Steel-iron based metal ceramic composite and integrated process for sintering and welding composite

A technology for iron-based metals and cermets, which is applied in metal layered products, chemical instruments and methods, layered products, etc., can solve the problems of expensive iron-based cermets, restricting the promotion and application of iron-based cermets, etc. Welding problems, easy to promote and use on a large scale, and the effect of reducing thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

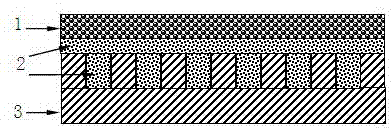

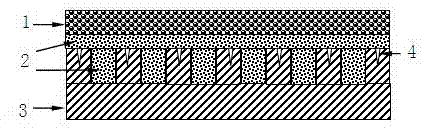

[0020] see figure 1 : A kind of steel and iron-based metal-ceramic composite body and its sintering and welding integration process, wherein the composite body is successively high ceramic layer, high metal layer, and metal layer from outside to inside, and the specific formula of the high ceramic layer is 50wt % of 400 mesh TiC powder, Fe powder is 39wt%, Mo powder is 1wt%, Ni powder is 3wt%, Cr powder is 7wt%; the transition layer is a high metal layer, and the specific formula is 25wt% 400 mesh TiC powder, Fe Powder is 62wt%, Mo powder is 1wt%, Ni powder is 4wt%, Cr powder is 8wt%; the particle size of the above metal powders is 200 mesh; the complex sintering and welding integration process is as follows, 1) After the good powders are mixed evenly, they pass through the mold, and the upper surface of the steel 3 is first laid with a high metal layer 2, also called a high metal transition layer, and then a high ceramic layer 1 is laid, and pressed to form an outer high cera...

Embodiment 2

[0021] Example 2: see figure 1, a steel and iron-based cermet composite body and its sintering and welding integration process, wherein the composite body consists of a high ceramic layer 1, a high metal layer 2, and a metal layer 3 from outside to inside, and the specific details of the high ceramic layer The formula is: 40wt% 400 mesh TiC powder, 47wt% Fe powder, 1wt% Mo powder, 4wt% Ni powder, 8wt% Cr powder; 400 mesh TiC powder of 20wt% inner layer formula, Fe powder is 67wt%, Mo powder is 1wt%, Ni powder is 4wt%, Cr powder is 8wt%; the particle size of the above metal powders are all 200 mesh. The details of the complex sintering and welding integration process are as follows: 1) After mixing the prepared powders evenly, pass through the mold, and lay the high metal layer 2 on the upper surface of the steel 3, also called the high metal transition layer, and then lay the High ceramic layer 1, pressed into a composite blank with an outer high ceramic layer, a high metal...

Embodiment 3

[0022] Example 3: see figure 1 , a steel and iron-based cermet composite body and its sintering and welding integration process, wherein the composite body consists of a high ceramic layer 1, a high metal layer 2, and a metal layer 3 from outside to inside, and the specific details of the high ceramic layer The formula is: 30wt% 400 mesh TiC powder, 57wt% Fe powder, 2wt% Mo powder, 4wt% Ni powder, 7wt% Cr powder; 400 mesh TiC powder of 15wt% inner layer formula, Fe powder is 72wt%, Mo powder 2wt%, Ni powder 4wt%, Cr powder 7wt%; the particle size of the above metal powders are all 200 mesh. The details of the complex sintering and welding integration process are as follows: 1) After mixing the prepared powders evenly, pass through the mold, and lay the high metal layer 2 on the upper surface of the steel 3, also called the high metal transition layer, and then lay the High ceramic layer 1, pressed into a composite blank with an outer high ceramic layer, a high metal transit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com