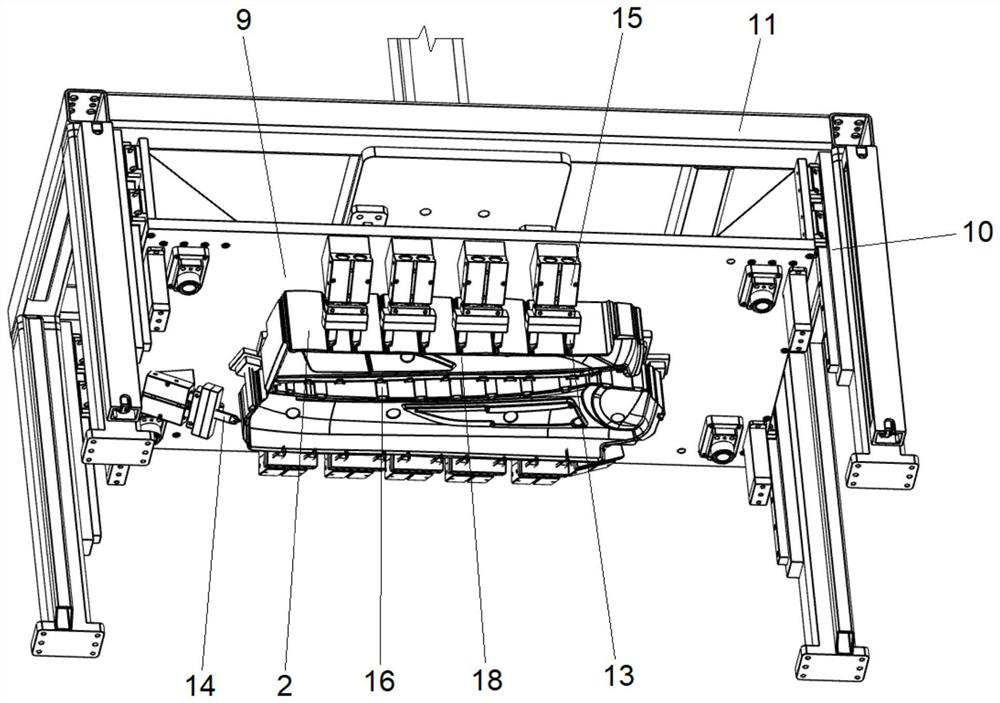

Large pipe fitting assembly equipment

InactiveCN111805201AStable supportFlip reliableMetal working apparatusPipe fittingStructural engineering

The invention provides large pipe fitting assembly equipment. The large pipe fitting assembly equipment comprises an assembly mechanism, a turnover mechanism and a movable feeding mechanism, wherein the turnover mechanism comprises a supporting base, at least two longitudinal roller racks arranged on the supporting base, and a longitudinal roller which is rotatably arranged on each longitudinal roller rack; the movable feeding mechanism comprises at least two feeding guide rails, a bridge rack movably arranged on the feeding guide rails, a bearing frame arranged on the bridge frame, a transverse roller rack arranged on the bearing frame and a transverse roller which is rotatably arranged on the transverse roller rack; and a jacking drive part which drives the transverse roller rack to liftis further arranged on the bearing frame. The large pipe fitting assembly equipment is reasonable in integral structure design, is compact in jointing fitting, is reliable in large pipe fitting support, turnover and displacement, effectively improves assembly type processing efficiency of large pipe fittings, and reduces production cost.

Owner:SHAODONG INTELLIGENT MFG INNOVATIVE INST

Elevator traction bearing component and elevator

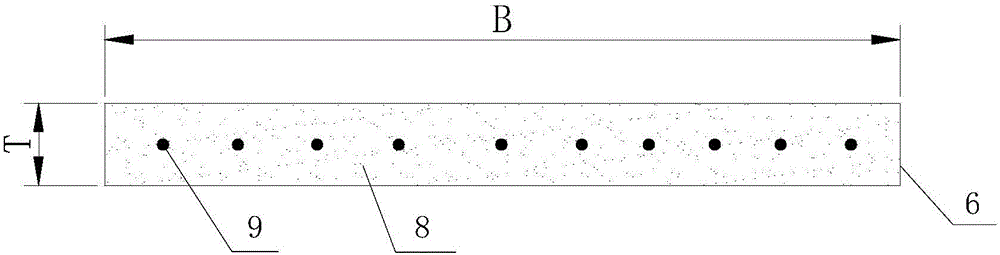

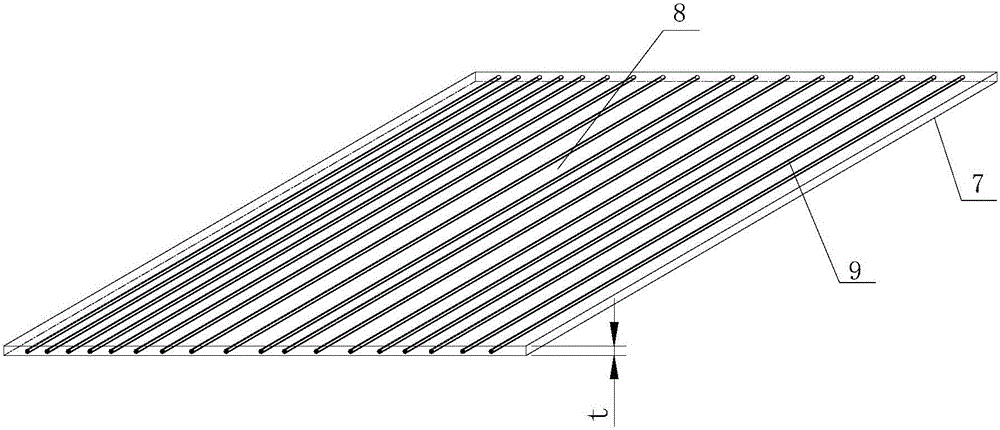

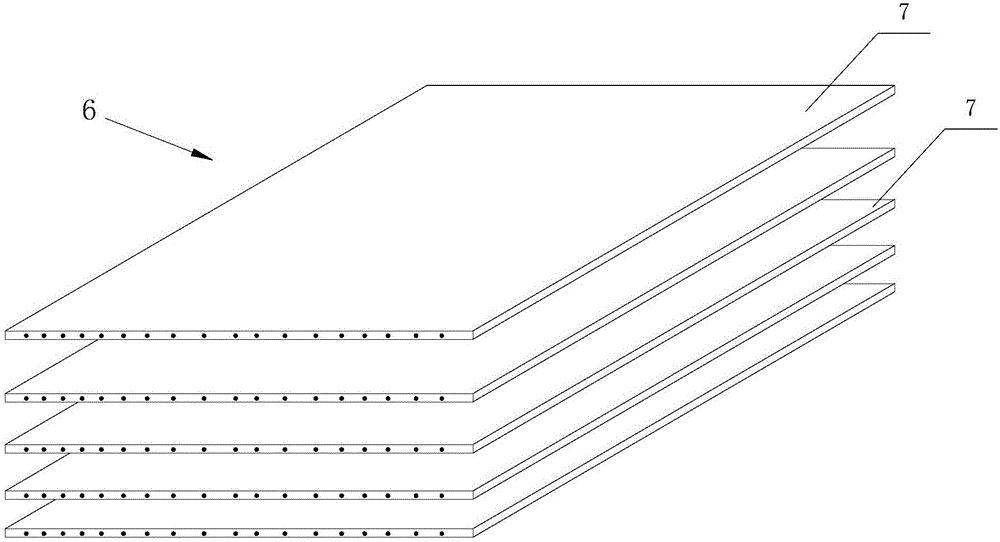

The invention discloses an elevator traction bearing component and an elevator. The elevator traction bearing component comprises one or more traction bearing units; each traction bearing unit includes a polymer substrate, and at least one nonmetal fiber embedded in the polymer substrate and continuously extending in the length direction of the traction bearing unit; the nonmetal fibers are glass fibers, carbon fibers or nylon fibers; and diameters d of the nonmetal fibers are 3-80 microns. The nonmetal fibers are leaded into the elevator traction bearing component to realize lighter design of the elevator traction bearing component, so that the weight of the elevator traction bearing component is largely reduced, and the use noise of the elevator traction bearing component is lowered. The elevator adopting the elevator traction bearing component with lighter design can be more suitable for a compact building hoistway to improve the elevator operation comfort.

Owner:SJEC CORP

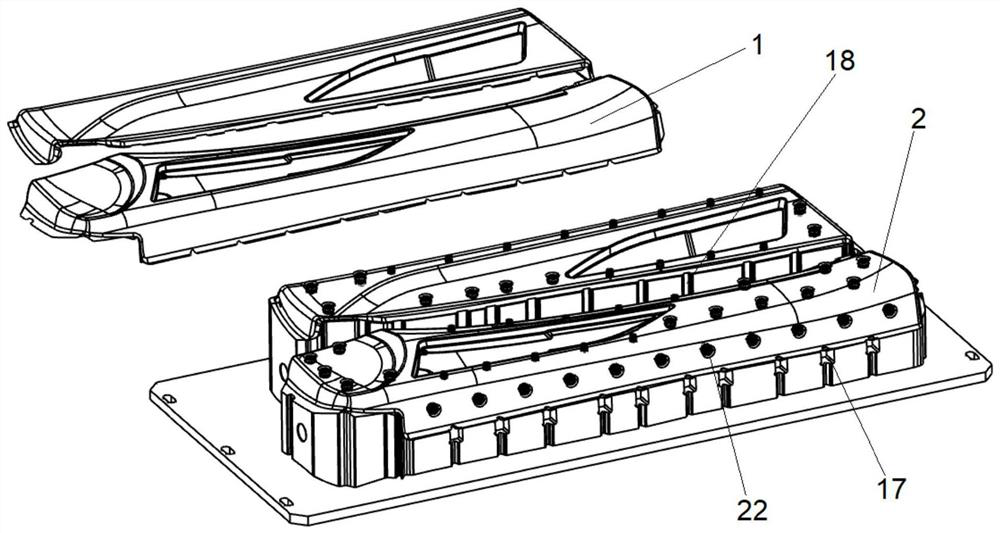

Decorating plate skin die cutting equipment

InactiveCN111673834AReasonable structural designFit compactMetal working apparatusDrill holeEngineering

The invention relates to the field of decorating plate machining equipment, in particular to decorating plate skin die cutting equipment. The equipment comprises an upper die and a lower die, whereinthe upper die and the lower die clamp and locate a decorating plate. The lower die is arranged on a feeding mechanism. The decorating plate is laid on the upper surface of the lower die. The upper dieis arranged on a vertical lifting mechanism. The vertical lifting mechanism is further provided with multiple die cutting cutters. The feeding mechanism moves the lower die right below the upper die.The upper die descends along with the vertical lifting mechanism and is attached to the upper surface of the lower die to compress and locate the decorating plate. The die cutting cutters carry out die cutting machining on the decorating plate. The equipment is reasonable in overall structural design, compact in connecting and matching, and capable of completing die cutting technologies of edge cutting, drilling and the like of decorating plate injection molding part fully automatically.

Owner:SHAODONG INTELLIGENT MFG INNOVATIVE INST

Automatic wrapping equipment for box body

ActiveCN113401392AReliable coatingCover firmlyFinal product manufactureWeb rotation wrappingStructural engineeringMechanical engineering

The invention provides automatic wrapping equipment for a box body. The equipment comprises a mounting frame, three rotating wrapping mechanisms are arranged on the mounting frame, a packaging film cylinder is arranged on each rotating wrapping mechanism, rotating shafts of the three rotating wrapping mechanisms are parallel to an X axis, a Y axis and a Z axis respectively, packaging films on the packaging film cylinders are wrapped on the box body from three directions, a plurality of material jacking mechanisms are further arranged on the mounting frame, and the box body is fixed to a preset position through the material jacking mechanisms. A box-type object is wrapped in an all-dimensional manner through the three rotating wrapping mechanisms, each face can be wrapped twice, it is ensured that overall wrapping of the object is more reliable and firmer, the box body does not need to be moved or rotated in the whole process, meanwhile, the box body is fixed through the multiple material jacking mechanisms, a sequential fixing manner is adopted, connection and matching are compact, the wrapping operation of the rotating wrapping mechanisms is not interfered, so that the equipment arrangement is reduced, the efficiency of the wrapping operation is improved, and the operation cost is reduced.

Owner:SHAODONG INTELLIGENT MFG INNOVATIVE INST

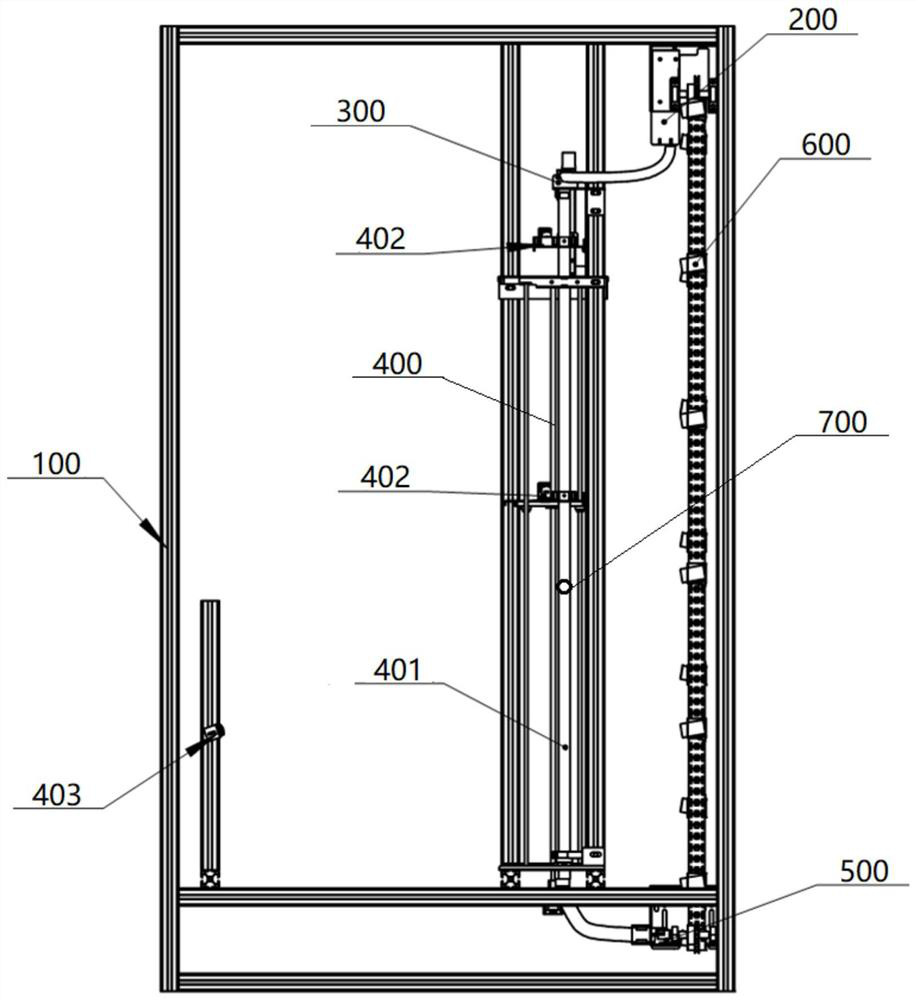

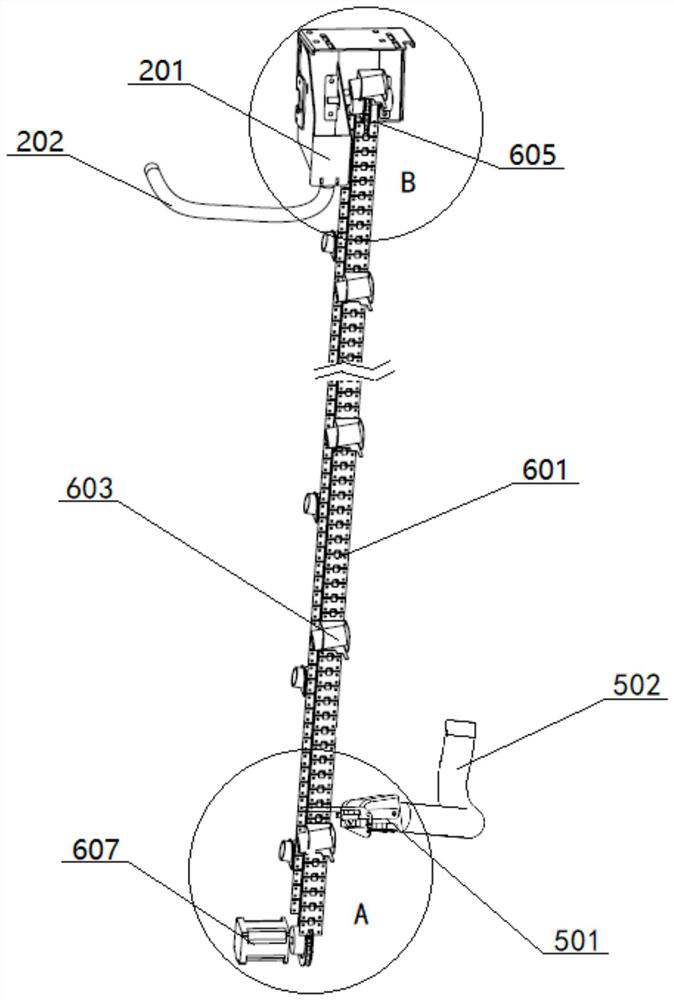

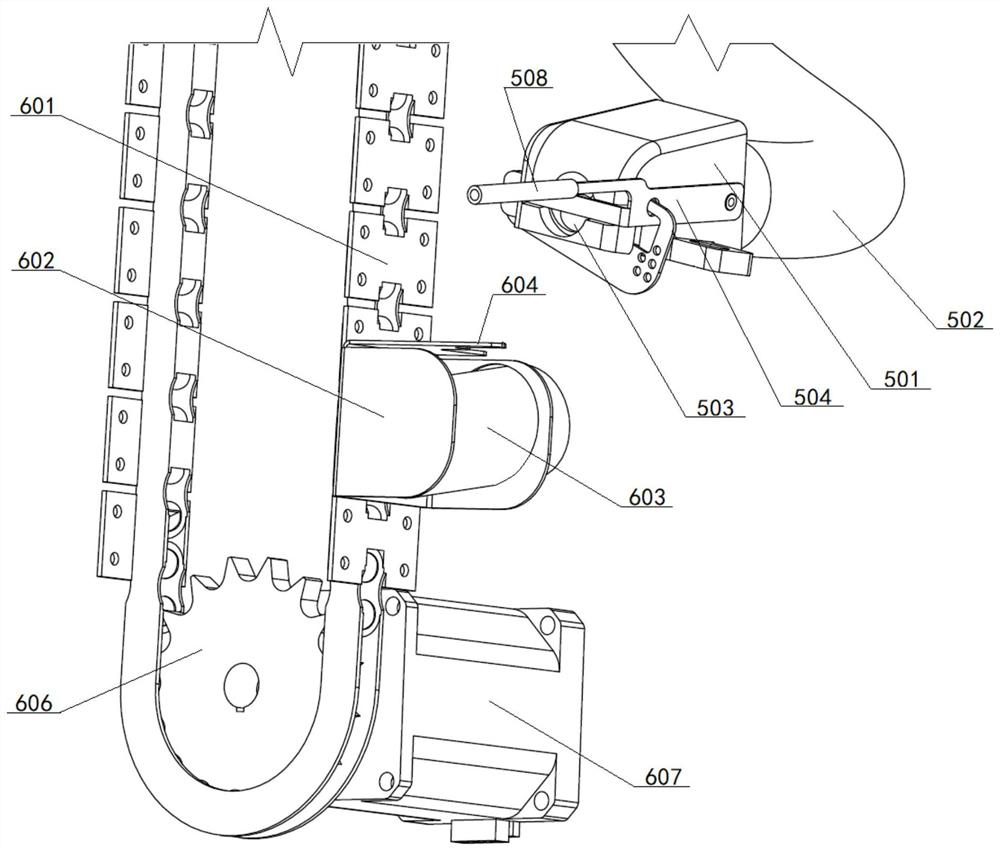

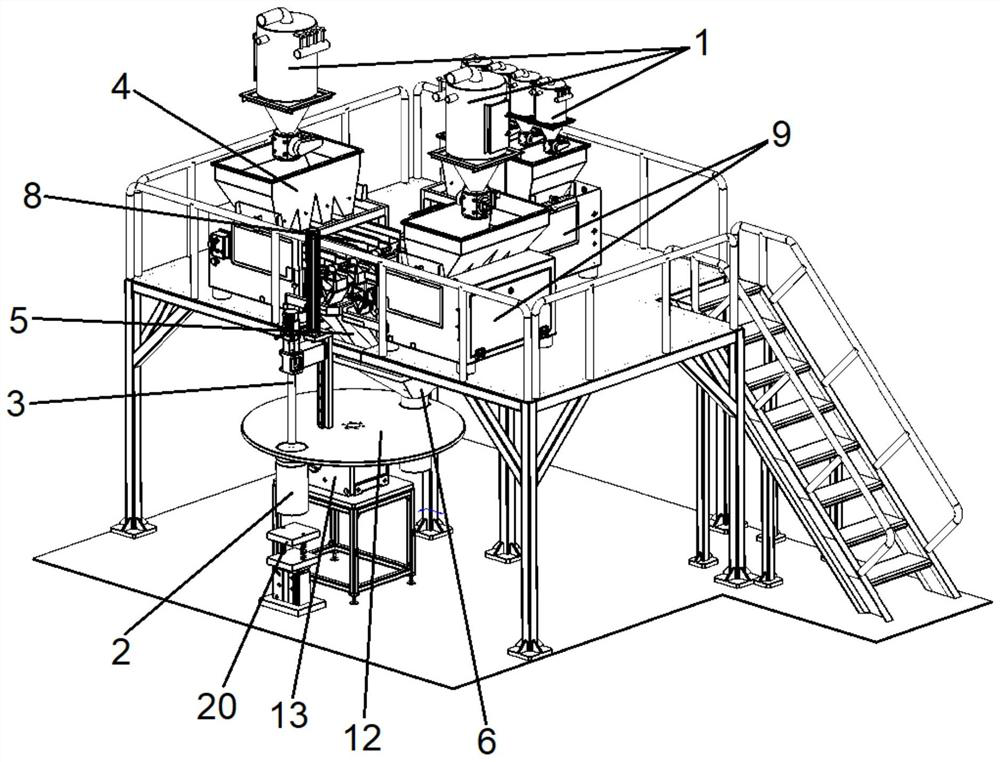

Intelligent free-fall motion experiment instrument

ActiveCN113870669AImprove experienceReasonable structural designEducational modelsFree fallingAutomatic control

The invention provides an intelligent free-fall motion experiment instrument, which comprises a structural frame provided with a ball receiving assembly, a ball stopping assembly, a free-fall assembly, a ball feeding assembly and a ball conveying assembly. The ball receiving assembly conveys a small ball to the ball stopping assembly, the ball stopping assembly enables the small ball to be positioned at a falling starting point of the free-fall assembly and triggers the small ball to freely fall, the free-fall assembly comprises a vertical free-fall channel, the free-fall channel is provided with a monitoring device for monitoring the free-fall experiment process, the ball feeding assembly is used for collecting experiment-completed small ball and then feeding the small ball to the ball conveying assembly, the ball conveying assembly is used for lifting the small ball and conveying the small ball to the ball receiving assembly, so that the small ball can be recycled, the connection and matching are compact, full-automatic control is adopted, field operation of an operator is not needed, falling small balls are manually collected, and the experiment efficiency and accuracy are remarkably improved.

Owner:NAT UNIV OF DEFENSE TECH

Medicine pillow packaging machine

ActiveCN111994316BImprove packaging efficiencyImprove packaging qualitySolid materialPharmacy medicineEngineering

The invention provides a medicine pillow packaging machine, which includes a mixing component and a pillow case pressing component. The mixing component is provided with at least two layers of mixing hoppers, and the top of the uppermost layer of the mixing hopper is equipped with a feeding device. The lower opening of the mixing hopper on one layer is aligned with the upper opening of the mixing hopper on the next layer, and the lower opening of the mixing hopper on the bottom layer is aligned with the upper opening of the charging cylinder of the pillowcase pressing assembly. It is sleeved on the charging tube from bottom to top, and the medicine in the pillowcase is compressed after passing through the charging tube through a pressing mechanism arranged above the charging tube. The overall structure design of the present invention is reasonable, and the connection and coordination of each component is compact, and the degree of automation is high, which effectively improves the packaging efficiency and quality of the medicine pillow, and reduces the production cost.

Owner:SHAODONG INTELLIGENT MFG INNOVATIVE INST

Screw assembling and disassembling clamp suitable for mechanical arm

ActiveCN113798840AReasonable structural designFit compactWork holdersMetal working apparatusEngineeringMechanical engineering

The invention provides a screw assembling and disassembling clamp suitable for a mechanical arm. The clamp comprises a mounting table connected with the tail end of the mechanical arm, a first movable table is arranged on the mounting table, the first movable table is movably connected with the mounting table, a second movable table is arranged on the first movable table, and the second movable table is movably connected with the first movable table. The first movable table is connected with a screw chuck, the second movable table is connected with a screwdriver shaft, a screwdriver head matched with a screw is formed at the second end of the screwdriver shaft, the screwdriver head is aligned with the screw chuck, after the screw chuck is fed along with the first movable table to position the screw, the screwdriver shaft is fed along with the second movable table, and the screwdriver head makes contact with a nut of the screw. A rotary driving part drives the screwdriver shaft to rotate so as to twist the screw, the screw is mounted or dismounted, the structural design is reasonable, connection and matching are compact, the degree of adaptation to an industrial robot is high, and the screw mounting and dismounting efficiency and quality of a robot are improved.

Owner:SHAODONG INTELLIGENT MFG INNOVATIVE INST

Ceramic atomization core cutting and wire loading mechanism

PendingCN112643311AReasonable structural designFit compactMetal working apparatusControl mannerMechanical engineering

The invention provides a ceramic atomization core cutting and wire loading mechanism which comprises a first cutting part and a second cutting part which are oppositely arranged. Hole-shaped structures corresponding to each other are arranged on the first cutting part and the second cutting part, and the first cutting part moves relative to the second cutting part to enable the corresponding hole-shaped structures to be staggered. Materials in the corresponding hole-shaped structures located at the first cutting part and the second cutting part at the same time are cut, and a wire tube of a preset length is loaded onto a ceramic body. The ceramic atomization core cutting and wire loading mechanism is reasonable in structural design and compact in connection fit, wire loading operation can be conducted on a plurality of ceramic bodies at the same time, and a full-mechanical operation mode and a full-automatic control mode are adopted. And the wire loading efficiency and quality are improved, the defective product rate is decreased and the production cost is reduced.

Owner:SHAODONG INTELLIGENT MFG INNOVATIVE INST

Packaging equipment and method of polarization maintaining optical fiber butterfly-shaped laser

ActiveCN111934177AReasonable structural designFit compactWelding/cutting auxillary devicesAuxillary welding devicesErbium lasersLaser soldering

The invention provides packaging equipment of a polarization maintaining optical fiber butterfly-shaped laser. The packaging equipment comprises an optical fiber clamp module, a pipe shell clamp module, a welding module and a visual monitoring module, wherein the optical fiber clamp module clamps an optical fiber and sends the optical fiber into the pipe shell, adjusts the position and angle of the optical fiber for coupling, the pipe shell clamp module clamps and positions the pipe shell and can electrify the pipe shell, the welding module welds a metal sleeve on the coupled optical fiber inthe pipe shell, and the visual monitoring module is used for monitoring the position and angle of the optical fiber; and the welding module comprises a tail pipe welding assembly arranged on one sideof the pipe shell clamp module, and at least two electrodes are arranged on the tail pipe welding assembly and can make contact with the two sides of the through hole of the pipe shell to be electrified. The modules are reasonable in structural design and compact in connection fit, the packaging process is simplified, the production efficiency is improved, meanwhile, the problem that a tail end metal sleeve is difficult to weld through a laser welding assembly is solved, and the beneficial effects that weldment deformation is small, and automatic control is easy to achieve are achieved.

Owner:CENT SOUTH UNIV

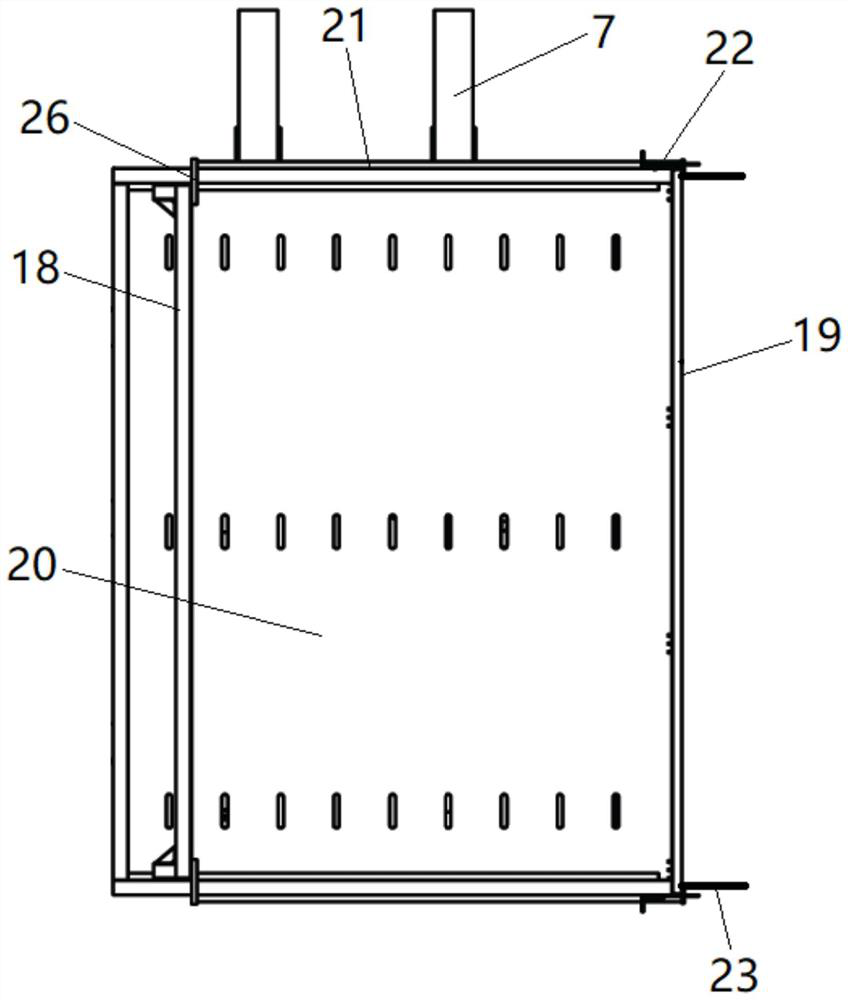

Multistage haze purifier

PendingCN107062417ASimple structureEasy to assemble and disassembleMechanical apparatusDispersed particle filtrationWaste management

The invention relates to a multistage haze purifier which comprises an air inlet barrel assembly, an impeller, a drive device, a filtering shell and a multistage filtering cylinder assembly. The air inlet barrel assembly comprises a hollow air barrel with the two ends open and a netty grating. The netty grating is mounted in an opening in one end of the air barrel. The impeller is coaxially arranged in the air barrel. The drive device is mounted in the air inlet barrel assembly, and the drive end of the drive device is fixedly connected with the impeller. The filtering shell is hollow, and one end of the filtering shell is open. The open end of the filtering shell is necking down and is in sealed connection with the other end of the air barrel in a matched mode. The filtering cylinder assembly is mounted in the filtering shell and internally provided with an air inlet cavity communicating with the air barrel. An air outlet cavity is formed between the multistage filtering cylinder assembly and the inner wall of the filtering shell. A plurality of exhaust outlets are uniformly formed in the position, corresponding to the air outlet cavity, of the closed end of the filtering shell at intervals. The multistage haze purifier has the advantages of being simple in structure, convenient to dismount, mount and use, and good in filtering effect.

Owner:山东速得机电有限公司

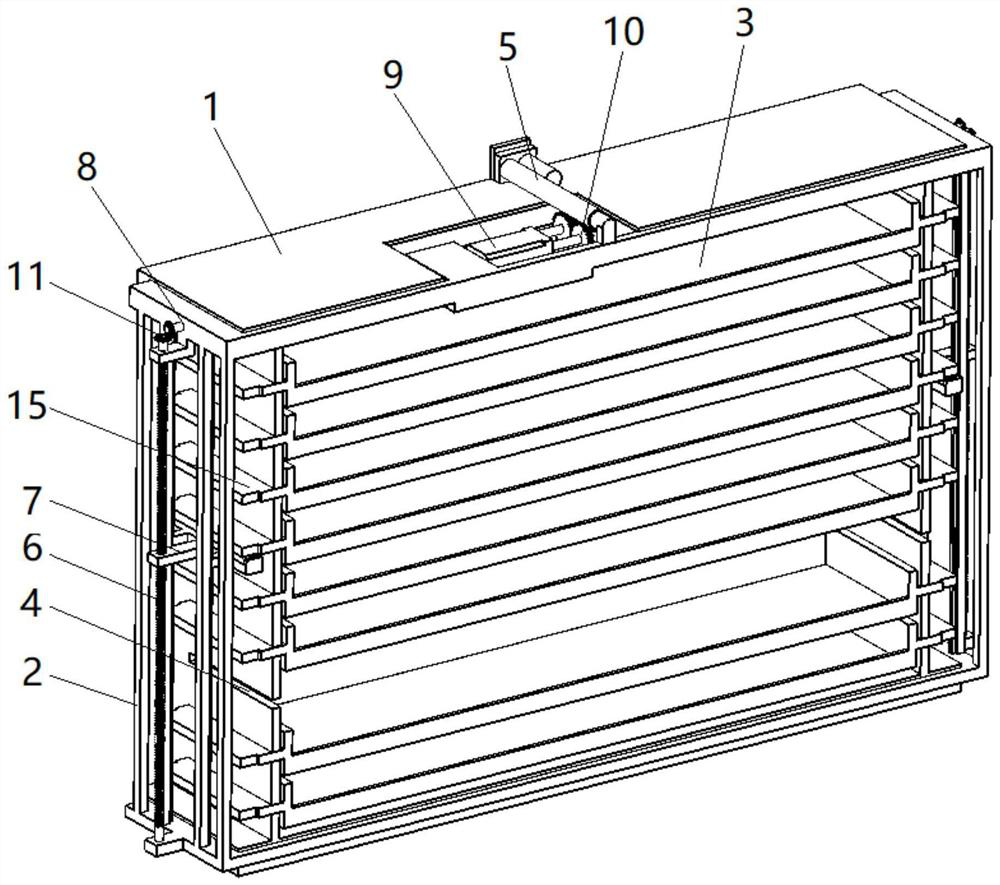

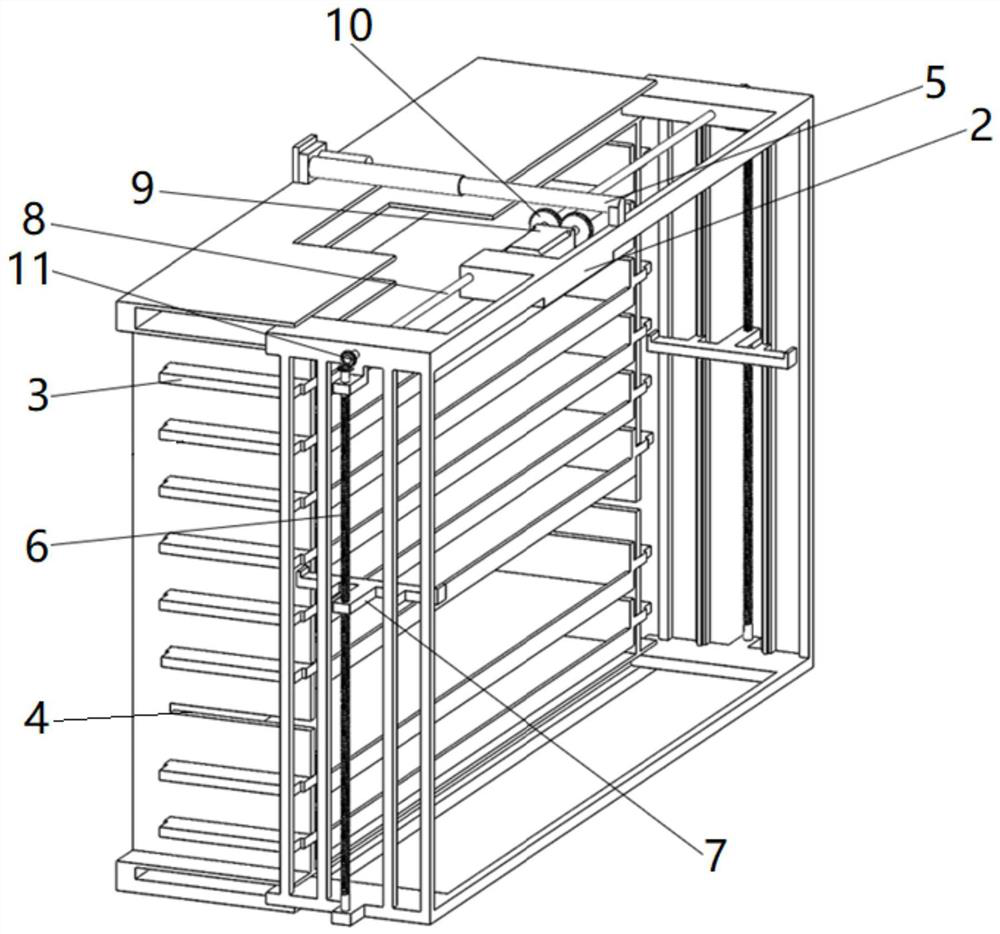

Automatic material storing and taking storage device

ActiveCN112429448AImprove convenienceImprove efficiencyStorage devicesStructural engineeringObject store

The invention provides an automatic material storing and taking storage device which comprises a storage rack and a taking rack, multiple layers of storage plates are arranged on the storage rack, thetwo ends of each storage plate are clamped into a fixing groove of the storage rack from the front side of the storage rack, and the taking rack can move front and back relative to the storage rack.Lifting devices are arranged on the left side and the right side of the taking rack respectively, each lifting device is connected with a taking block, a clamping groove is formed in the upper surfaceof each taking block, and the clamping grooves correspond to the ends of the storage plates. According to the automatic material storing and taking storage device, each of the storage plates is movedfrom the highest position or the lowest position to the position most suitable for people to store and take objects, the storage plates are put back through the opposite process, the convenience andefficiency of object storing and taking are improved, the overall structure is simple, connection matching is compact, extra space is not occupied when the storage plate is not used, and the use costis lower.

Owner:SHAODONG INTELLIGENT MFG INNOVATIVE INST

Drive switching and transmission variable speed system of hollow motor type electric vehicle

PendingCN106956579AFit compactReduce occupancyElectric propulsion mountingControl devicesElectric machineryElectric vehicle

The invention discloses a drive switching and transmission variable speed system of a hollow motor type electric vehicle. The drive switching and transmission variable speed system of the hollow motor type electric vehicle comprises a hollow motor and a transmission, wherein the transmission comprises a variable speed drive component and a front output shaft, the front output shaft is penetrated through a hollow power shaft and can rotate relatively; the drive switching and transmission variable speed system further comprises a rear output shaft which can be matched with the front output shaft in a clutching mode for outputting power to a vehicle rear wheel to switch between two-wheel driving and four-wheel driving; the hollow power shaft of the hollow motor is used for inputting the power to the transmission, and the front output shaft taken as the power output end of the transmission can penetrate the hollow power shaft in a relatively rotating way for driving a vehicle front wheel, so that a matching structure of the hollow motor and the transmission is quite compact to reduce the occupied space, and the rear output shaft which is matched with the front output shaft in the clutching mode realizes switching between the two-wheel driving and the four-wheel driving, and a variable speed output component can be together used to realize output of multiple working modes, so that the drive switching and transmission variable speed system of the hollow motor type electric vehicle can be used under multiple working conditions.

Owner:CHONGQING UNIV

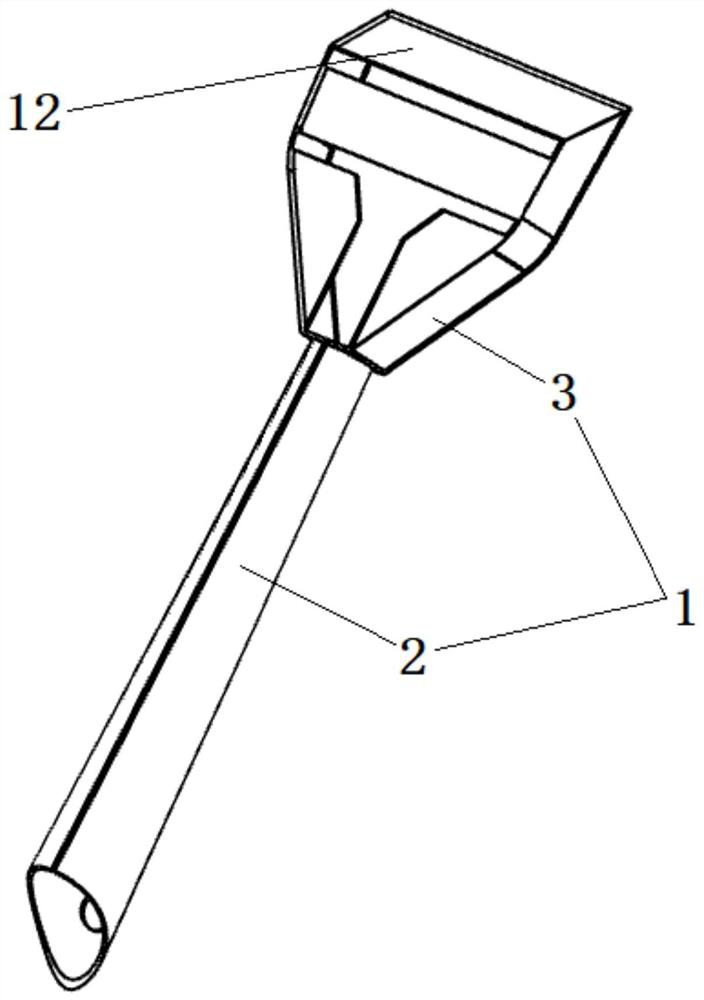

Automatic processing device for peelers

ActiveCN111660031AImprove the defects caused by manual assisted operationImprove product qualityWelding/cutting auxillary devicesAuxillary welding devicesTool bitProcess engineering

The invention relates to the field of automatic production and processing, and in particular relates to an automatic processing device for peelers. The automatic processing device comprises a feedingplatform, a peeler body feeding station, a peeler blade feeding station, a welding station and a discharging station are arranged on the feeding platform, a peeler blade feeding mechanism is arrangedon the peeler blade feeding station, a welding mechanism is arranged on the welding station, the discharging station is provided with a discharging mechanism, the peelers are fed from the peeler bodyfeeding station, peeler blades are fed from the peeler blade feeding station, the peeler blades are fed to the front end faces of peeler heads through the peeler blade feeding mechanism and then integrally moved to the welding station to be welded, and the discharging station discharges the peelers completing machining. A full-mechanical mode is adopted for welding process, a full-automatic mode is adopted for control, the device is suitable for flow line production of the peelers, the defects caused by manual auxiliary operation are improved, the production quality and efficiency are improved, and the production cost is reduced.

Owner:SHAODONG INTELLIGENT MFG INNOVATIVE INST

Packaging equipment and method for polarization maintaining fiber butterfly laser

ActiveCN111934177BSolving Welding DifficultiesReduce distortionWelding/cutting auxillary devicesAuxillary welding devicesVisual monitoringPolarization-maintaining optical fiber

The invention provides a packaging device for a polarization-maintaining optical fiber butterfly laser, which includes an optical fiber clamp module, a shell clamp module, a welding module and a visual monitoring module. The optical fiber clamp module clamps the optical fiber and sends it into the shell, adjust The position and angle of the optical fiber are coupled, the shell fixture module clamps and positions the shell, and can power on the shell, the welding module welds the metal sleeve on the coupled optical fiber in the shell, and is used for the visual monitoring module For monitoring the position and angle of the optical fiber; the welding module includes a tail pipe welding assembly arranged on one side of the shell fixture module, on which at least two electrodes are arranged, which can contact and conduct electricity on both sides of the through hole of the shell. The structure design of each module in the present invention is reasonable, and the connection and cooperation are compact, which simplifies the packaging process and improves the production efficiency. At the same time, it solves the problem that it is difficult to weld the metal sleeve at the tail end by using laser welding components, and has the advantages of small deformation of welding parts and easy realization of automatic control. The advantages.

Owner:CENT SOUTH UNIV

Lens coupling equipment for multi-channel single-mode cob modules

ActiveCN111367029BImprove coupling efficiencyHigh precisionCoupling light guidesMountingsVisual inspectionEngineering

The invention provides a lens coupling device for multi-channel single-mode COB modules, including a lens feeding assembly, a lens fixture assembly, a PCB clamping assembly, a dispensing module, a curing module and a visual detection module; Multiple lenses are installed, and the lenses are loaded sequentially. The lens fixture assembly clamps and moves the lens loaded by the lens loading assembly to the corresponding packaging position on the PCB, and couples with the light-emitting element and the receiving element on the PCB. The PCB is fixed by the PCB. The clamping component is clamped and fixed, the dispensing module dispenses glue to the coupled lens, the curing module cures the dispensed lens, and the visual inspection module is used for visual inspection of the lens feeding and coupling process. The lens of the present invention adopts the method of automatic feeding, and is successively clamped to the surface of the PCB board by the lens clamping components, and is automatically coupled, glued and cured one by one. efficiency, precision and package quality.

Owner:CENT SOUTH UNIV

Pipeline Bowl Washing Machine

ActiveCN113814248BImprove cleaning efficiencyImprove cleaning qualityHollow article cleaningDrying gas arrangementsProcess engineeringAssembly line

The invention provides an assembly line type bowl cleaning machine, which includes a conveyor line consisting of three conveyors for continuously conveying the bowl. The drying assembly for bowl drying is separated by partitions. The cleaning assembly includes the first cleaning structure arranged on both sides of the conveying line, the second cleaning structure arranged below the conveying line, and the third cleaning structure arranged above the conveying line structure, the bowl is continuously reciprocated through the conveying line, and when it is transferred to the adjacent conveying line, the bowl and the contact surface of the conveying line will move relative to each other and change direction. There is no need to stop during the continuous conveying process, and the 360-degree full cleaning and drying without dead angle can be obtained through multiple reversing movements. It is suitable for industrial assembly line production and improves the cleaning efficiency and quality of the bowl.

Owner:长沙精功包装机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com