Automatic auxiliary mechanism for flowing aluminum water tank of aluminum furnace

An auxiliary mechanism and water tank technology, applied in the direction of furnace, furnace cooling, crucible furnace, etc., can solve the problems of unproposed solutions, dangers, shortened service life, etc., and achieve the effect of preventing heat from being transferred to the outer wall of the pipeline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

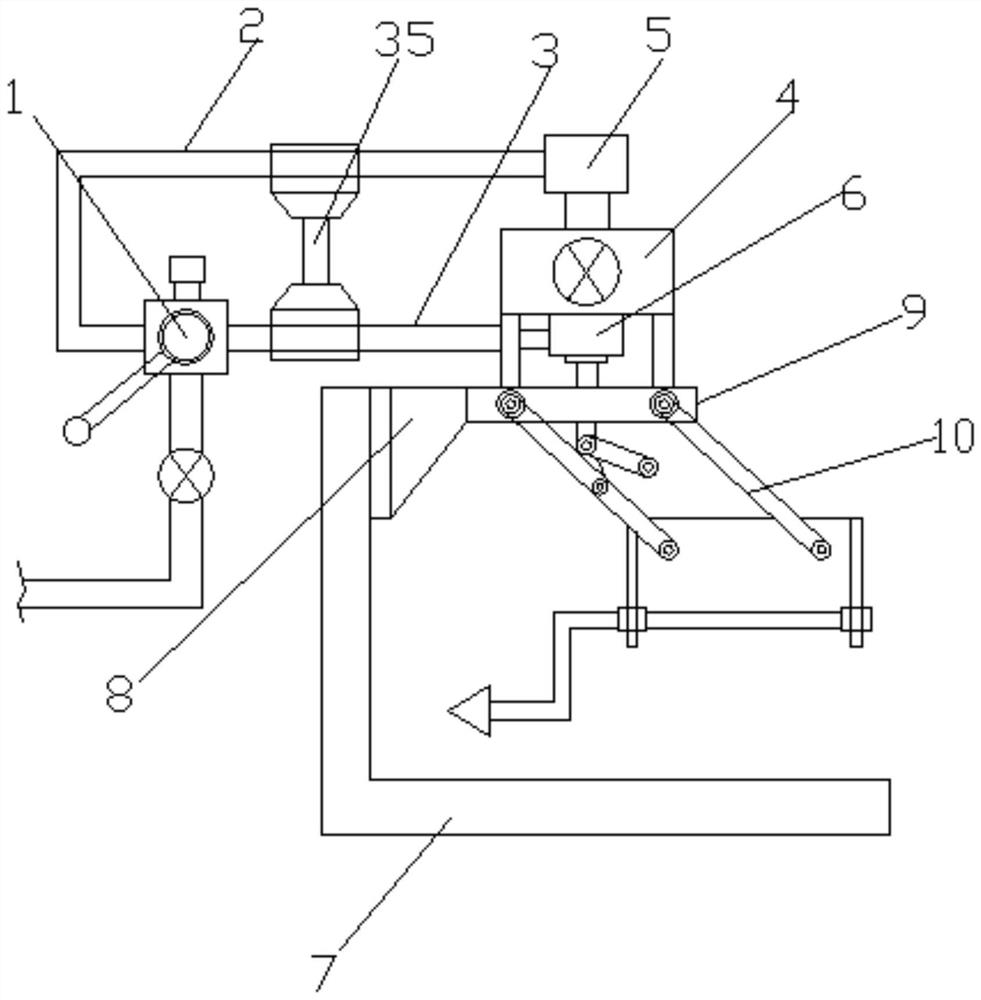

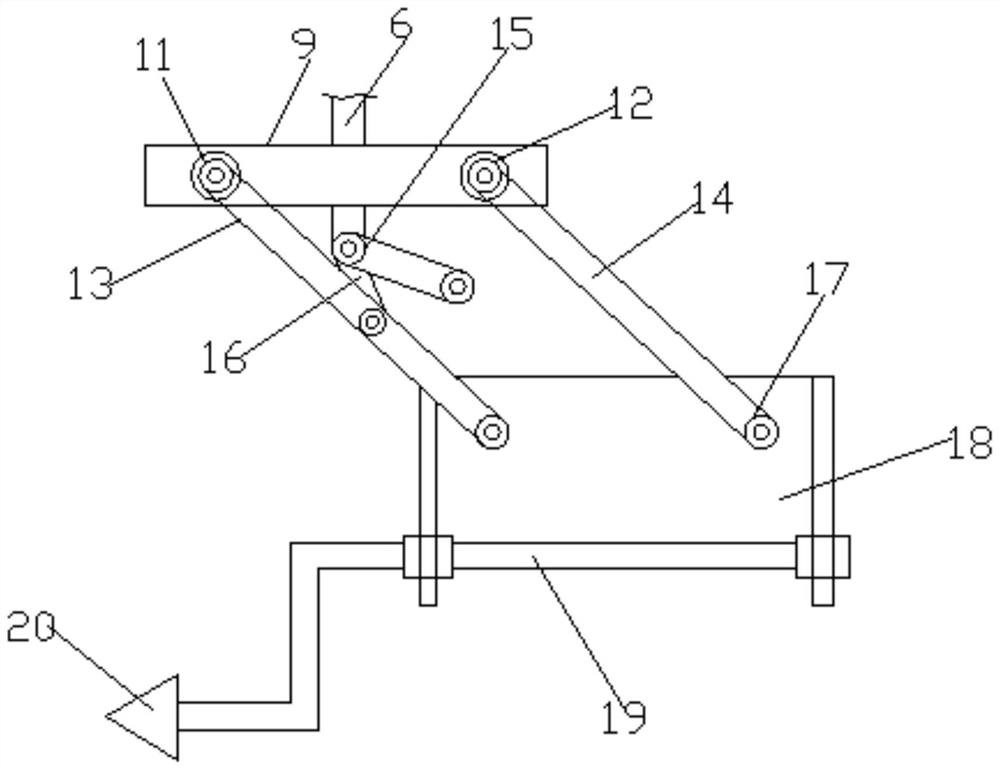

[0034] see Figure 1-7, according to an embodiment of the present invention, an automatic auxiliary mechanism for a flowing aluminum water tank of an aluminum furnace includes a valve body switch 1, and the two ends of the valve body switch 1 are respectively connected with a connecting pipe 1 2 and a connecting pipe 2 3, and the connecting pipe 2 A circulation cooling device 35 is provided between the pipe one 2 and the connecting pipe two 3, and the circulation cooling device 35 includes a cooling box one 36 and a cooling box two 37, and inside the cooling box one 36 and the cooling box two 37 Both are provided with a cavity 38, and the first connecting steel pipe 39 and the second connecting steel pipe 40 are respectively connected between the first temperature box 36 and the second cooling box 37, and the first connecting steel pipe 39 extends into the second cooling box 37 A circulation pump 41 is provided at one end of the pipe, a cooling box 42 is connected between the ...

Embodiment 2

[0037] Such as Figure 4 As shown, the valve body switch 1 includes a valve body 25 on which a rolling ball head 26 is arranged, and a valve body switch 27 is connected to the valve body 25 to facilitate the switching of the valve body 25 .

Embodiment 3

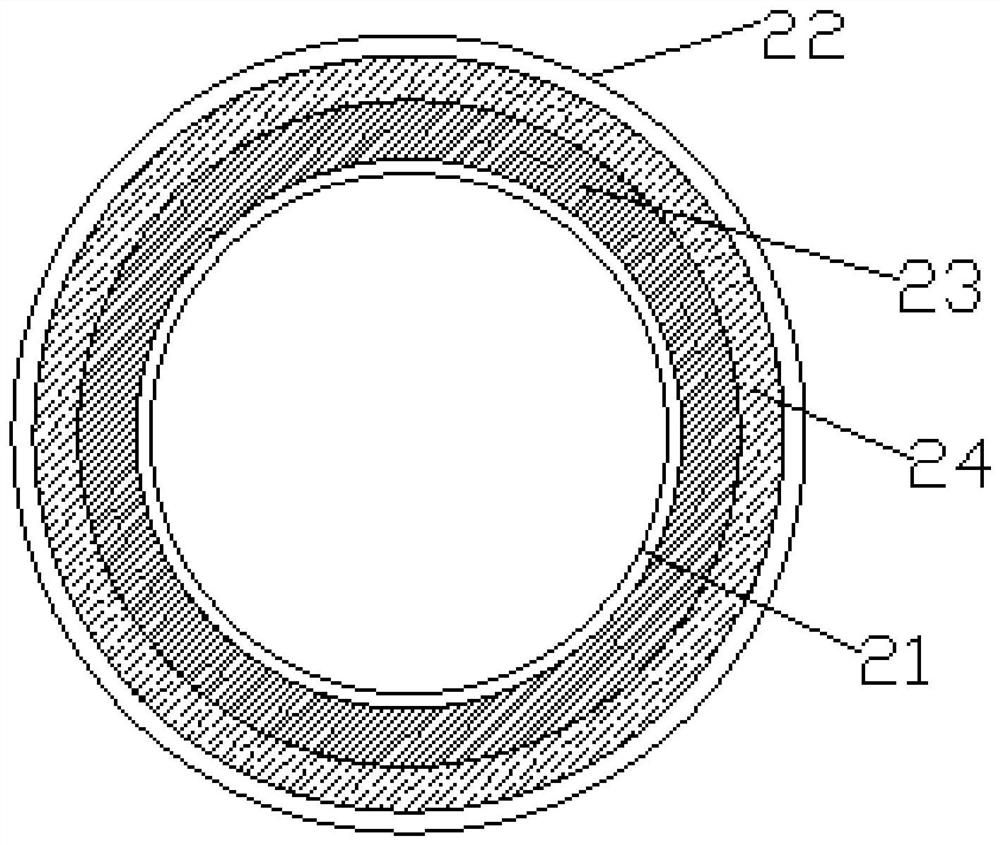

[0039] Such as Figure 5 As shown, the cooling structure layer 23 includes a thermal insulation jacket 28, and the thermal insulation jacket 28 is provided with an outer ring 29, and a cooling liquid storage cavity 31 is formed between the outer jacket ring 29 and the thermal insulation jacket 28. The outer ring 29 is connected to the heat-insulating outer jacket 28 through a ceramic fixing column 30, and the temperature thereof can be lowered by using the cooling liquid to further protect it.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com