Hidden type reinforcing and damping energy dissipation device applicable to sidespan mortise and tenon joints of wood structure

A technology of energy-consuming devices and wooden structures, which is applied in the direction of earthquake resistance, building components, and building structures, can solve the problems of increasing energy consumption, tenon pulling damage, tenon and mortise extrusion damage, etc., so as to achieve easy deterioration, Improved energy consumption and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

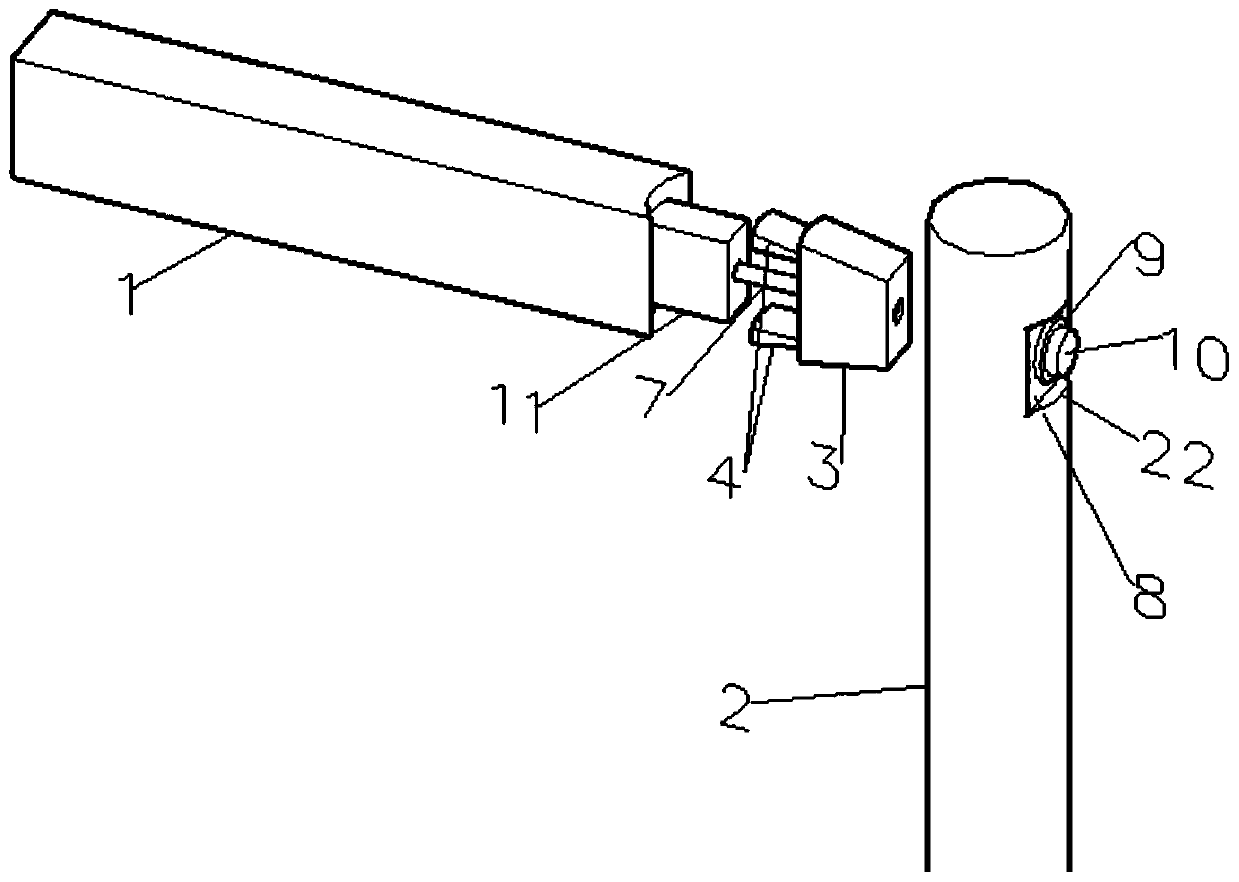

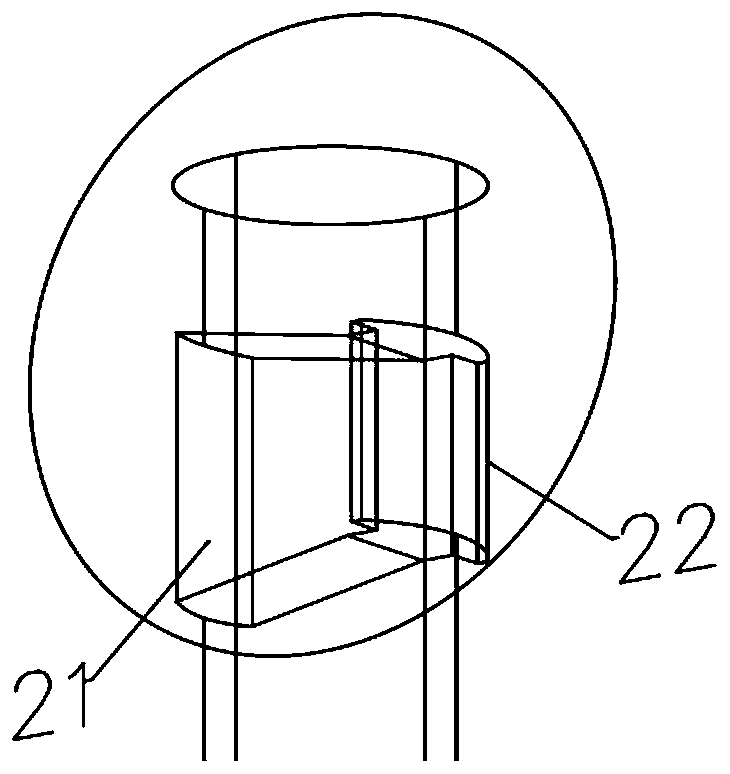

[0029] Such as figure 1 As shown, the present invention is suitable for concealed reinforcement and shock-absorbing energy-dissipating devices for side-span mortise and tenon joints of wooden structures. It is used for mortise and tenon joints at the joints of wooden beams 1 and wooden columns 2, including the peripheral and mortise joints arranged on the tenon 11 The metal steel cover 3 of 21 inner peripheries. In the present invention, the tenon 11 can be a through tenon or a half through tenon.

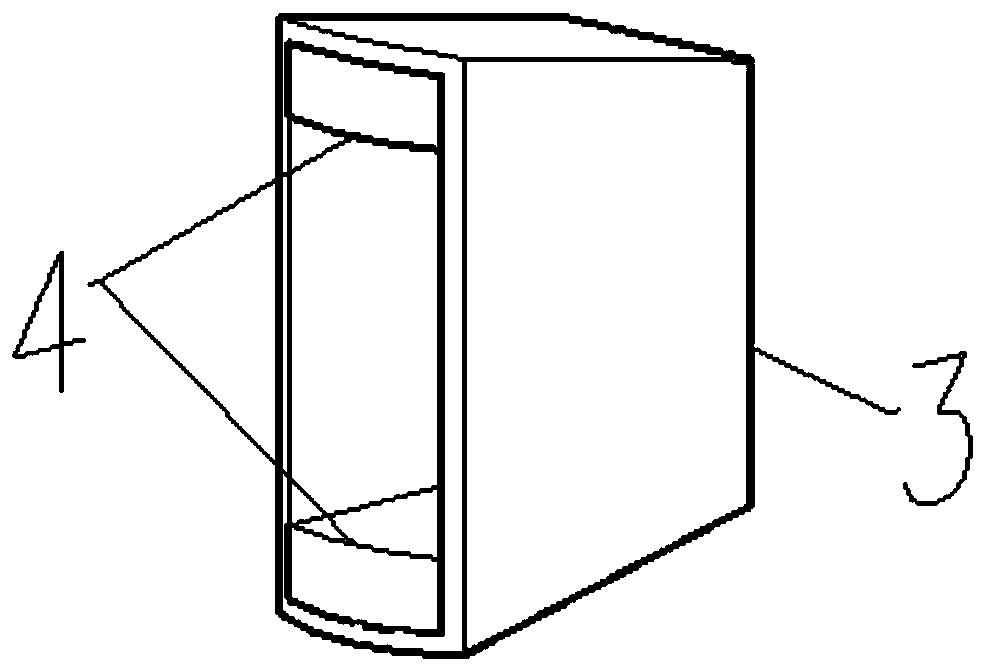

[0030] The structure of the metal steel sleeve 3 is as figure 2 As shown, its longitudinal section along the length direction of wooden beam 1 is trapezoidal. This embodiment is isosceles trapezoidal. It is a circular hole with a radius of 3-5 times of the shape memory alloy SMA7, and the lower bottom faces the wooden beam 1 and is in an open sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com