Telescopic hose and garment steamer with same

A technology of telescopic hose and garment ironing machine, which is applied in the direction of hoses, pipes/pipe joints/fittings, pipes, etc. It can solve the problems of poor ironing effect, weakened hose flexibility, and unsightly appearance, so as to prevent skin Accidental burns, good bending resistance, beautiful and simple appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

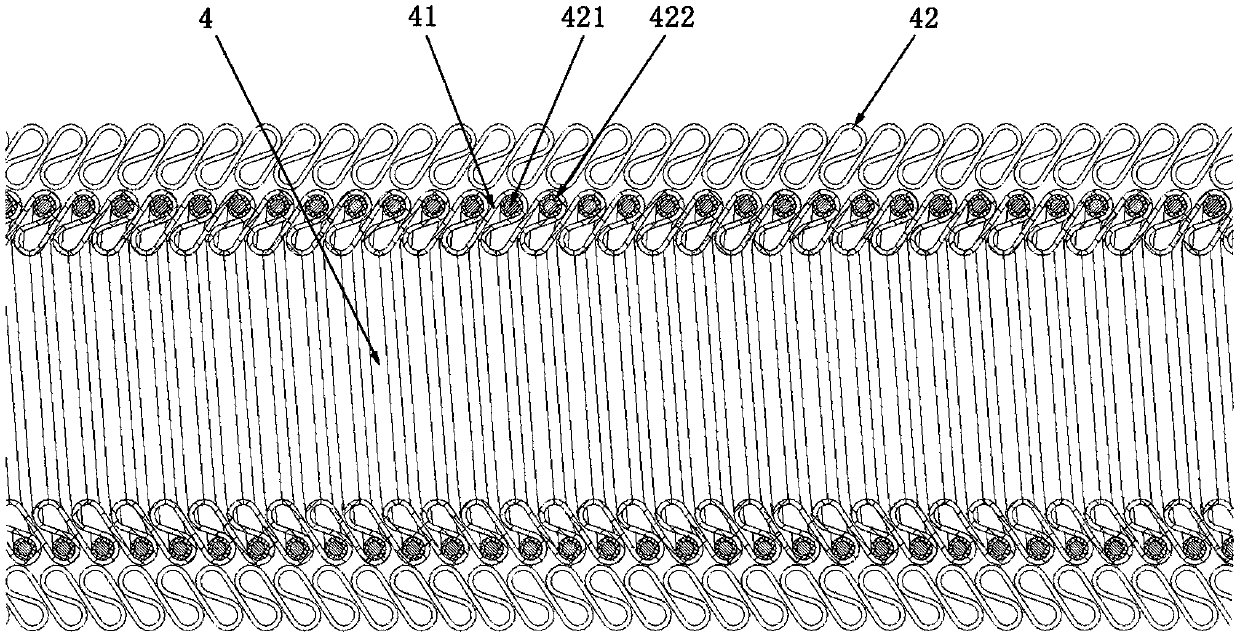

[0029] In this embodiment, a telescopic hose such as figure 1 , 4 As shown in , 5, the telescopic hose 4 of the present embodiment comprises a telescopic heat insulation net 41 (outer pipe) formed through braiding and a corrugated telescopic hose 42 (inner pipe) with undulating and helically wound pipe walls. For its specific structure, see Figure 4 , telescopic heat insulation net 41 is formed independently, and is sleeved on corrugated type telescopic hose 42 outsides. The two ends of the telescopic heat insulation net 41 and the corrugated telescopic hose 42 are connected to each other through the connection head 5 .

[0030] The stretchable heat-insulation net 41 is a tight mesh formed by weaving heat-resistant materials. Specifically, fiber strips can be used, such as high-strength polyester filaments, or relatively hard thin plastic strips can be used. The stretch ratio of the fiber braided structure can reach 8 times, and the stretch ratio of the plastic strip can o...

Embodiment 2

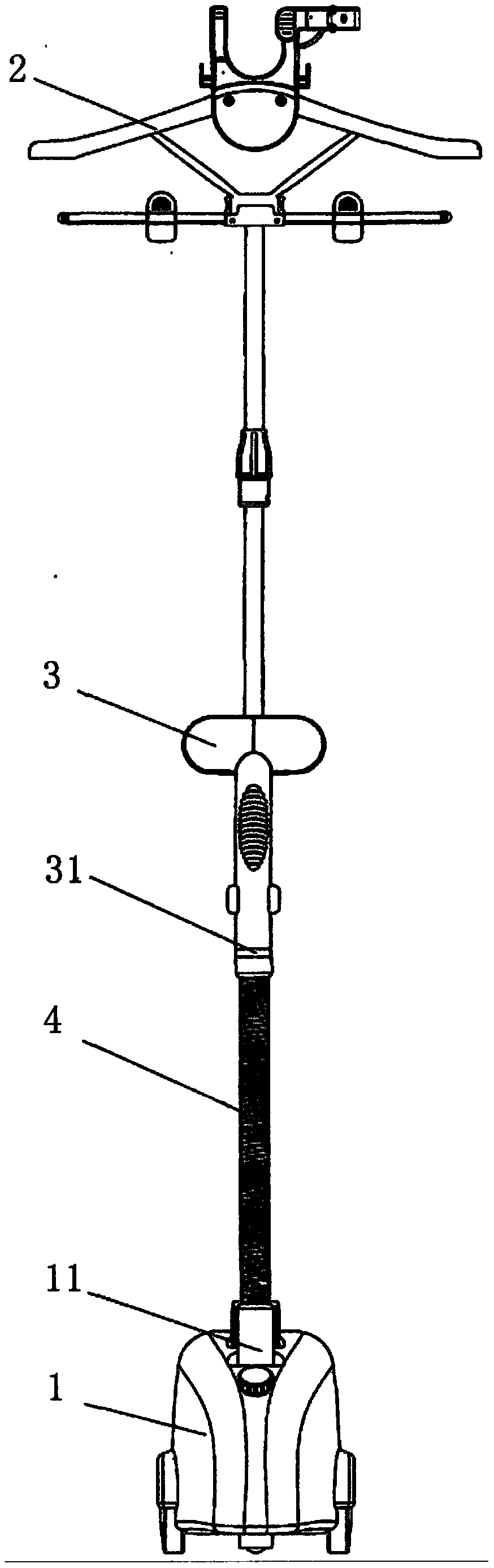

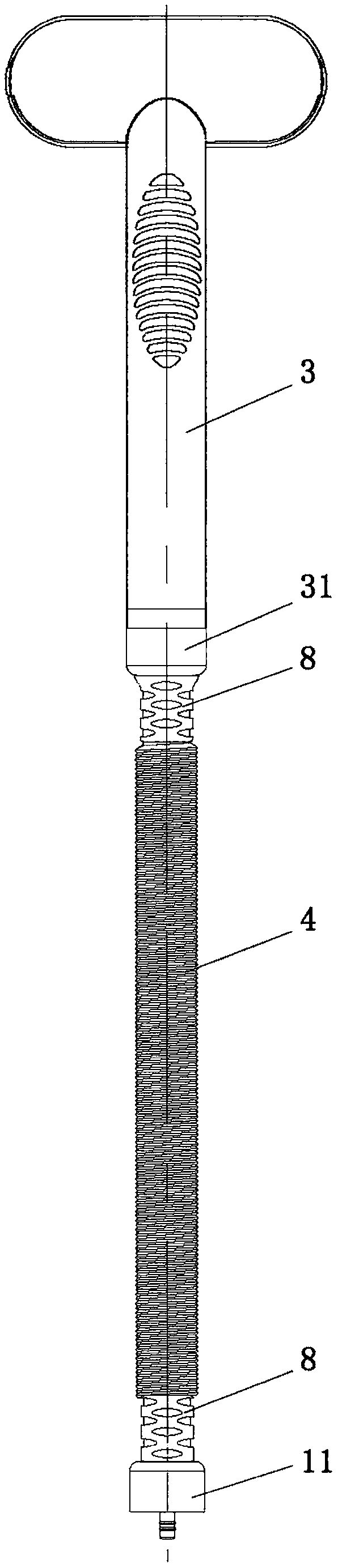

[0033] In this embodiment, the garment steamer with telescopic hose is as figure 2 , 3 , 4, 5, including a telescopic rod hanger 2 and an ironing head 3 supported on the base 1 of the main machine with rollers. The main body base 1 has a steam output port 11, and the ironing head 3 has a steam input port 31, and the steam output port 11 and the steam input port 31 are connected by a flexible hose 4. in, figure 2 and image 3 The difference is that image 3 The steam output end 11 and the steam input end 31 of the clothes steamer are designed with a protective net 6, and the protective net 6 is made of plastic material, which is used to prevent the telescopic hose 4 from collapsing during use.

[0034] The telescopic hose 4 of the present embodiment comprises a telescopic heat insulation net 41 formed through braiding and a corrugated telescopic hose 42 that is helically wound with concave and convex pipe walls. For its specific structure, see Figure 4 , the telescopic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com