Patents

Literature

79results about How to "Solving Welding Difficulties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

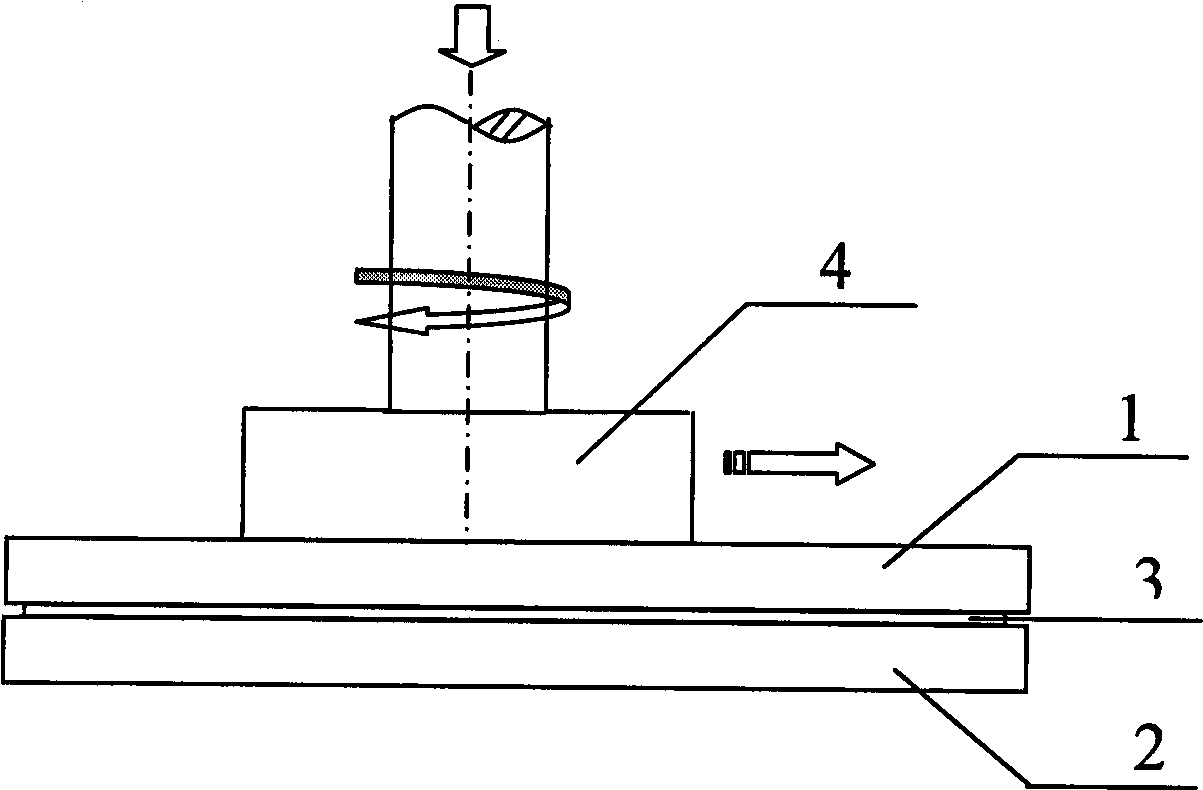

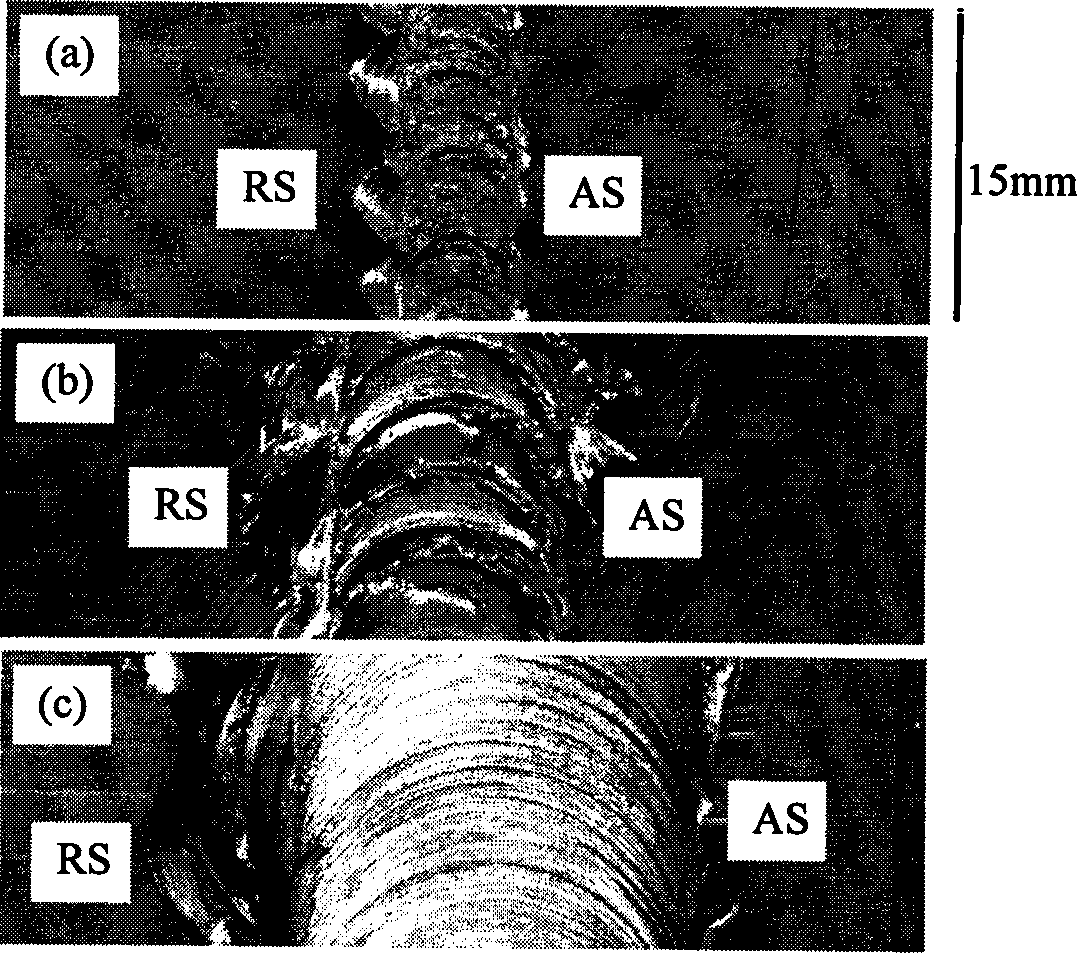

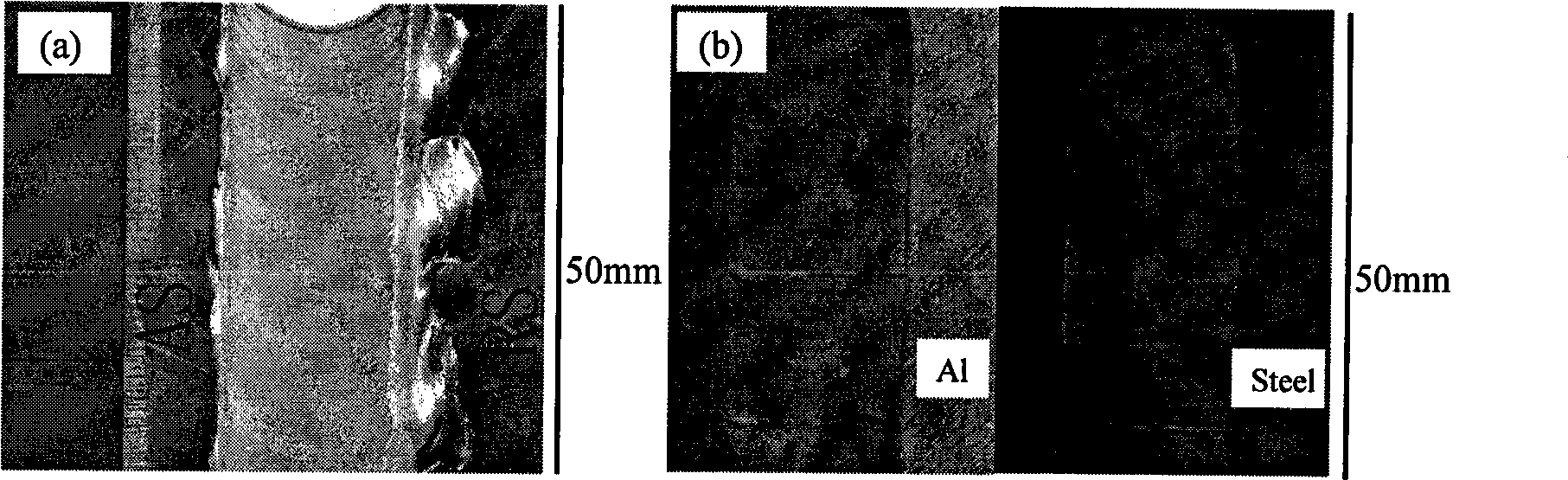

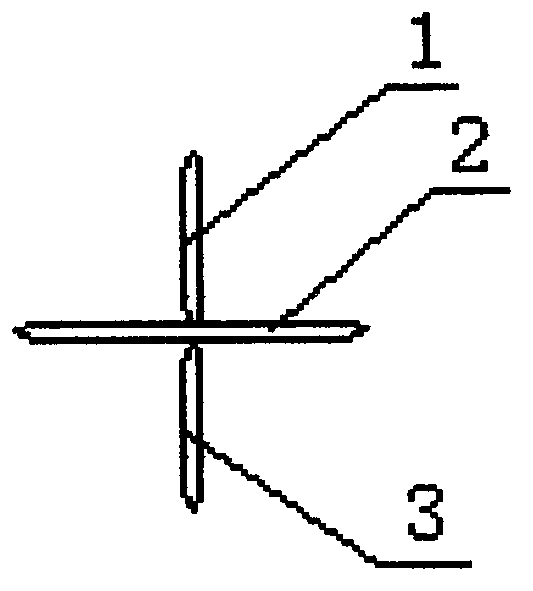

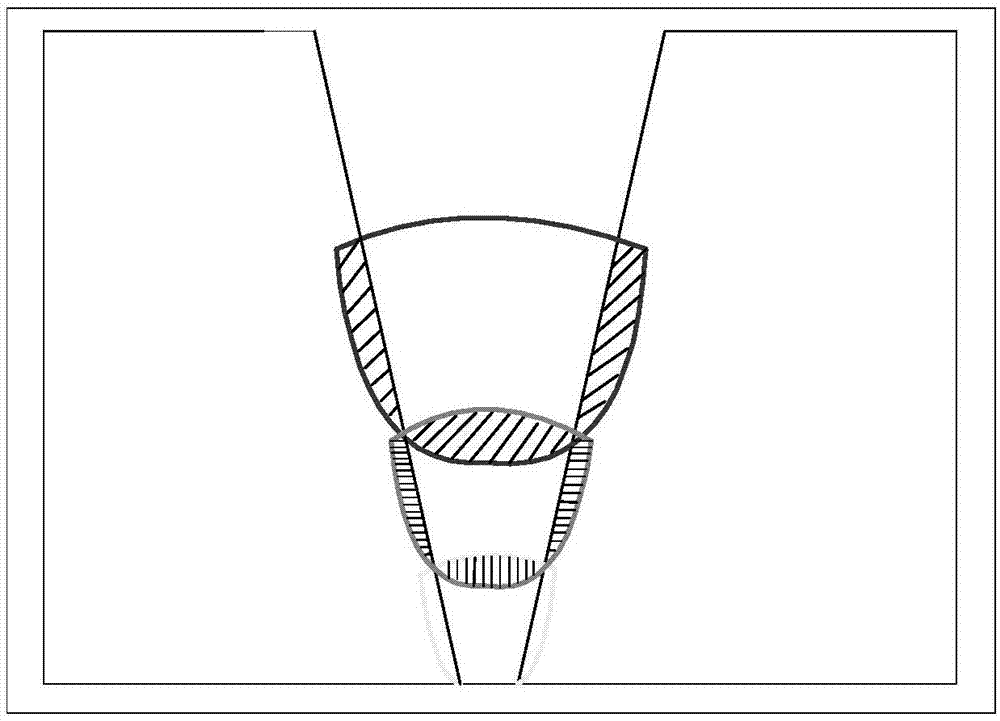

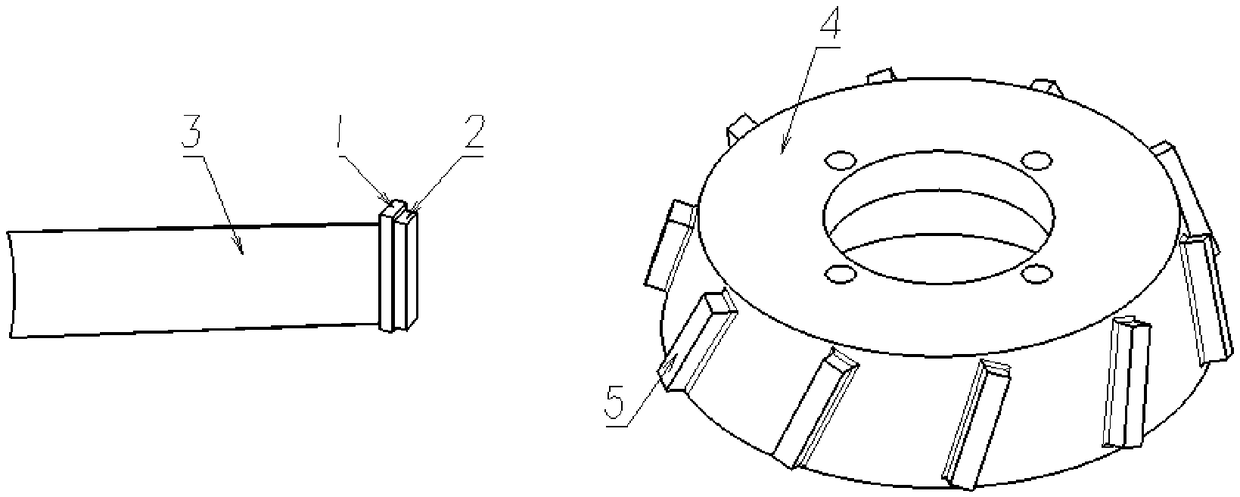

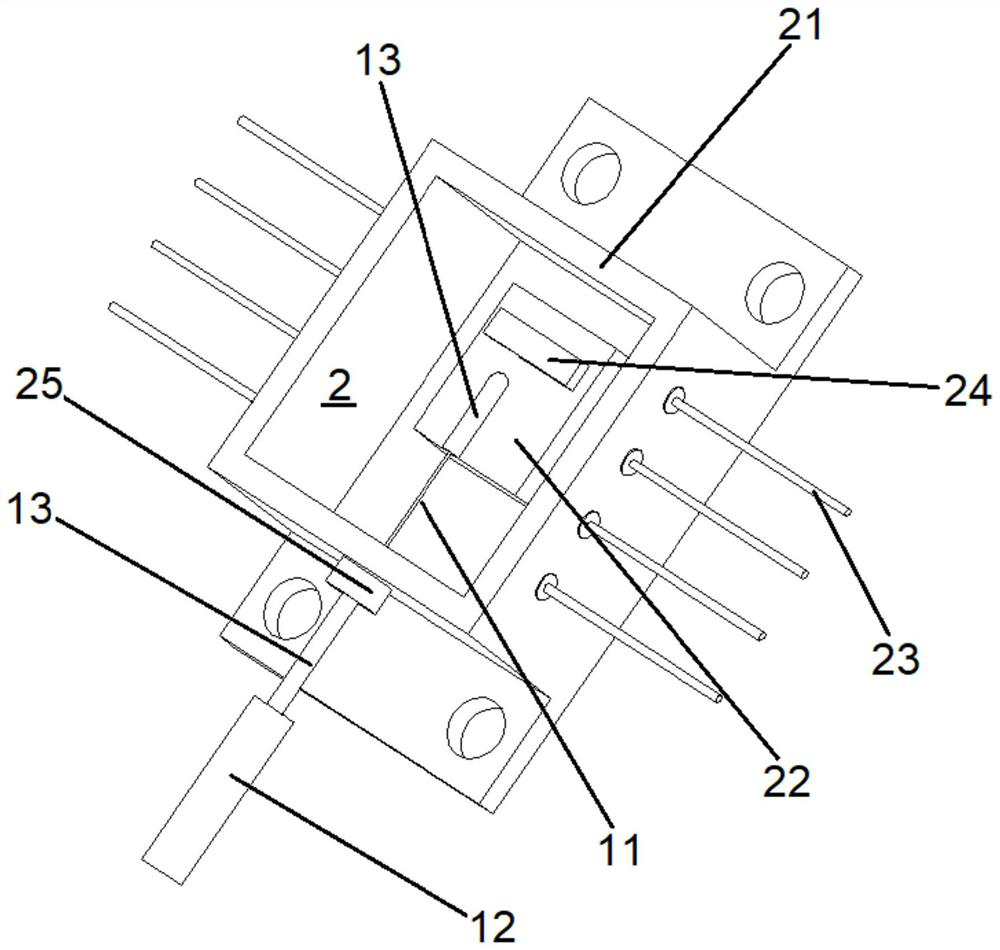

Method for preparing bimetal composite plate by stirring friction braze welding

InactiveCN101530947APrevent thinningAvoid direct contactNon-electric welding apparatusSurface layerShielding gas

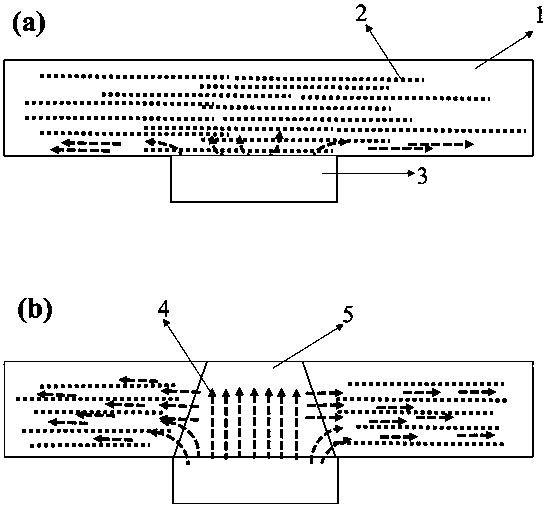

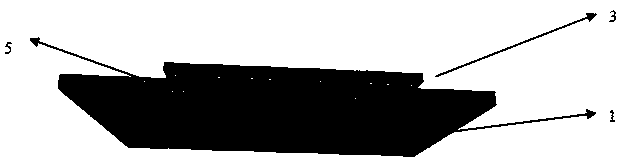

The invention discloses a method for preparing a bimetal composite plate by stirring friction braze welding. The method comprises that: a plate with small hardness is used as a covering layer metal plate; a plate with high hardness is used as a base layer metal plate; the covering layer metal plate and the base layer metal plate are horizontally fixed on a working platform surface in a lap joint mode; solders which can generate eutectic reaction with one of the upper / base layer metal plates are preset between the upper / base layer metal plates; a non-needle type cylinder friction device is arranged over the covering layer metal plate; the non-needle type cylindrical friction device is made to rotate and be pressed to be closely contacted with the surface layer of the covering layer metal plate, but not penetrate the covering layer metal plate, and the non-needle type cylindrical friction device rotates in the original position or moves forward along the surface of the covering layer metal plate while rotating; by utilizing frictional heat to melt the solders, the upper / base layer metal plates are both quickly melted in the solders, thereby achieving excellent interface combination; and the excessive solders are squeezed out, and a thin and dense soldering seam is formed, so that the bimetal composite plate is prepared. Compared with the braze welding in a furnace, the method has the advantages of high efficiency, energy conservation, pressure lead-in, unnecessary soldering flux and gas protection and short holding time at a high temperature.

Owner:XI AN JIAOTONG UNIV

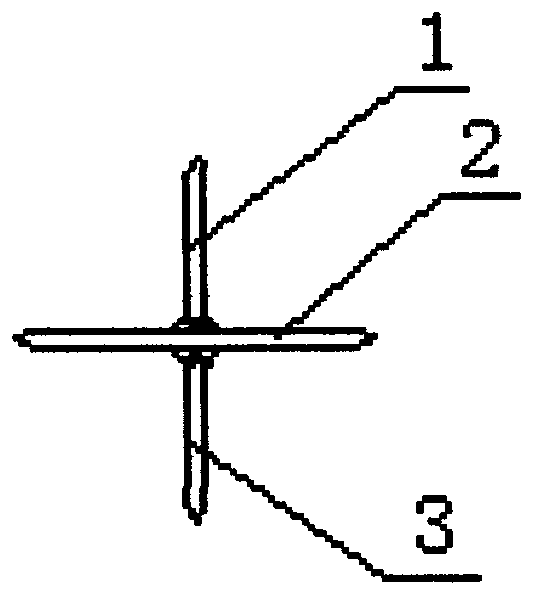

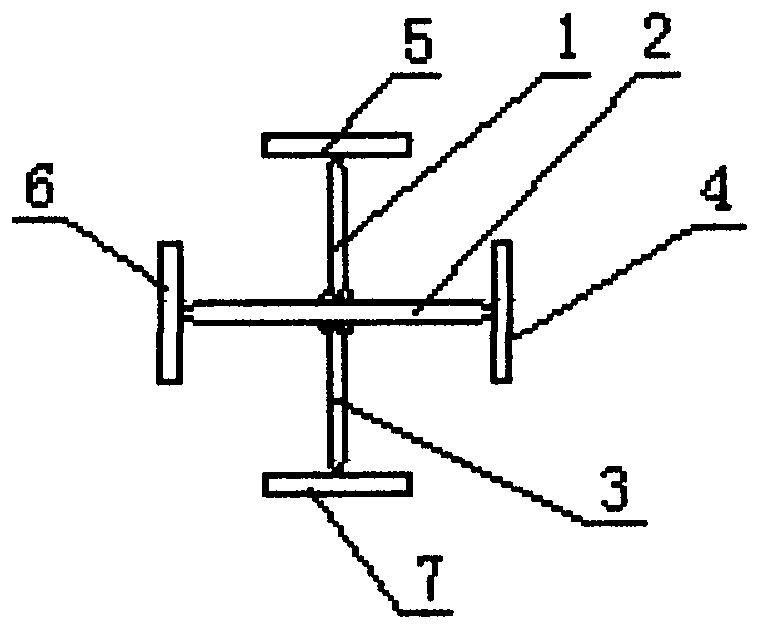

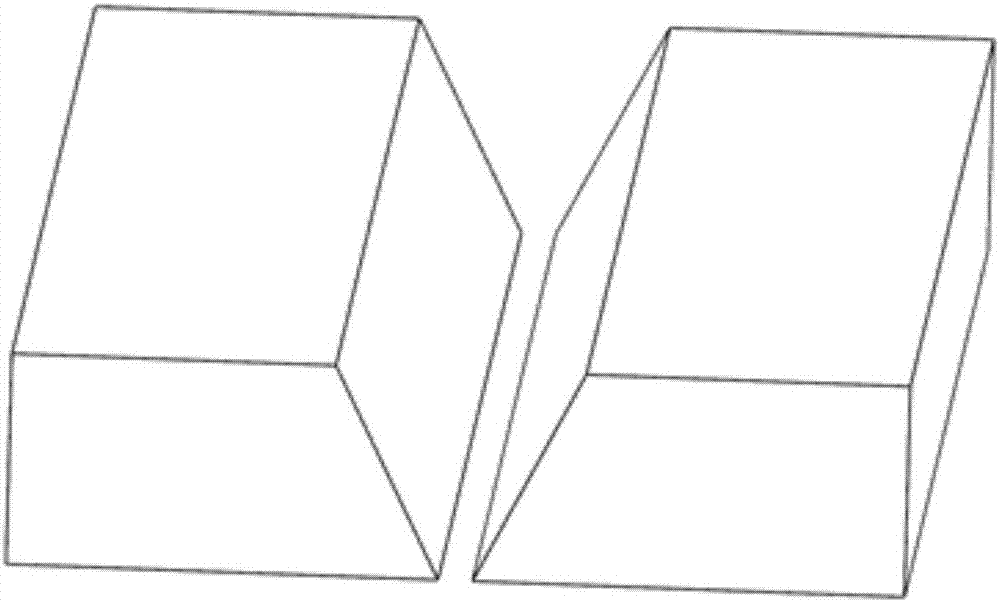

Cross column steel member assembling and welding process

InactiveCN103231146ASolving Welding DifficultiesReduce labor intensityArc welding apparatusFillet weldEngineering

The invention discloses a cross column steel member assembling and welding process. The cross column steel member assembling and welding process comprises the following steps: a, combining three web plate strips into a cross welding line welding groove, and the width of two of the web plate strips is identical and half of that of the other web plate strip; b, subjecting the cross welding line welding groove formed after combining the three web strips to welding to form a cross web plate; c, combining four flange plate strips with the cross web plate, and two welding line welding grooves are arranged between every flange plate strip and the cross web plate; and d, subjecting the two welding line welding grooves arranged between every flange plate strip and the cross web plate to welding to form a cross column member. According to the cross column steel member assembling and welding process, the problem that the central cross welding line in the cross column is difficult to weld due to a prolonged contact tube and welding on a fillet welding position can be solved, the production efficiency is improved, the welding quality can be guaranteed, and the labor intensity of workers can be reduced.

Owner:ANHUI HONGLU STEEL CONSTR (GROUP) CO LTD

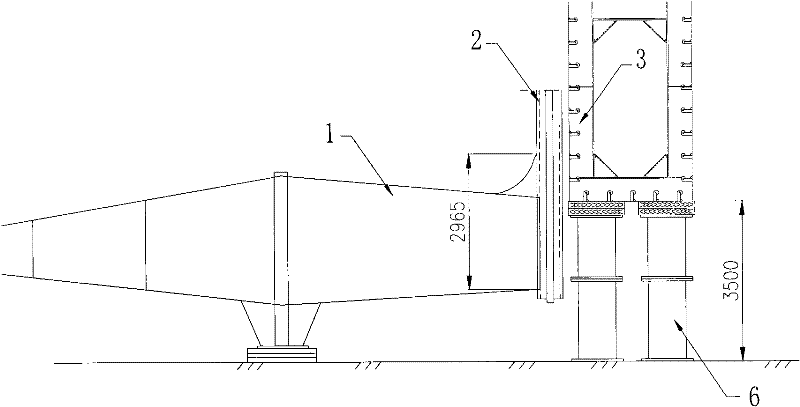

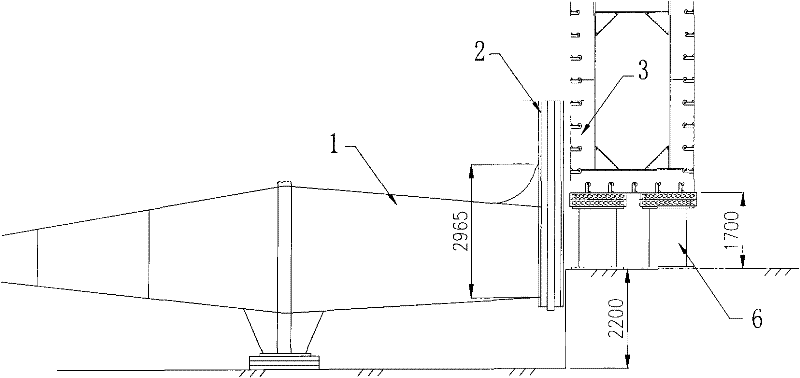

Method for welding pile leg and pile shoe of drill platform

ActiveCN101745748AImprove welding qualityEasy constructionWelding apparatusBuilding constructionDrill

The invention discloses a method for welding a pile leg and a pile shoe of a drill platform. The pile shoe comprises a pile shoe main body and an upright plate component. The method comprises the following steps of: a) welding the upright plate component on the pile leg; b) inserting the upright plate component connected with the pile leg into the pile shoe main body, and c) welding the upright plate component inside the pile shoe main body. The method of the invention solves the problem that the exterior of the pile shoe is difficult to weld because the working station space is narrow. The welding quality is ensured, the welding cost is saved and the construction period is shortened.

Owner:CHINA MERCHANTS HEAVY IND JIANGSU +1

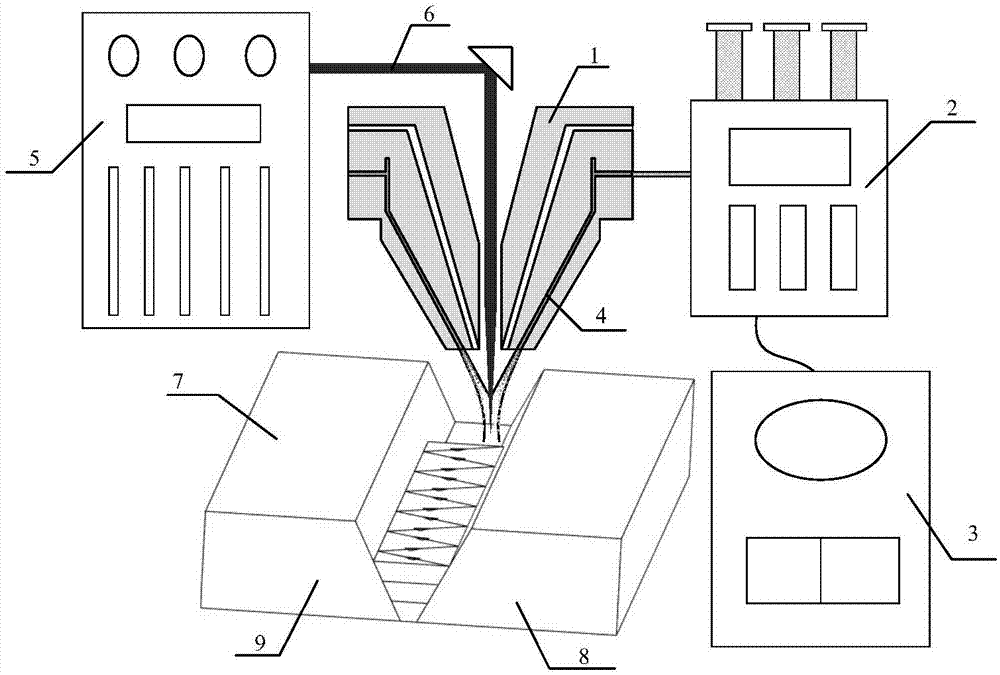

Additive welding method for large-thickness frame metal parts

InactiveCN107876985ASolving Welding DifficultiesSolve unfusedWorkpiece edge portionsLaser beam welding apparatusNumerical controlCoupling

The invention discloses an additive welding method for large-thickness frame metal parts, which comprises the following steps: (1) groove shape design and welding preparation: preparing a single-facegroove which is a U-shaped groove or a V-shaped groove, sanding the to-be-welded part with the groove, cleaning the part with acetone to remove surface impurities, taking out and blow-drying the to-be-welded part, and clamping the to-be-welded part by a reversible deformation method, wherein the welding flux is alloy powder by ball milling, and the particle diameter is 100 to 150 microns; (2) laser additive welding experiment: a powder head and a powder supply box are connected in a selected welding device, the powder supply device is connected with a numerical control machine tool on a welding machine tool, according to a preset track, the powder head supplies the alloy powder which is in a coaxial coupling relationship with the laser light output by a laser, the fused surface of the to-be-welded part and the alloy powder form a large multi-layered fused area, and the weld pool Is cooled and solidified to form a stack layer, and the connection between two to-be-welded parts is realized.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

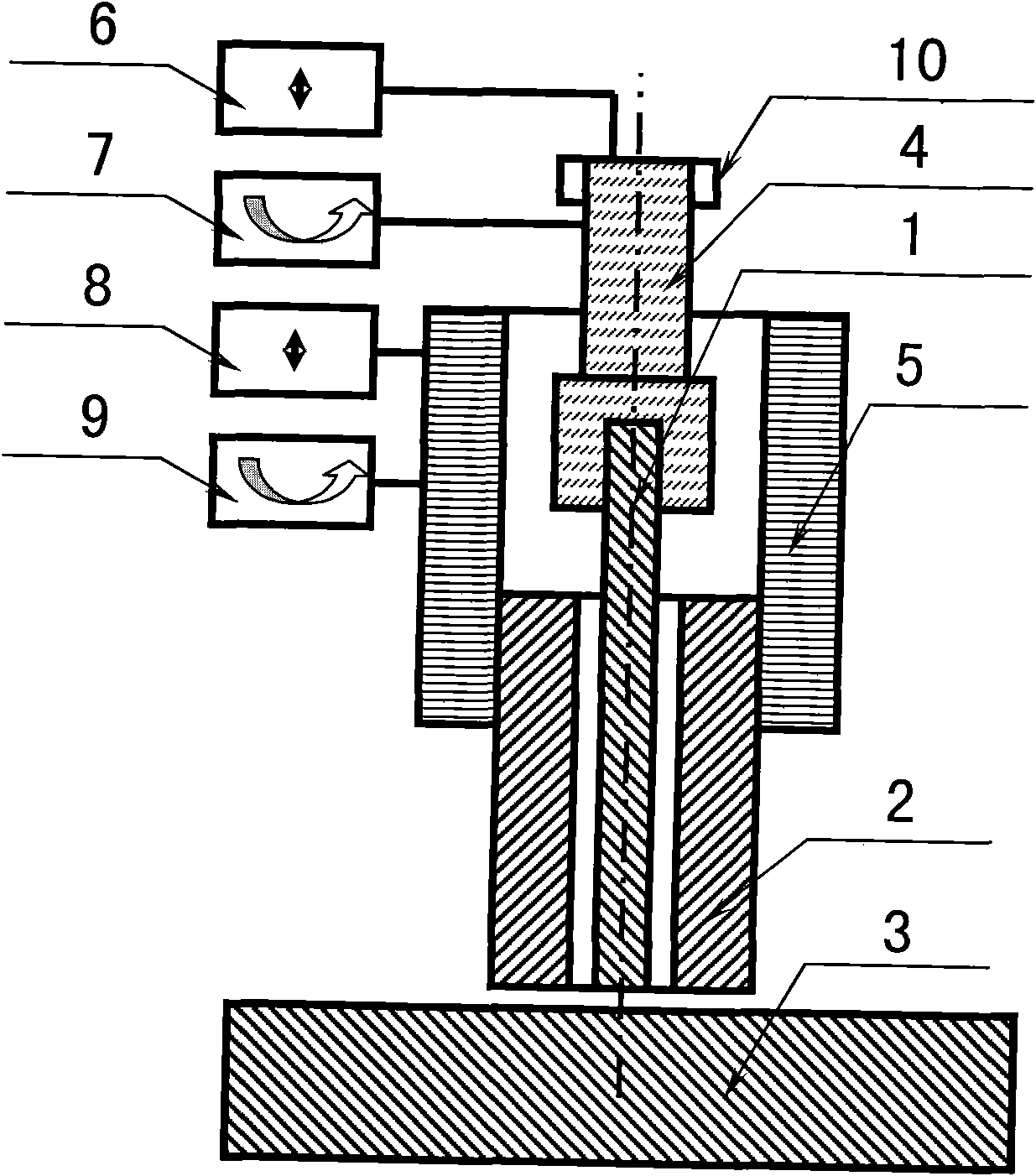

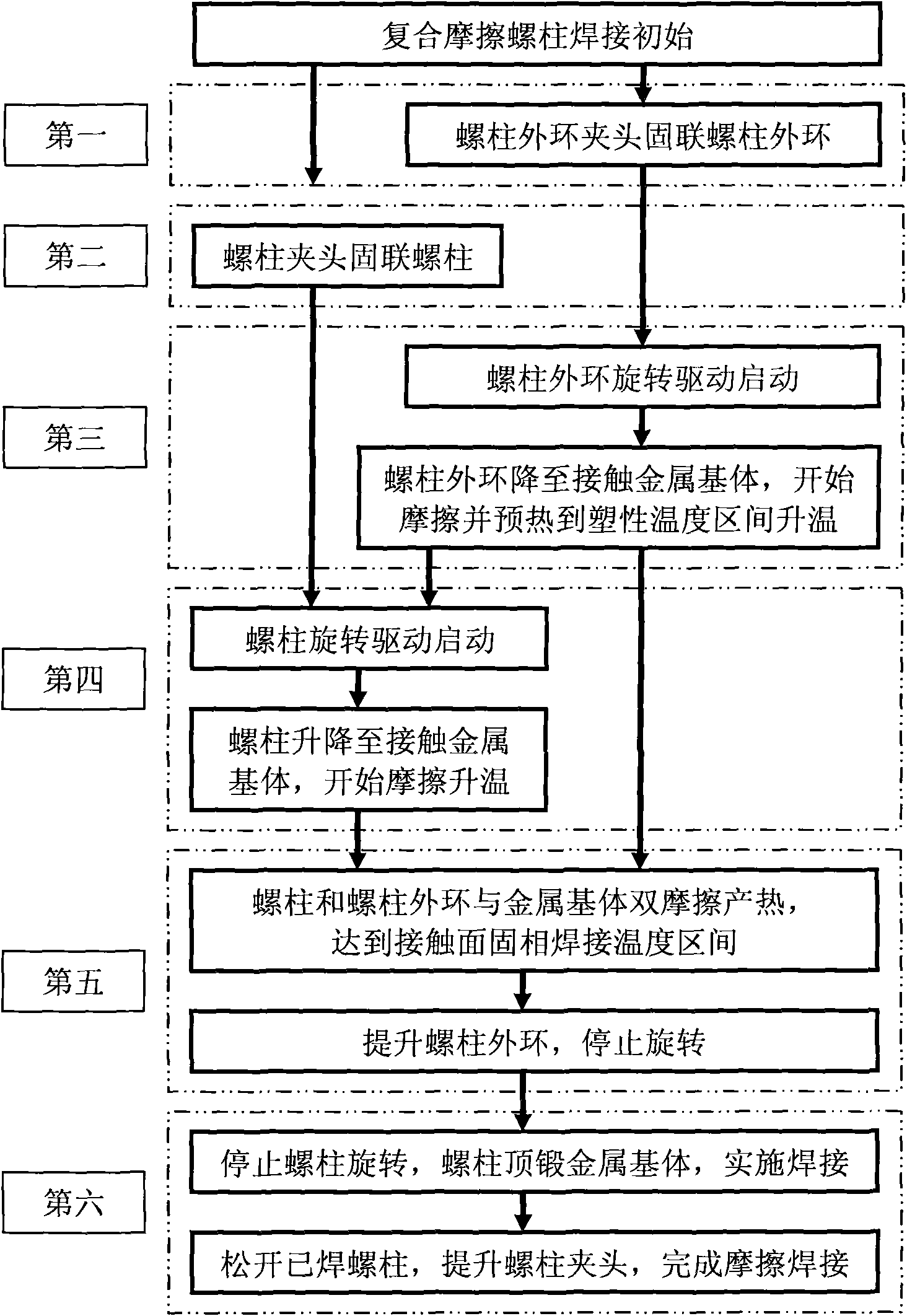

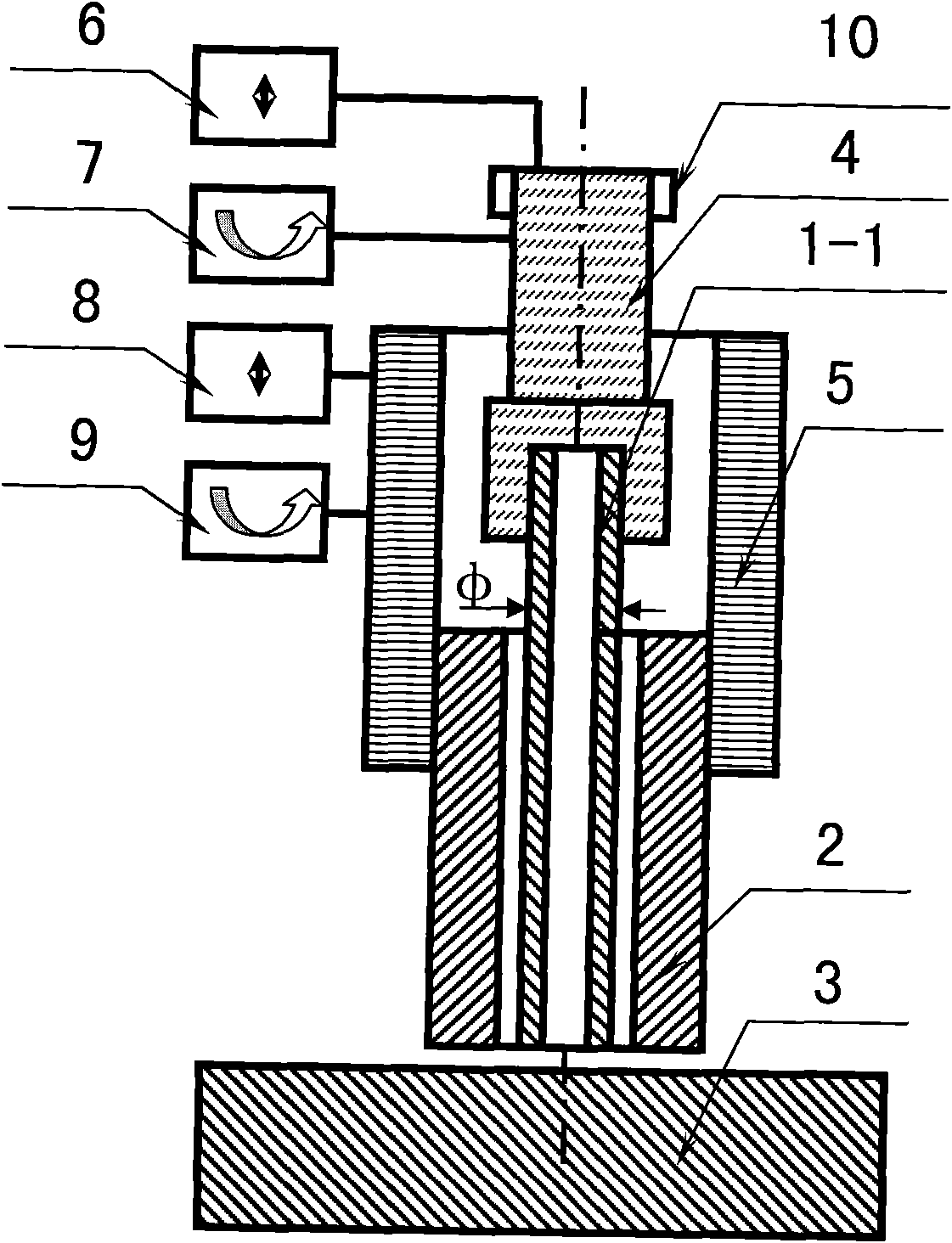

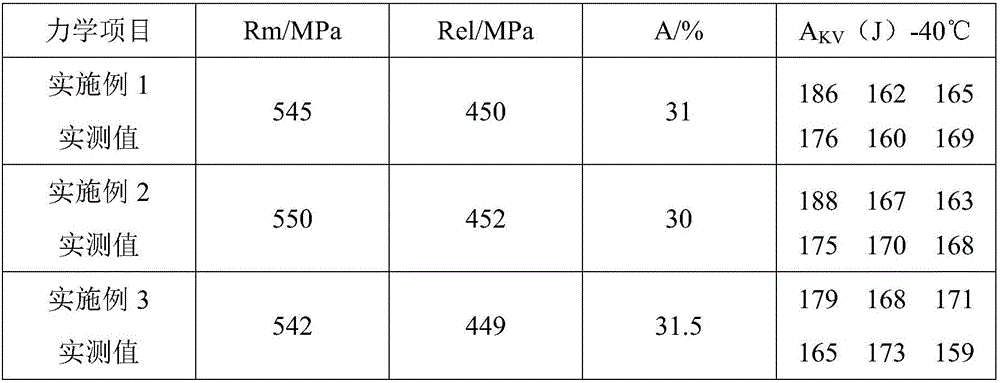

Metal stud welding system combined with friction heat source

ActiveCN102091861ASolving Welding DifficultiesSolve the problem that only small studs can be weldedNon-electric welding apparatusFriction weldingAxial displacement

The invention relates to a metal stud welding system, and in particular relates to a metal stud welding system combined with a friction heat source. A stud outer ring is directly driven by the axial displacement of the stud outer ring and a rotation device to move up and down and rotate, so as to achieve the large-area auxiliary friction pre-heating between the stud outer ring and a metal substrate, thereby increasing the total heat input for welding; the metal stud is directly driven by the axial displacement of the stud and a rotation device to move up and down and rotate so as to generate heat by rotation friction; the temperatures of the metal stud and the metal substrate respectively reach the solid-phase welding temperature range of a contact surface material due to the friction heat between the stud outer ring and the metal substrate, and between the metal stud and the metal substrate; and a stud chuck is driven to upset the metal stud so as to achieve the friction welding of the metal stud. The metal stud welding system can improve the effective welding area of metal studs, in particular to a large-diameter stud, enhance the interface bonding strength and the deformation resistance, and improve the metal stud welding efficiency and the like.

Owner:NANJING INST OF TECH +1

Ship-building steel small-groove submerged-arc welding agent and preparation method thereof

InactiveCN106736044ALow hygroscopicityLow costWelding/cutting media/materialsSoldering mediaSlagRutile

The invention discloses a ship-building steel small-groove submerged-arc welding agent and a preparation method thereof. The ship-building steel small-groove submerged-arc welding agent comprises the following raw materials, by weight, of 15-28% of magnesite, 15-30% of white corundum, 10-25% of grammite, 10-20% of fluorite, 10-20% of rutile, 1-10% of manganese ores and 1-7% of silicon iron. The sum of the weight percentage of the components is 100%. The ship-building steel small-groove submerged-arc welding agent has low hygroscopicity; electric arc welding is stable; the slag detachability of the welding agent after welding is good; the appearance of a welded joint is attractive after forming; slag shells can automatic cock after welding; and no defects such as undercuts exist. The production efficiency is high, the comprehensive cost is low, the welding quality is good, and the welding agent is quite suitable for submerged arc welding under the condition of small grooves of ship-building steel.

Owner:SHANGHAI HULIN HEAVY IND +2

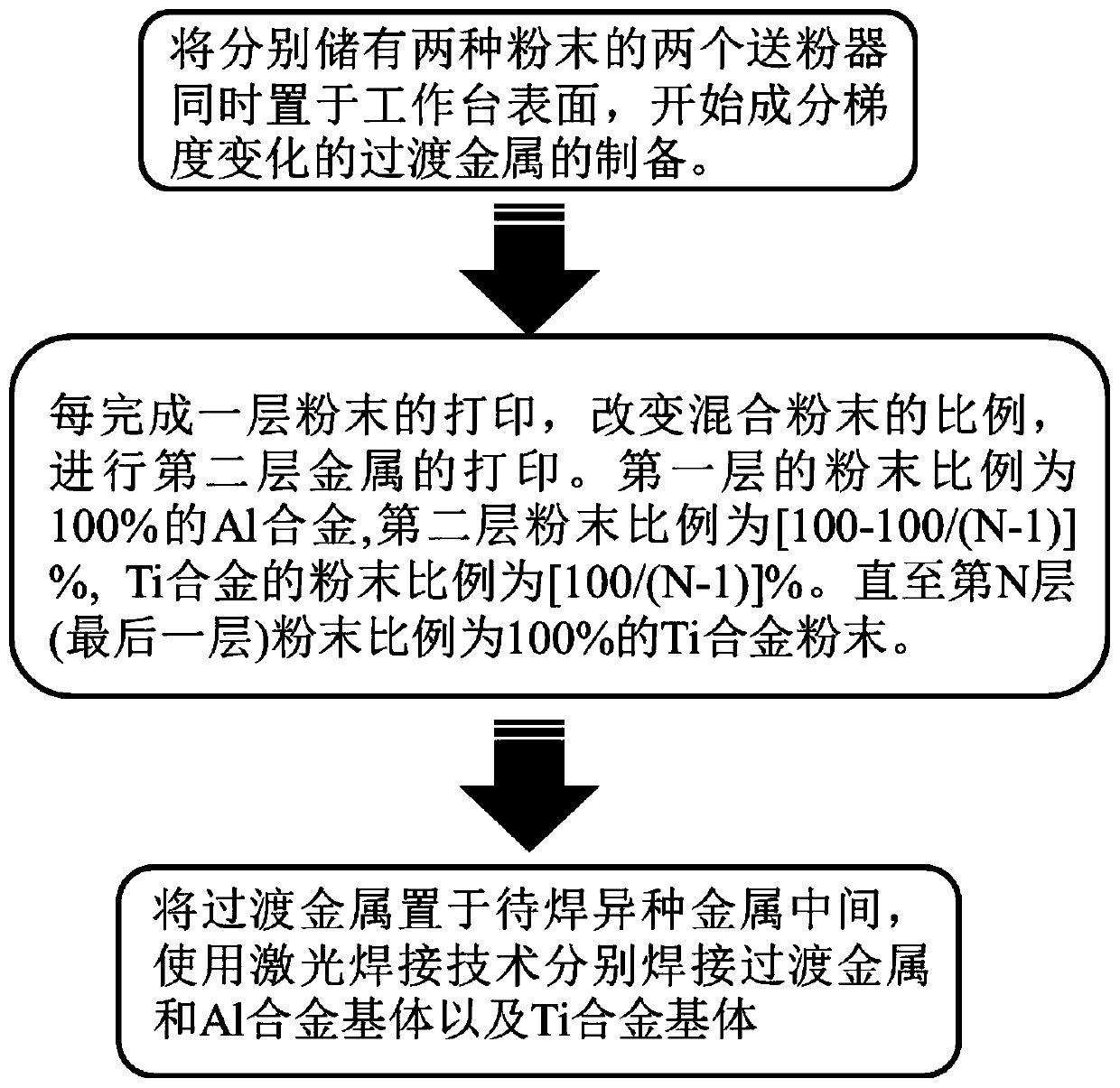

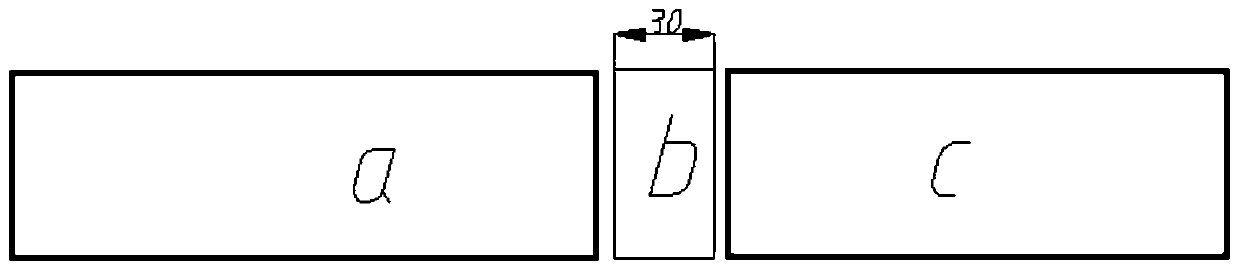

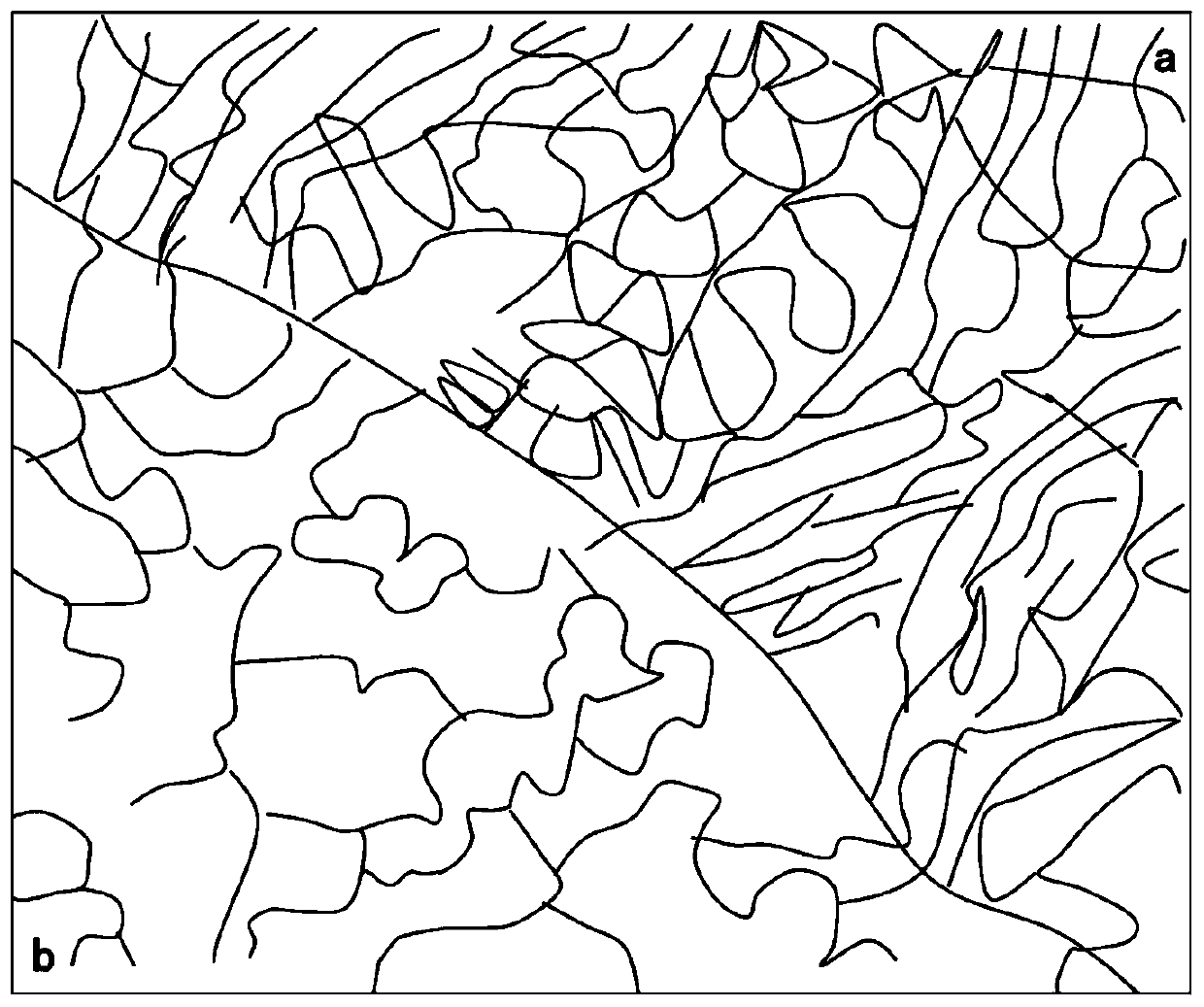

Al-Ti alloy dissimilar metal welding method

InactiveCN109822094AImprove welding qualitySolving Welding DifficultiesAdditive manufacturing apparatusIncreasing energy efficiencyAlloyTitanium

The invention relates to the fields of laser welding and laser additive manufacturing, in particular to an Al-Ti alloy dissimilar metal welding method. According to the Al-Ti alloy dissimilar metal welding method, the mode that a transition metal plate variable in compositional gradient is connected with Al-Ti alloy dissimilar metal is adopted, accordingly, welding between dissimilar metals is converted into welding of similar metals, and the problem that the difference between the melting point of aluminum and the melting point of titanium is too large, and thus, the aluminum and the titaniumare difficult to weld is effectively solved; and in addition, Al-Ti brittle phase forming in the welding process of the Al-Ti alloy dissimilar metal is effectively avoided, accordingly, the welding quality of the Al-Ti alloy dissimilar metal is improved, and the service life of a Al-Ti alloy dissimilar metal welding piece is prolonged.

Owner:JIANGSU HAIYU MACHINERY

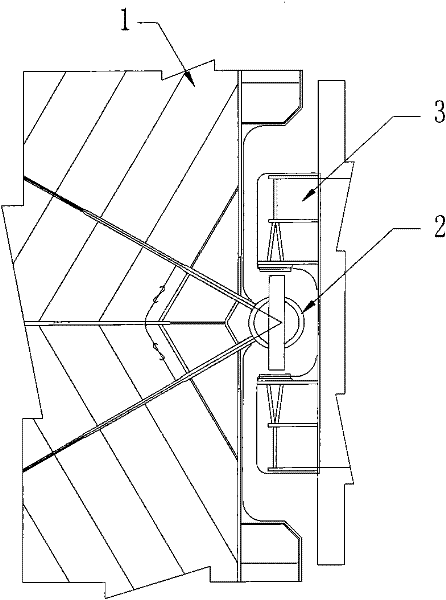

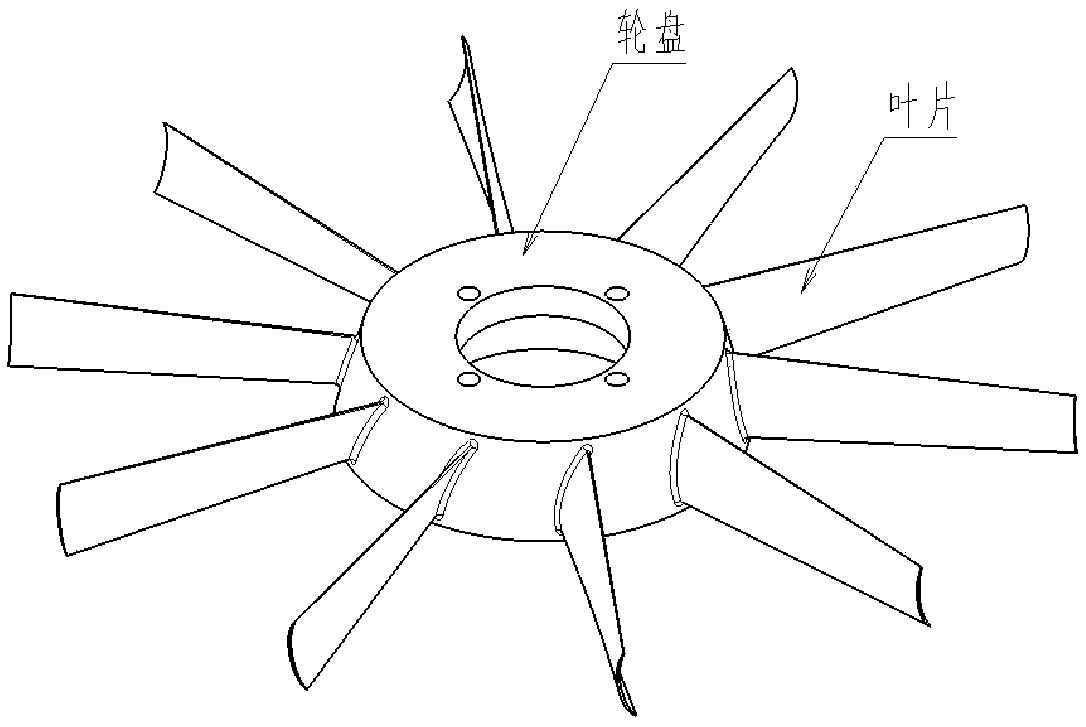

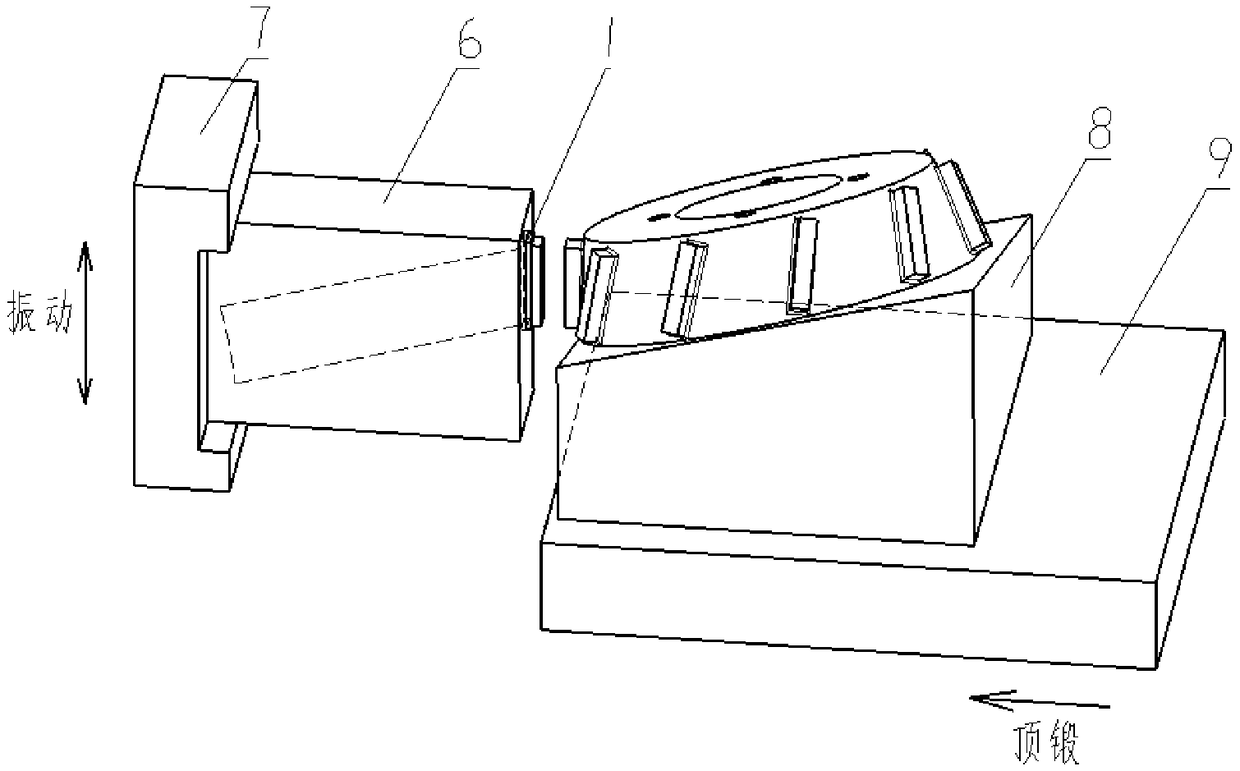

Blisk swing friction welding equipment and method

ActiveCN109262132AHigh welding efficiency and welding position accuracySolving Welding DifficultiesWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention relates to blisk swing friction welding equipment and method. The equipment comprises a base, a blade driving unit and a blisk driving unit, wherein the base is of a disc structure witha blisk as the center, and a plurality of blade driving mechanisms are arranged on the base; the blade driving unit comprises a blade clamp and an upsetting driving mechanism, the blade clamp is usedfor clamping blades, the blade clamp is provided with a through hole structure for clamping the blades, and the blades can penetrate through and be clamped in the through hole structure; the upsettingdriving mechanism is used for driving the blade clamp to drive the blades to move linearly relative to the base; the blisk driving unit comprises a blisk clamp and a swing driving mechanism, the blisk clamp is used for clamping the blisk, the blisk clamp is provided with a mounting surface for clamping the blisk, and the blisk and the blisk clamp are coaxially arranged in the center of the base;the swing driving mechanism is used for driving the blisk clamp to drive the blisk to swing in a preset angle range relative to the base.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

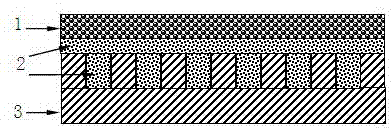

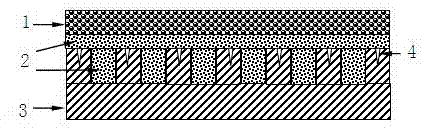

Steel-iron based metal ceramic composite and integrated process for sintering and welding composite

ActiveCN104118166ASolving Welding DifficultiesHigh ceramic contentMetal layered productsCeramic compositeIron based

The invention relates to a steel-iron based metal ceramic composite. The steel-iron based metal ceramic composite comprises a high-ceramic layer, a high-metal layer and a metal layer which are sequentially arranged from outside to inside, wherein the high-ceramic layer comprises the following components in percentage by weight: 30%-70% of 400-mesh TiC powder, 35%-60% of Fe powder, 1%-3% of Mo powder, 2%-5% of Ni powder and 6%-8% of Cr powder; the high-metal layer is a transition layer and comprises the following components in percentage by weight: 15%-25% of 400-mesh TiC powder, 60%-75% of Fe powder, 1%-2% of Mo powder, 3%-5% of Ni powder and 6%-9% of Cr powder.

Owner:南京彬华新材料有限公司 +1

Heat-conducting structure of aluminum alloy-inlaid graphene-based composite substrate and manufacturing method of heat-conducting structure

InactiveCN108925108AHigh in-plane thermal conductivityLimit Lightweight High Thermal ConductivityCooling/ventilation/heating modificationsCopper platingHeat conducting

The invention discloses a heat-conducting structure of an aluminum alloy-inlaid graphene-based composite substrate and a manufacturing method of the heat-conducting structure. The heat-conducting structure comprises a graphene-based composite substrate and an aluminum block, wherein the graphene-based composite substrate is longitudinally perforated; and the aluminum block is inlaid into a hole ofthe graphene-based composite substrate. The method comprises the following steps of (1) longitudinally perforating the graphene-based composite substrate; (2) preparing the aluminum block; (3) carrying out surface metalization on the surface of the hole of the graphene-based composite substrate; (4) carrying out surface copper plating on the aluminum block of which the surface is polished; and (5) inlaying the copper-plated aluminum block into the hole of the graphene-based composite substrate of which the surface is metalized and obtaining the heat-conducting structure of the aluminum alloy-inlaid graphene-based composite substrate. Through the heat-conducting structure, the longitudinal heat-conducting efficiency of the graphene-based composite substrate can be greatly improved, therebyimproving the overall cooling efficiency.

Owner:深圳烯创技术有限公司

Manufacturing method for N type crystalline silicon solar cell

ActiveCN103594532AAvoid inefficiencySolving Welding DifficultiesFinal product manufacturePhotovoltaic energy generationCrystalline siliconBoron

The invention discloses a manufacturing method for an N type crystalline silicon solar cell. The manufacturing method includes the following steps that (1), N type monocrystal silicon is adopted as a substrate, and the substrate is cleaned and texturized; (2), boron paste is printed in the electrode area on the back face of the silicon wafer, boron-doped PN junctions are formed after drying and annealing, and meanwhile an oxidation layer is formed on the back face of the silicon wafer; (3), phosphorus diffusion is performed on one single face; (4), the back face of the silicon wafer is etched partially; (5), an impurity glass layer is removed; (6), an antireflection film is deposited and passivated; (7), aluminum paste is printed to form aluminum back junctions; (8), a front face electrode and a back face electrode are printed and dried to obtain the N type crystalline silicon solar cell. Aluminum paste doping is performed in a non-electrode area of the back face of the silicon wafer to form the aluminum back junctions, boron paste doping is adopted for the electrode area of the back face to manufacture the electrodes, and not only is the problem of assembly welding solved, but also the problem that cell efficiency is reduced because the area of the back face PN junctions is reduced is avoided.

Owner:CSI CELLS CO LTD

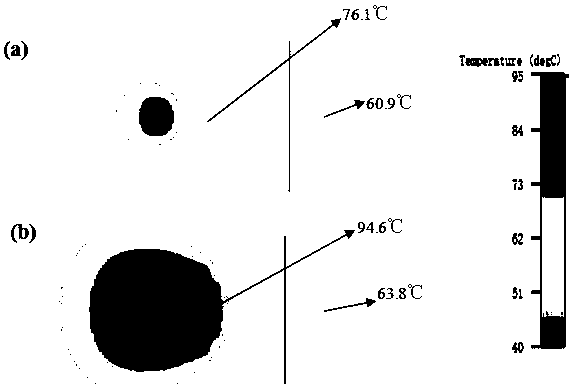

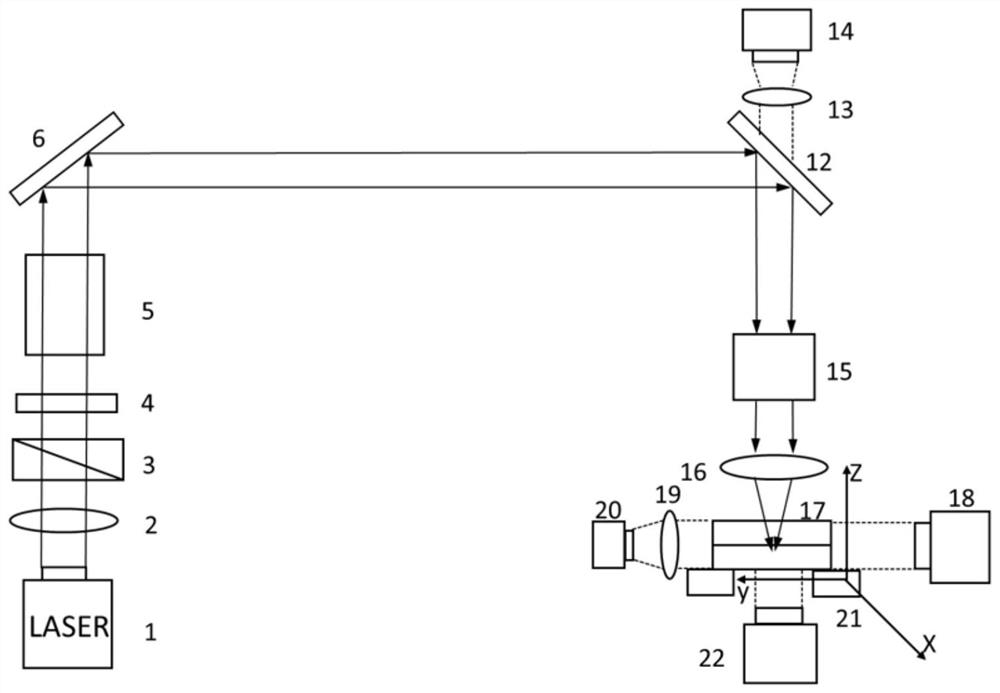

Double-light-path ultrafast laser welding device based on light beam shaping and machining method

InactiveCN113199143ASolving the challenge of non-optical contact solderingSolving Ultrafast Laser Welding ChallengesLaser beam welding apparatusFemto second laserPrism

The invention provides a double-light-path ultrafast laser welding device based on light beam shaping. The double-light-path ultrafast laser welding device comprises a femtosecond laser, a half-wave plate, a polarization splitting prism, an electric control shutter, a laser beam expander, a first holophote, a dichroscope, a galvanometer system, a field lens, a to-be-welded sample and an XYZ movable welding platform. Gaussian beams emitted by the femtosecond laser sequentially pass through the half-wave plate, the polarization splitting prism, the electric control shutter, the laser beam expander, the first holophote, the dichroscope, the galvanometer system and the field lens and then are gathered on a to-be-welded sample, and the to-be-welded sample is fixed on the XYZ movable welding platform to form a Gaussian light beam welding light path. A Bessel light beam conversion system is arranged between the first holophote and the dichroscope to form a Bessel light beam laser welding light path. The invention further provides a machining method using the device. According to the welding device, double-light-path welding of different laser beams is achieved, the welding device is suitable for non-optical contact welding and optical contact welding, the welding quality can be effectively improved, and the production cost can be effectively reduced.

Owner:GUANGXI UNIV

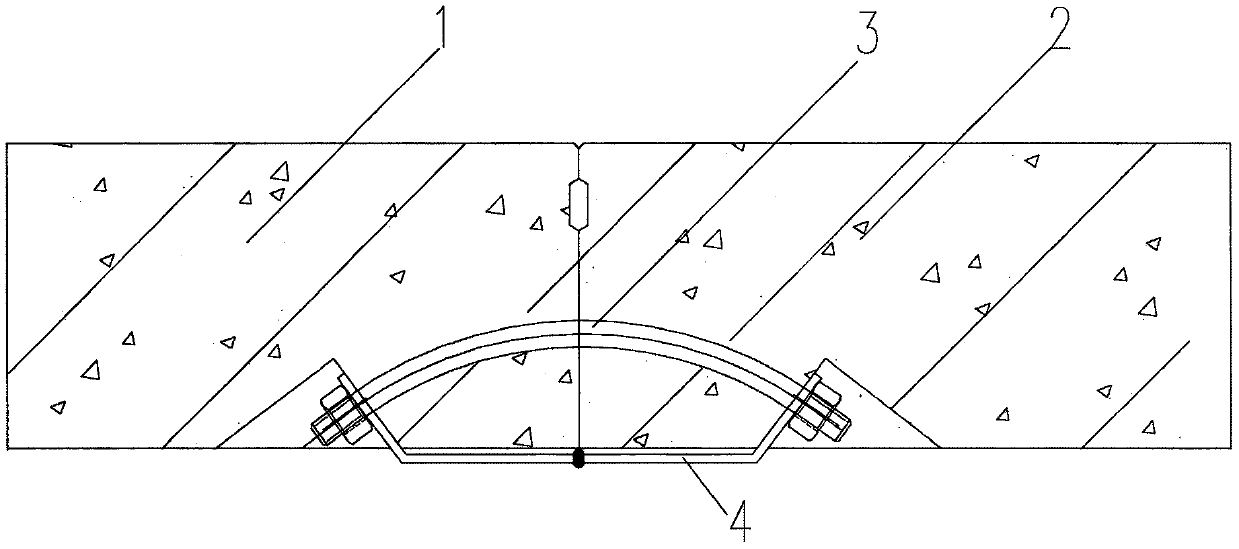

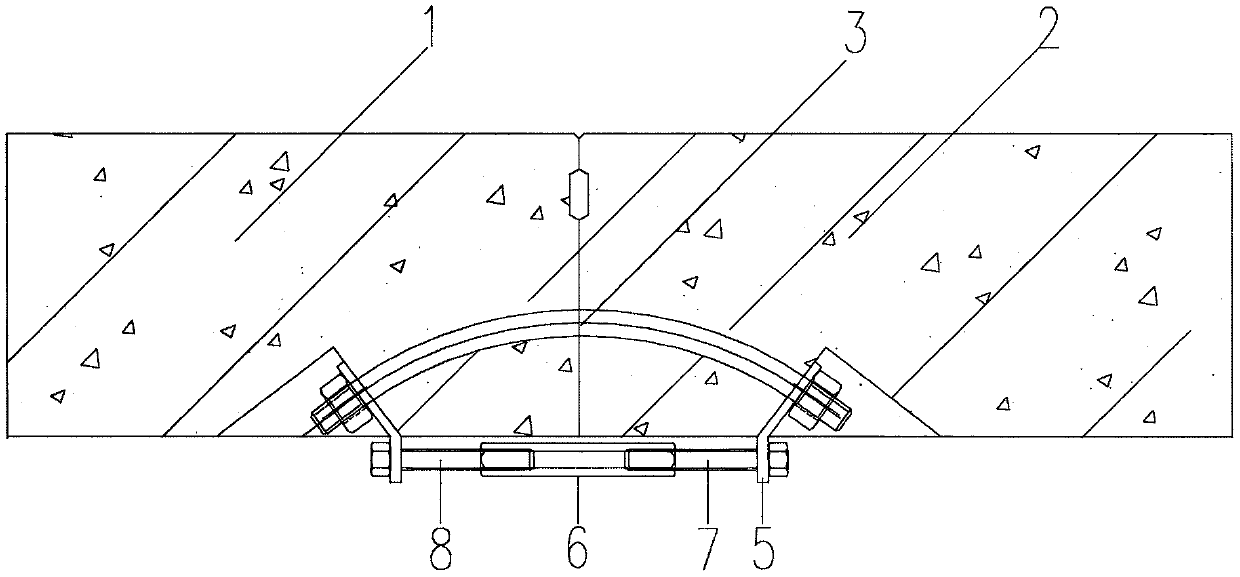

Improved method for connection tensioning and dismantling of adjacent tunnel pipe segments

ActiveCN110173277AImproving the efficiency of joint tensioning constructionSolving Welding DifficultiesUnderground chambersTunnel liningButt weldingSlag

The invention provides an improved method for connection tensioning and dismantling of adjacent tunnel pipe segments. According to the improved method, pipe segment bolts, small connecting plates, hexagonal threaded sleeves, forward threaded nut bolts and reverse threaded nut bolts are used. By means of the method, the construction difficulty of connection tensioning or dismantling of the adjacentpipe segments can be solved, the potential safety hazards, caused by a damp working environment, to butt welding or gas cutting are eliminated, and the construction cost and time are saved. By meansof pure physical construction, and damage caused by welding slags and electric arcs to the pipe segments, and welding high-temperature cracking are avoided; and in addition, construction can be conducted in the damp environment, and the damp-environment safety electric shock hazard is eliminated. By means of the improved method, the construction time is short, some auxiliary welding machines and cutting gun tools are omitted, the adjacent pipe segments are connected and tensioned after tunnel holing-through, semi-connecting plates are physically dismantled, secondary damage of previous hot cutting to the pipe segments is avoided, and the safety reliability of adjacent tunnel pipe segment connection tensioning construction is improved.

Owner:ERCHU CO LTD OF CHINA RAILWAY TUNNEL GRP

Large-size planar energy converter array acoustic window and system

ActiveCN105554626AImprove reliabilityImprove sound transmission efficiencyMicrophonesLoudspeakersEnergy converterCorrosion

The invention provides a large-size planar energy converter array acoustic window and system, and the window comprises a sound transmission film and an enclosure frame. The sound transmission film is connected to one side surface of the enclosure frame. The sound transmission film is provided with a closed elastic groove. The outer edge of the enclosure frame is provided with a heat dissipation step frame. The thickness of the heat dissipation step frame is the same as the thickness of the sound transmission film. The sound transmission film is made of industrial pure titanium TA2. The enclosure frame employs a rigid rectangular structural part. The sound transmission film is made of industrial pure titanium TA2, thereby improving the reliability of an energy converter which works in the sea for a long time. The corrosion resistance performance of a TA2 material is better than the corrosion resistance performance of a conventional stainless steel material. The plane of the window tends to constant amplitude vibration, and improves the efficiency of sound transmission.

Owner:中国船舶重工集团公司第七二六研究所

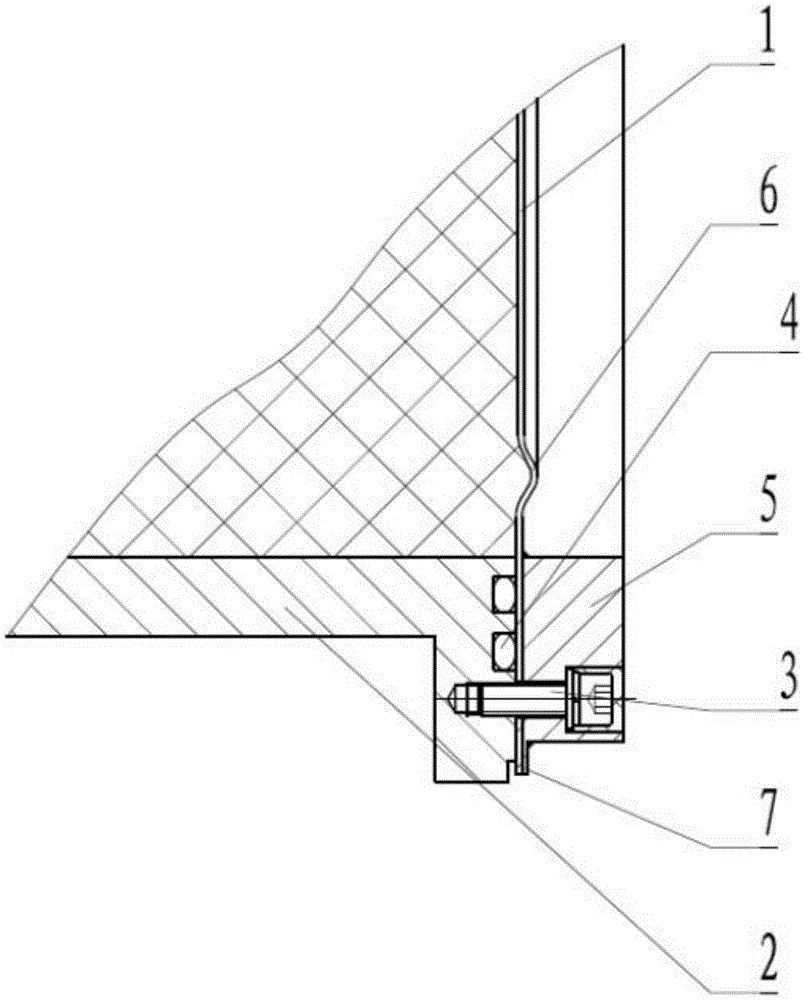

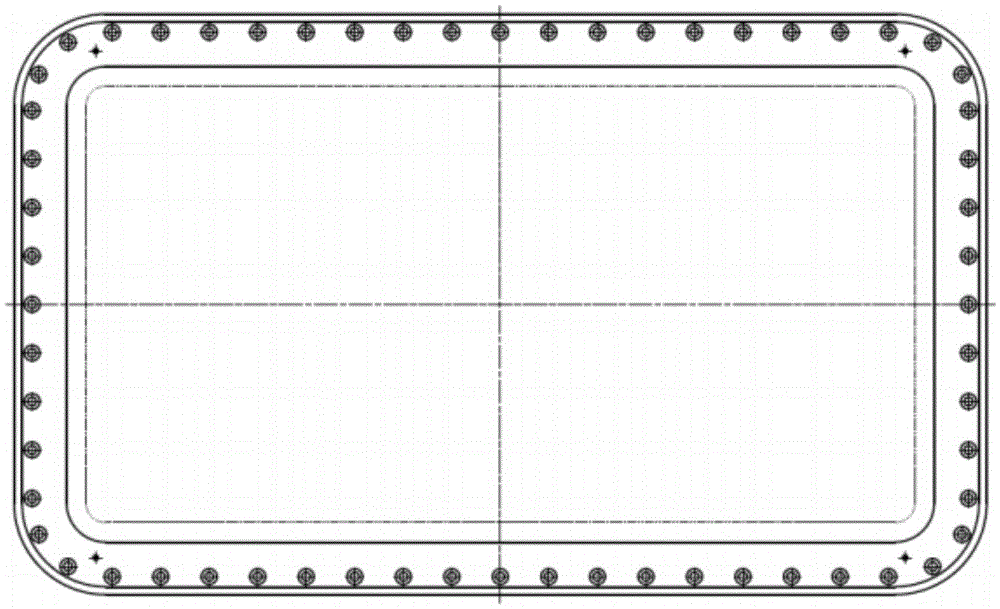

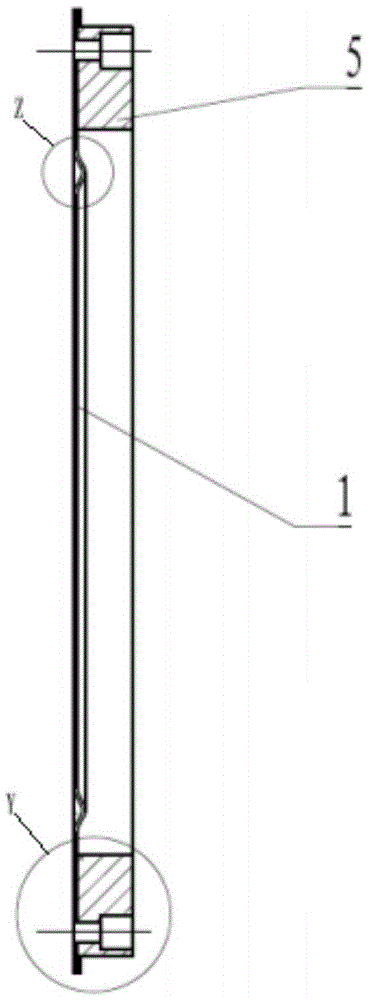

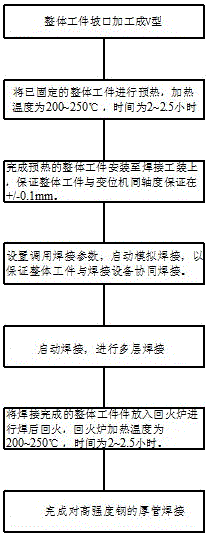

Thick pipe welding process of high-strength steel

InactiveCN106425042ASolving Welding DifficultiesImprove welding efficiencyArc welding apparatusWelding/soldering/cutting articlesPipe weldingEngineering

A thick pipe welding process of high-strength steel comprises the following steps: firstly, performing butt joint on two workpieces to be welded according to welding process requirements and forming an integrated workpiece with symmetrical grooves after butt joint; secondly, cleaning the surface of the integrated workpiece before welding, preheating the integrated workpiece, and performing multi-layer multi-channel welding, including a TIG base layer, a TIG filling layer and a TIG covering layer, on the integrated workpiece after preheating is finished; and finally, putting the welded integrated workpiece into a tempering furnace, and performing tempering after welding and then cooling to finish thick pipe welding of the high-strength steel. By the thick pipe welding process of the high-strength steel, a high-strength steel thick plate is subjected to automatic multi-layer swinging wire filling TIG welding and the welding problem is effectively solved, so that the welding efficiency and the stability are high, the one-time welding formation is good, the first-class weld joint requirements of the workpieces are met, and the high-speed and high-efficiency welding effect is guaranteed; meanwhile, the process flow is simplified, the welding quality is improved and the welding processing cycle is shortened, so that the production cost is saved, the labor intensity of workers is reduced and the working environment is improved.

Owner:JIANGXI HONGDU AVIATION IND GRP

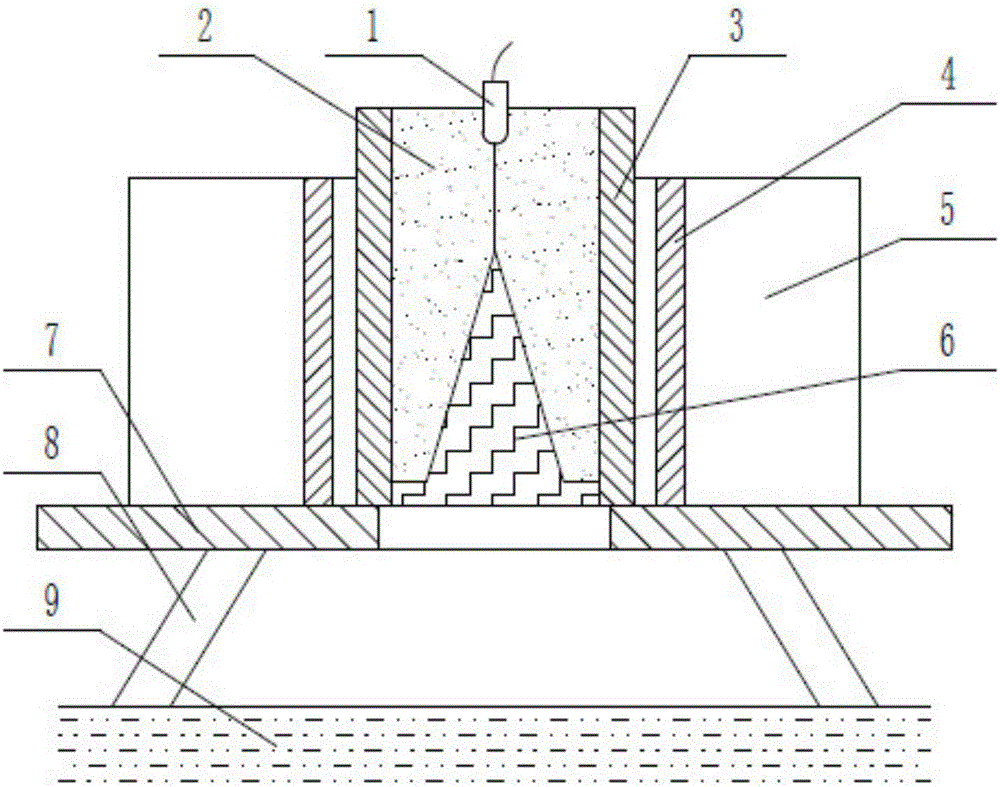

Explosive welding device for joint of zirconium-alloy transition tube and stainless-steel transition tube

InactiveCN105057876AAchieve moldingWell bound blockWelding/soldering/cutting articlesMetal working apparatusDetonatorRound table

The invention belongs to the technical field of explosive welding, and particularly relates to an explosive welding device for the joint of a zirconium-alloy transition tube and a stainless-steel transition tube. The explosive welding device comprises a detonator, explosive, a zirconium-alloy compound tube, a stainless-steel base tube, a mold, a bracket, supporting legs and a non-metallic conical body, wherein the supporting legs are symmetrically arranged under the bracket; the bracket is placed on the ground through the supporting legs under the bracket; the mold is arranged on the bracket; the mold is in the shape of a hollow round table; the stainless-steel base tube is mounted in the mold in a sleeving manner; the zirconium-alloy compound tube is coaxially arranged in the stainless-steel base tube; a gap is formed between the inner surface of the stainless-steel base tube and the outer surface of the zirconium-alloy compound tube; the non-metallic conical body is arranged in the zirconium-alloy compound tube; the explosive is stuffed between the non-metallic conical body and the zirconium-alloy compound tube; the detonator is placed on the explosive. Through the adoption of the explosive welding device disclosed by the invention, the production quality of joints of zirconium-alloy transition tubes and stainless-steel transition tubes is greatly improved.

Owner:成都佰世成科技有限公司

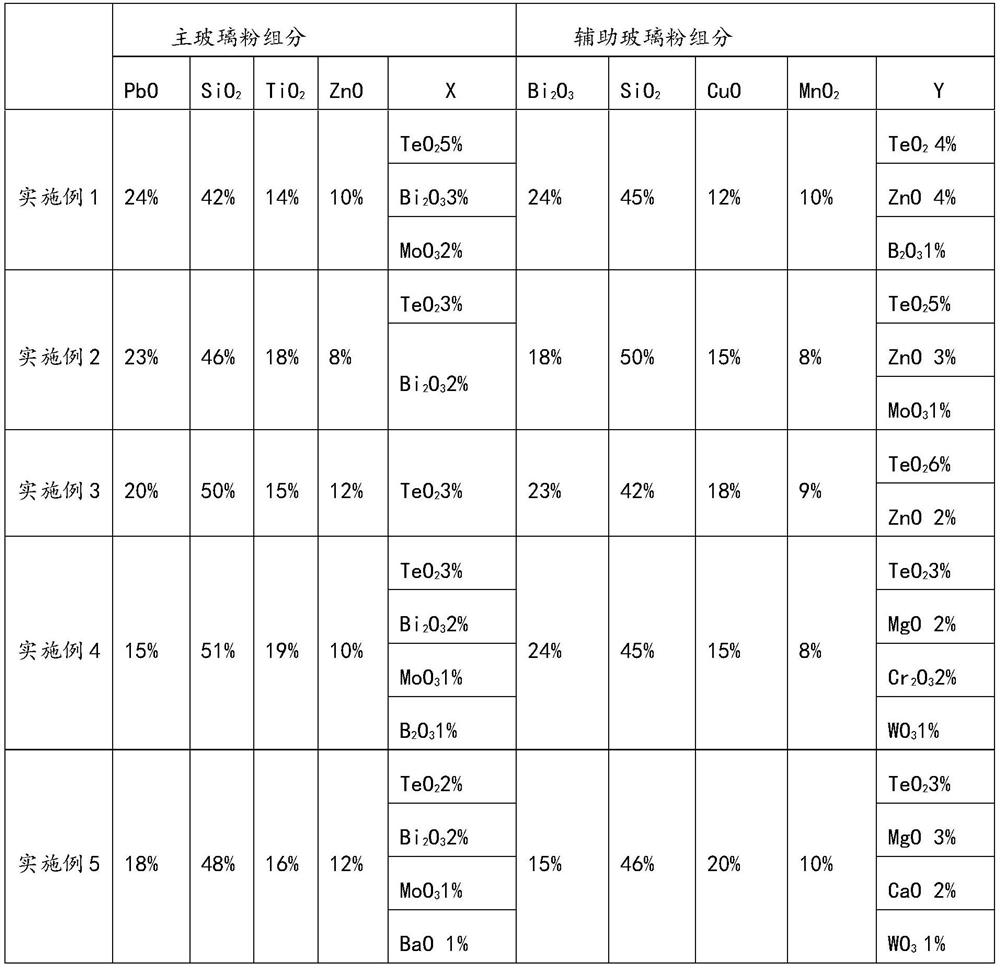

Glass powder for main gate electrode silver paste of TOPCon battery as well as preparation method and application of glass powder

PendingCN114315159AHigh opening pressure characteristicsImprove adhesionGlass furnace apparatusNon-conductive material with dispersed conductive materialSilver pastePhysical chemistry

The invention relates to glass powder for crystalline silicon solar TOPCon battery main gate electrode silver paste, which is characterized by comprising main glass powder and auxiliary glass powder, the main glass powder is Pb-Si-Ti-Zn oxide, the auxiliary glass powder is Bi-Si-Mn-Cu oxide, and the main glass powder accounts for 60-90 wt%; the particle size D50 of the main glass powder and the auxiliary glass powder is smaller than or equal to 4 micrometers. After the main glass powder and the auxiliary glass powder are matched, the main grid silver paste is not sensitive to the change of the sintering temperature, so that the main grid silver paste has a wider sintering window, and the use of main grid electrodes on the front surface and the back surface of a crystalline silicon solar TOPCon battery can be met at the same time.

Owner:ZHEJIANG GUANGDA ELECTRONICS TECH

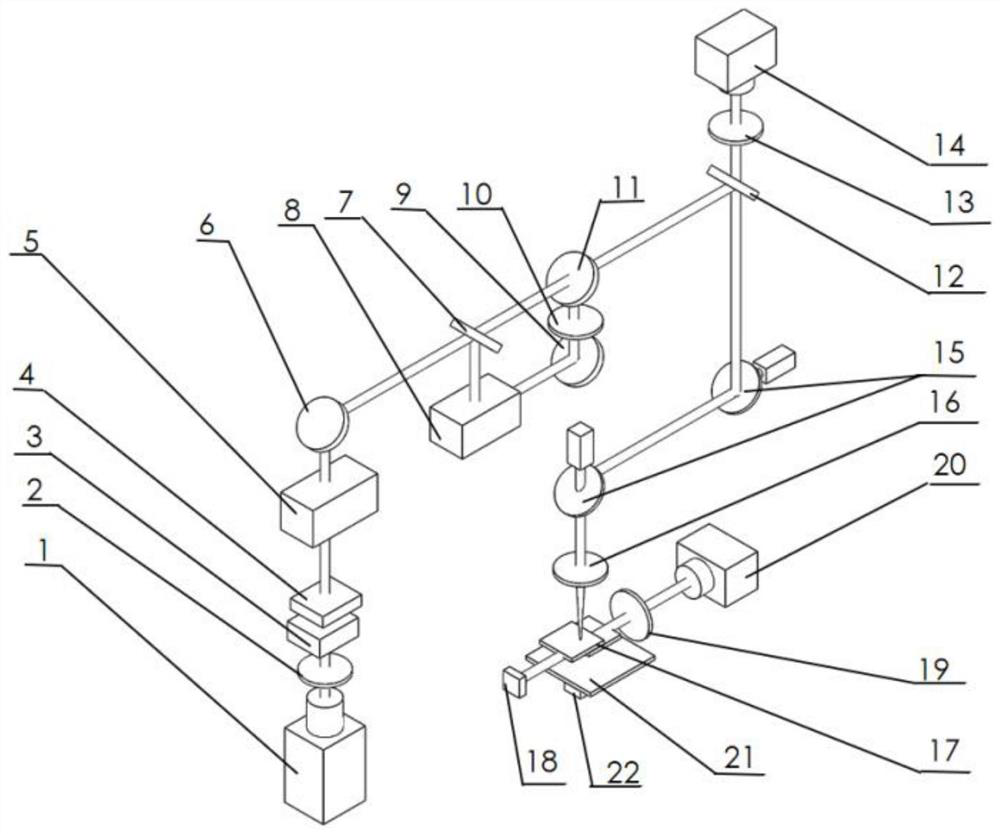

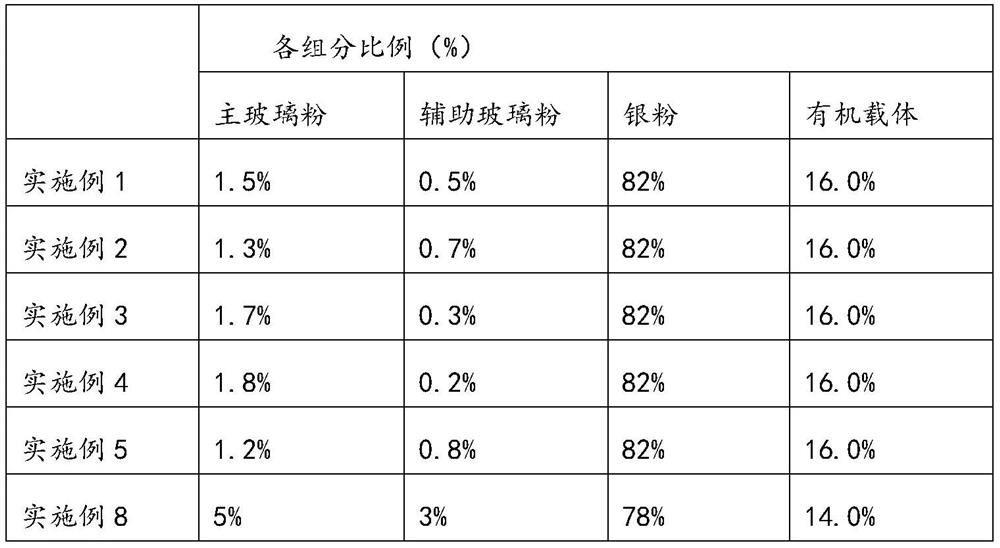

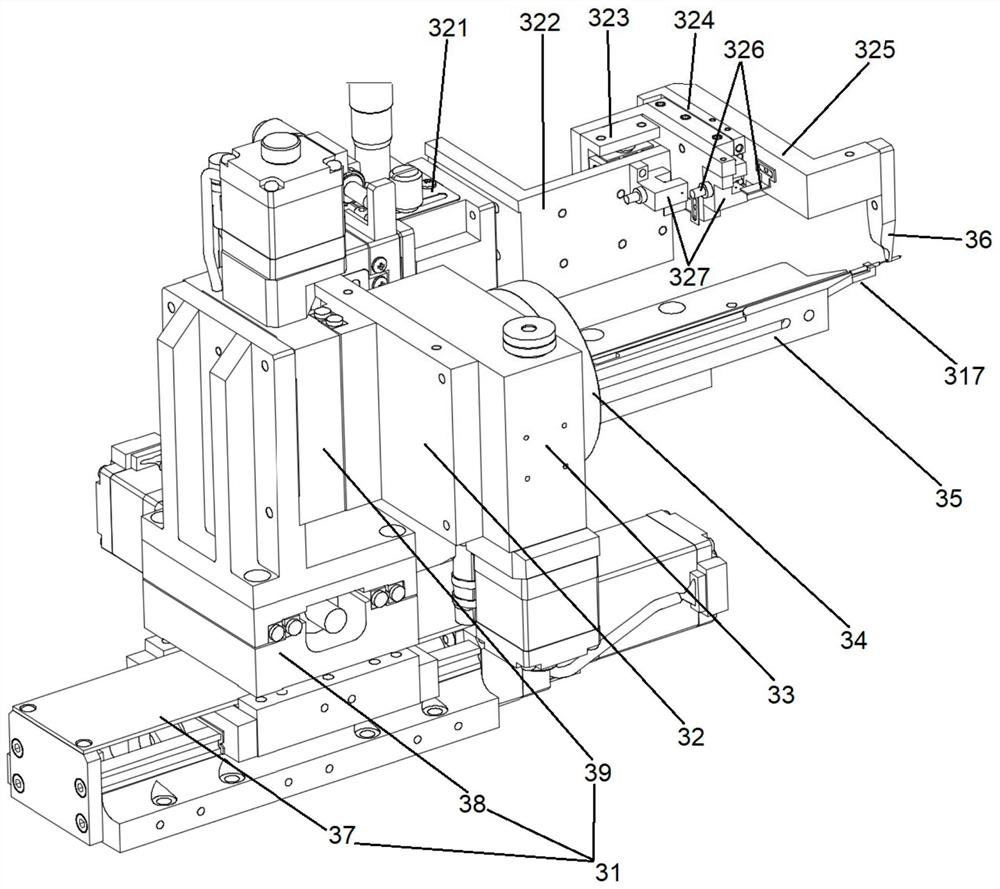

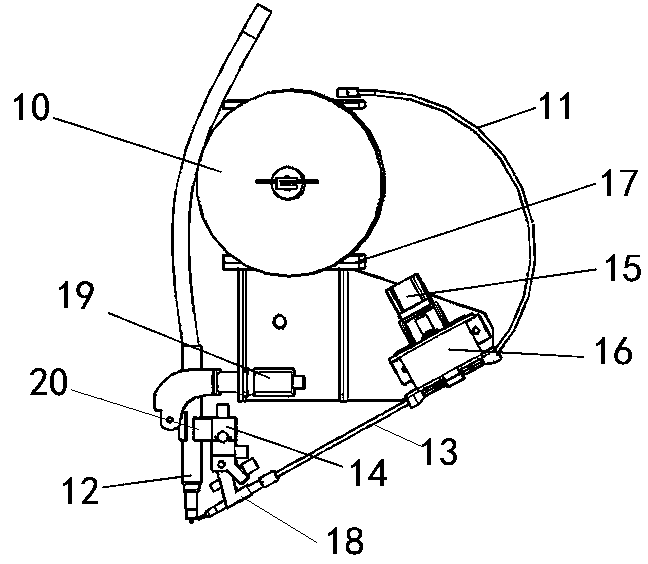

Butterfly laser coupling and welding equipment with polarization-maintaining fiber

ActiveCN111922520AReasonable structural designFit compactLaser beam welding apparatusErbium lasersEngineering

The invention provides butterfly laser coupling and welding equipment with a polarization-maintaining fiber. The butterfly laser coupling and welding equipment comprises an optical fiber clamp module,a pipe shell clamp module, a welding module and a visual monitoring module; the optical fiber clamp module clamps an optical fiber to feed the optical fiber in a pipe shell and adjusts the position and angle of the optical fiber for coupling; the pipe shell clamp module clamps and positions the pipe shell and electrifies the pipe shell; the welding module welds a metal sleeve on a coupled opticalfiber in the pipe shell; the visual monitoring module is used for monitoring the position and angle of the optical fiber; the optical fiber clamp module comprises a mounting plate arranged on a coupling displacement table, an optical fiber rotary support table arranged at one end of the mounting plate, and a front end chuck component arranged at the other end of the mounting plate. According to the butterfly laser coupling and welding equipment, all modules are reasonable in structural design and compact in joining and matching, so that the packaging process is simplified, and the productionefficiency is improved; and when a front end chuck moves, and adsorbs and fixes the metal sleeve at the front end of the optical fiber, the front end chuck does not generate obvious mutual interference with the optical fiber rotary support table, so that the coupling precision is improved.

Owner:CENT SOUTH UNIV

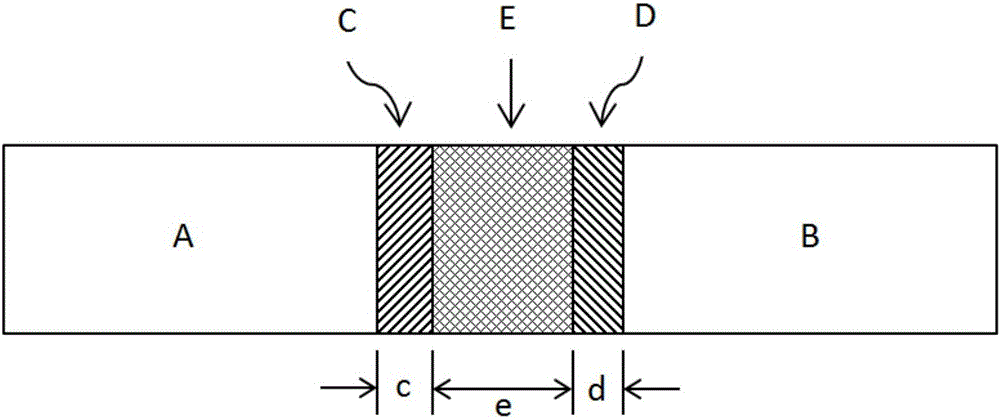

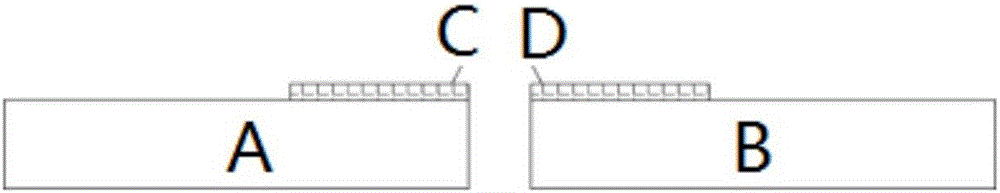

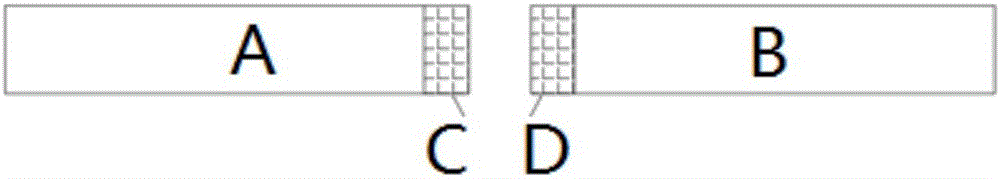

Three-step approach four-interface system-based heterogeneous material joint structure and heterogeneous material connection method

ActiveCN106563887AReduce performance degradationImprove connection strengthWelding/cutting auxillary devicesAuxillary welding devicesButt jointSpray coating

The invention discloses a three-step approach four-interface system-based heterogeneous material joint structure and heterogeneous material connection method. The method includes the following steps that: 1) the connecting surfaces of a base material A and a base material B are pre-treated; 2) cold spraying is performed on the connecting surface of the base material A, so that a coating C can be formed, cold spraying is performed on the connecting surface of the base material B, so that a coating layer D can be formed; and 3) the coating C and the coating D are welded through a butt-joint or lap-joint manner, so that a welding seam E is formed, welding parameters are controlled in a welding process, so that the interfaces of the base materials A, B and the cold-sprayed coatings C, D will not be melt or locally melt. According to the three-step approach four-interface system-based heterogeneous material joint structure and heterogeneous material connection method of the present invention, the connection of two heterogeneous materials which have little possibility of being connected is converted into the connection of materials which have high possibility of being connected through coating technologies; and the thermal input of the interfaces is reasonably controlled, so that various limitations caused by huge thermal performance difference of heterogeneous materials in conventional connection methods can be eliminated, and the connection performance of the joint can be improved. A novel method is provided for the connection of the heterogeneous materials.

Owner:XI AN JIAOTONG UNIV

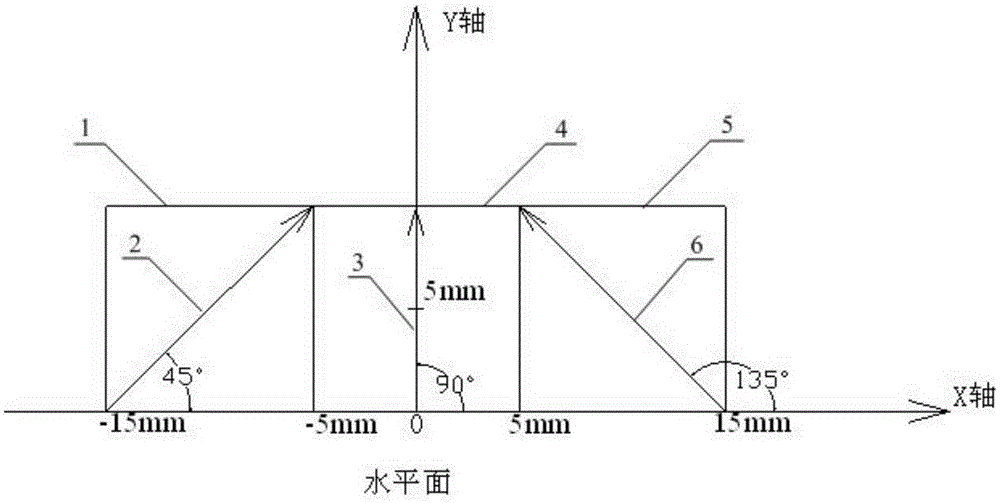

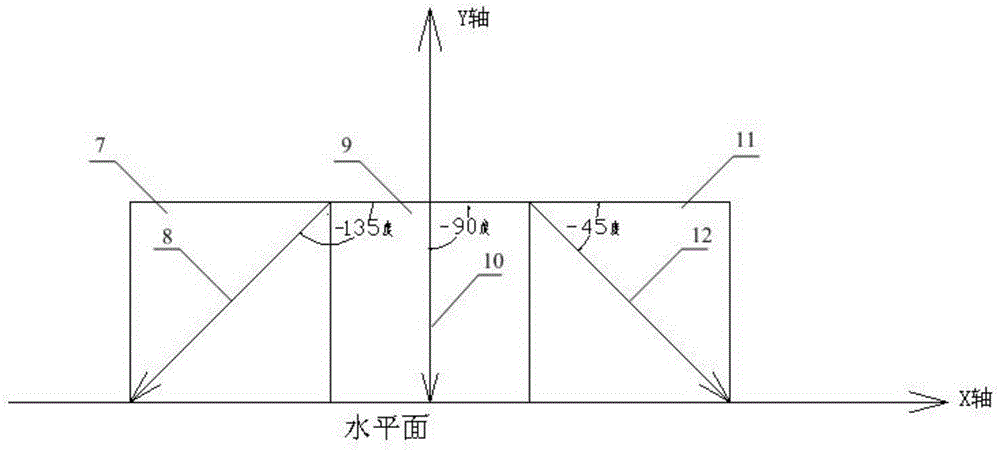

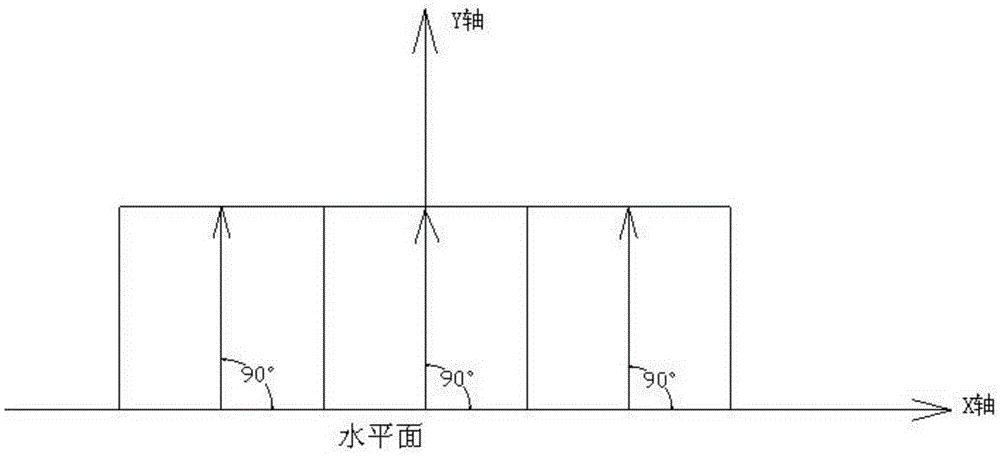

A combined permanent magnet with enhanced regional magnetic field strength

InactiveCN103123844BSolving Welding DifficultiesSolve the problem of serious demagnetizationPermanent magnetsInductances/transformers/magnets manufactureHigh energyUltimate tensile strength

The invention relates to a regional magnetic field intensity enhancing combination permanent magnet. The regional magnetic field intensity enhancing combination permanent magnet comprises the following two sizes: a positive size combination permanent magnet and a negative size permanent magnet. Sub-magnets with single magnetizing direction are combined based on different magnetic field directions, and then are effectively welded to a combination permanent magnet through a manner of high energy density beam welding; the combination permanent magnet which is prepared is used for the regional magnetic field enhancing combination permanent magnet of a minitype permanent magnet generator, therefore a high effective magnetic field design is realized, and working efficiency of the minitype permanent magnet generator is prominently improved.

Owner:TONGJI UNIV

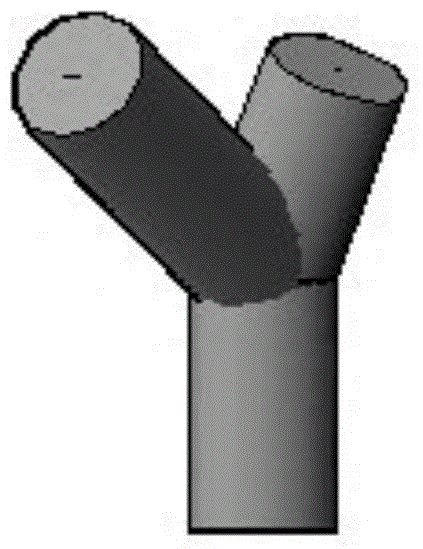

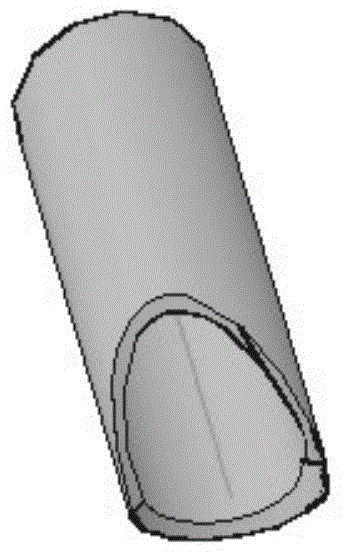

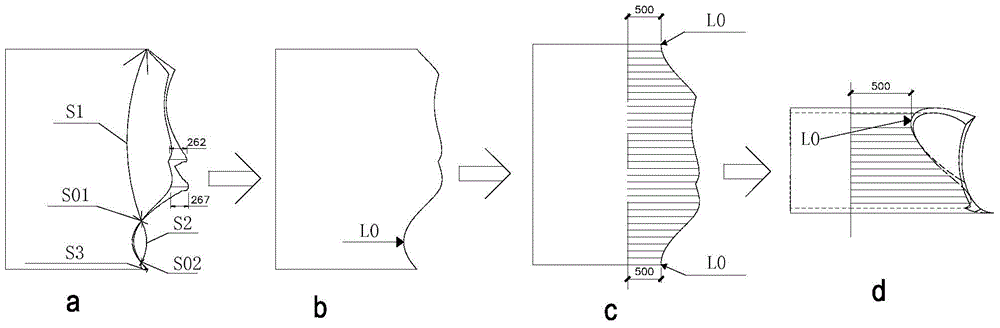

Method for manufacturing complex intersecting line hot rolling steel tube joint

ActiveCN105014319ASolving Welding DifficultiesReduce processing timeMechanical engineeringMachining time

The invention discloses a method for manufacturing a complex intersecting line hot rolling steel tube joint. Each branch steel tube on the joint is unfolded, and an inner wall line and an outer wall line of an intersecting opening are selected with the cross point of the intersecting lines of the inner walls and the outer walls of the branch tubes as a datum point; the inner wall line is selected in the toe area, the outer wall line is selected in the root area, and the shape of the intersecting opening is obtained; the lowest point of the intersecting opening serves as a starting point, a steel plate is equally divided into N parts, and the intersecting point is cut. The hot rolling technology is adopted for manufacturing the multi-tube intersecting joint to replace a cast steel joint, so that machining time is shortened, and efficiency is improved; quality is guaranteed, cost input is reduced, and environment is protected. When the intersecting opening is unfolded to be blanked, selection of the intersecting lines of the inner walls and the outer walls is considered, and assembly precision is guaranteed. The technology of carrying out unfolding blanking and rolling in sequence is adopted, so that materials are saved.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD +1

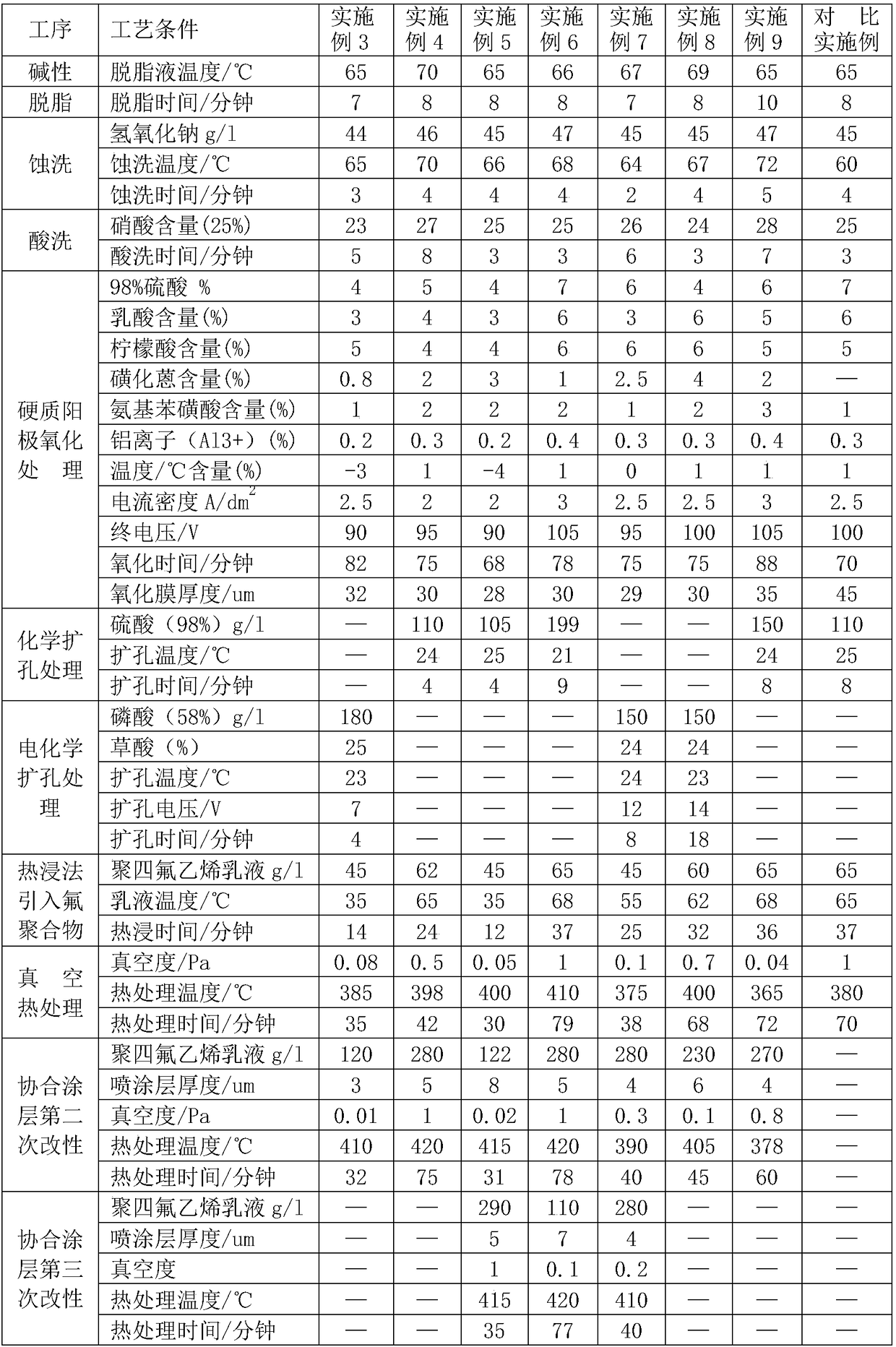

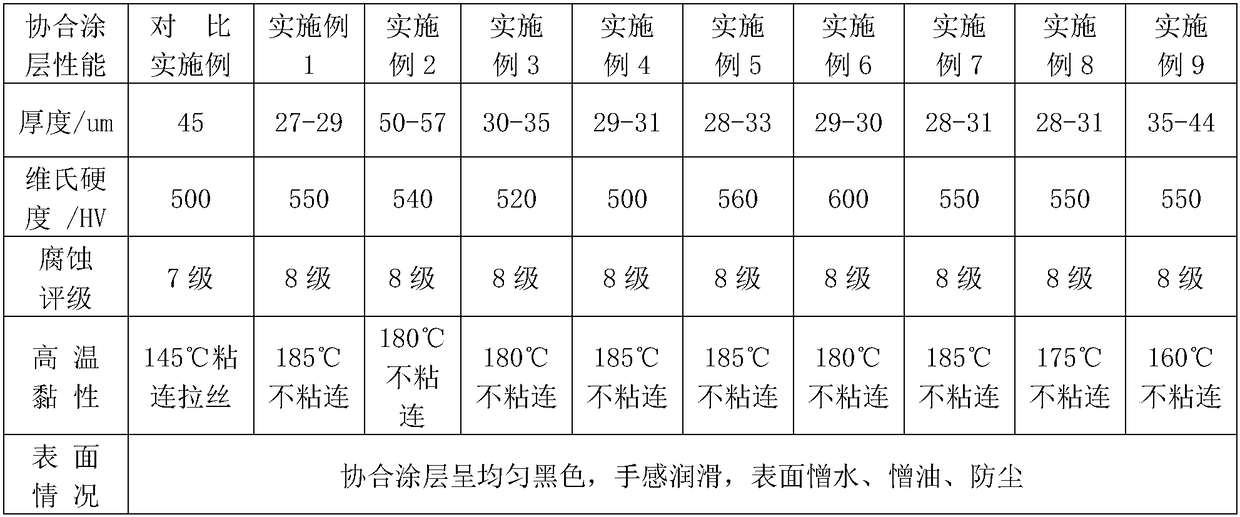

Treatment method for aluminium-alloy synergistic fluoropolymer coating with high-temperature viscosity resistance

The invention provides a treatment method for an aluminium-alloy synergistic fluoropolymer coating with high-temperature viscosity resistance. The method comprises the following steps: firstly, a mixed acid solution containing sulfonated anthracene is used for preparing an aluminium-alloy hard anodic oxide film by electrolysis; then chambering is performed on the aluminium-alloy hard anodic oxidefilm, and a fluoropolymer is introduced; the fluoropolymer and the aluminium-alloy hard anodic oxide film are fused into a whole by vacuum heat treatment, and the synergistic coating with the high-temperature viscosity resistance is prepared. The prepared aluminium-alloy synergistic fluoropolymer coating with high-temperature viscosity resistance is uniformly black, has quite good uniformity, still has high-temperature viscosity resistance in the range of 160-185 DEG C, and meets use requirements of aluminium alloy under high-temperature viscosity resistant condition; the problem of high-temperature viscosity in a non-PVC bag making process is solved effectively, and non-PVC bag making efficiency can be increased remarkably when the method is applied to a non-PVC bag making production line; besides, the method has quite important application value in solving the welding problems of three-layer films and five-layer films of the aluminium alloy and the problem of poor soldering of films.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

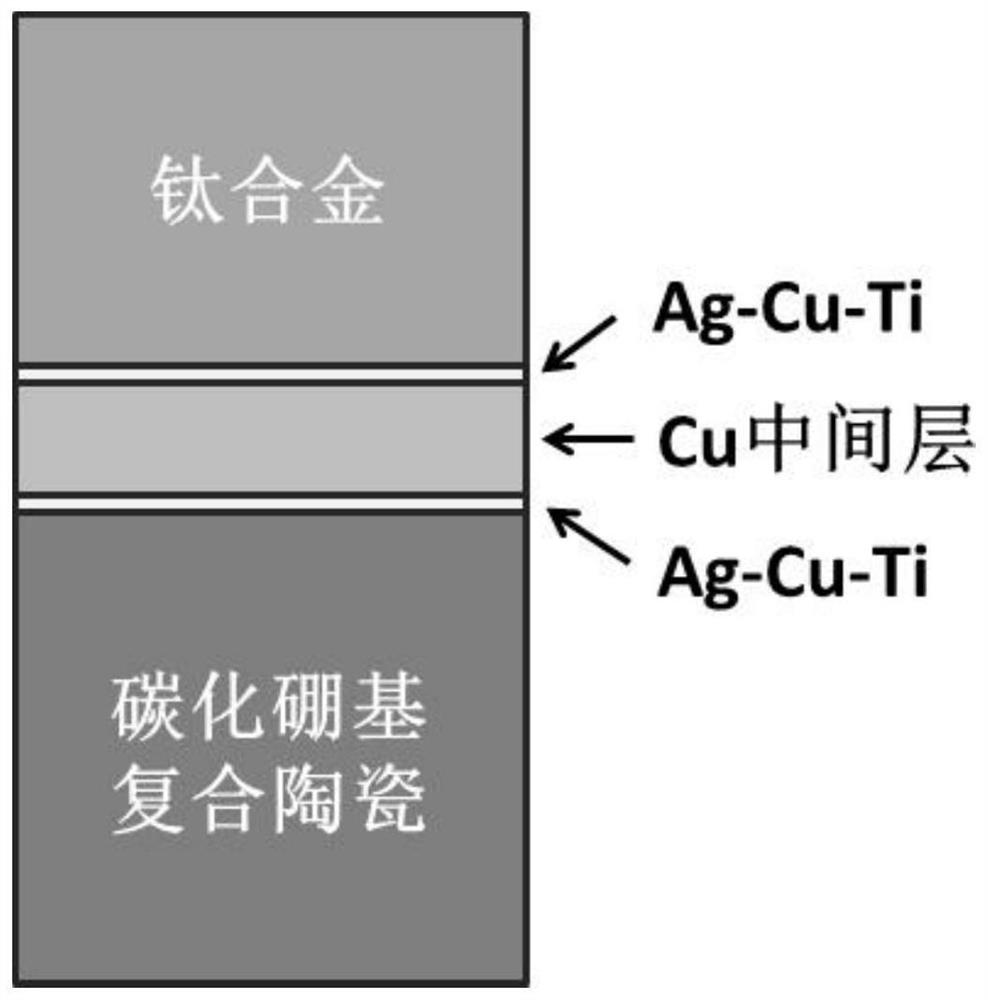

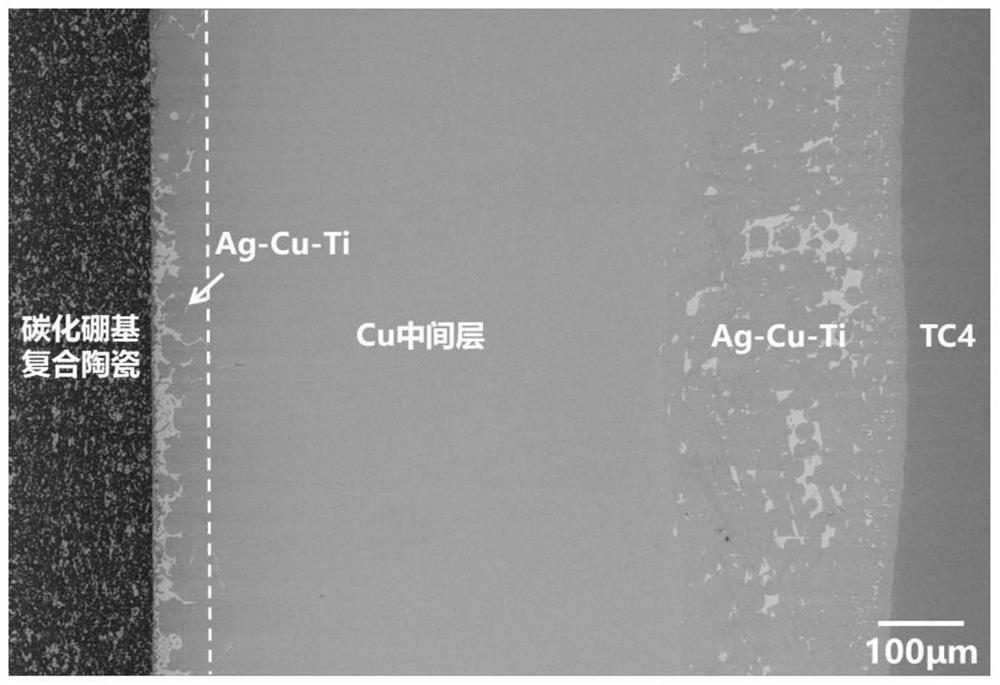

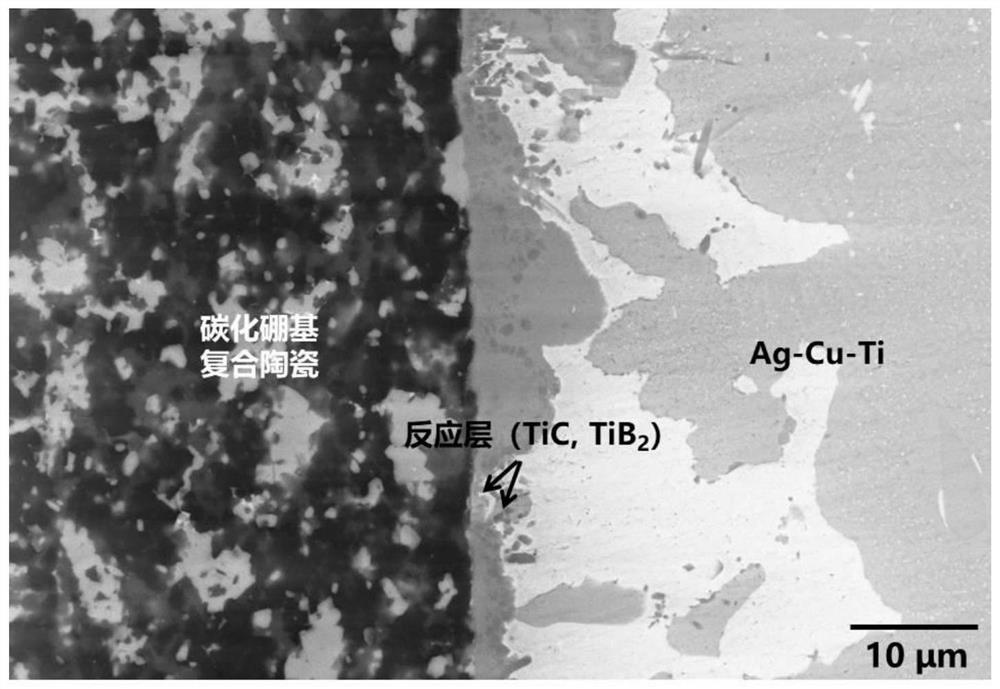

Composite middle layer and method for brazing boron carbide composite ceramic and titanium alloy through composite middle layer

PendingCN113600957AImprove bending strengthSolving Welding DifficultiesSoldering apparatusWelding/soldering/cutting articlesComposite ceramicTitanium alloy

The invention discloses a composite middle layer and a method for brazing boron carbide composite ceramic and a titanium alloy through the composite middle layer. The composite middle layer is composed of an upper brazing filler metal layer, a middle metal layer and a lower brazing filler metal layer. The upper brazing filler metal layer and the lower brazing filler metal layer both adopt Ag-Cu-Ti brazing filler metal, and the middle metal layer is made of copper. According to the method for brazing the boron carbide composite ceramic and the titanium alloy through the composite middle layer, the composite middle layer and the titanium alloy are sequentially placed on the to-be-brazed surface of the boron carbide composite ceramic to be assembled into a to-be-brazed workpiece of a sandwich structure, the to-be-brazed workpiece is subjected to high-temperature brazing connection under the vacuum condition, and a brazed joint obtained through the manner has excellent bending strength.

Owner:HEFEI UNIV OF TECH

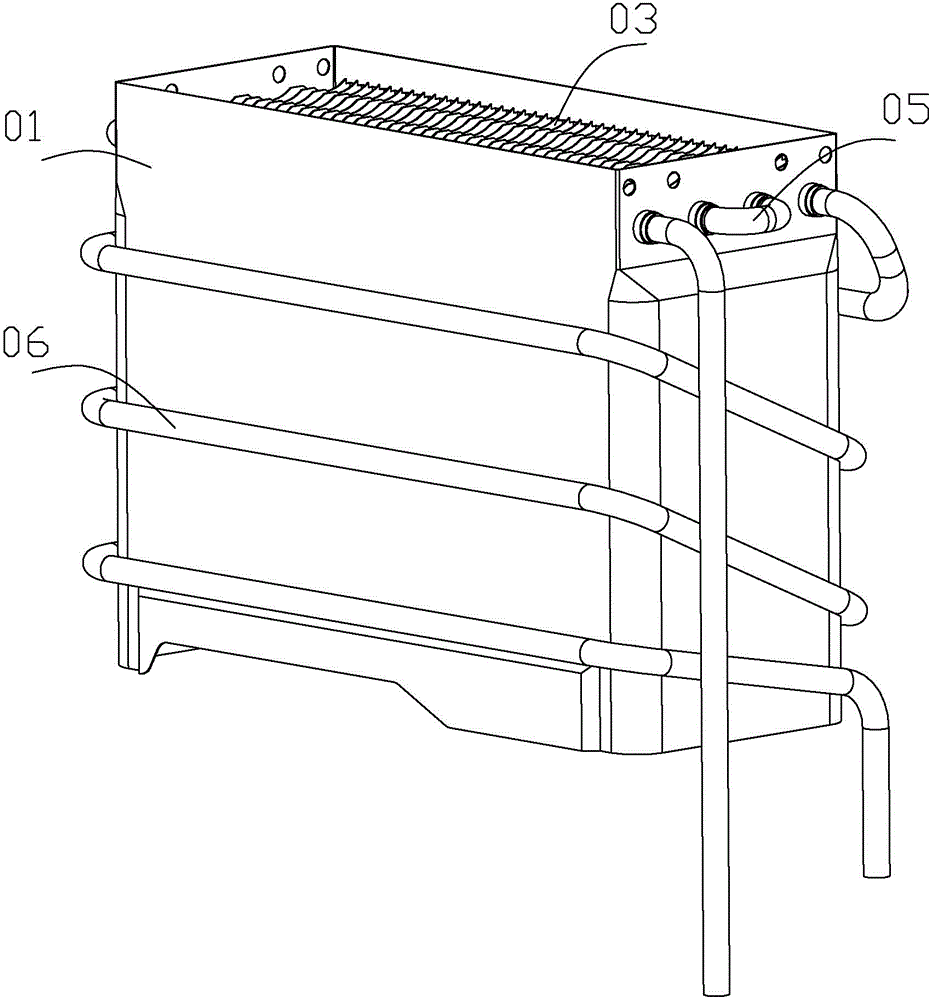

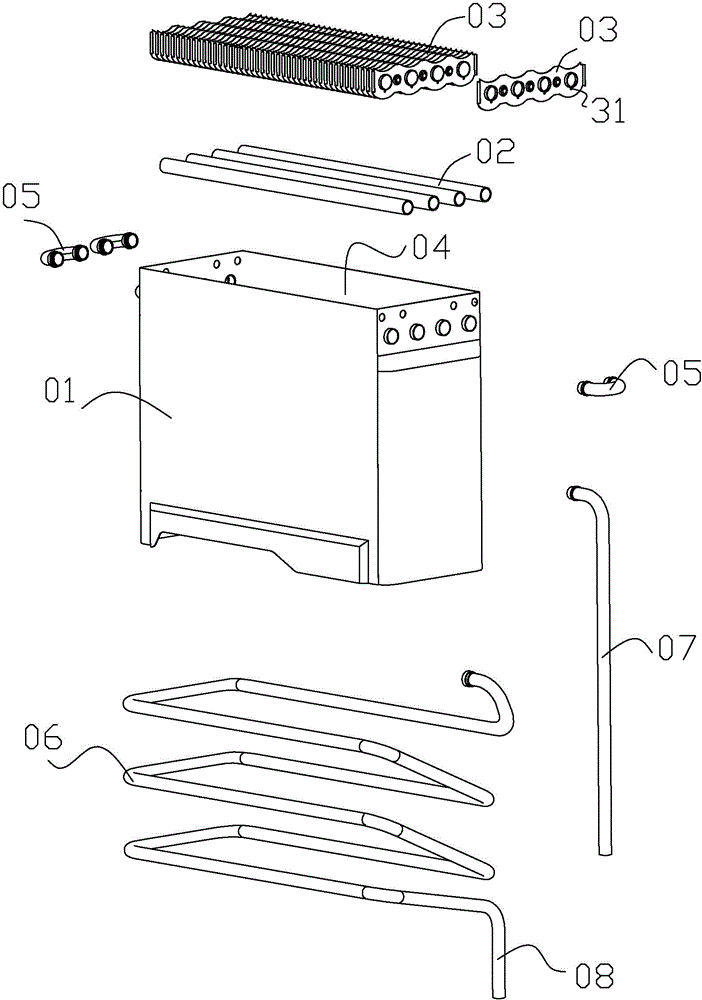

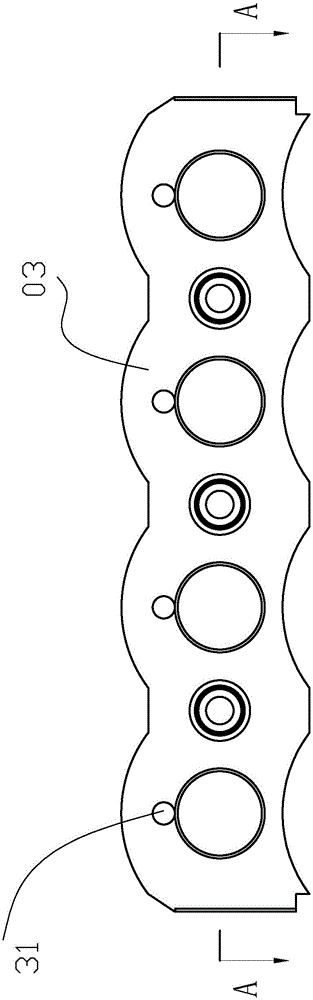

Copper aluminum heat exchanger of gas water heater and connecting method thereof

ActiveCN104913664AReduce material costsEnsure smoothnessFluid heatersSoldering apparatusCopperCopper in heat exchangers

A copper aluminum heat exchanger of a gas water heater comprises a shell, a straight pipe, heat exchanging fins, a U-shaped pipe, a coiler and a water inlet and outlet pipe. The copper aluminum heat exchanger is mainly characterized in that the shell and the heat exchanging fins are made of and formed through copper aluminum materials, and the straight pipe, the U-shaped pipe and the coiler are made of and formed through copper aluminum materials or copper materials; the copper aluminum materials comprise an aluminum material base body and a copper material covering layer arranged on the outer wall of the base body. The material cost of the heat exchanger can be effectively controlled, the heat exchanging efficiency is high, meanwhile, the smoothness of a heat exchanger water pipe can be ensured, and the service life of products is long. The invention further provides a connecting method for the copper aluminum heat exchanger of the gas water heater. The integral assembling procedure, the pre-welding procedure, the brazing filler metal assembling procedure and the integral brazing procedure are adopted, and therefore the welding problem between components in the heat exchanger can be effectively solved, and the production cost of the connecting procedure can be effectively reduced.

Owner:GUANGDONG VANWARD NEW ELECTRIC CO LTD

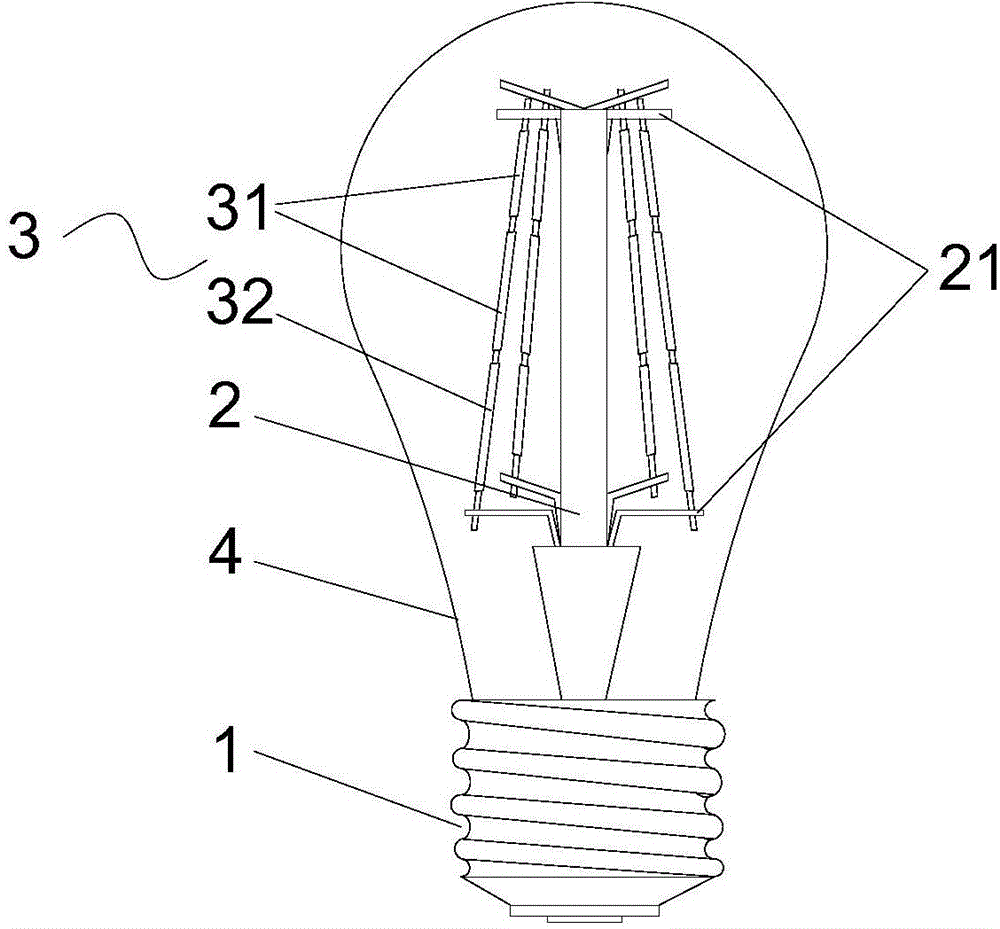

Lamp bulb of LED lamp filament structure

InactiveCN104896340AEasy to touch weldingSolving Welding DifficultiesPoint-like light sourceElectric circuit arrangementsButt weldingEngineering

The invention discloses a lamp bulb of an LED lamp filament structure. The lamp bulb comprises a lamp base, a core column, more than two LED lamp bars and a lampshade; the lampshade is fixedly connected with the lamp base; the more than two LED lamp bars and the core columns are sealed by the lampshade; more than two LED lamp bars are arranged to surround the core column; more than two electrodes are arranged on the core column; the two ends of each LED lamp bar are connected with one end of an electrode on the core column by virtue of butt-welding, respectively, and the other end of the electrode is connected with the lamp base and connected with an external AC or DC circuit by use of a lamp base; each LED lamp bar comprises a thread-like LED and an LED driving power source; the LED driving power source is connected in series with the thread-like LED and drives the thread-like LED to work. According to the lamp bulb structure, only the LED lamp bar is butt-welded on the electrode of the core column; as a result, the welding process is simplified and batch production can be realized.

Owner:LONGYAN DEYU LIGHTING

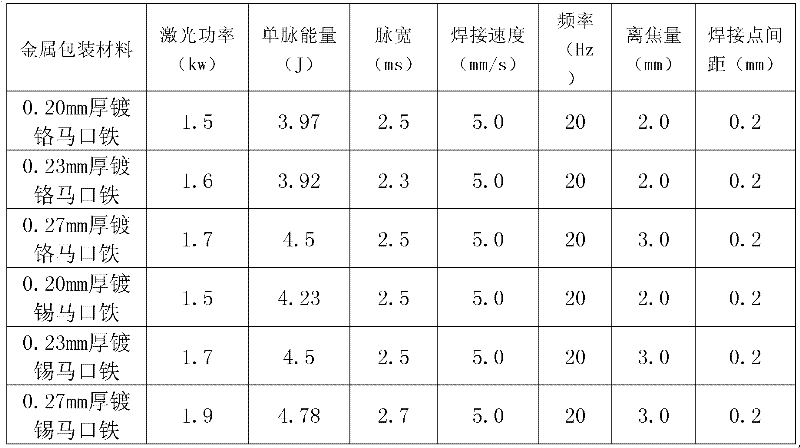

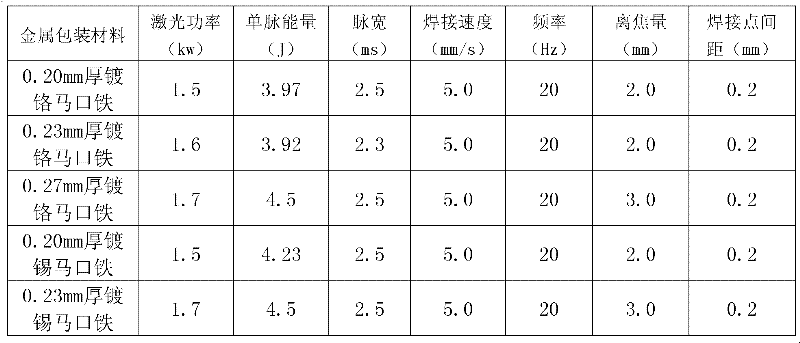

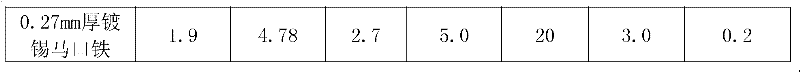

Laser welding process for thin-wall tinplate packaging material

The invention discloses a laser welding process for a thin-wall tinplate packaging material, which is used for realizing welding of a chrome plated tinplate and a tin plate tinplate which have the thicknesses of 0.20mm to 0.27mm by selection of parameters of a laser welding machine. Welding seam strips are of a fish scale shape and are uniformly distributed, are smooth and attractive and have no obvious welding defects of cracks, air holes and the like. The deformation of a metal tank and the damage to coatings on the inner and outer walls of the metal tank can be avoided. Welding seams are molten with a parent metal into one whole body. The laser welding process is reliable in welding, is beneficial to avoidance of damage to a metal packaging container and leakage of contents in the metal packaging container and reduction of loss of enterprises and consumers and can be used for effectively preventing spoilage of the contents and ensuring the body health of eaters. Due to a small light spot and high power density of the laser welding, the energy required by the laser welding is less than that required by the conventional welding by one order of magnitude, so that the daily operating cost of the laser welding is not higher than that of the conventional welding, the power consumption is reduced, the production cost is reduced, the problem of difficulty in welding of the thin wall of the chrome plated tinplate is also solved, the environment is not polluted, and the laser welding process has good social benefits.

Owner:山东省阳信金缘纺化有限公司

Iridium-nickel alloy and preparation method and application thereof

The invention provides an iridium-nickel alloy and a preparation method and application of the iridium-nickel alloy. The iridium-nickel alloy is composed of, by mass, 40%-70% of iridium and 30%-60% ofnickel. The preparation method of the iridium-nickel alloy comprises the following steps that (1) the iridium and the nickel are weighed according to the mass percent and placed in a vacuum environment; (2) the mixture of the iridium and the nickel are heated, and alloy liquid is obtained; (3) the alloy liquid obtained in the step (2) is poured into a smelting mold for casting; (4) homogenizationtreatment is conducted on an iridium-nickel alloy ingot obtained in the step (3). The iridium-nickel alloy is an intermediate layer welding material, good welding between iridium, IrRh10, IrRh25, IrRh40, Inconel 600 and the like and the iridium-nickel alloy can be achieved, and the problem of welding between the iridium-nickel alloy and the iridium, the IrRh10, the IrRh25, the IrRh40 and the Inconel 600 alloy is finally solved. The iridium-nickel alloy is used for preparation of a sparking plug electrode, and noble metal can be saved by 30%-60%.

Owner:HUNAN UNIV OF SCI & TECH

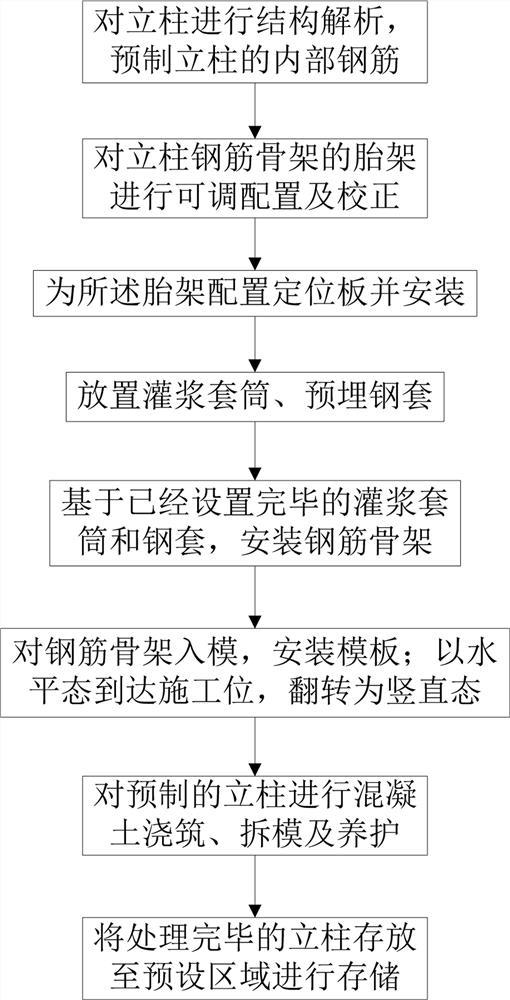

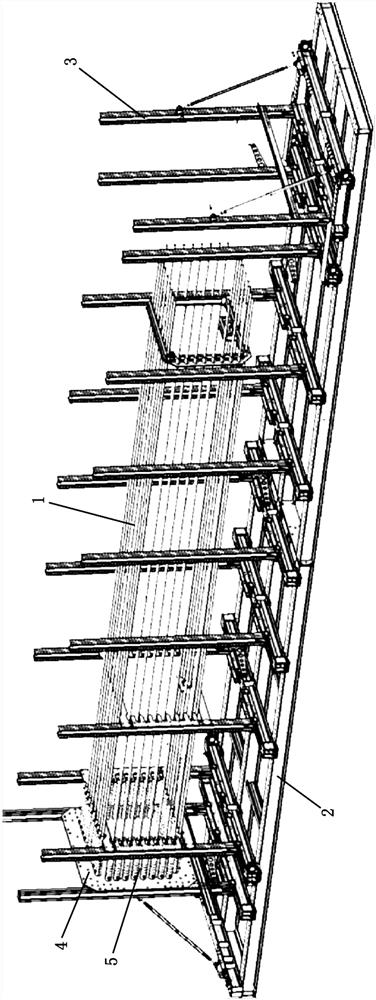

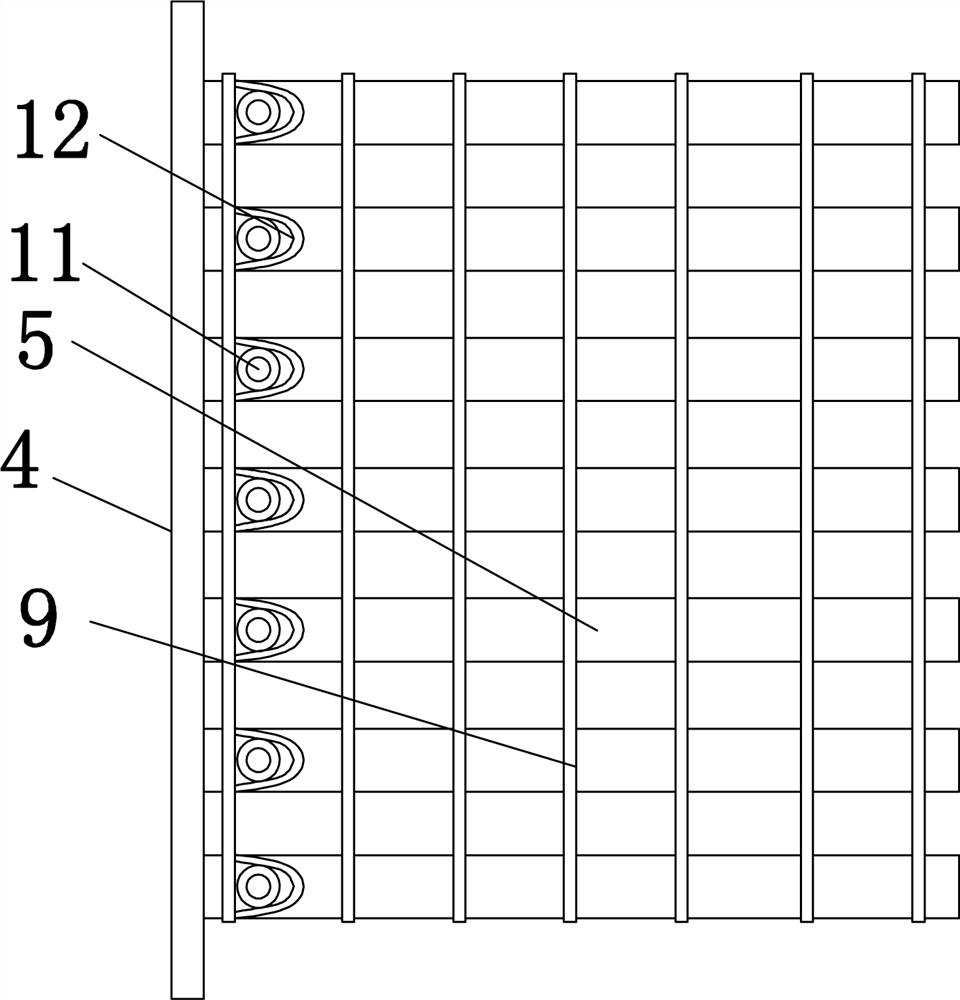

Construction method for prefabricated bridge steel jacket stand column

PendingCN113021602AOvercoming the problem of poor adaptability and unadjustableSolve the problem of grouting sleeve deviationCeramic shaping plantsWire networkSteel jacketArchitectural engineering

The invention relates to a construction method for a prefabricated bridge steel jacket stand column. Internal steel bars of the stand column are prefabricated after structural analysis; and a jig frame is arranged in an adjustable mode so as to be matched with binding of reinforcement frameworks of different lengths, fine construction of installation and welding of annular stirrups in a steel jacket, pouring of steel jacket stand column and turnover and transportation of a finished product is facilitated, and the problem that due to the fact that the self weight of the steel jacket stand column reinforcement framework is large and loads are not evenly distributed, and a grouting sleeve deviates in the reinforcement framework hoisting process is solved. The reinforcement framework is put into a mold, a template is installed, and the reinforcement framework reaches a construction position in a horizontal state and is overturned to be in a vertical state; and the prefabricated stand column is stored in a preset area for storage after being subjected to concrete pouring, mold removal and curing. According to the method, material waste is reduced, cost is saved, an assembly type treatment mode replaces integrated treatment, repeated use of all parts and templates is achieved, efficiency is improved, waste is reduced, operability is high, precision is high, the construction progress is fast, the utilization rate of machine tools and equipment is improved, and the method is safe, environmentally friendly and free of pollution.

Owner:ZHEJIANG COMM CONSTR GRP CO LTD +1

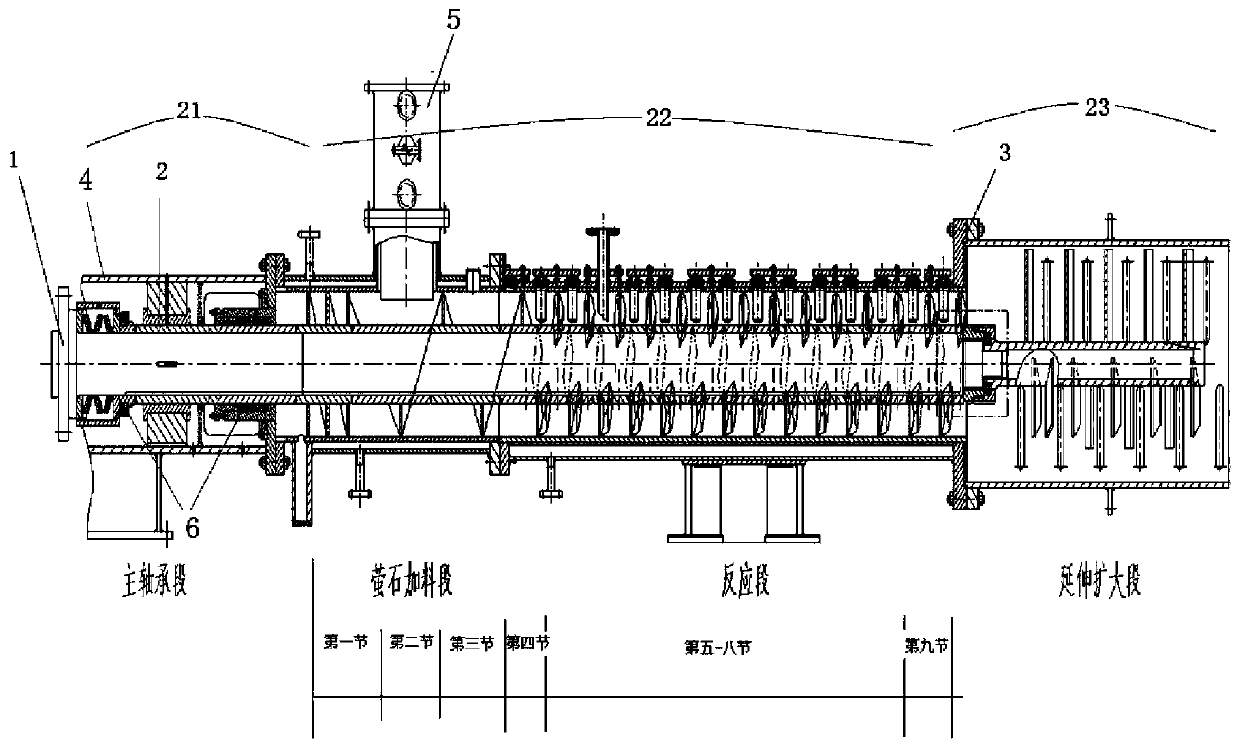

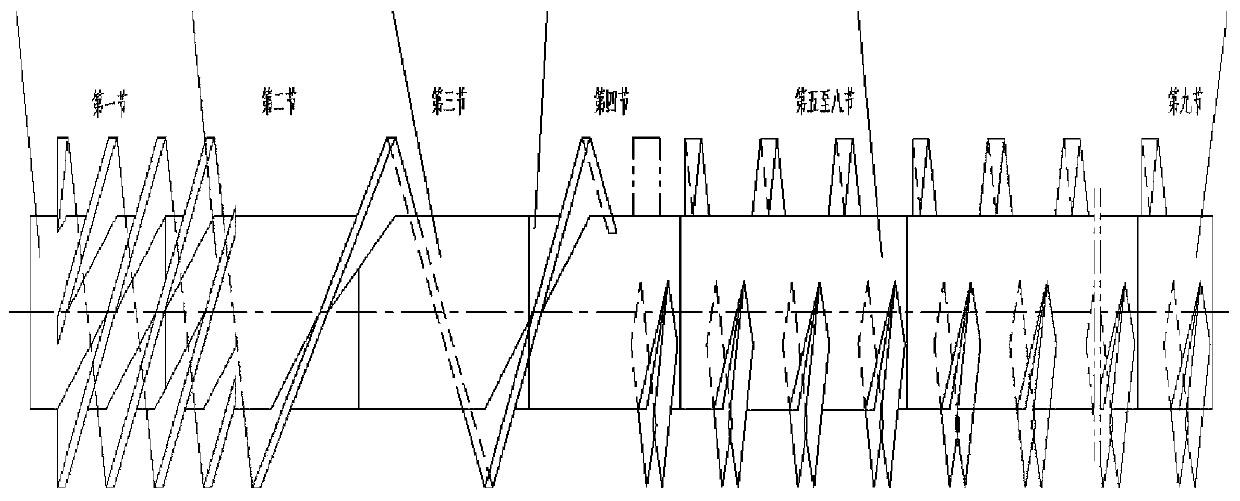

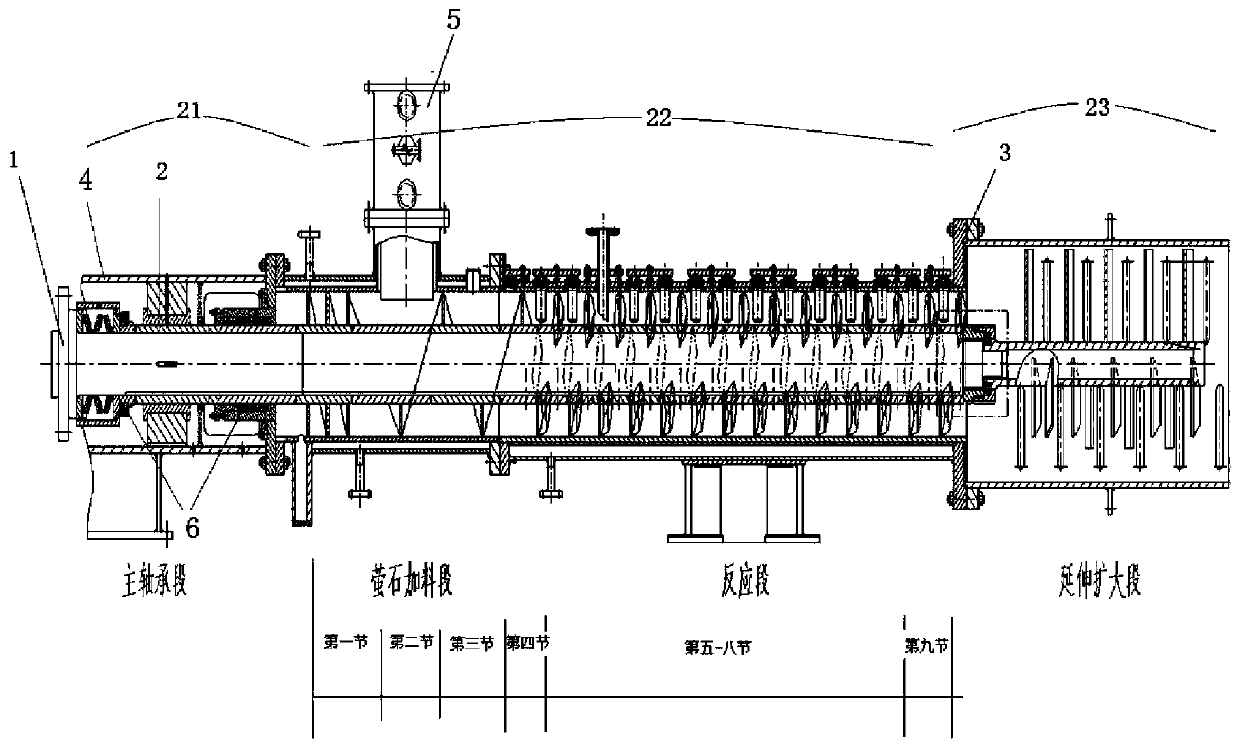

Double-support prereactor for hydrogen fluoride

PendingCN110694556AImprove corrosion resistanceSolving Welding DifficultiesHydrogen fluorideFeed devicesCorrosion resistantMain bearing

The invention discloses a double-support prereactor for hydrogen fluoride. A main shaft consists of a front shaft head, a hollow shaft and a rear shaft head, wherein the front shaft head, the rear shaft head and the hollow shaft are welded into a whole; the front section of the hollow shaft corresponds to a main bearing section, the middle section of the hollow shaft corresponds to a fluorite feeding section and a reaction section, and the rear section of the hollow shaft corresponds to an extension expansion section. A spiral main shaft is made of a 40CrMoNiA thick-wall pipe and a 40CrMoNiA forging piece after welding and quenching and tempering treatment. Spiral components with different materials and shapes are installed on the main shaft to not only improve the corrosion resistance ofdifferent sections of the prereactor, but also solve the welding problem between different alloys and reduce the cost.

Owner:沈阳派司钛设备有限公司

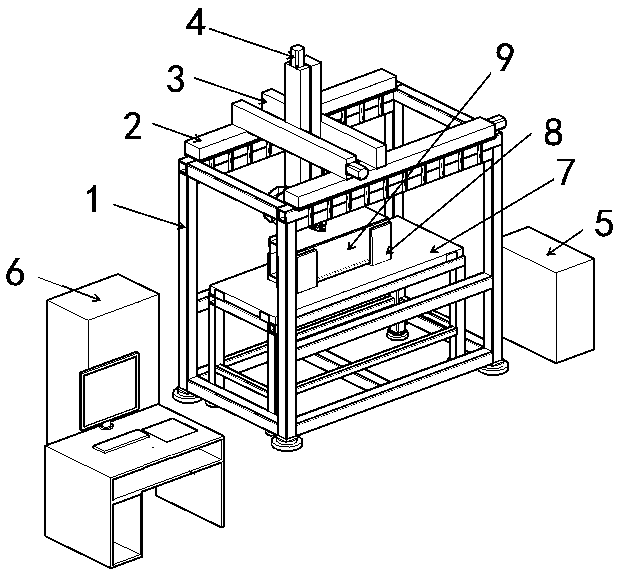

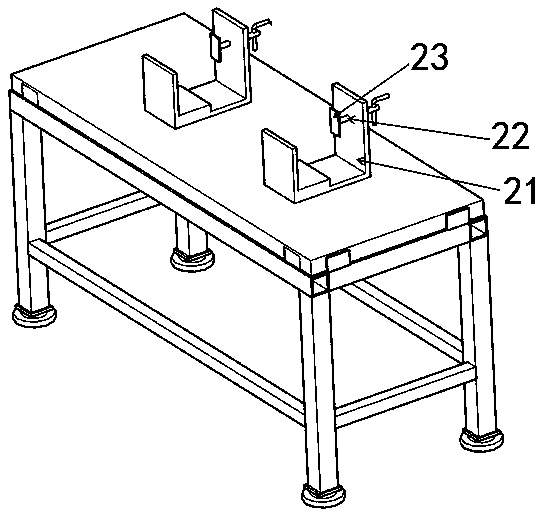

Sheathing straight seam automatic argon arc welding equipment and welding process

PendingCN109590577ARealize automatic weldingImprove welding qualityArc welding apparatusEngineeringWelding process

The invention provides a sheathing straight seam automatic argon arc welding equipment and a welding process. The sheathing straight seam automatic argon arc welding equipment comprises a welding machine frame, a workpiece table, a welding machine, an argon arc welding power supply and a control device, workpiece tools are installed on the workpiece table, and a three-dimensional linear module isinstalled on the upper portion of the welding machine frame, an automatic wire feeding mechanism and welding guns are arranged at the lower part of the Z-direction linear module. The sheathing straight seam automatic argon arc welding process is characterized in that four points A, B, C and D are defined on the length of the whole straight seam, arc striking is carried out on the point A and the arc striking is kept for a certain time, then the welding of the AB section is carried out at a constant speed V1, and the speed is increased after the point B is reached, the speed V2 is used for carrying out the welding of the BD section, and the arc extinguishing is carried out and kept for a certain time after the point D is reached, and then arc striking is carried out at a speed V3 to carry out the welding of the DC section, the arc extinguishing is carried out and kept for a certain time after the point C is reached, and then secondary arc striking is carried out for a certain time. According to the equipment and process, the welding quality can be effectively ensured.

Owner:焦作智造机电设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com