Sampling channel switching system of partial flow dilution sampling system

A sampling channel and switching system technology, applied in the field of sampling channel switching system of partial flow dilution sampling system, can solve the problems of poor joint sealing, difficult disassembly and assembly, easy to be interfered, etc., so as to improve stability and accuracy, and avoid personnel accidents. The effect of scalding and improving the efficiency of test preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the specific embodiments in the accompanying drawings.

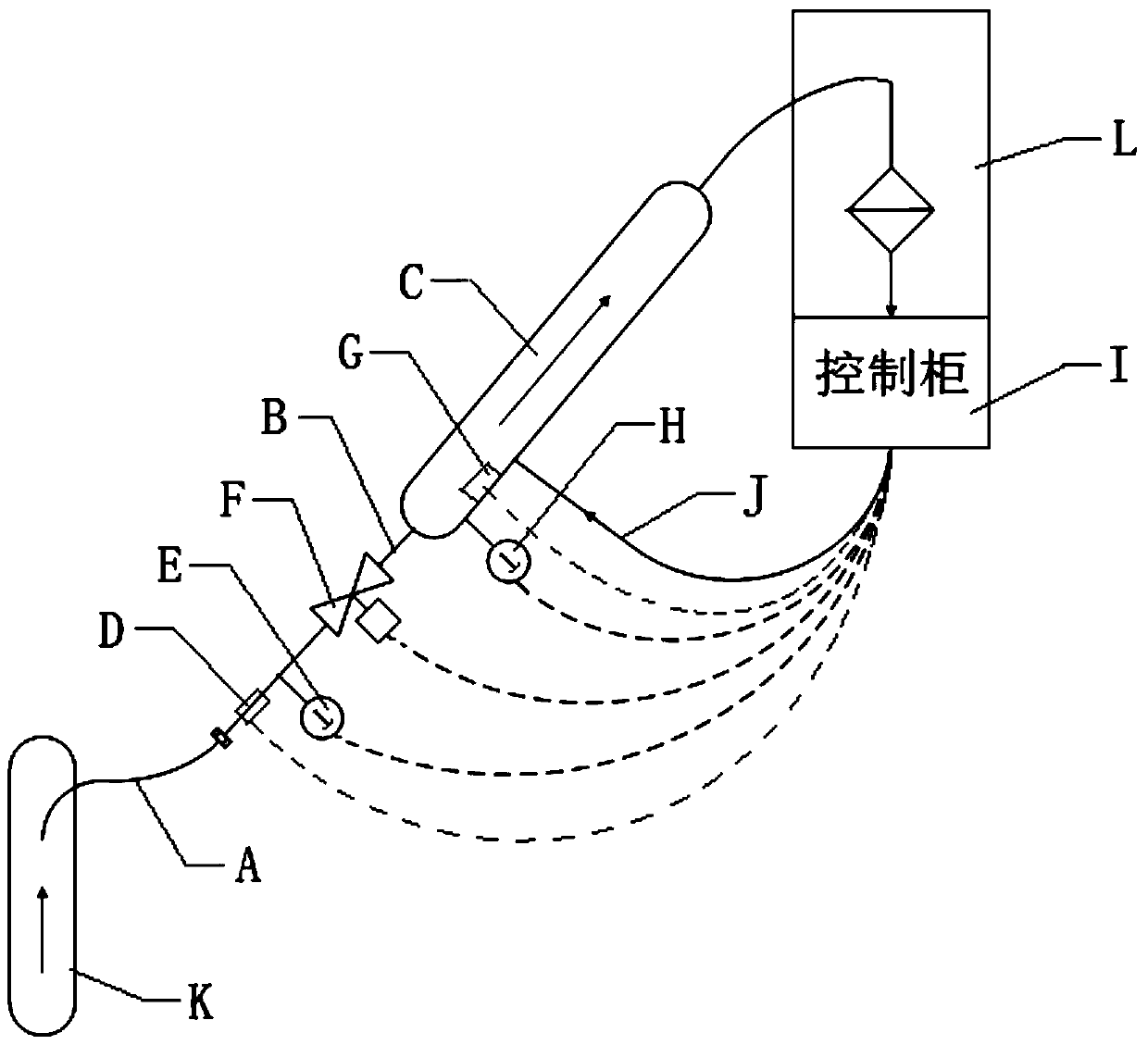

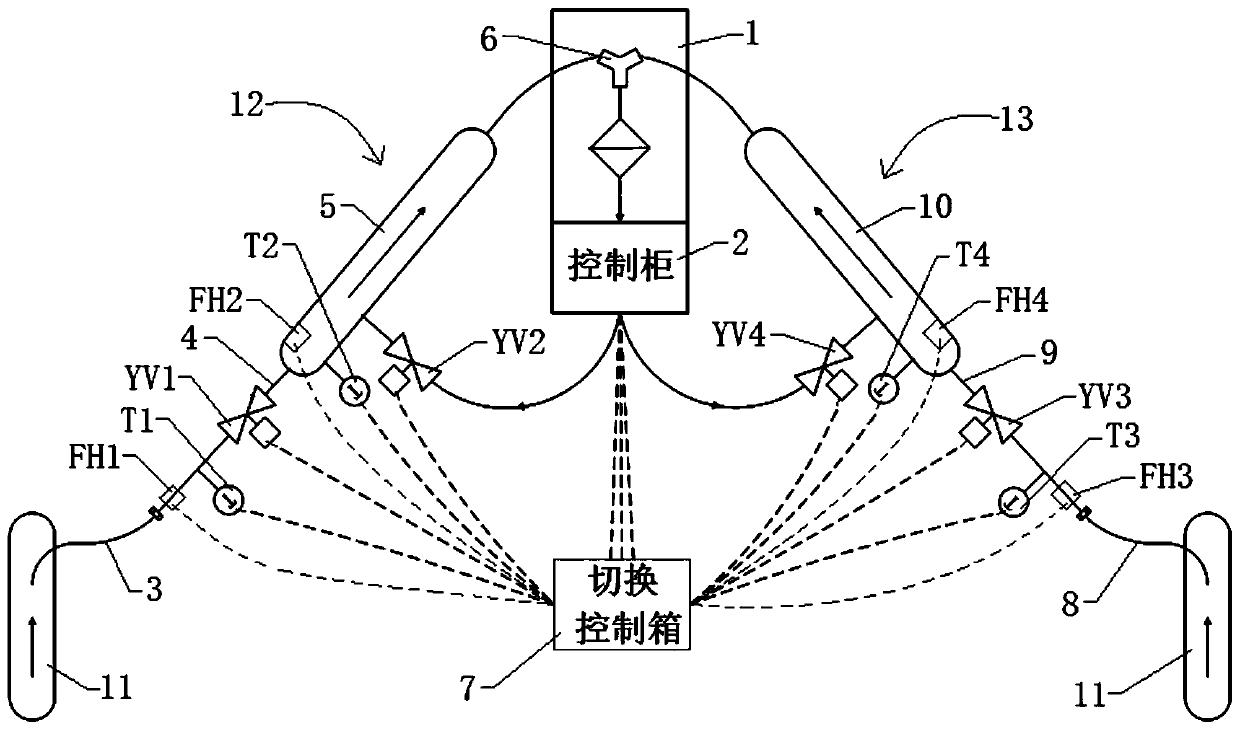

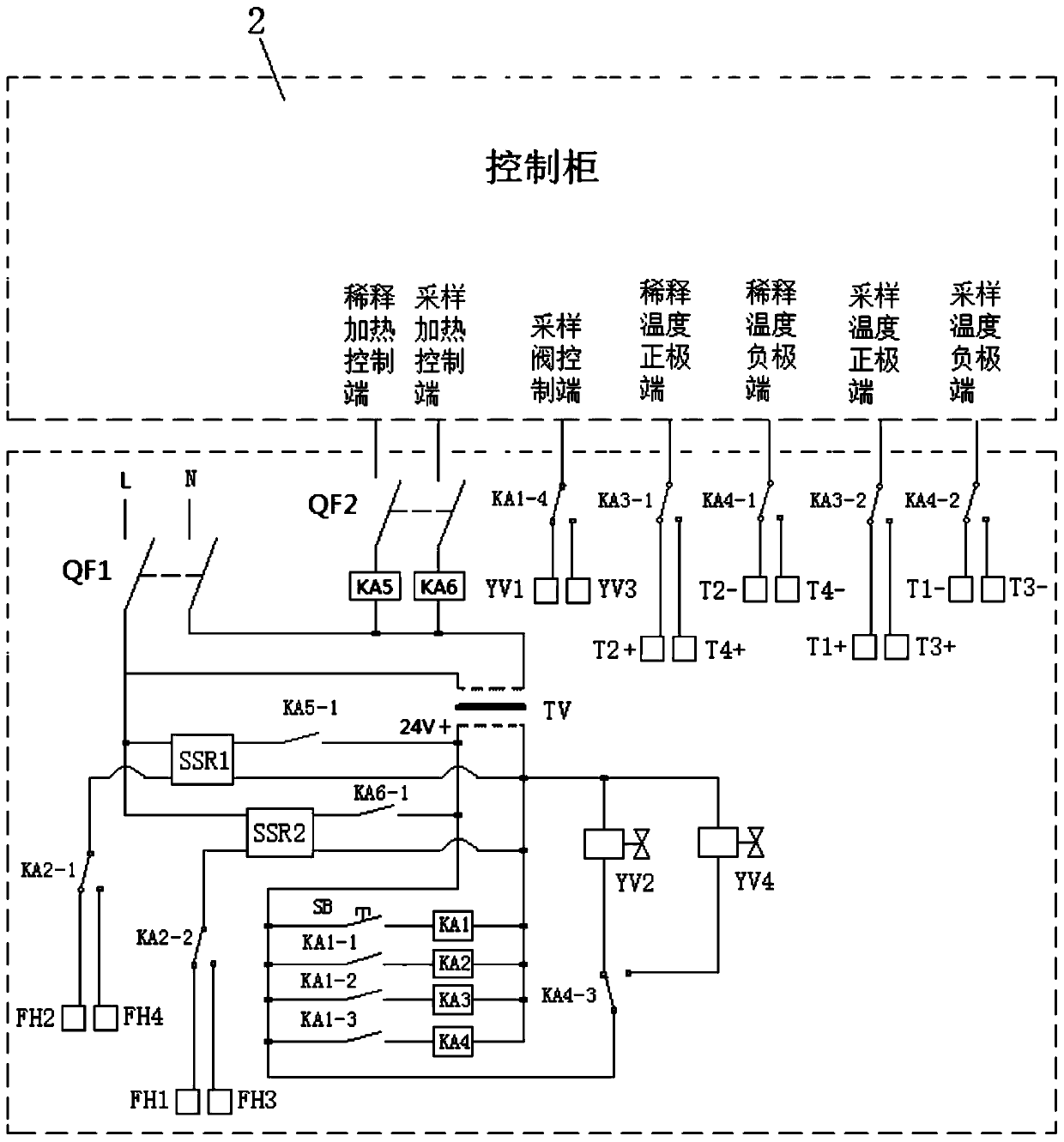

[0036] refer to Figure 2-3 , a partial flow dilution sampling system sampling channel switching system, including a first sampling pipeline 12 and a second sampling pipeline 13 respectively used to connect different exhaust pipes 11, the first sampling pipeline 12 includes first sampling pipelines connected in sequence The sampling probe 3, the first delivery tube 4, the first dilution tube 5, and the second sampling pipeline 13 include the second sampling probe 8, the second delivery tube 9, the second dilution tube 10, and the first sampling pipeline 12 connected in sequence. and the second sampling line 13 are respectively provided with electric control components. The switching system also includes a three-way joint 6 and a switching control box 7. The first sampling pipeline 12 and the second sampling pipeline 13 are connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com