Steel-copper bimetallic axle sleeve and process for producing same

A technology of bimetallic shafts and production methods, which is applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of complex production methods, waste of raw materials, and bulky products, so as to save manpower, high reliability, and reduce production costs. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings.

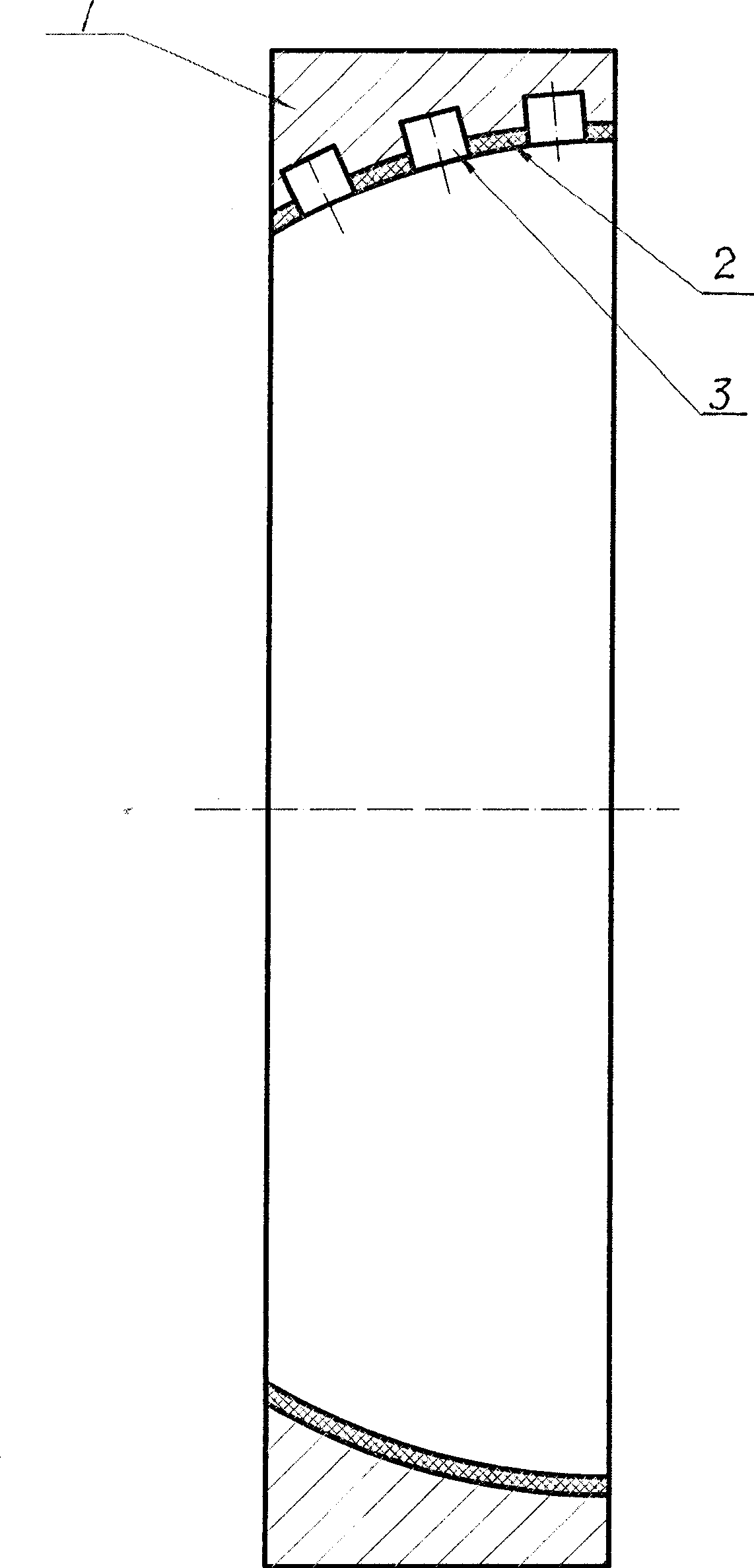

[0023] figure 1 Shown is a GEW140HFZ5B shaped spherical plain bearing.

[0024] a. The steel sleeve 1 is a double-half outer ring with axially symmetrical two petals combined together for assembly. It can be made by the existing technology, that is, 45 steel is used for rough turning (including the inner spherical surface) after forging and annealing, and then Use Fancheng method on the internal grinding machine to roughly grind the inner spherical surface to make the surface roughness reach Ra3.2-6.3μm, and chamfer the end; then use a sandblasting machine to sandblast the inner spherical surface to clean the inner surface of the steel sleeve. The compressed air used for sandblasting of alumina or silicon carbide can be used to remove oil and water. The air pressure is 0.15-0.4MPa, and the sand size is 0.5-1mm. It can be cleaned by other m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com