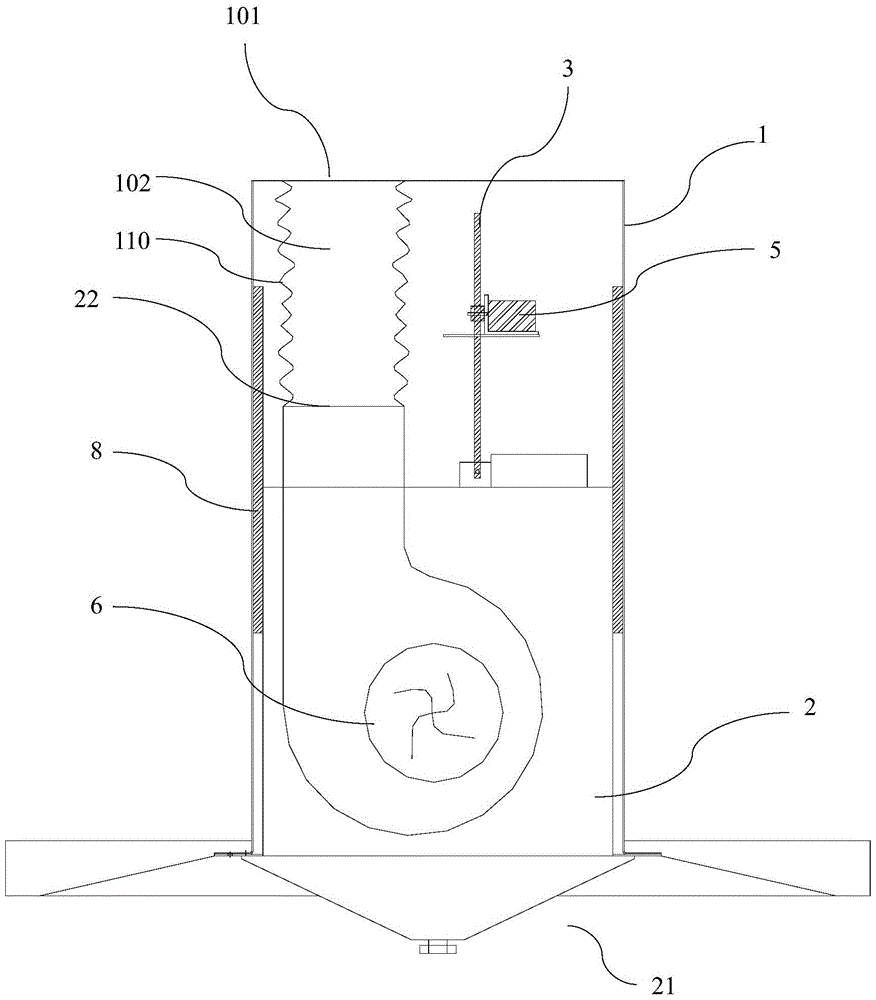

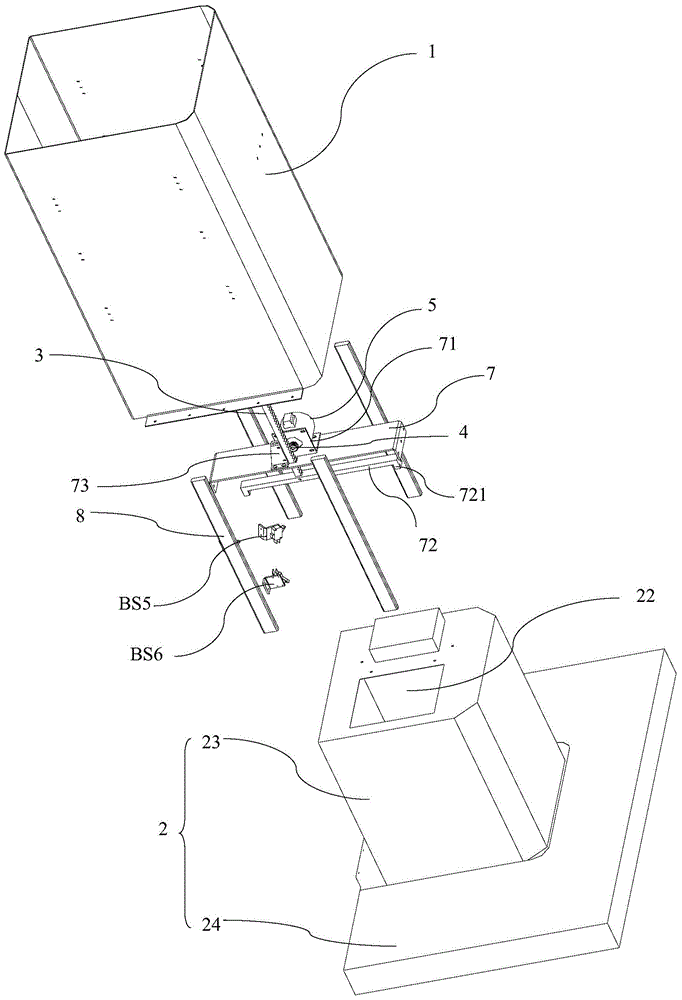

Movable negative pressure purification device and mobile negative pressure purification system

A purification device and negative pressure technology, applied in heating methods, chemical instruments and methods, and dust removal, etc., can solve problems such as pollution and corrosion of driving structures, achieve wide applicability, reduce maintenance and replacement frequency, and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

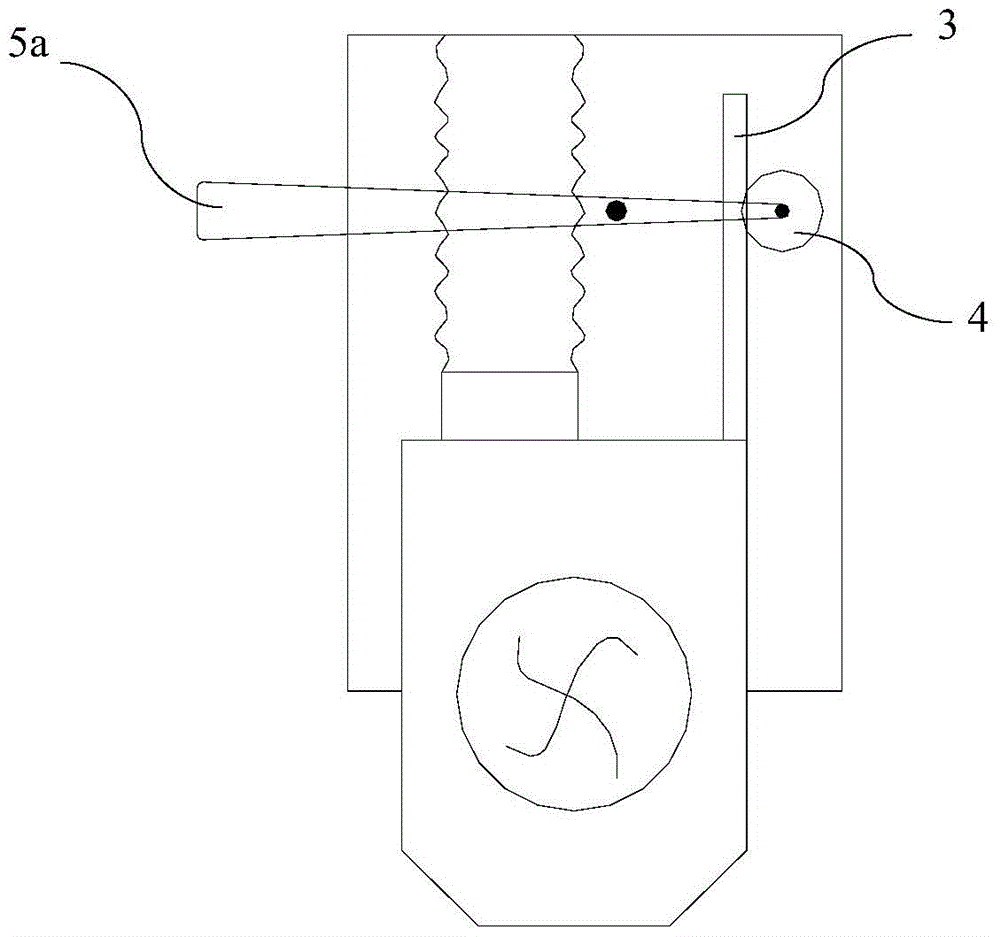

[0037] Such as image 3 As shown, the driving source 5 is a long manual handle 5a, one end of the manual handle 5a is connected to the rotation axis of the transmission gear 4, and the other end of the manual handle 5a protrudes from the housing 1 for manual swing. By manually swinging the manual handle 5a, the transmission gear 4 is driven to rotate, and then the rack 3 is driven to move, so that the air cylinder 2 realizes telescopic movement.

Embodiment 2

[0039] Such as Figure 4 As shown, the driving source 5 is a manual rotating wheel 5b, which has a rotating disc 51 and a rotating axis connected to each other. The rotating disc 51 protrudes from the housing 1 to facilitate the manual rotation operation. The rotation of the manual rotating wheel 5b The axis and the rotation axis of the transmission gear 4 are connected in series to realize linkage, that is, with the rotation of the manual wheel 5b, the transmission gear 4 also rotates synchronously; or the manual wheel 5b has a driving gear that meshes with the transmission gear 4 52. When the manual wheel 5b is rotated, the driving gear 52 will drive the transmission gear 4 to rotate, so with the rotation of the transmission gear 4, it will drive the rack 3 to move, so that the air duct 2 can realize telescopic movement.

Embodiment 3

[0041] Such as Figure 5 As shown, the drive source 5 is a drive motor 5c, and a control module 9 for controlling the drive motor 5c is installed on the inner wall of the housing 1. The gas channels 102 are isolated from each other to avoid pollution and corrosion by exhaust gas smoke.

[0042] Such as Image 6 As shown, the control module 9 includes a fan control unit 91 for controlling the startup and shutdown of the fan 6 and a fan displacement control unit 92 for controlling the relative telescopic displacement distance of the fan 2 by controlling the drive motor 5c; A plurality of electric buttons 11 are installed on the outside, and the control module 9 controls the drive motor 5c and the blower 6 by receiving electrical signals from the plurality of electric buttons 11 .

[0043] Such as Figure 7 Shown is the circuit diagram of the fan control unit 91, the circuit diagram shows the first switch BS1-1 and the second switch BS1-2 linked with each other, the first swit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com