Sheathing straight seam automatic argon arc welding equipment and welding process

A technology of argon arc welding and argon arc welding, applied in the field of welding equipment, can solve the problems of high labor intensity of workers, easy collapse of welding base metal, smooth and timely control of wire feeding, etc., so as to improve welding quality and sealing performance. Avoid the formation of slag inclusions in pores and the effect of uneven welding formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to more fully explain the implementation of the present invention, the implementation examples of the present invention are provided, and these implementation examples are only illustrations of the present invention, and do not limit the scope of the present invention.

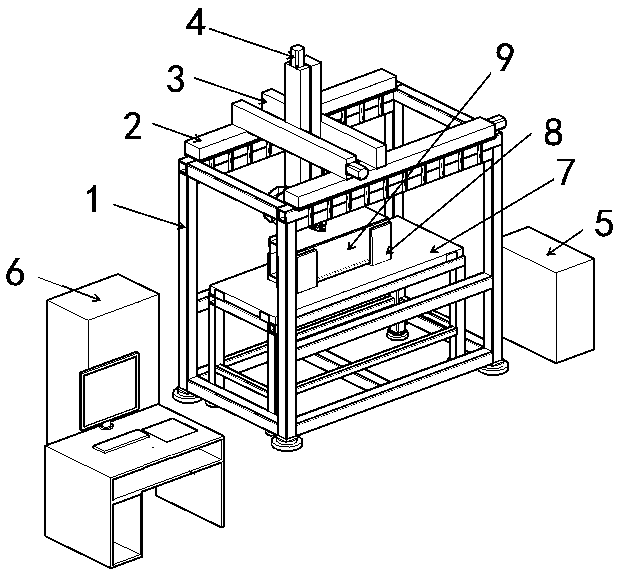

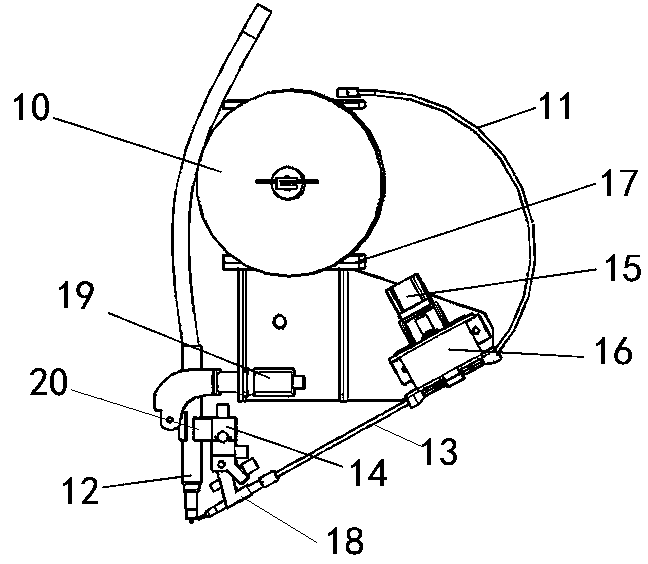

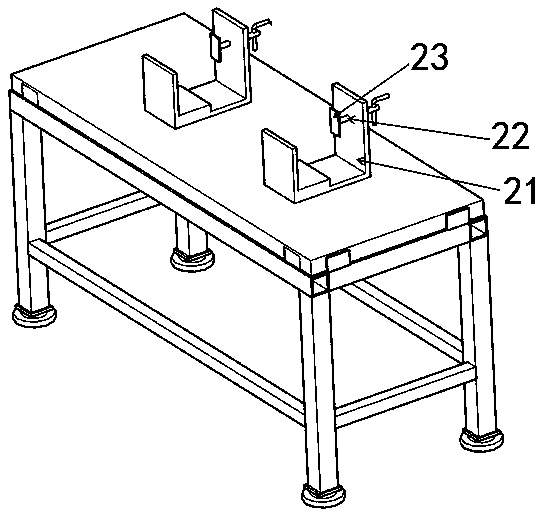

[0025] The present invention will be described in detail in conjunction with the accompanying drawings. In the accompanying drawings, each mark is: 1: welding machine frame; 2: linear module in the X direction; 3: linear module in the Y direction; 4: linear module in the Z direction; 5: Argon arc welding power supply; 6: Control device; 7: Workpiece platform; 8: Workpiece tooling; 9: Cover; 10: Welding wire reel; 11: First wire feeding hose; 12: Welding gun; 13: Second feeding Wire hose; 14: manual three-dimensional adjustment sliding table; 15: stepping motor; 16: wire feeder; 17: base; 18: wire feeding nozzle; 19: swing motor; 21: welding torch clamp; 21: U-shaped frame ; 22: screw rod; 23: p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com