Double-support prereactor for hydrogen fluoride

A pre-reactor and double-support technology, applied in the field of reactors, can solve the problems of cost increase, short stroke of the spiral system, and easy cracks, etc., to achieve the effect of improving corrosion resistance, improving product quality, and increasing the stirring stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

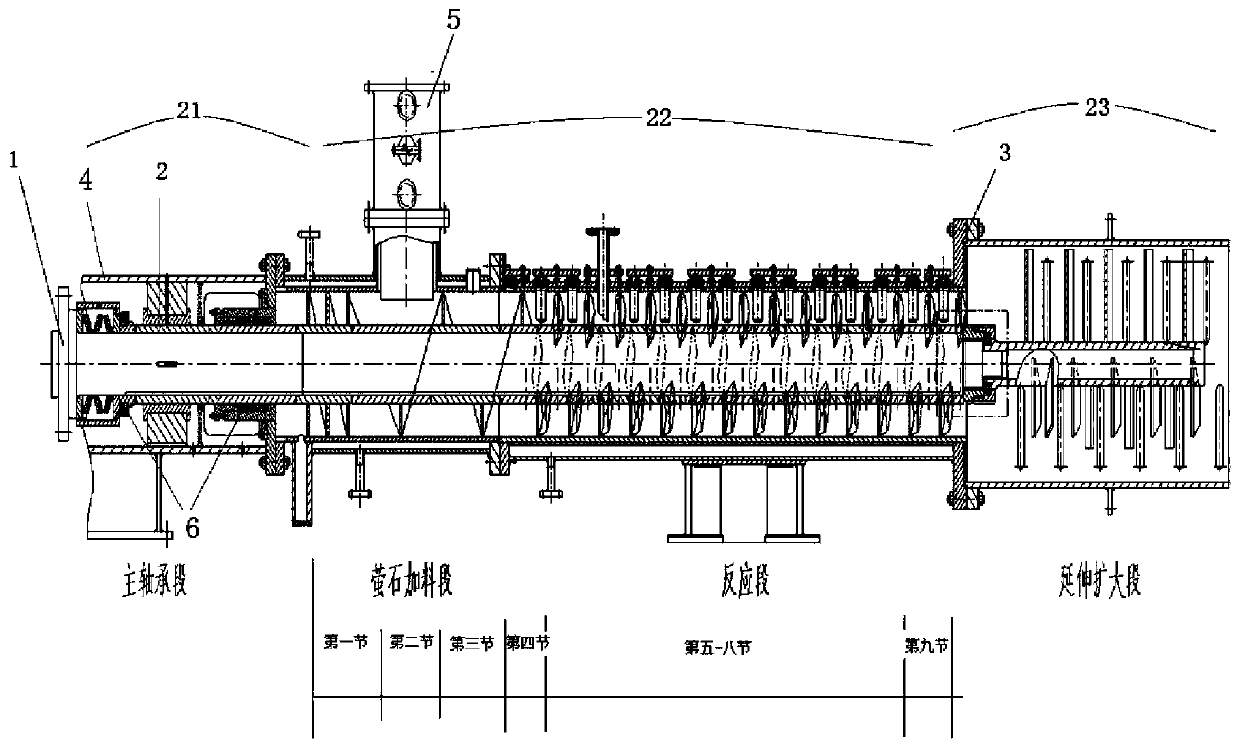

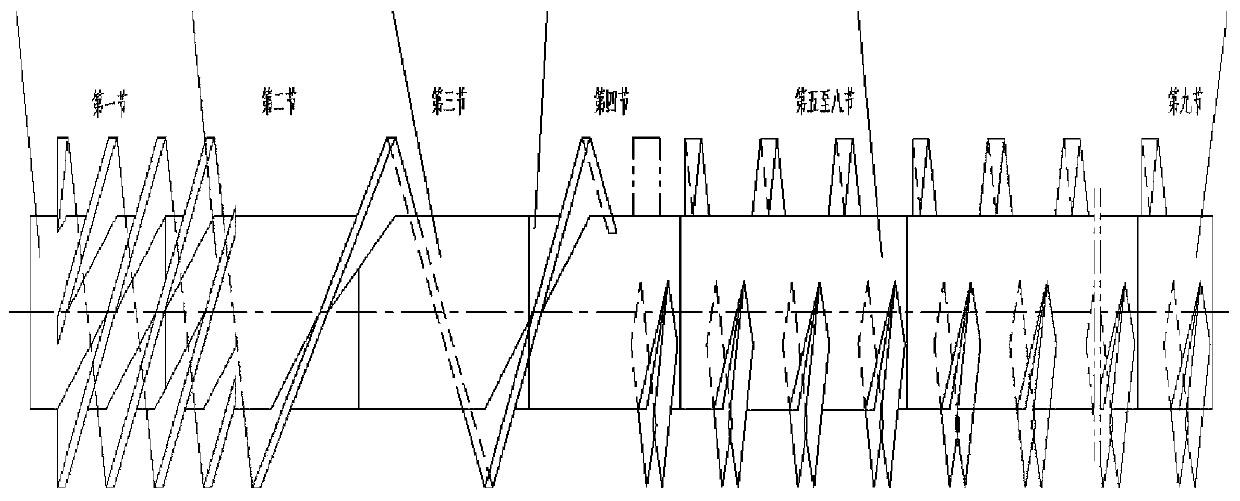

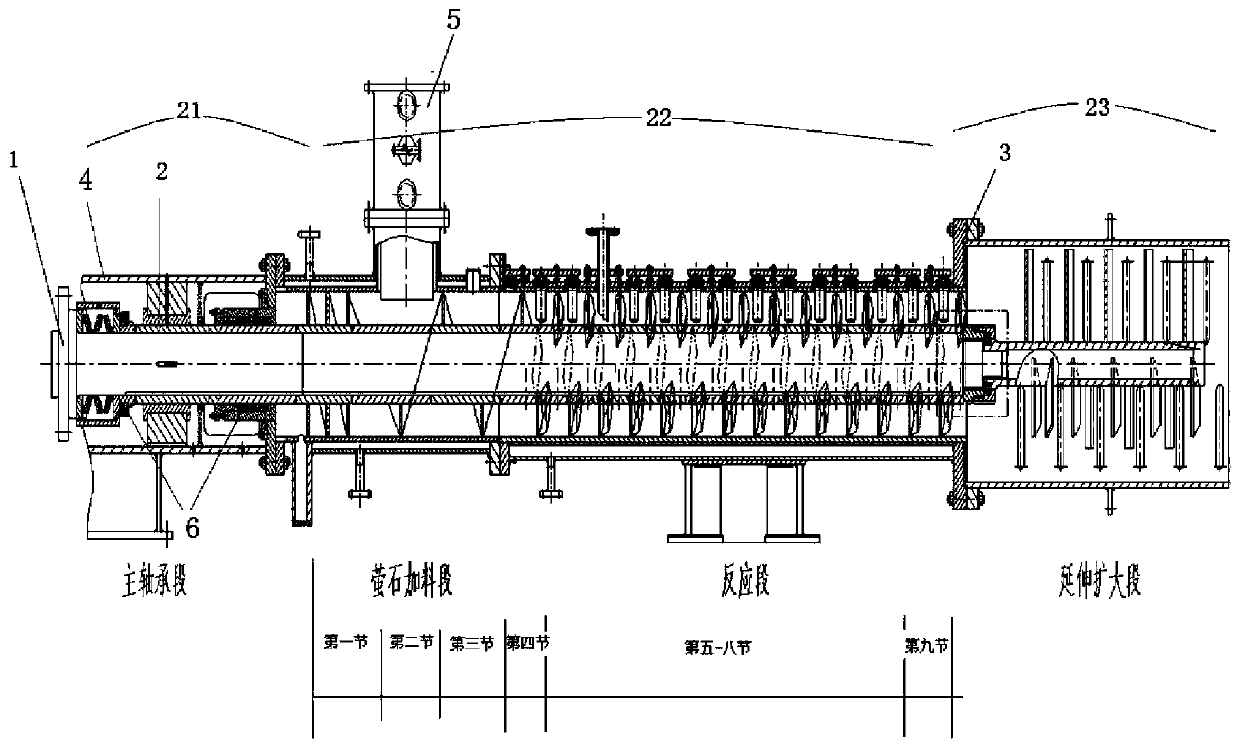

[0024] The present invention is specifically described below in conjunction with accompanying drawing, as shown in the figure,

[0025] The present invention comprises shell 4, and feed hole 5 is set on shell 4, and two groups of bearings 6 are set on one end of said shell, and main shaft is set on bearing, and main shaft is made up of front shaft head, hollow shaft, rear shaft head, front shaft The head and rear shaft head are welded together with the hollow shaft; the main bearing section between the two sets of bearings; the front section of the hollow shaft corresponds to the main bearing section, the middle section of the hollow shaft corresponds to the fluorite feeding section and the reaction section, and the rear section of the hollow shaft Corresponding to the extended section;

[0026] The double-supported pre-reactor for hydrogen fluoride is composed of a front shaft head 1, a hollow shaft 2, and a rear shaft head 3. The front shaft head 1, the rear shaft head 3 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com