Construction method for prefabricated bridge steel jacket stand column

A technology of prefabricated assembly and construction method, applied in the direction of bridges, manufacturing tools, bridge parts, etc., can solve the problem that the workload of processing material consumption does not match the frequency of use, the bearing performance and flatness of the embedded base are reduced, and the factory production income cannot be obtained. Security and other issues, to achieve the effect of fast construction progress, cost saving and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be described in further detail below in conjunction with the examples, but the protection scope of the present invention is not limited thereto.

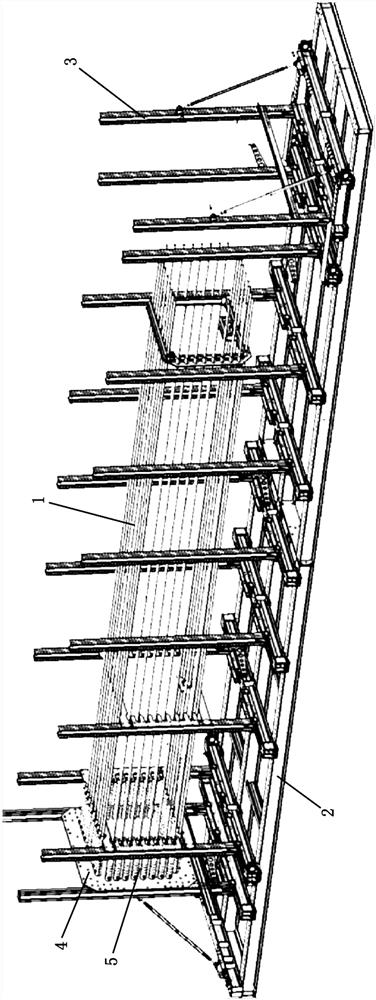

[0055] The invention relates to a construction method of a prefabricated assembled bridge steel sleeve column, which can set up a raw material stacking area, a steel bar processing area, a steel frame binding area, a formwork installation and pouring area, a finished product stacking area, and a finished product factory area in a standardized factory to form a flow The operation does not affect each other, and the loading space and transportation channel are set up in the stacking area.

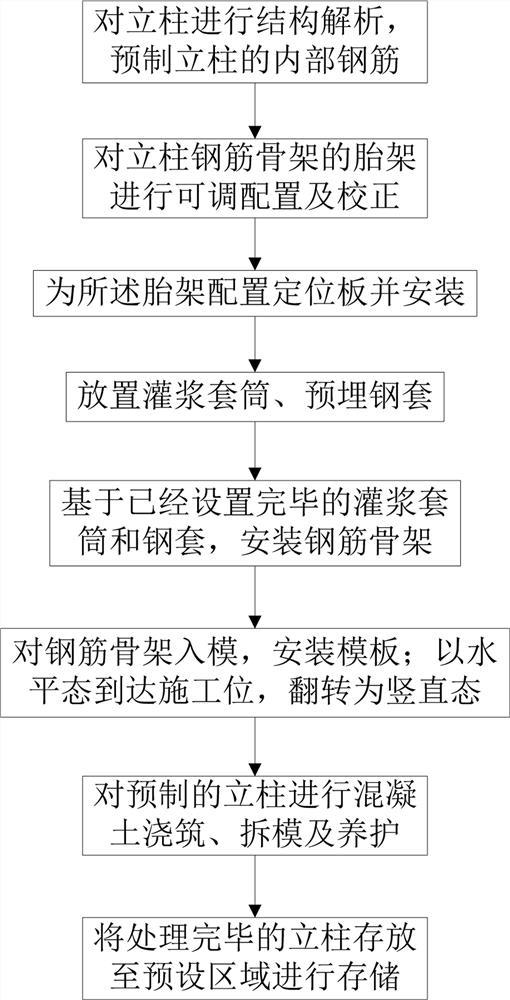

[0056] The method includes the following steps.

[0057] Step 1: Analyze the structure of the column and prefabricate the internal reinforcement of the column.

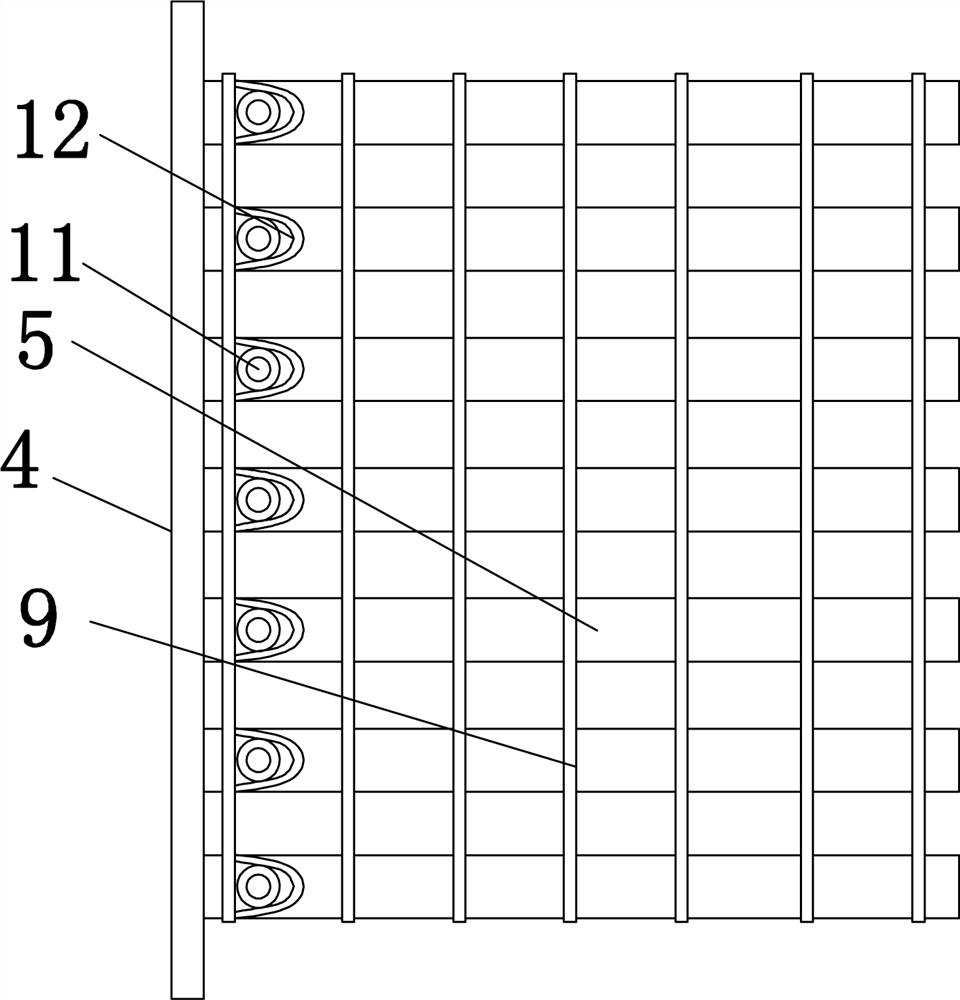

[0058] In the step 1, the structural analysis is to model and calculate the positions of the main reinforcement, stirrup, grouting sleeve and prestressed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com