Anti-abrasive device for heat exchange tube bundle in trichlorosilane synthetic furnace

A technology of heat exchange tube bundles and trichlorosilane, which is applied in the direction of silicon halide compounds, halosilanes, etc., can solve the problems of unchanged adverse effects of the system, high labor and material costs, and low relative hardness, and reduce the frequency of maintenance and replacement and costs, prolonging the service life of equipment, and reducing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

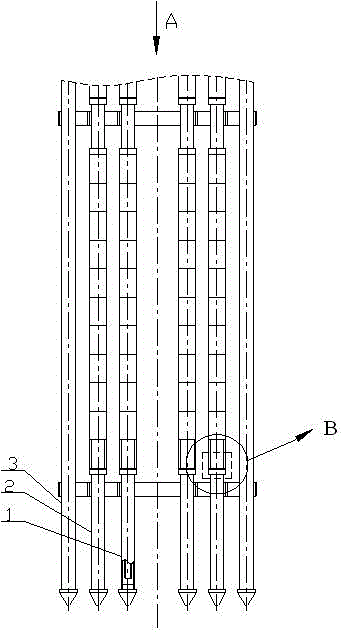

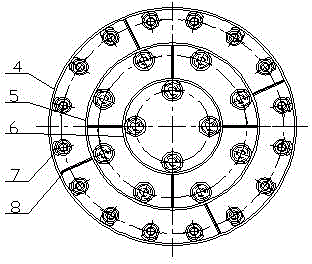

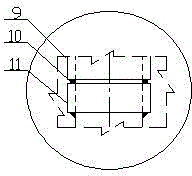

[0017] like Figures 1~3 As shown, a wear-resistant device for heat exchange tube bundles in a trichlorosilane synthesis furnace includes a synthesis furnace heat exchange tube bundle composed of an inner ring heat exchange tube bundle 1, a middle ring heat exchange tube bundle 2, and an outer ring heat exchange tube bundle 3. The outer side of the outer heat exchange tube bundle 3 is provided with an outer fixing ring 4; the outer side of the middle ring heat exchange tube bundle 2 is provided with a middle fixing ring 5; the outer side of the inner ring heat exchange tube bundle 1 is provided with an inner fixing ring 6; It is connected with the outer fixed ring 4 and the inner fixed ring 6 through the rib plate 8; A backing plate 7 is provided between the outer side of the heat exchange tube bundle 1 and the inner fixed ring 6 . The outer surface of the middle of the inner ring heat exchange tube bundle 1 and the middle ring heat exchange tube bundle 2 is equipped with a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com