A water-cooled radiator with a protective net

A technology of water-cooled radiators and protective nets, which is applied to the types of heat exchangers, heat exchanger shells, indirect heat exchangers, etc., and can solve the problem of affecting the heat dissipation effect of heat dissipation pipes, burns on the surface temperature of radiators, maintenance and management of equipment that cannot dissipate heat, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

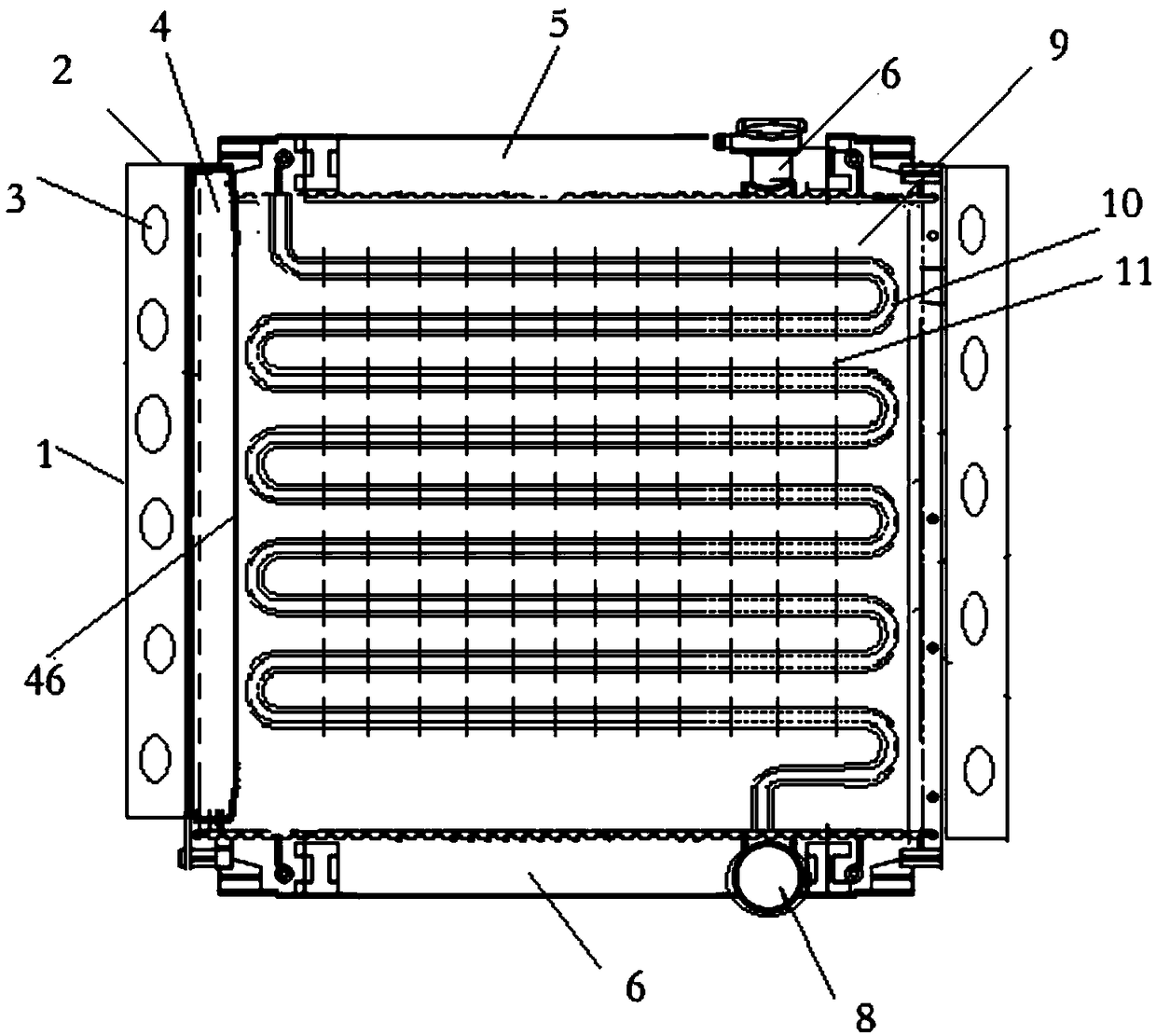

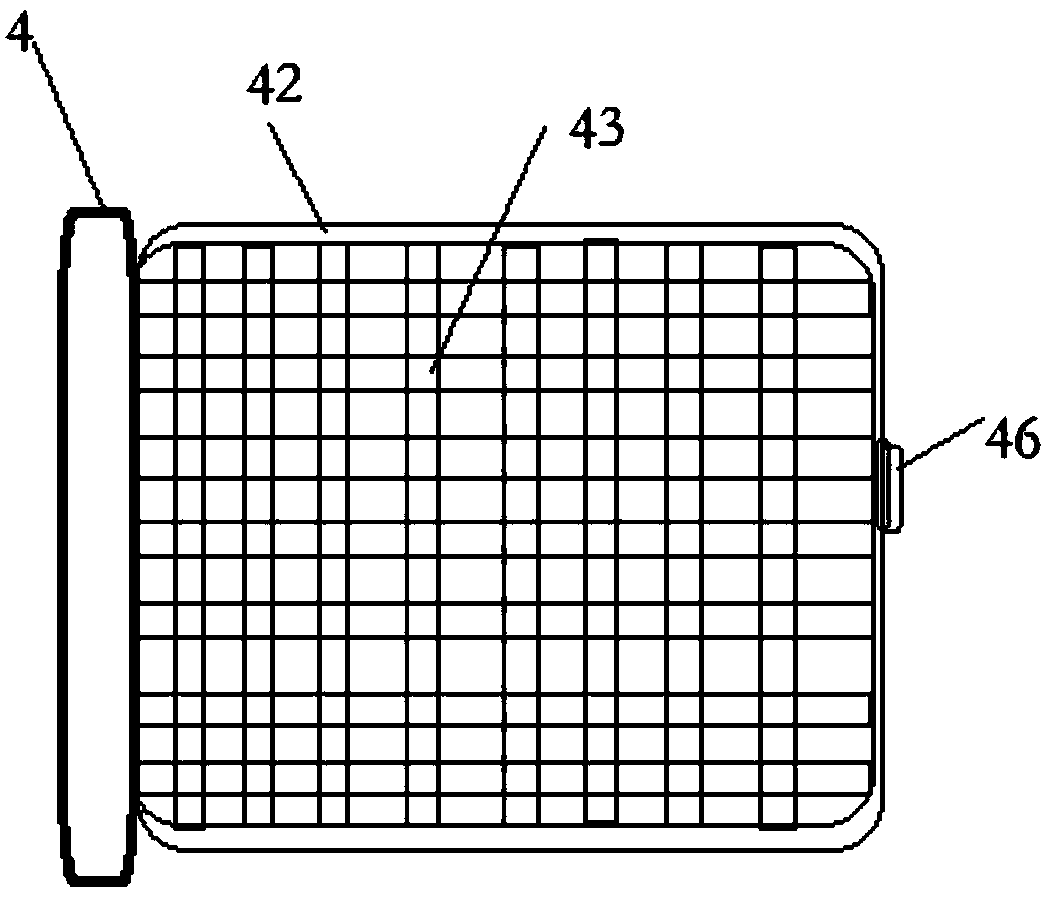

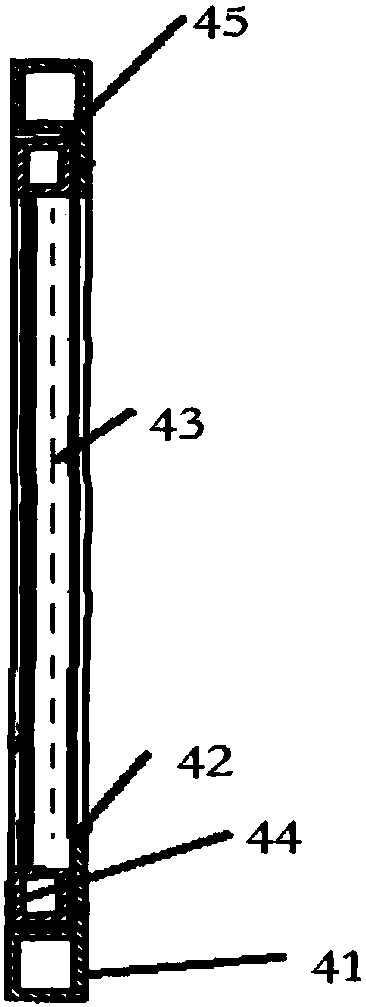

[0019] Such as Figure 1-3 Shown is a water-cooled radiator with a protective net, a frame 1, the left and right sides of the frame 1 are respectively provided with a fixed bracket 2, the fixed bracket is provided with a mounting hole 3 and a telescopic protective net 4, and the frame 1 is provided with a There is a first water chamber 5, a second water chamber 6 is provided under the frame 1, and the first water chamber 5 is provided with a water inlet 7, and a filter screen and a water chamber cover are arranged at the water inlet 7, and the second water chamber The chamber 6 is provided with a water outlet 8, the water outlet 8 is provided with a water chamber cover, the middle of the frame 1 is a heat dissipation core 9, and the heat dissipation core 9 includes a heat dissipation pipe 10 and fins 11, and the heat dissipation pipe 10 is hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com