Cooling and insulating material composition, cooling and insulating material and application thereof

A heat insulation material and composition technology, applied in the direction of coating, etc., can solve the problems of huge engineering quantity and cost consumption, unable to apply emergency treatment, etc., and achieve good protection effect, good viscosity and good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

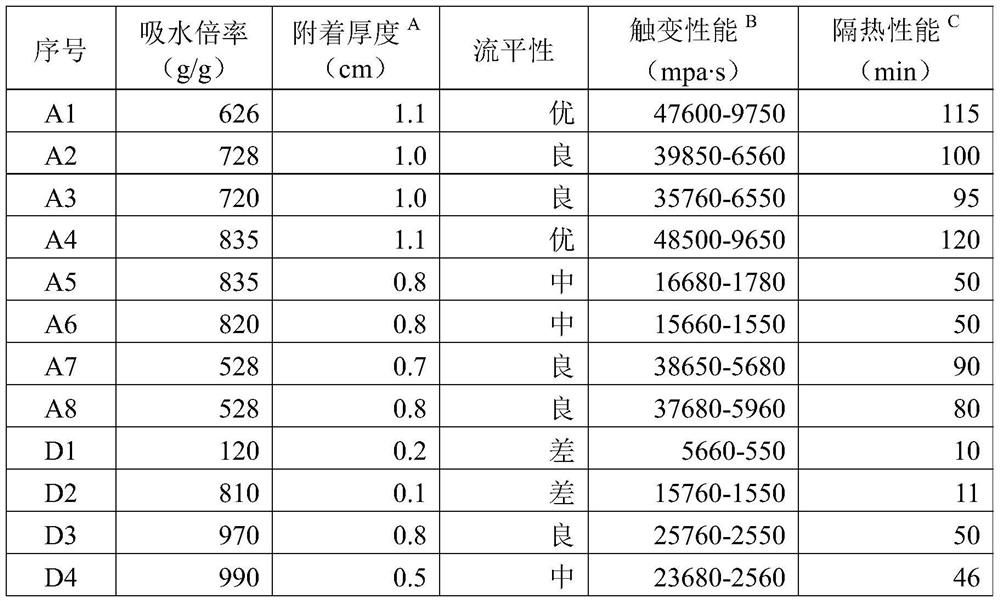

Examples

preparation example 1

[0068] 2 parts by weight of a crosslinking agent (N,N'-methylenebisacrylamide), 20 parts by weight of sodium bentonite and 500 parts by weight of water were added to the container, and stirred to be fully dissolved. After the complete dissolution, acrylic acid (70 parts by weight) and acrylamide (30 parts by weight) were added to make them fully dissolved, and sodium hydroxide solution (20 wt %) was added dropwise for neutralization, so that the neutralization degree of acrylic acid reached 70%. Then, 0.1 parts by weight of ammonium persulfate and 0.1 part by weight of sodium bisulfite were added, stirring was continued for 5 minutes, and a static polymerization reaction was performed at 60° C. for 3 hours to obtain a gel. The obtained gel was cut into pieces and sent to a desiccator at 200° C. for drying, pulverized, and sieved to obtain a superabsorbent resin with a particle size of 80-200 μm, and its water absorption ratio was 1029.1 g / g.

preparation example 2

[0070] 1 part by weight of a crosslinking agent (N,N'-methylenebisacrylamide), 20 parts by weight of sodium bentonite and 500 parts by weight of water were added to the container, and stirred to be fully dissolved. After the complete dissolution, acrylic acid (80 parts by weight) and acrylamide (20 parts by weight) were added to make them fully dissolved, and sodium hydroxide solution (20 wt %) was added dropwise for neutralization, so that the neutralization degree of acrylic acid reached 80%. Then, 0.1 parts by weight of ammonium persulfate and 0.1 part by weight of sodium bisulfite were added, stirring was continued for 5 minutes, and a static polymerization reaction was performed at 60° C. for 3 hours to obtain a gel. The obtained gel was cut into pieces and sent to a desiccator at 200° C. for drying, pulverized, and sieved to obtain a superabsorbent resin with a particle size of 80-200 μm, and its water absorption ratio was 882.5 g / g.

preparation example 3

[0072]2 parts by weight of a crosslinking agent (N,N'-methylenebisacrylamide), 30 parts by weight of sodium bentonite and 500 parts by weight of water were added to the container, and stirred to fully dissolve. After the complete dissolution, acrylic acid (80 parts by weight) and acrylamide (20 parts by weight) were added to make them fully dissolved, and sodium hydroxide solution (20 wt %) was added dropwise for neutralization, so that the neutralization degree of acrylic acid reached 80%. Then, 0.1 weight part of initiator ammonium persulfate and 0.1 weight part of sodium hydrogen sulfite were added, and the mixture was stirred for 5 minutes, and the static polymerization reaction was carried out at 60° C. for 3 hours to obtain a gel. The obtained gel was cut into pieces and sent to a desiccator at 200° C. for drying, pulverized, and sieved to obtain a superabsorbent resin with a particle size of 80-200 μm, and its water absorption ratio was 969.1 g / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com