Patents

Literature

146results about How to "Ensure smoothness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

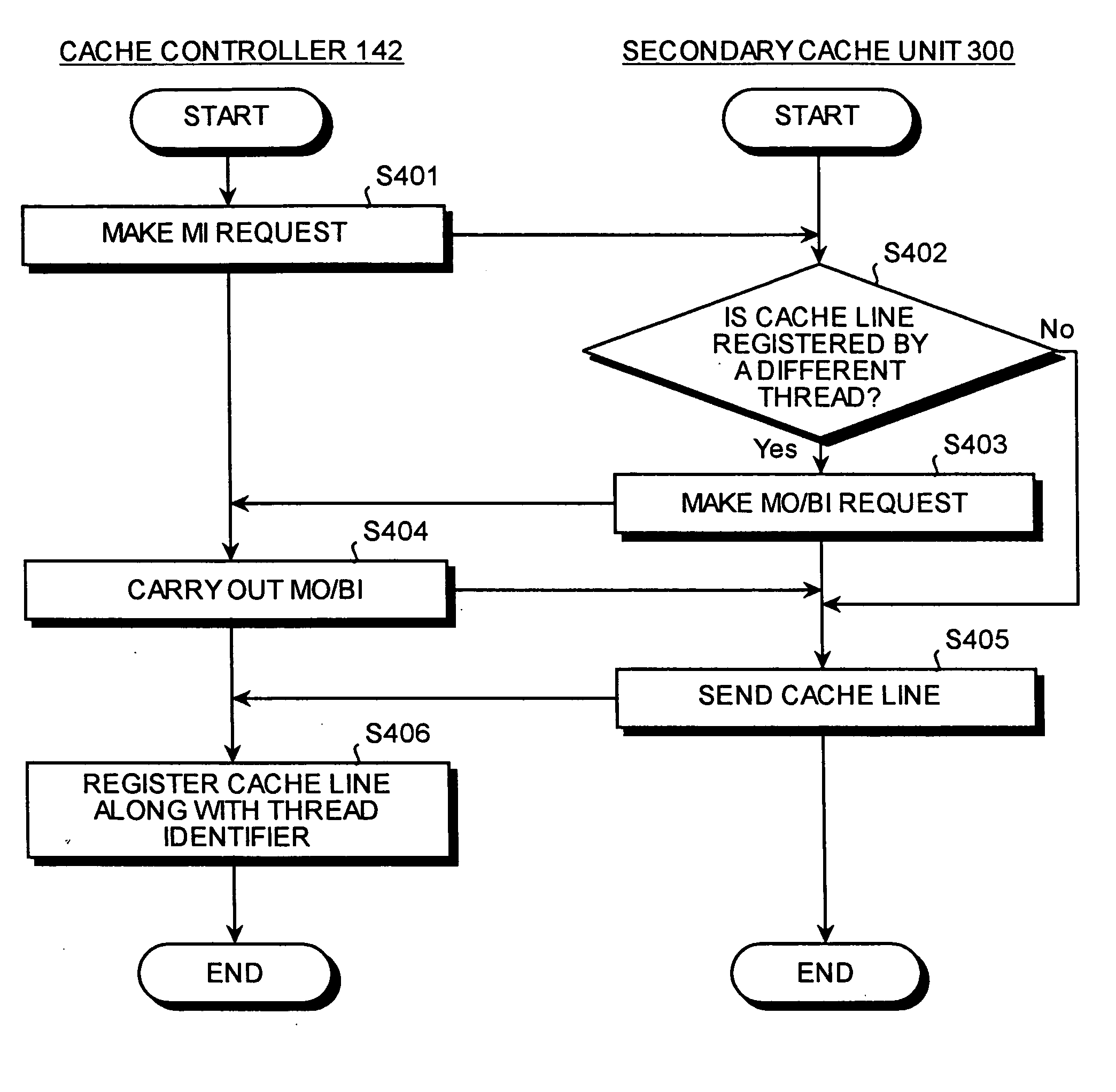

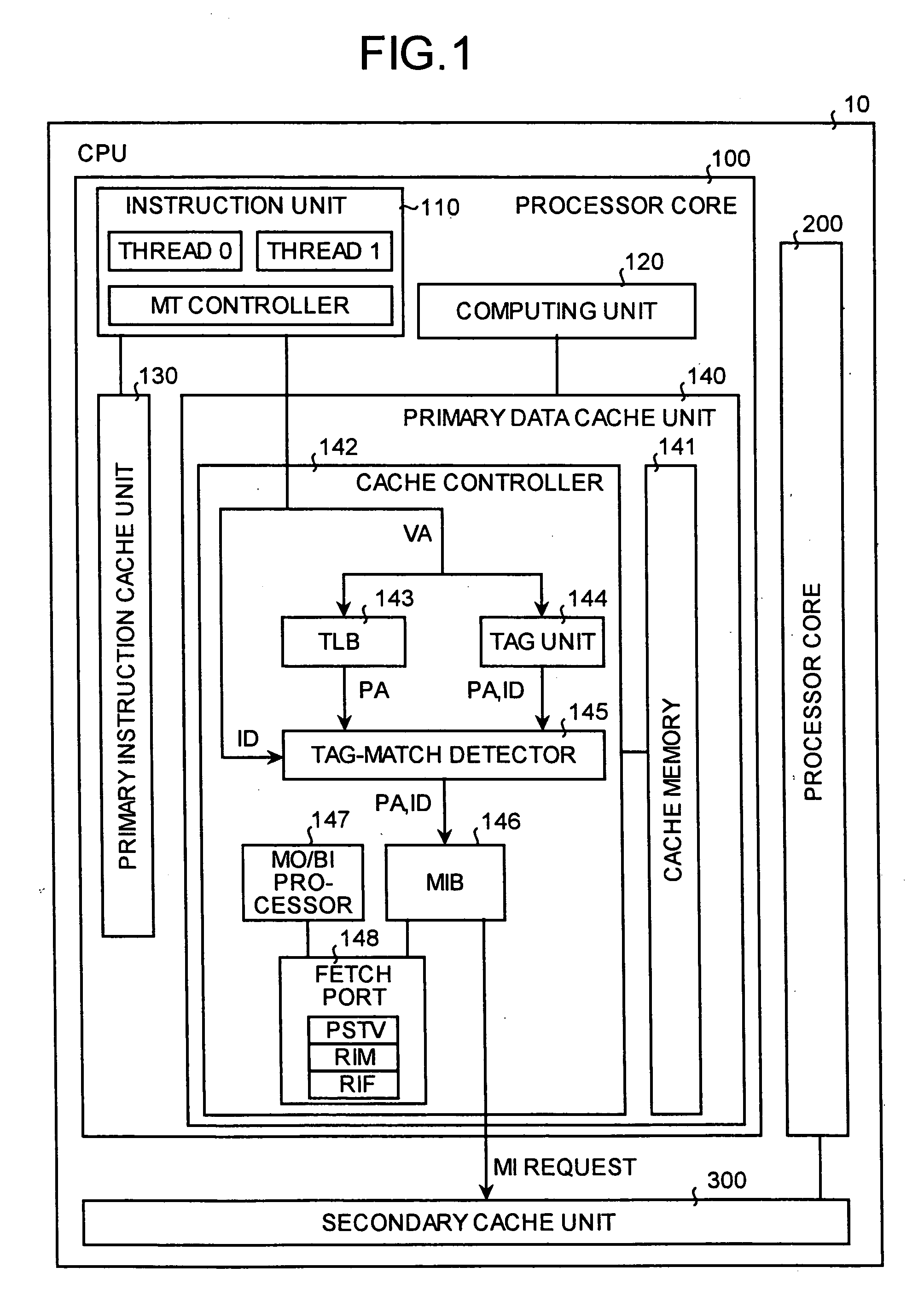

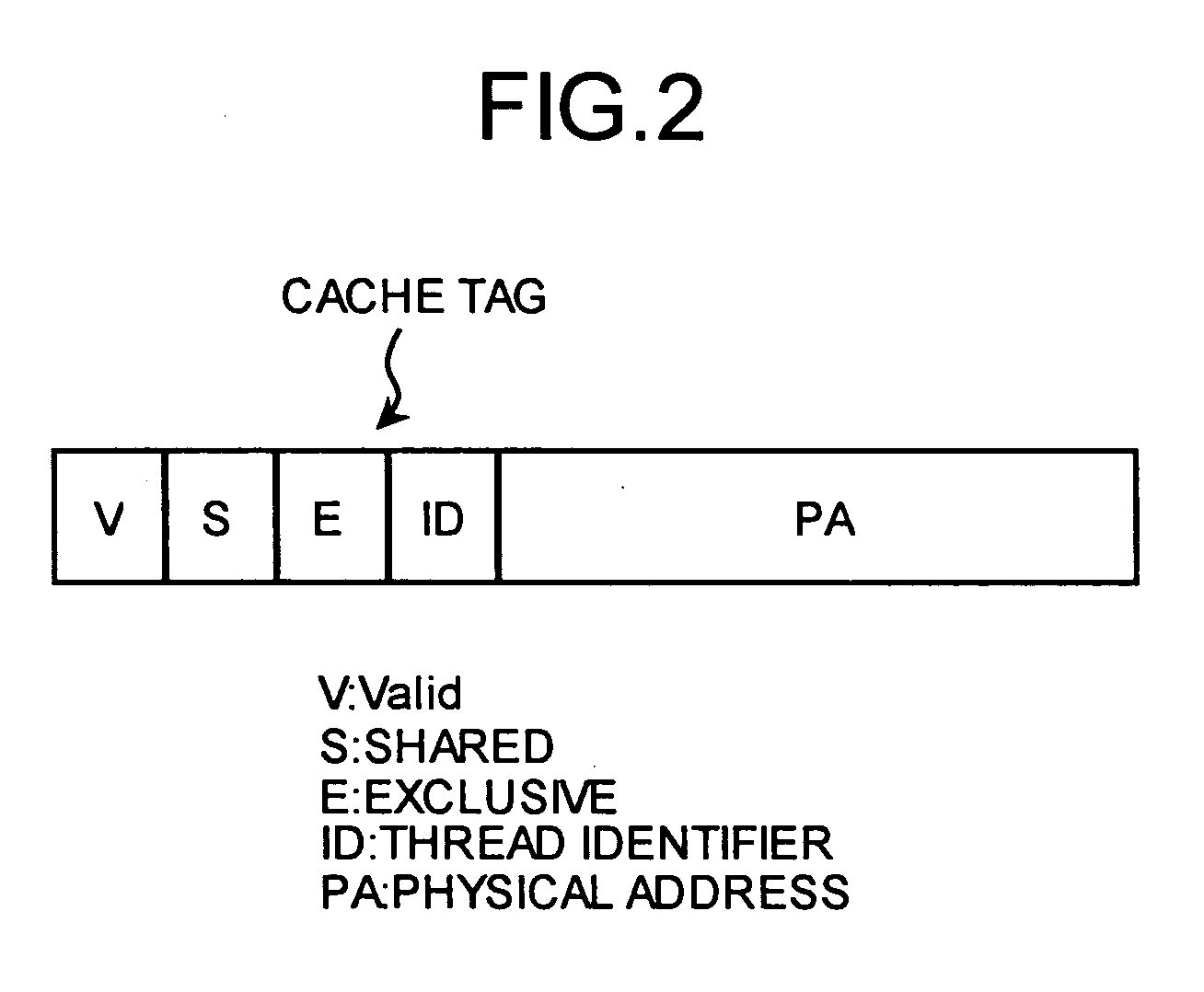

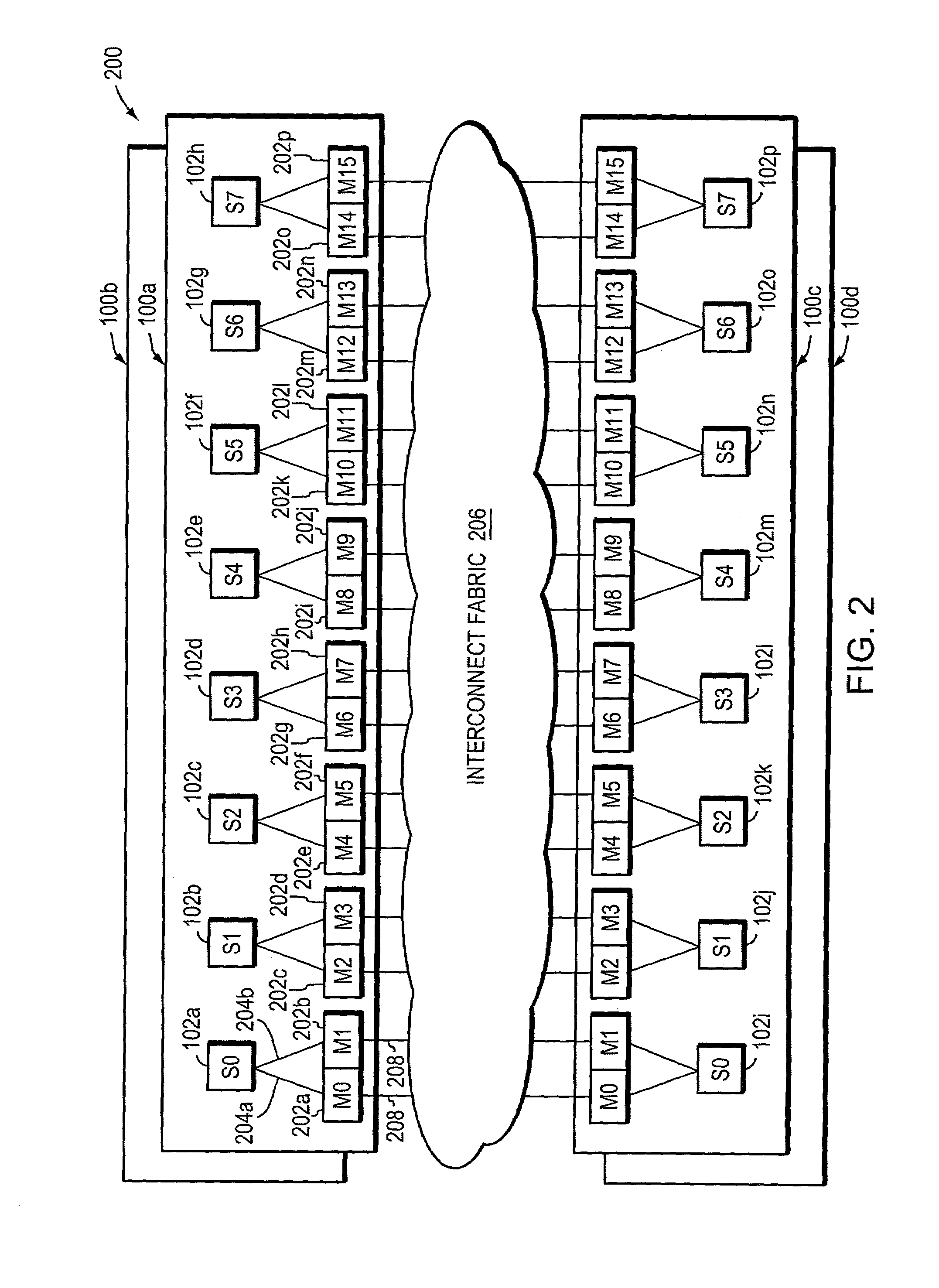

Memory control device, data cache control device, central processing device, storage device control method, data cache control method, and cache control method

InactiveUS20050210204A1Ensure smoothnessMemory adressing/allocation/relocationProgram controlParallel computingPhysical address

A central processing device includes a plurality of sets of instruction processors that concurrently execute a plurality of threads and primary data cache devices. A secondary cache device is shared by the primary data cache device belonging to different sets. The central processing device also includes a primary data cache unit and a secondary cache unit. The primary data cache unit makes an MI request to the secondary cache unit when a cache line with a matching physical address but a different thread identifier is registered in a cache memory, performs an MO / BI based on the request from the secondary cache unit, and sets a RIM flag of a fetch port. The secondary cache unit makes a request to the primary cache unit to perform the MO / BI when the cache line for which MI request is received is stored in the primary data cache unit by a different thread.

Owner:FUJITSU LTD

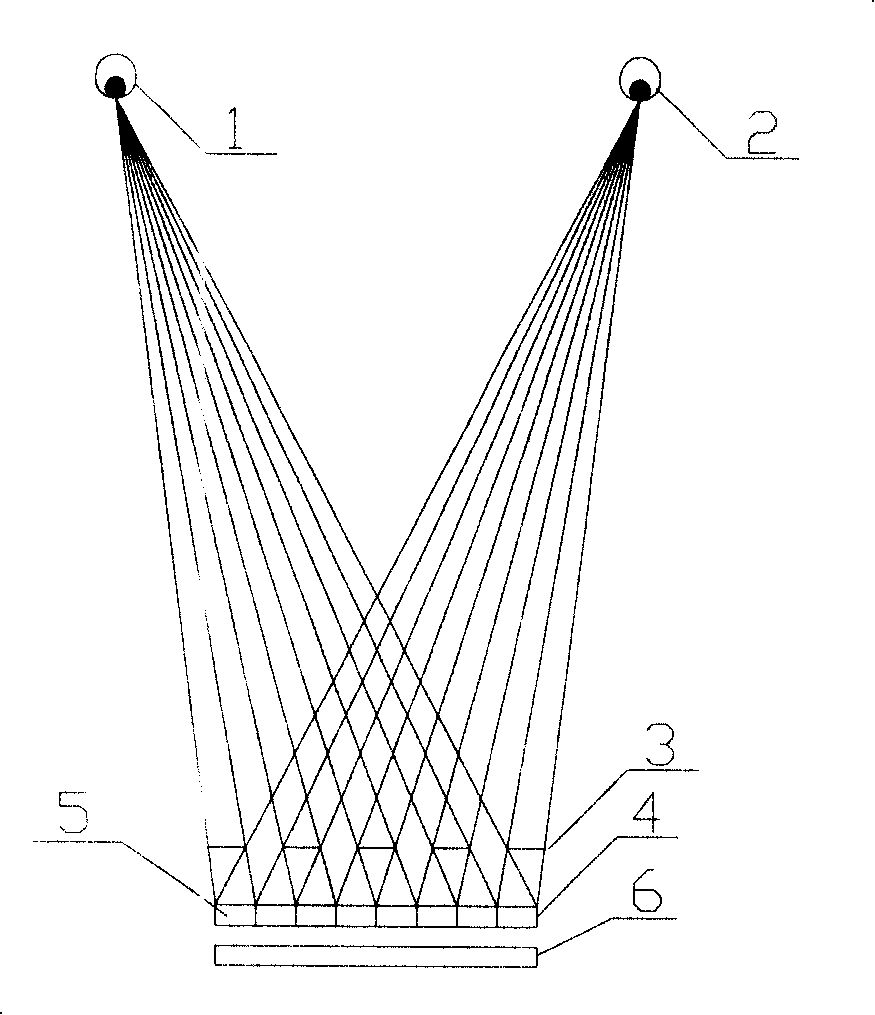

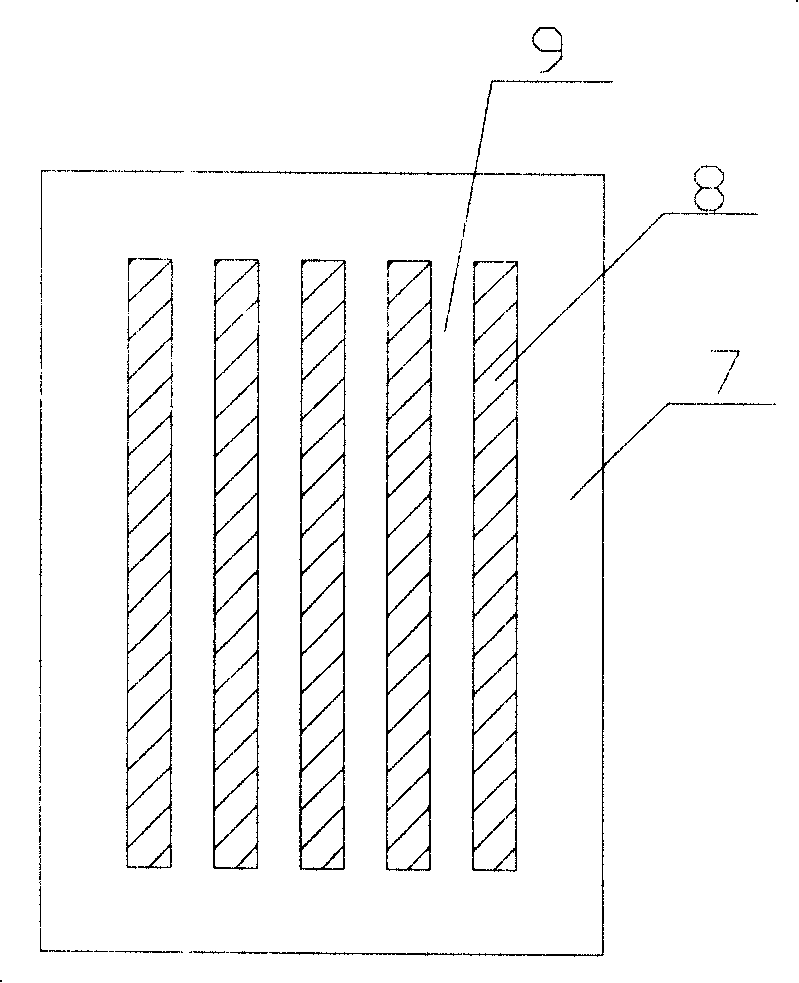

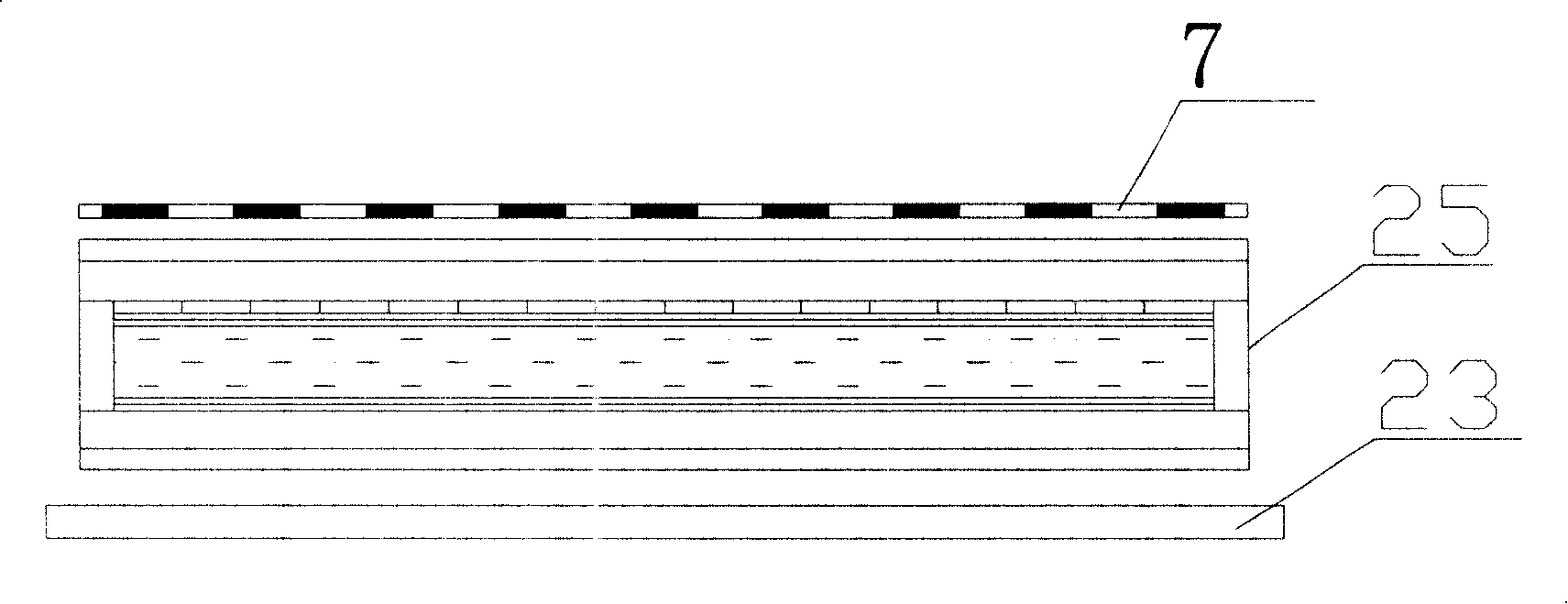

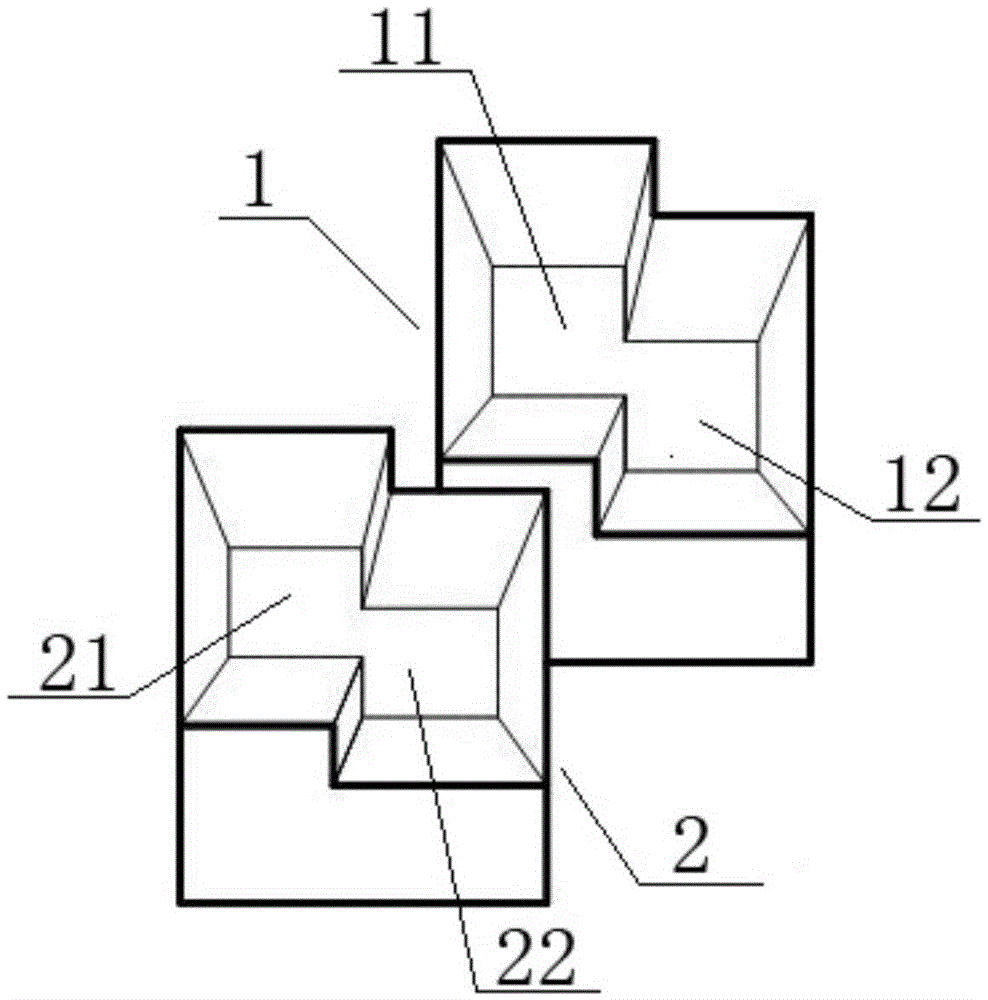

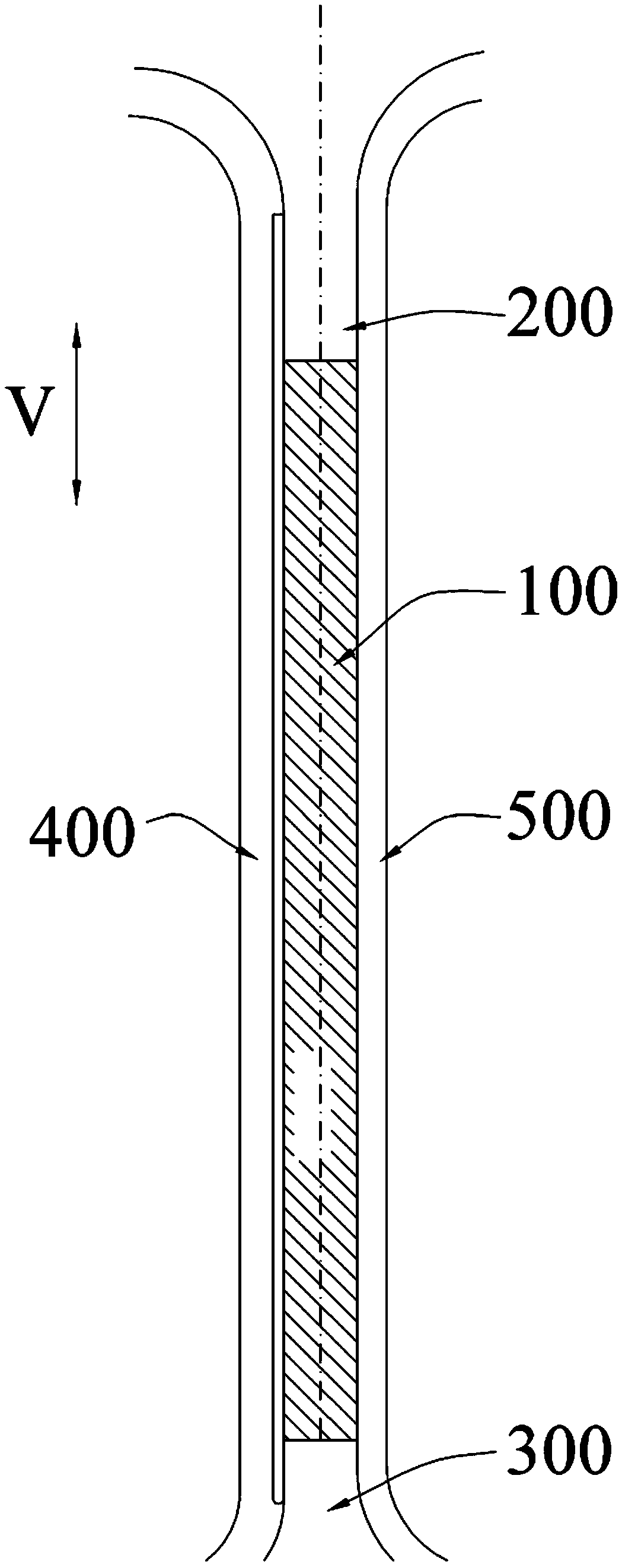

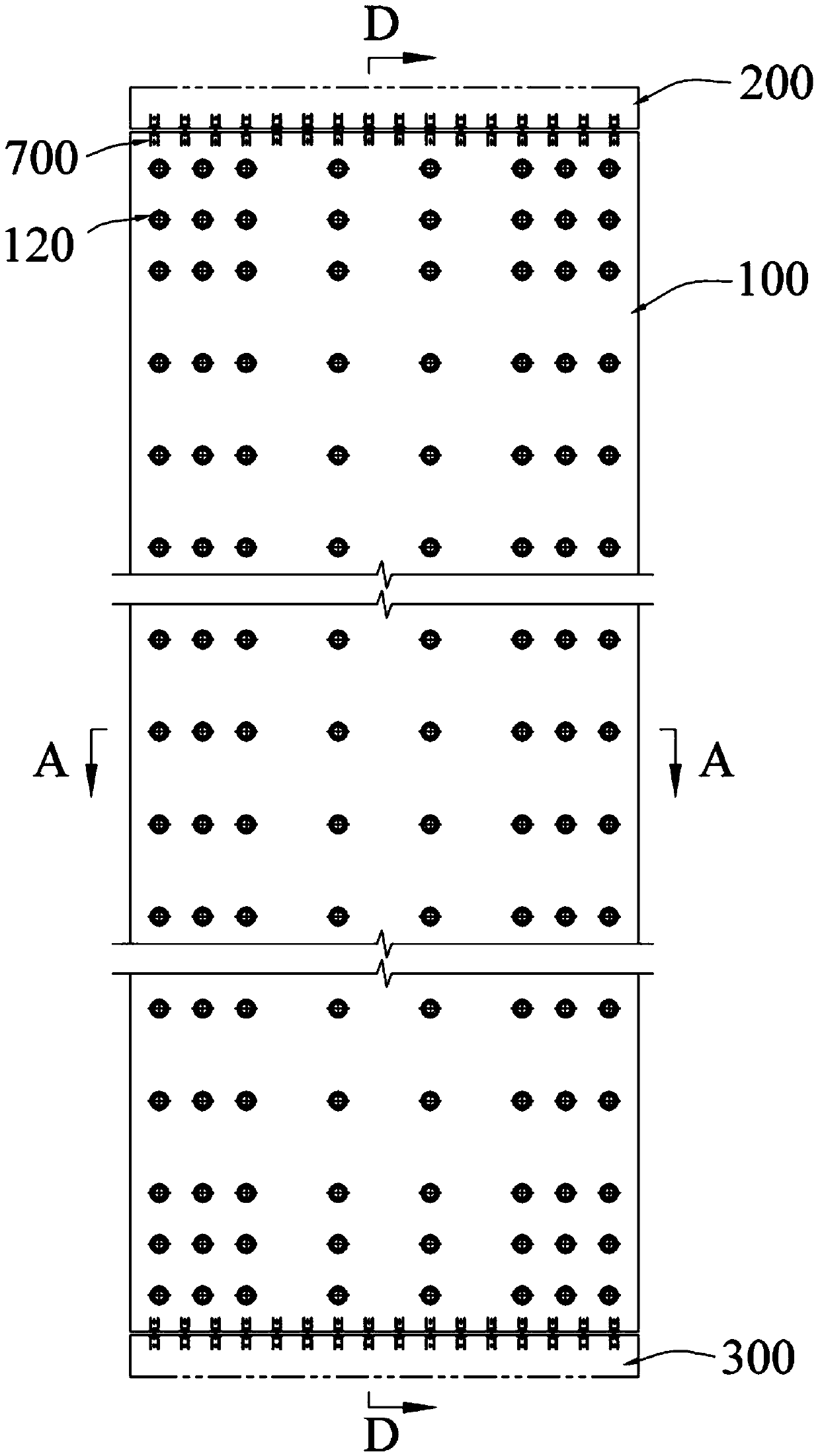

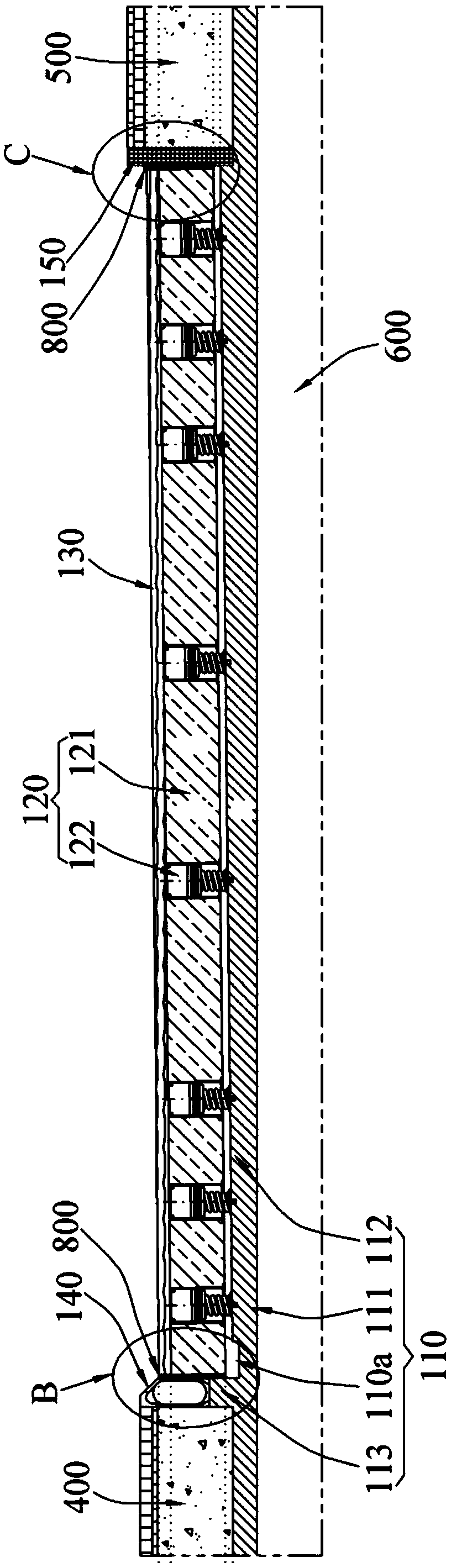

Stereo liquid crystal display device and method for making the same

ActiveCN101162311AUnlimited sizeHigh precisionDiffraction gratingsNon-linear opticsGratingLiquid-crystal display

The invention discloses a stereo liquid crystal displayer structure and a method for manufacturing the same, wherein, when the liquid crystal displayer is made, a raster layer is integrated between an upper plaroid and an upper glass plate of the displayer, forming a stereo liquid crystal displayer which has the advantages of high precision and accurate para position and is based on the parallax barrier technique. The invention can be widely applied to a plurality of liquid crystal displayers with different screen sizes; moreover, the invention has the advantages of easy technological transformation, low manufacturing cost and preferable stereo displaying effect.

Owner:BYD CO LTD

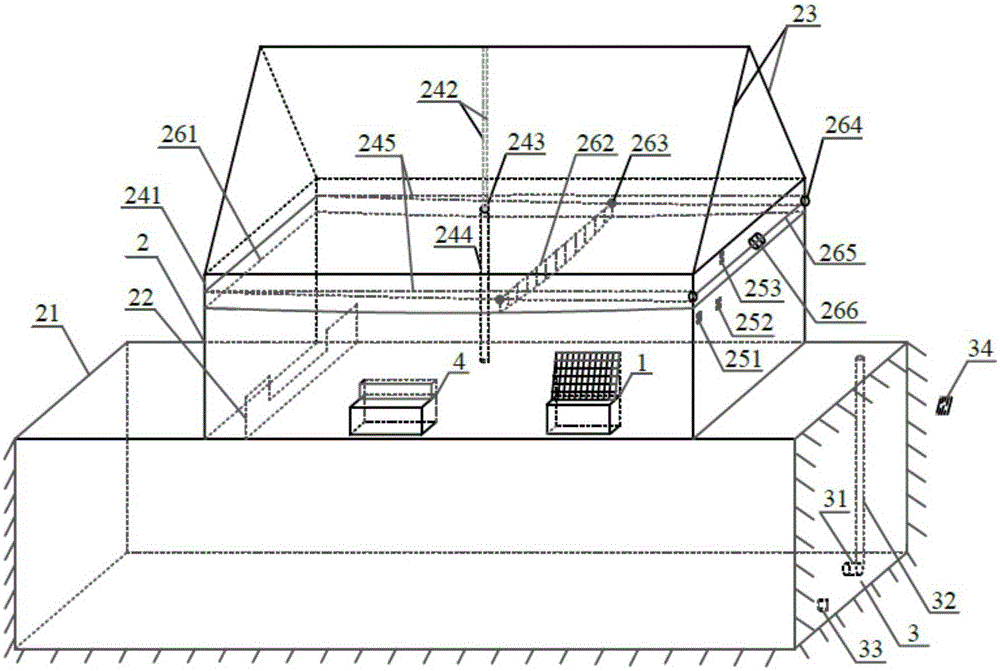

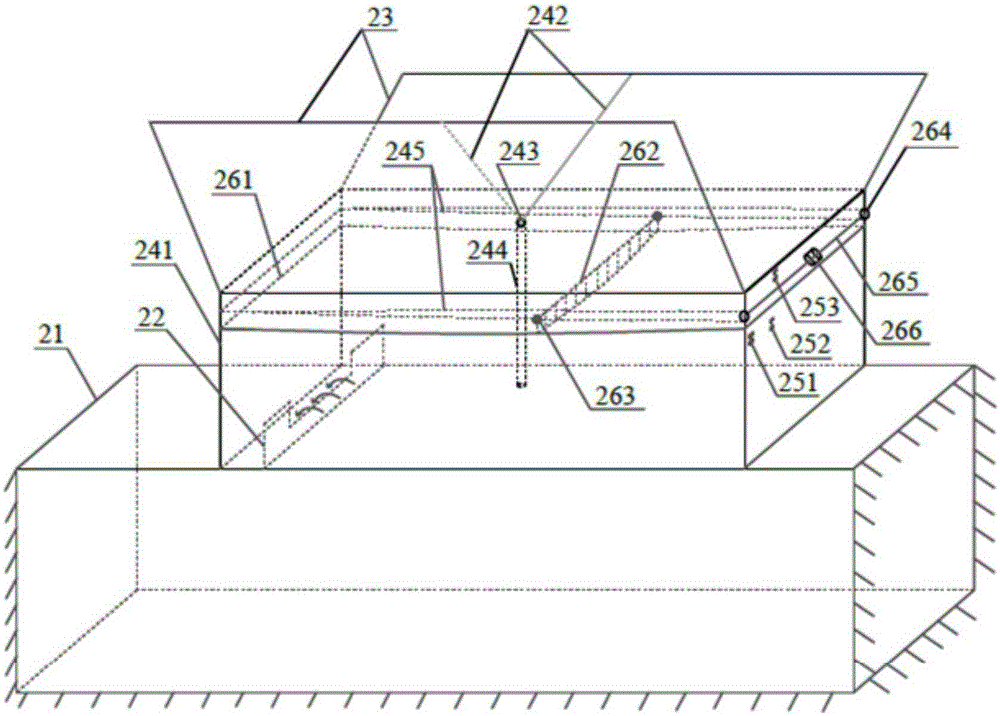

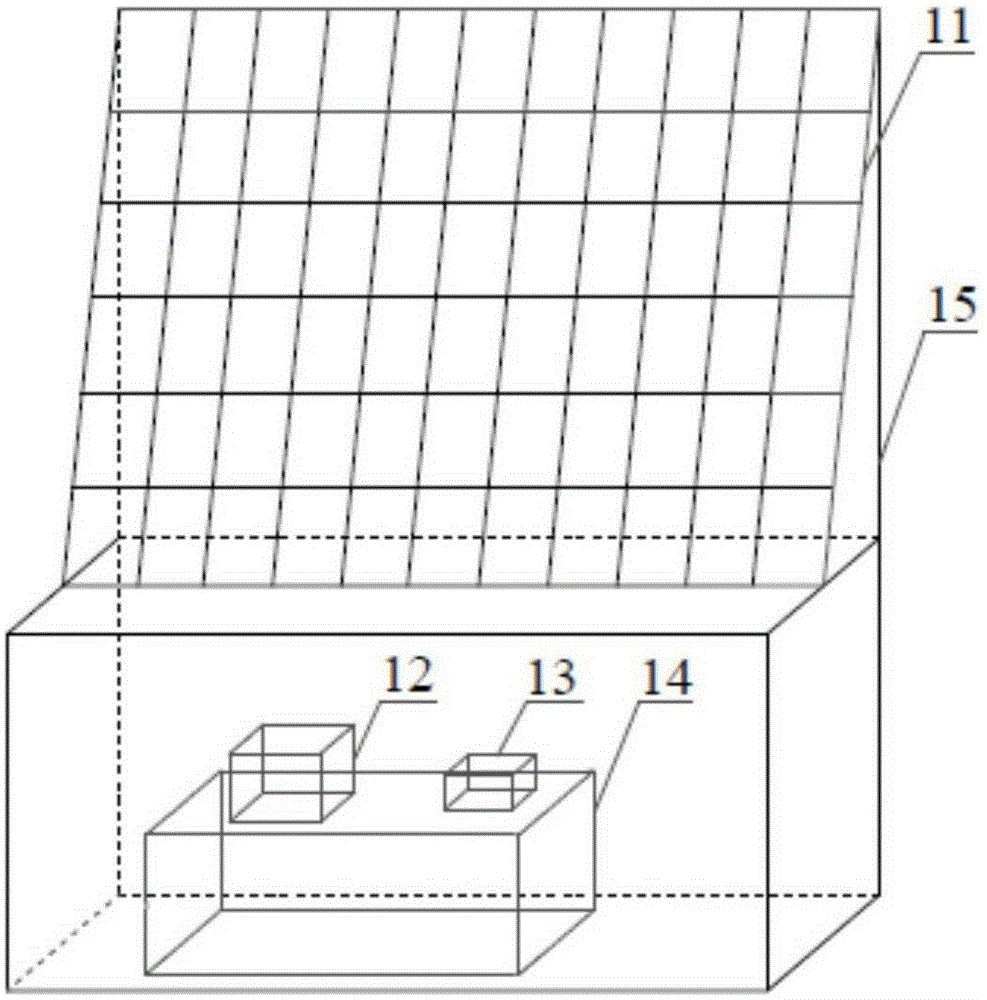

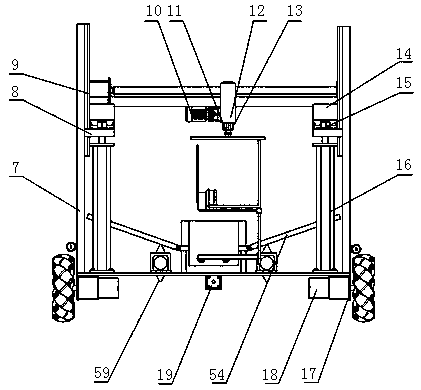

Full-automatic rainwater harvesting irrigation apparatus and operation method of same

ActiveCN105145291AHigh degree of intelligenceFully automatedWatering devicesRenewable energy machinesElectricityEngineering

The invention discloses a full-automatic rainwater harvesting irrigation apparatus and an operation method of the same and relates to the technical field of rainwater collection and utilization. The full-automatic rainwater harvesting irrigation apparatus comprises a solar energy photovoltaic power generation system, a rainwater collecting system, an irrigating system and an intelligent control system, wherein solar energy is directly converted into electricity through a solar energy panel by the solar energy photovoltaic power generation system, so energy can be provided for apparatus work; the rainwater collecting system collects rainwater according to an atmosphere raining condition; the irrigating system forms relative irrigation water-supply sources according to soil humidity and water amount required by the plants; and the intelligent control system receives signals of each sensor to control the other systems to work in a coordinate way. By the use of the method and equipment rainwater can be automatically collected and plants can be automatically irrigated; and the method and equipment have wide application range.

Owner:嘉善永升五金厂

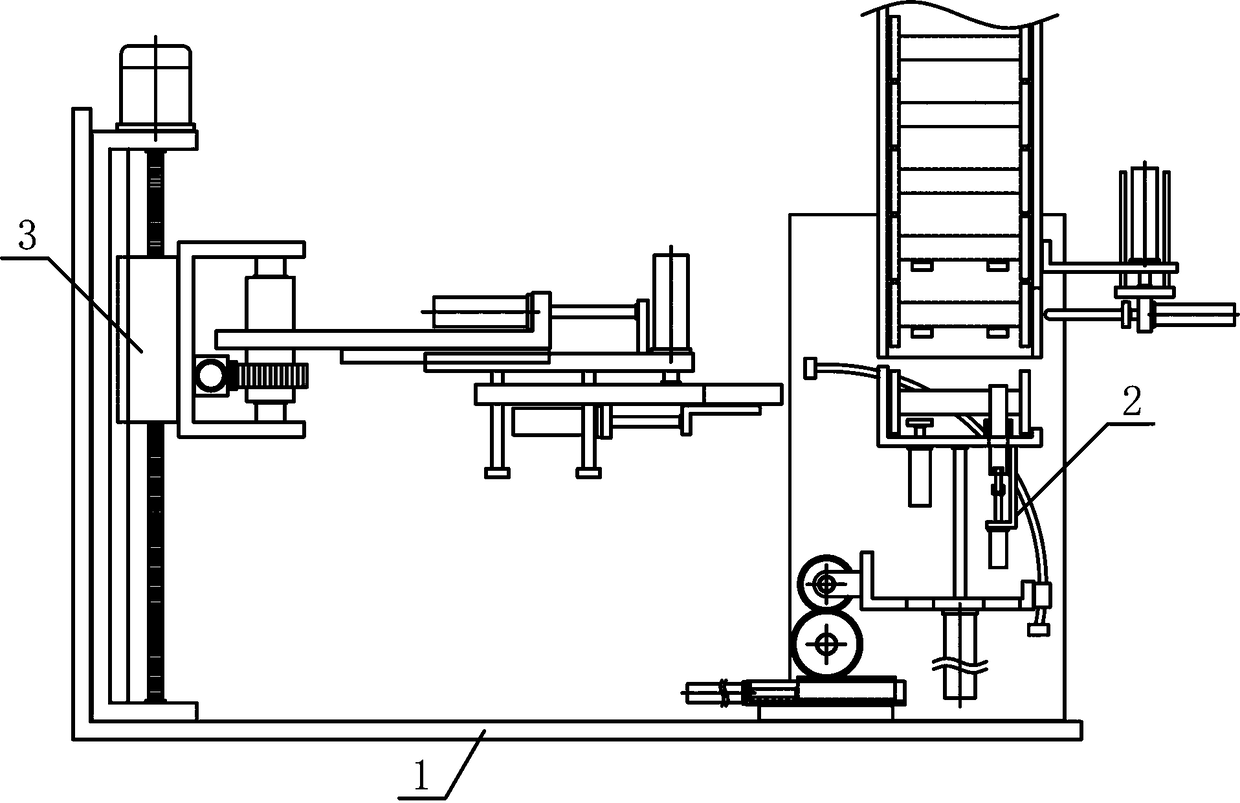

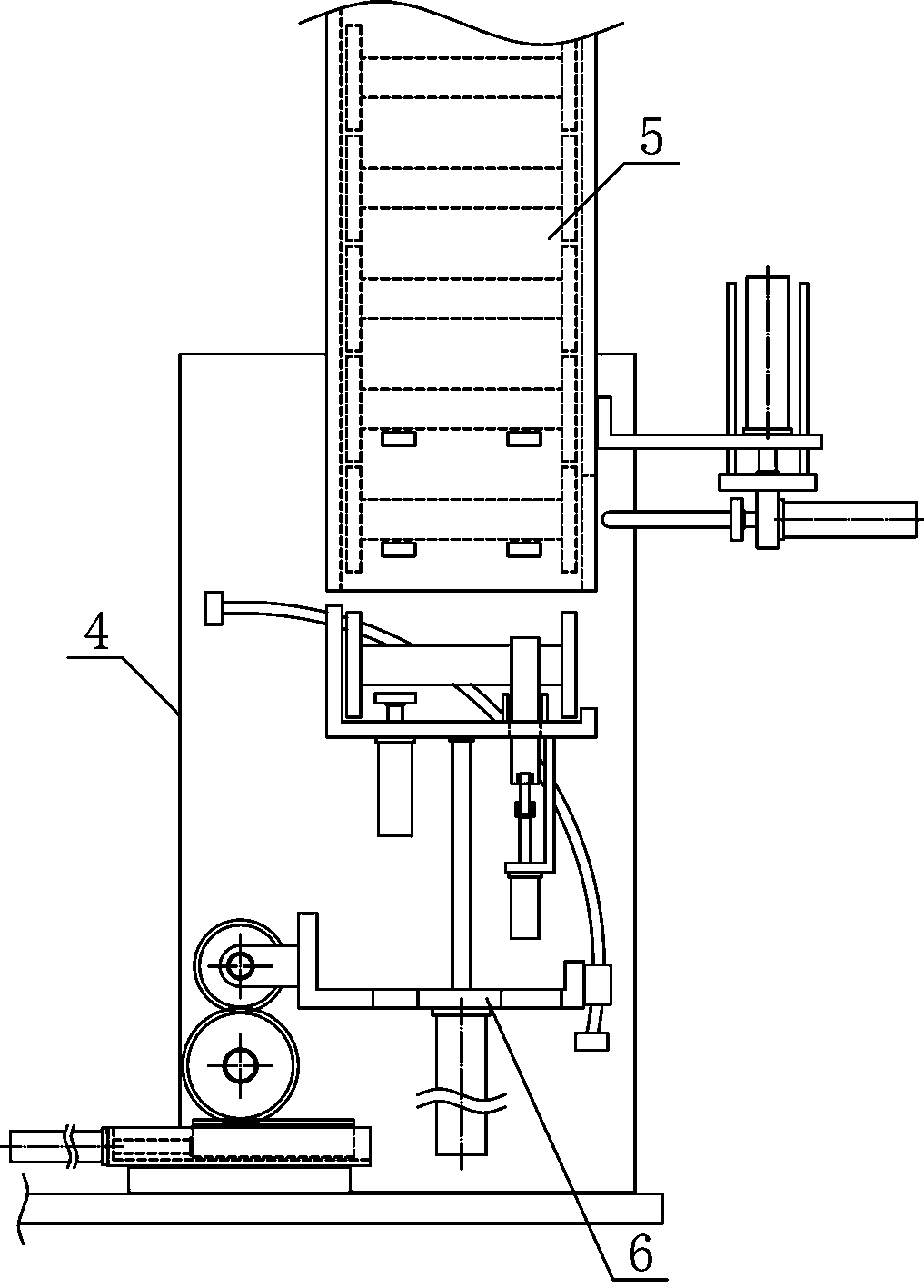

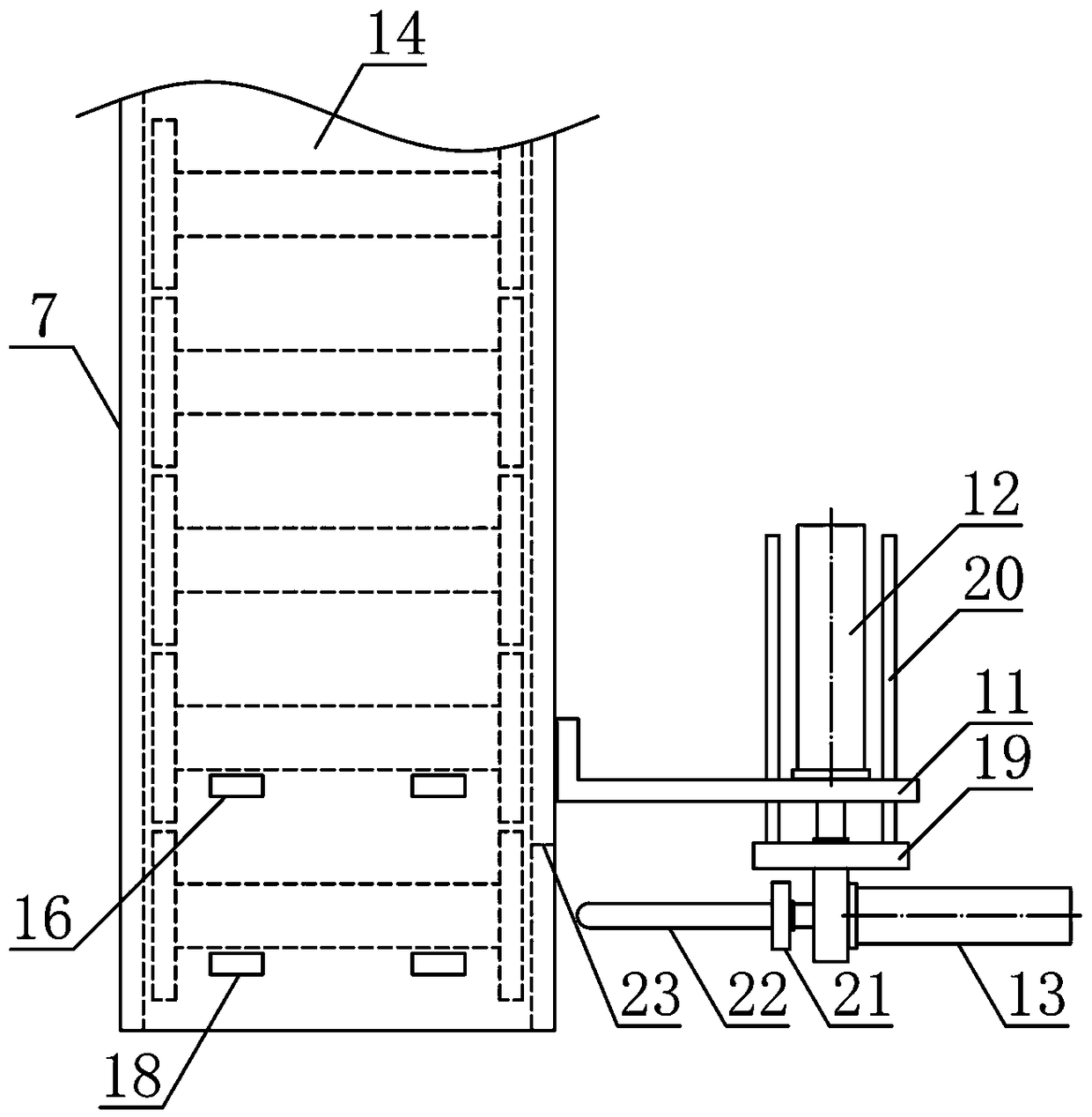

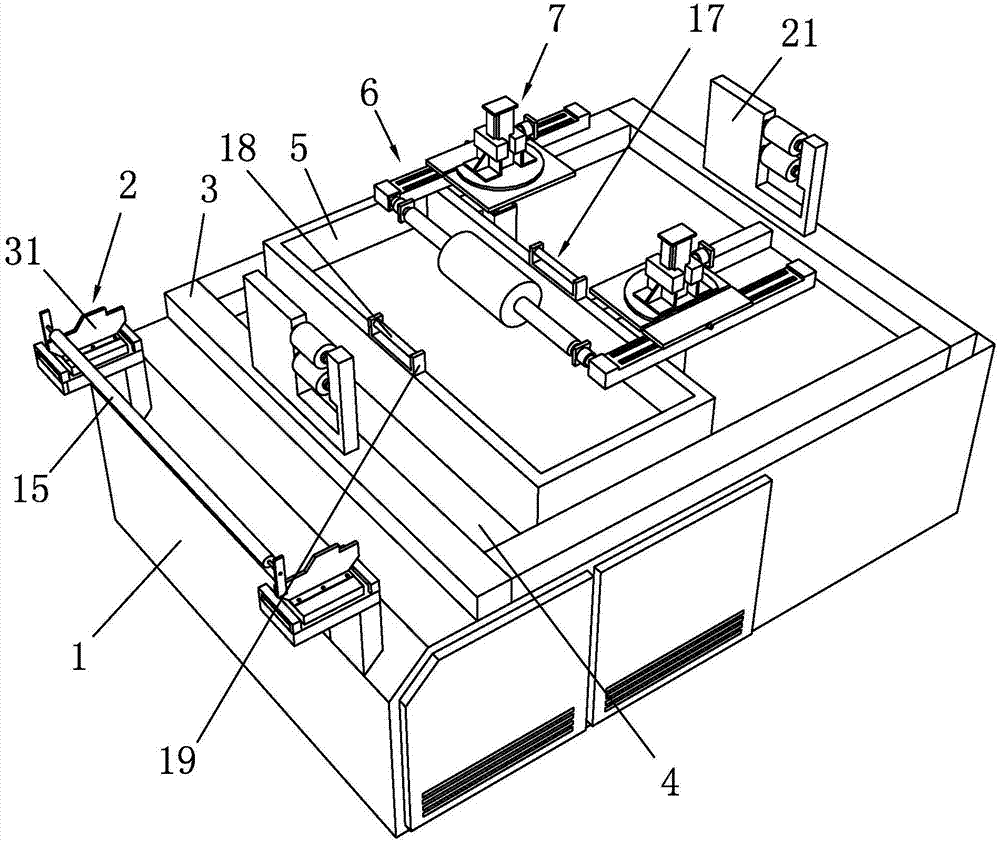

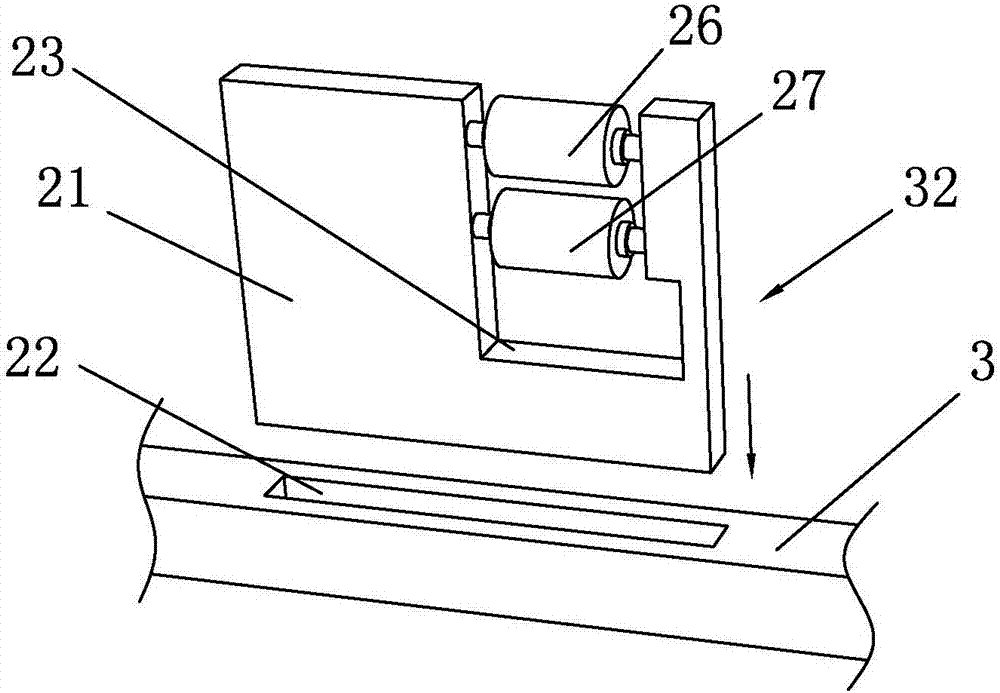

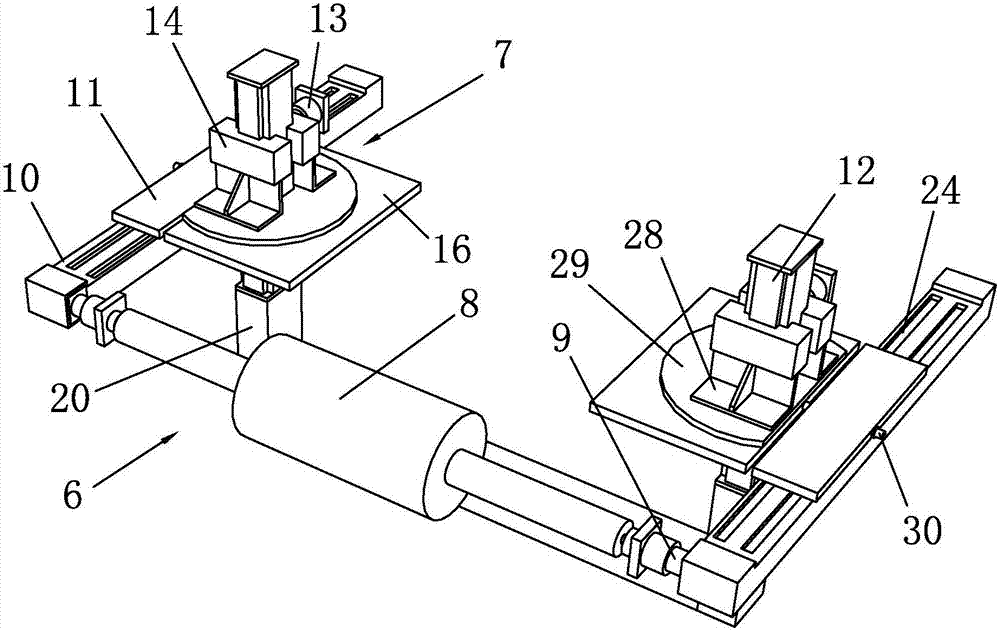

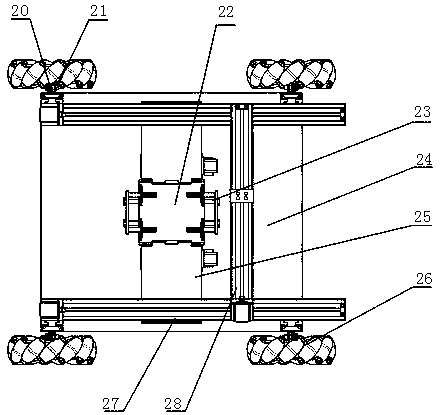

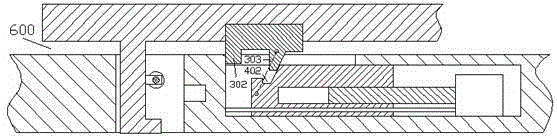

Automatic feeding mechanism for yarn winding drums

InactiveCN109292541AHigh degree of automationSmooth vertical flip loadingFilament handlingYarnEngineering

The invention discloses an automatic feeding mechanism for yarn winding drums, and belongs to the field of fabric production and processing machinery and equipment. A transfer mechanism and barrel moving mechanism of the automatic feeding mechanism are sequentially, vertically and fixedly arranged on the two sides of the upper portion of a feeding base in the horizontal direction. A barrel guidingmechanism and a barrel turning mechanism are sequentially, vertically and fixedly arranged on one side of a transfer bracket from top to bottom. A barrel guiding material pipe is vertically and fixedly arranged on one side of the transfer bracket. A barrel placing bracket is horizontally and fixedly arranged at the output end of a barrel bearing cylinder in the middle of the lower side of a reciprocating bracket. A rotating bracket is horizontally and fixedly arranged on the middle portion of a rotating sleeve of a barrel moving bracket. A barrel moving connecting plate is horizontally arranged at the lower side of a translation connecting plate, and a barrel bearing clamping plate is horizontally and fixedly arranged at the output end of a clamping plate cylinder. The automatic feeding mechanism is reasonable in structural design, can smoothly transfer and feed the yarn winding drums one by one and smoothly transfer and place the yarn winding drums to required positions, improves theautomation degree of feeding the yarn winding drums, and meets the requirements of production and use.

Owner:桐乡市富利来针织股份有限公司

Helicopter composite material paddle fatigue test piece molding method

InactiveCN102507275AGuaranteed symmetryShorten the manufacturing cycleMachine part testingPreparing sample for investigationEngineeringRejection rate

The invention belongs to a composite material molding technology, and relates to helicopter composite material paddle fatigue test piece molding technological process which is suitable for helicopter composite material technological process molding. According to the invention, a platform thickness spacing tool is adopted, an interval between two splints of a paddle fatigue test piece is effectively ensured, and simultaneously the positioning of the spacing tool can insure symmetry of the two splints; and a working procedure of numerical control processing is directly omitted from a technical process, furthermore a manufacturing cycle is also shortened, once alternating detection qualification rate of the paddle fatigue test piece is improved, the rejection rate of the paddle fatigue test piece is zero, and the stability and the smoothness of the assembly process of the paddle fatigue test piece are ensured.

Owner:中航直升机股份有限公司

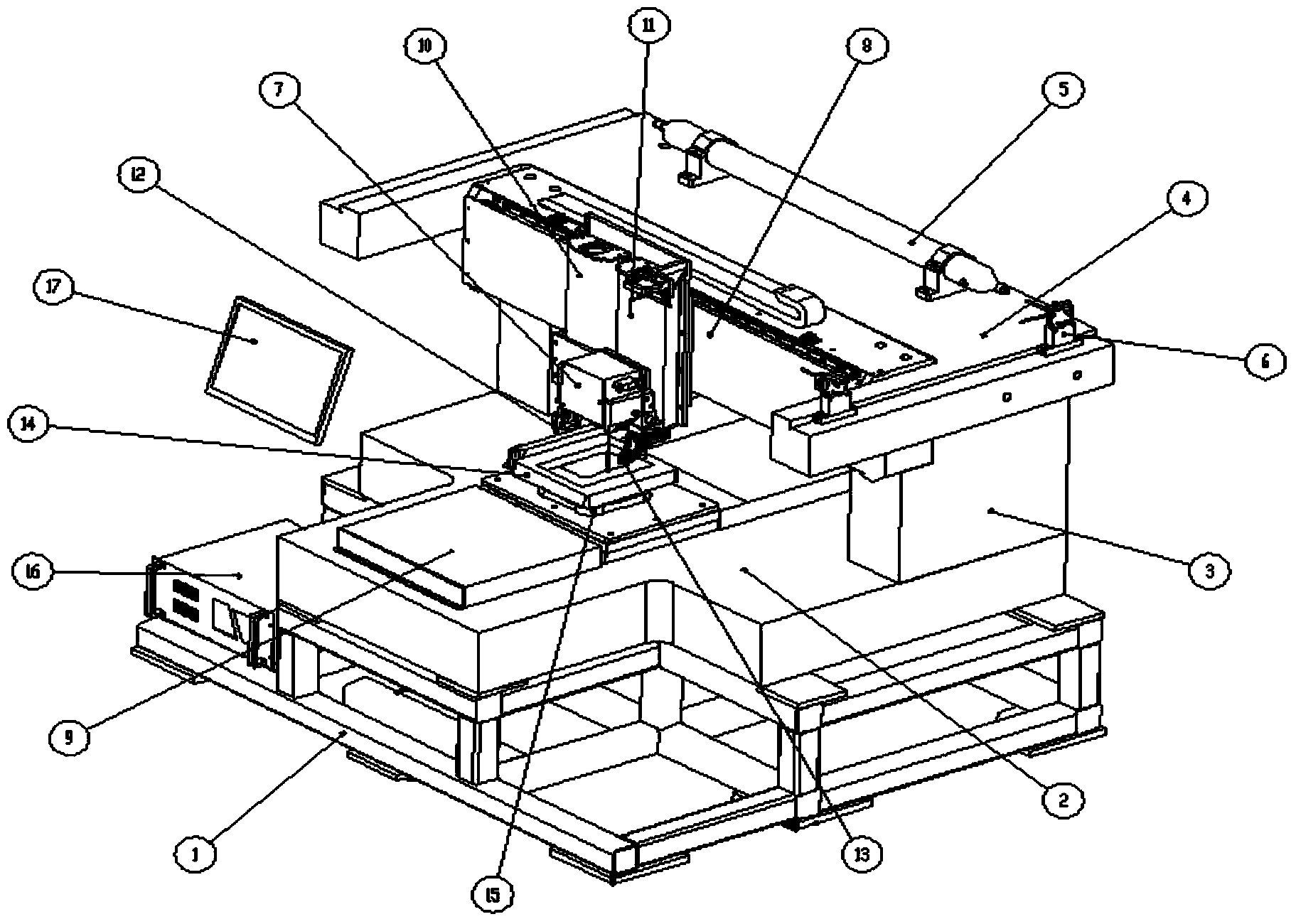

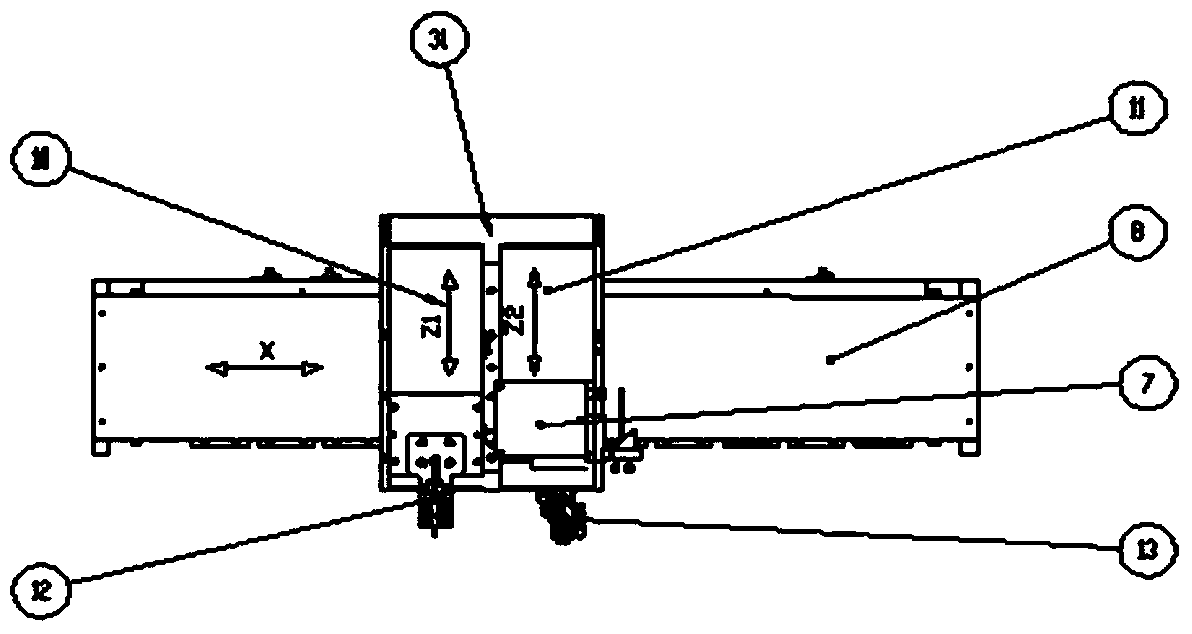

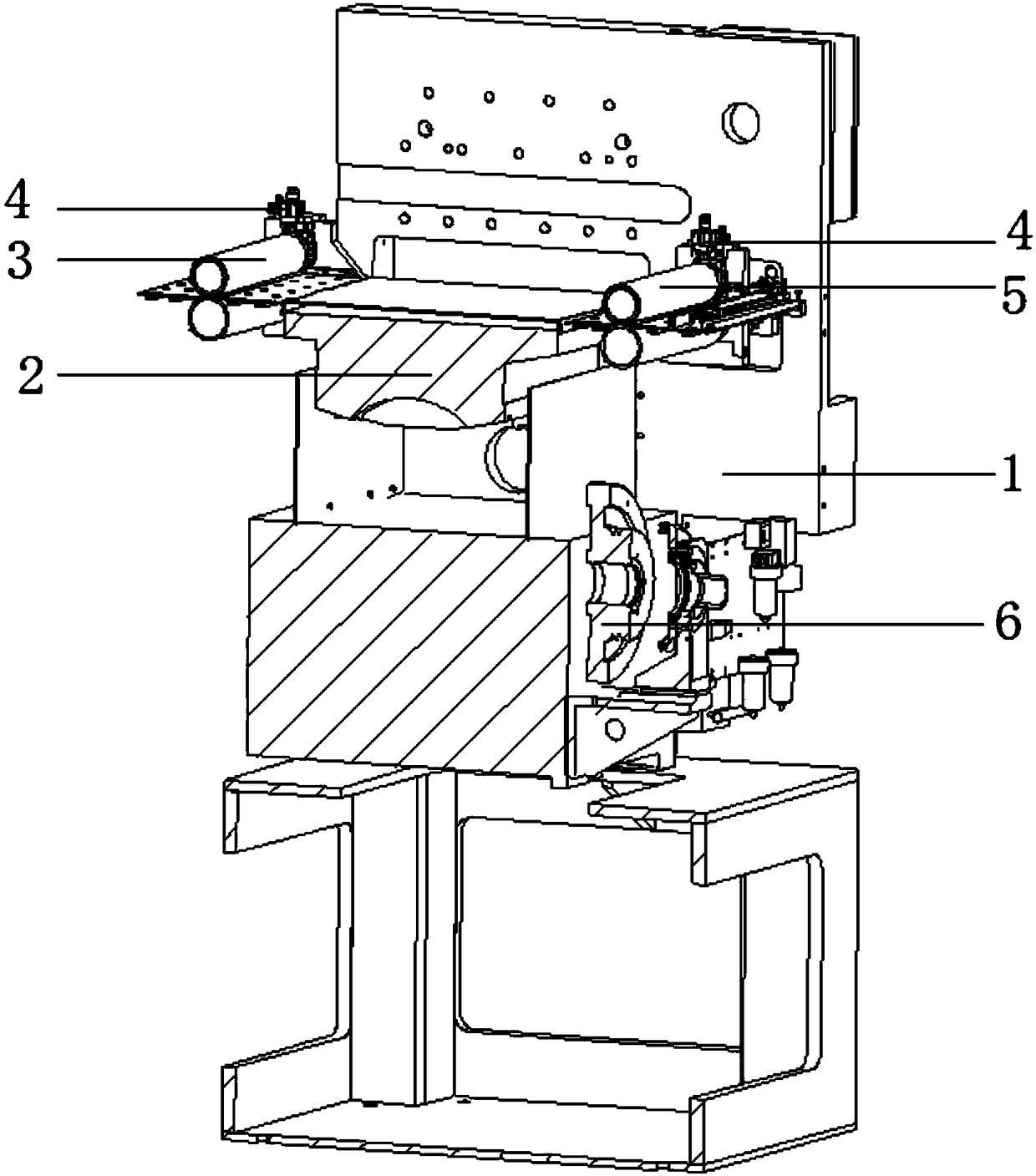

Laser equipment for cutting glass and cutting method

ActiveCN104071974AEnsure smoothnessEnsure dimensional accuracyGlass severing apparatusCommunications systemCutting glass

The invention discloses laser equipment for cutting glass and a cutting method. A laser generator and a galvanometric scanning system are in data communication with an industrial personal computer through a communication system so as to control a galvanometer to generate strip laser spots during a straight line machining process and generate arc-shaped laser spots during an arc line machining process, so that the laser machining spots precisely coincide with a preset cutting path. A cooling fluid nozzle is mounted below the galvanometer and is used for spraying fluids to cool regions on which the laser heating is carried out, so that a workpiece to be machined is cracked along the preset cutting path under the actions of cold and hot pressures. The workpiece to be machined is adsorbed by an adsorption platform which is mounted on a DD ((Direct Drive) motor; the DD motor is mounted on a Y-shaft moving system; and the galvanometer is mounted on a Z-shaft moving system which is mounted on an X-shaft moving system. When the arc line machining is carried out, the industrial personal computer controls the DD motor to drive the workpiece to rotate and is matched with the motions of an X shaft and a Y shaft at the same time, so that the rendezvous point of the laser spots and the cooling fluids is accurately positioned on the preset cutting path always. Thus, the precision cutting of an arc line position of the glass is realized.

Owner:江苏先河激光技术有限公司

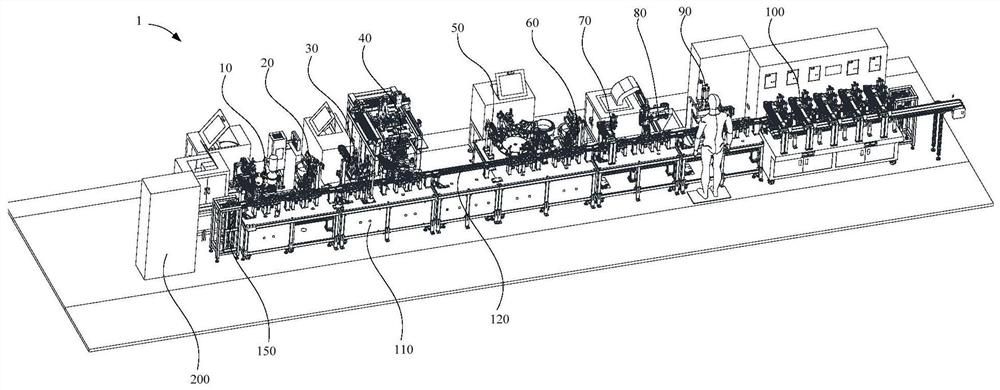

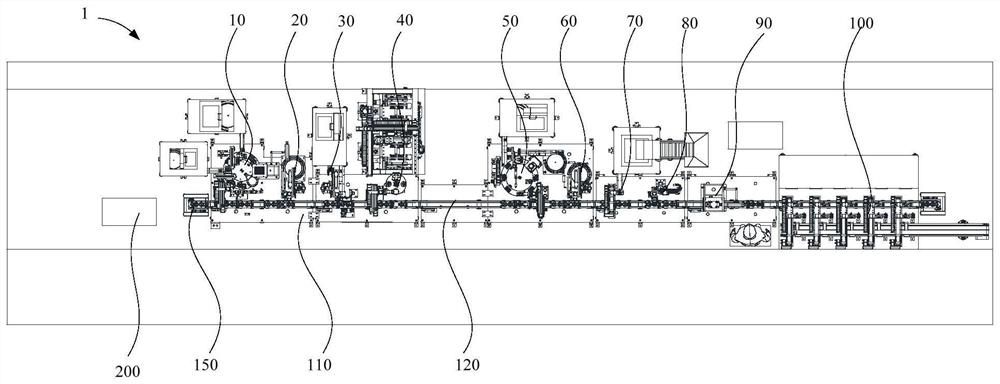

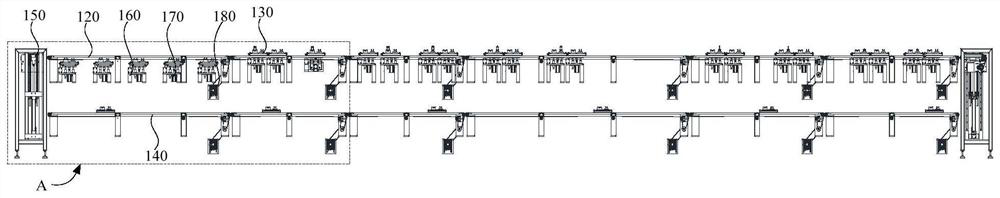

Valve body assembling system

ActiveCN112008393AImprove assembly efficiencyReduce labor costsAssembly machinesMetal working apparatusMachineReclaimer

The invention provides a valve body assembling system. The valve body assembling system comprises a first assembling station; the first assembling station comprises a first machine table, a first index plate, a taking mechanism, a riveting mechanism and a discharging mechanism; the first index plate is rotatably arranged on the first machine table, and a plurality of first jigs are arranged on thefirst index plate; the taking mechanism is arranged on the first machine table and used for placing materials into the first jigs; the riveting mechanism is arranged on the first machine table and used for riveting the materials in the first jigs to obtain a first semi-finished product material; and the discharging mechanism is arranged on the first machine table and used for taking down the first semi-finished product material and placing the first semi-finished product material onto a tool plate. According to the valve body assembling system provided by the invention, actions of assembling,feeding, discharging and the like of valve body parts are completely and automatically completed by machine equipment, the labor cost is reduced while the product assembling efficiency is improved, the actions are stable, errors are not prone to happening, the yield of a product is further increased, and the reliable guarantee is provided for normal production of other subsequent stations.

Owner:KUKA ROBOTICS GUANGDONG CO LTD

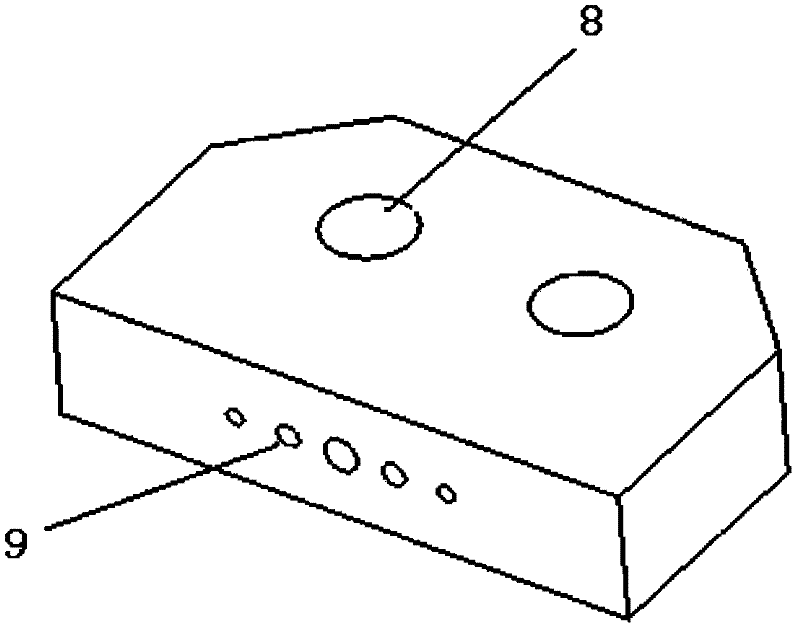

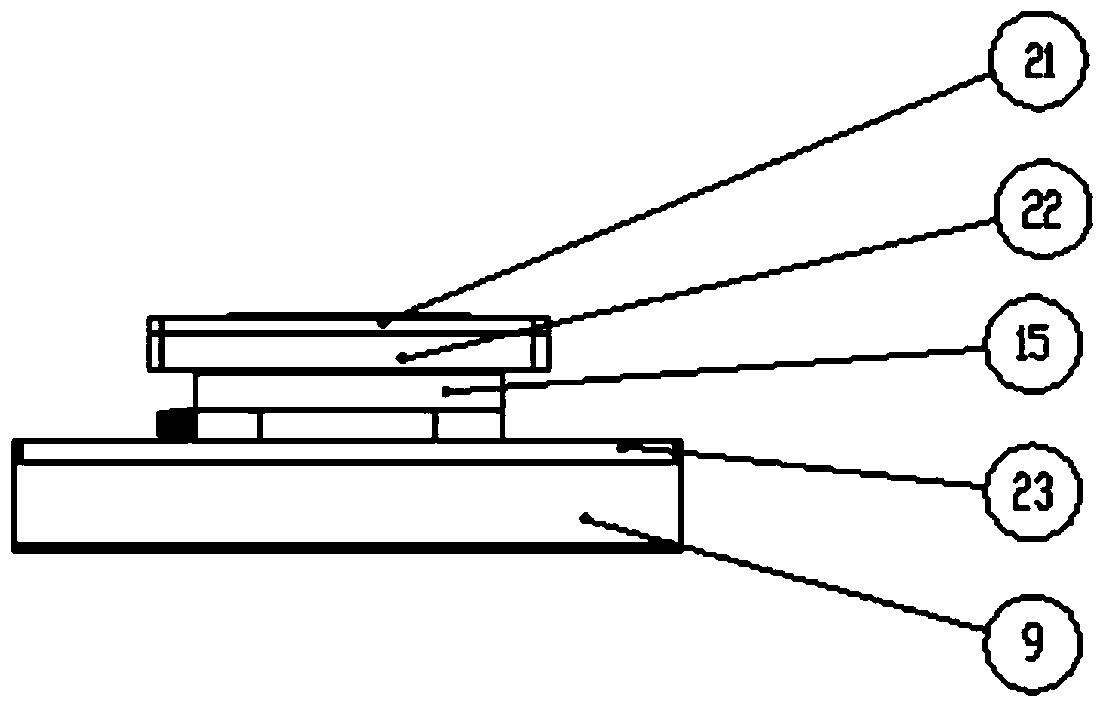

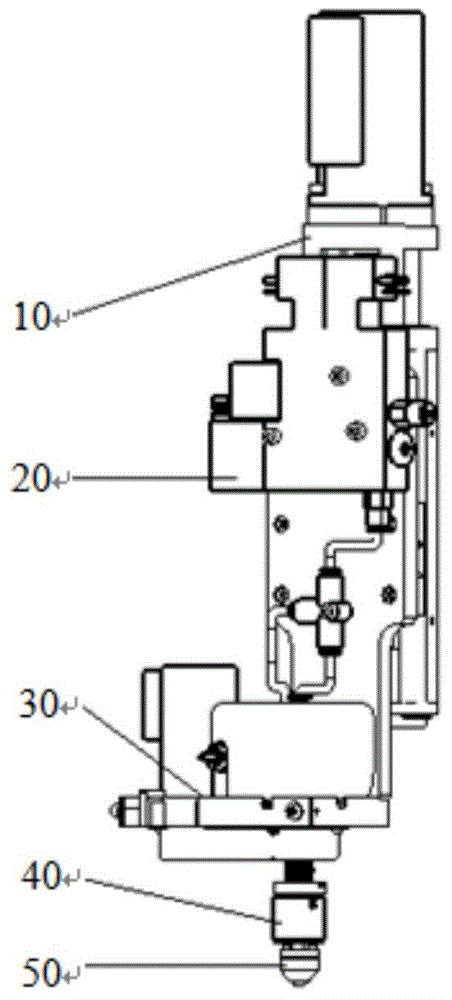

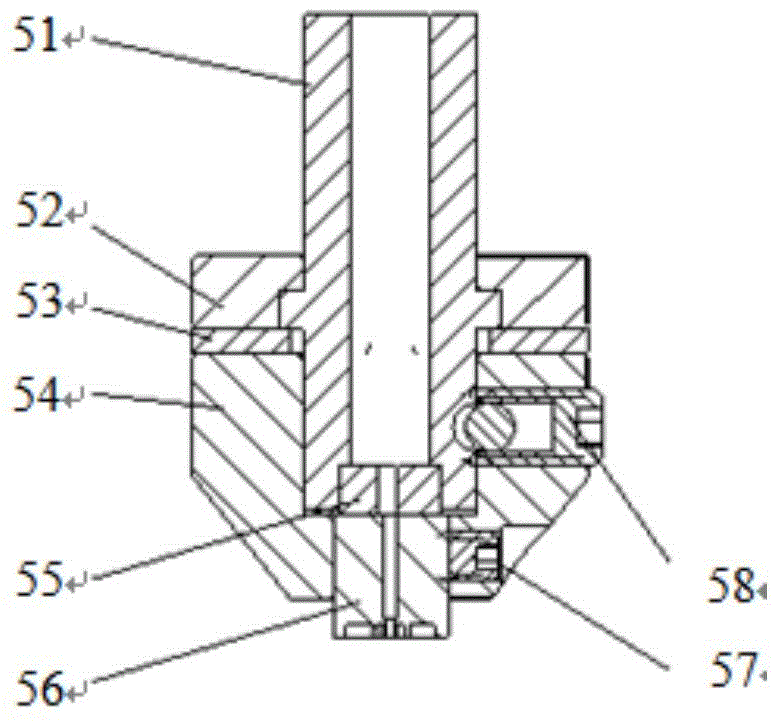

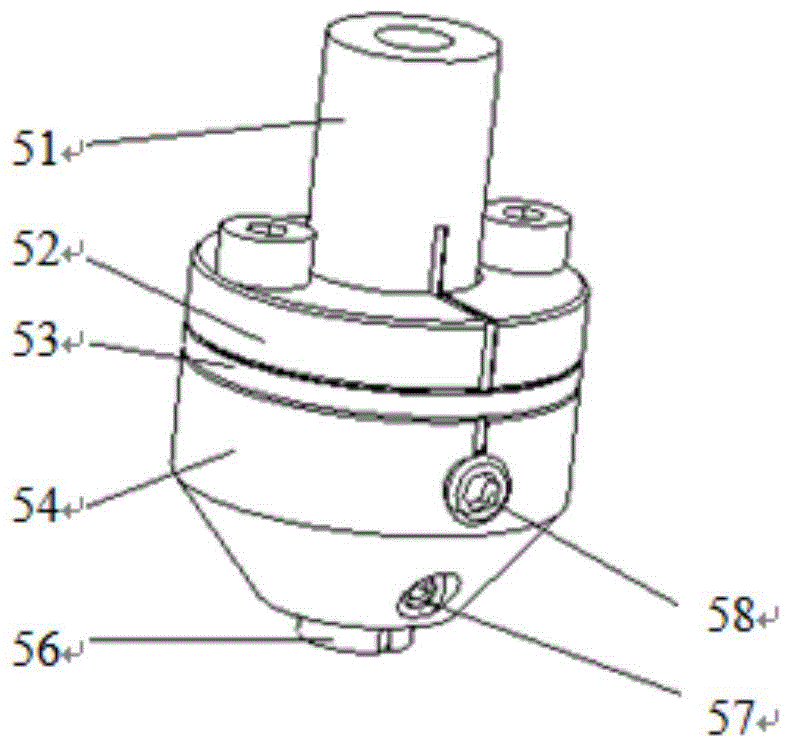

Surface mounting machine picking device suitable for multi-specification chips

ActiveCN104411109AImprove work efficiencyEnsure fluency and precisionPrinted circuit assemblingBackplaneEngineering

The invention discloses a surface mounting machine picking device suitable for multi-specification chips. The surface mounting machine picking device comprises a Z-direction feeding module, a transmission module, an air passage module, a spline shaft module and a nozzle module, wherein the Z-direction feeding module is used for driving a back board to move up and down, a vacuum generator in the air passage module is used for generating a vacuum space, realizes connection through an air pipe, a rapid connection connector and a spline shaft and generates a vacuum environment in the spline shaft, the transmission module is used for guaranteeing attitude precision of absorbed chips during mounting, the spline shaft module is used for transmitting rotation motion and providing the buffer effect, the nozzle module through a nozzle head and a sealing pad embedded in a nozzle rod generates different matching and controls opening and closing of through holes in different combinations, and thereby the nozzle head generates vacuum domains in different dimensions. Through only employing one nozzle, the surface mounting machine picking device can adapt to large-scope dimension change of chips, and the surface mounting machine picking device further has advantages of compact structure, convenient control and smooth and accurate integral mounting operation.

Owner:HUAZHONG UNIV OF SCI & TECH

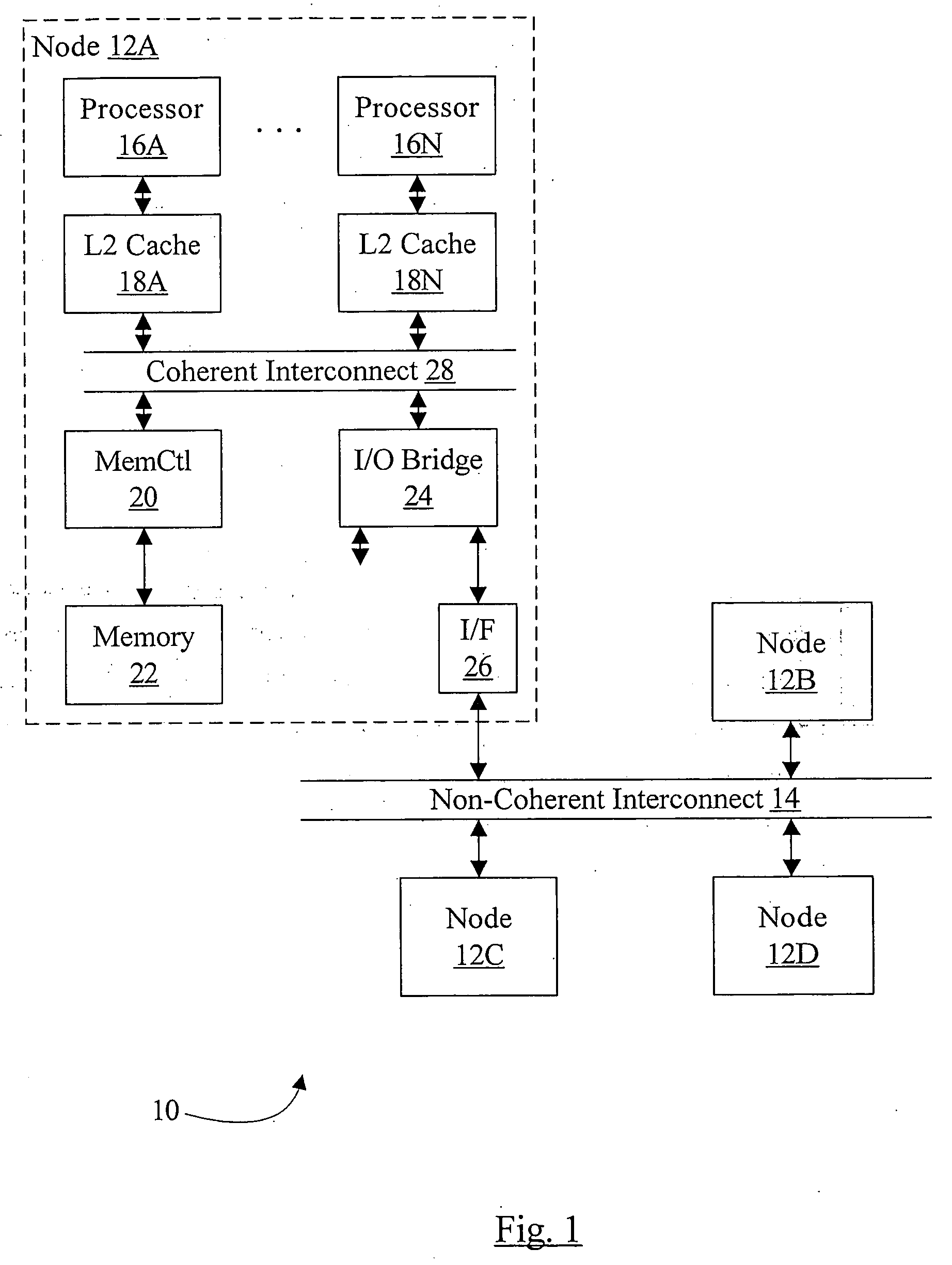

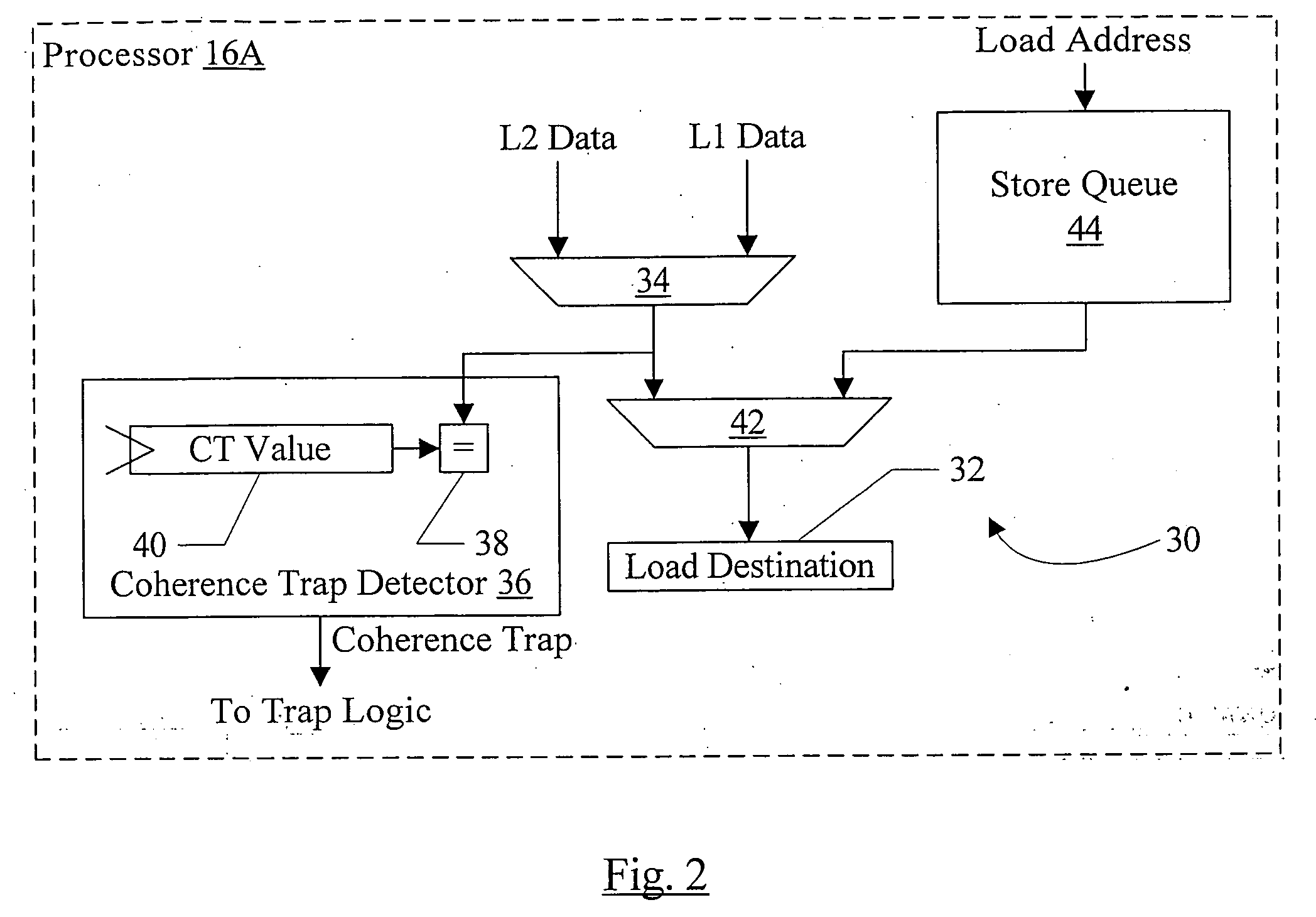

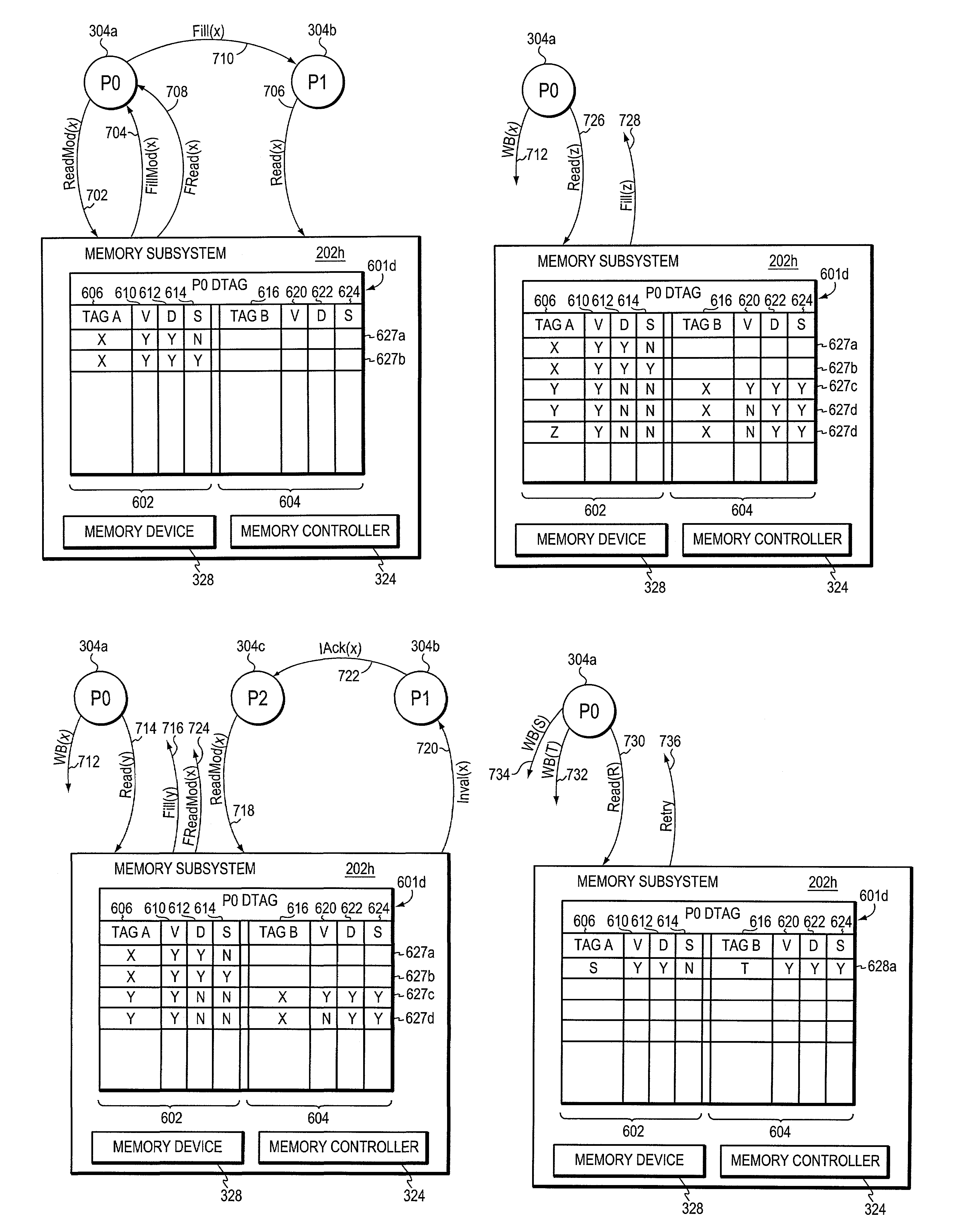

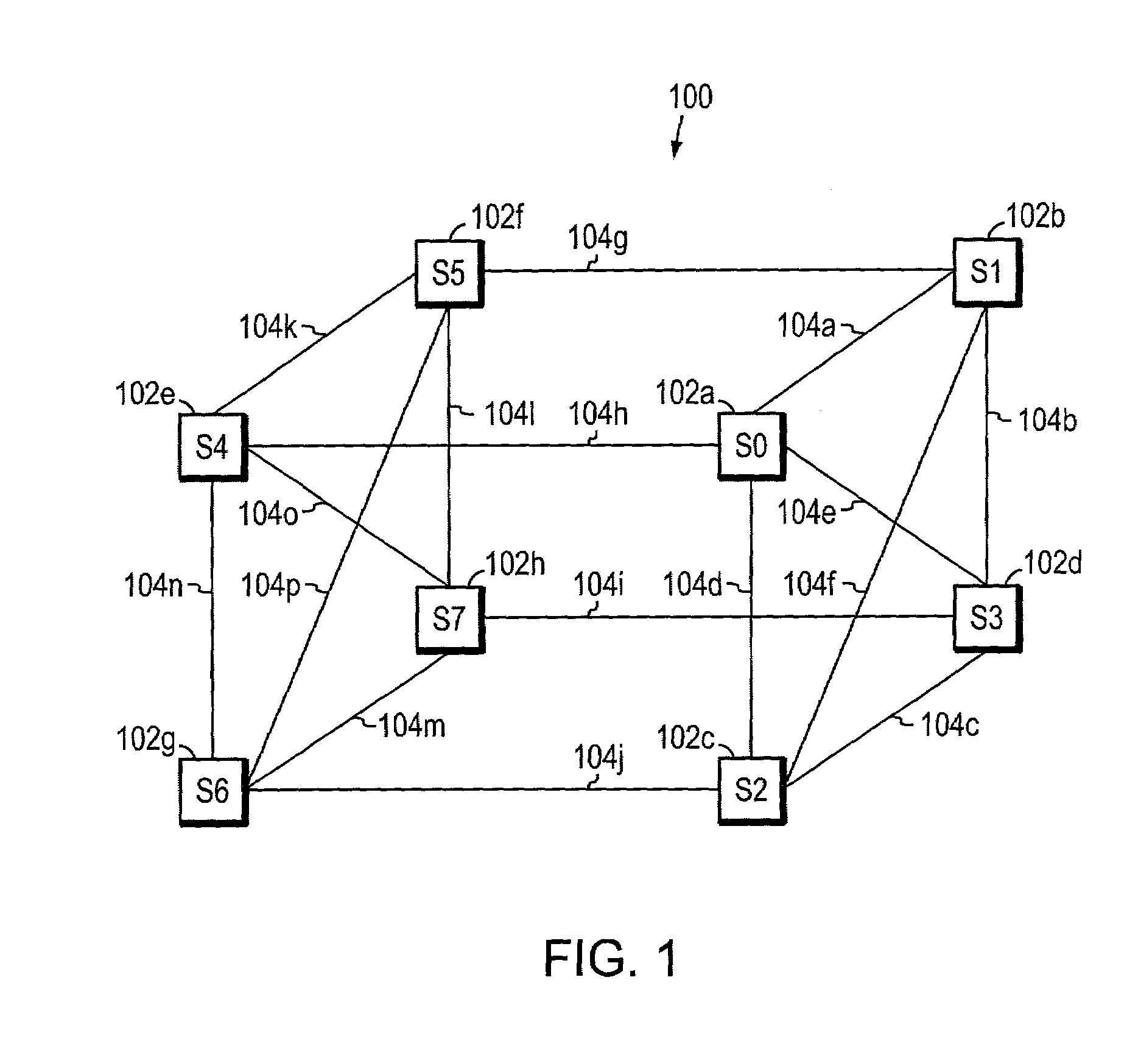

Value-based memory coherence support

In one embodiment, a processor comprises a coherence trap unit and a trap logic coupled to the coherence trap unit. The coherence trap unit is also coupled to receive data accessed in response to the processor executing a memory operation. The coherence trap unit is configured to detect that the data matches a designated value indicating that a coherence trap is to be initiated to coherently perform the memory operation. The trap logic is configured to trap to a designated software routine responsive to the coherence trap unit detecting the designated value. In some embodiments, a cache tag in a cache may track whether or not the corresponding cache line has the designated value, and the cache tag may be used to trigger a trap in response to an access to the corresponding cache line.

Owner:ORACLE INT CORP

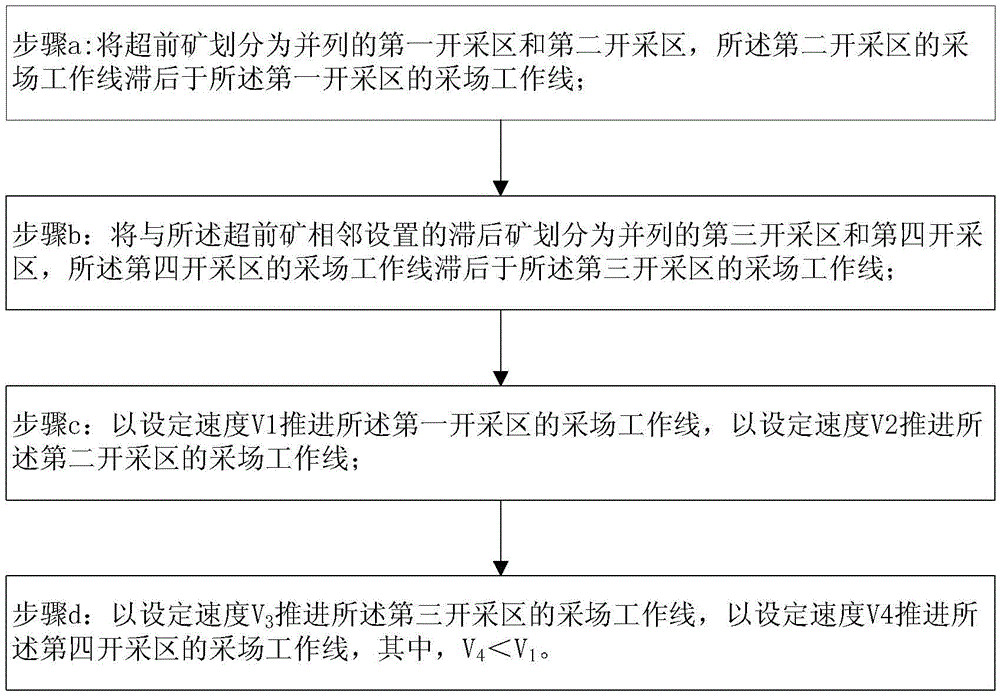

Open-cast coal mine and mining method thereof

ActiveCN105484750AEnsure smoothnessOptimize layoutUnderground miningSurface miningPolygonal lineCoal

The invention discloses open-cast coal mine and a mining method thereof. The open-cast coal mine comprises lead ore and lagging ore which are arranged adjacently, wherein the lead ore comprises a first mining region and a second mining region which are arranged in parallel, the lagging ore comprises a third mining region and a fourth mining region which are arranged in parallel, the inner dump working line of the first mining region is adjacent to the stope mining region of the fourth mining region, the inner dump working line of the second mining region lags the inner dump working line of the first mining region, and the stope working line of the fourth mining region lags the stope working line of the third mining region. By adjusting the stope working line and the inner dump working line of the adjacent ore regions to be in a polygonal line shape, the distance between the lead ore inner dump working line and the lagging ore stope working line at juncture of the adjacent ore regions is increased, and the completeness and smoothness of the end slope transportation line at the juncture of the adjacent ore regions are ensured, so that the transportation equipment is convenient to arrange, the transportation cost is lowered, and the economical benefit and safety of the opencast pit are favorably improved.

Owner:CHINA SHENHUA ENERGY CO LTD +2

Hot air punching film and forming method thereof

InactiveCN103921447ASolve the anxiety phenomenonGuaranteed flexibilityAdhesive dressingsPunchingAtmospheric air

The invention relates to a hot air punching film and a forming method thereof, wherein high-temperature hot air is combined with a punching hole forming die roller to forcedly form a hot air punching film with naturally shrinkable convex edge on a polymer plastic film surface. The plastic film surface is provided with a plurality of through holes, and the edges of the through holes in the plastic film surface are naturally shrinkable convex edges. The hot air punching film has the advantages that: firstly, the hot air punching film formed by high-temperature air flow radically solves the problems that the edge of a hole punched by flames is burned, the flexibility of the plastic film is damaged by the burned hole edge, and secondary injury to skin, particularly to skin wound is caused, thereby ensuring the flexibility of the punched hole edge; secondly, due to adoption of the hot air punching, pollution of harmful gases to the punched plastic film surface and to atmosphere environment is completely avoided, so that the safety of the punched plastic film is guaranteed fundamentally; and thirdly, the hot air punching is adopted to ensure the flexibility and the smoothness of the plastic convex edge.

Owner:黄利光

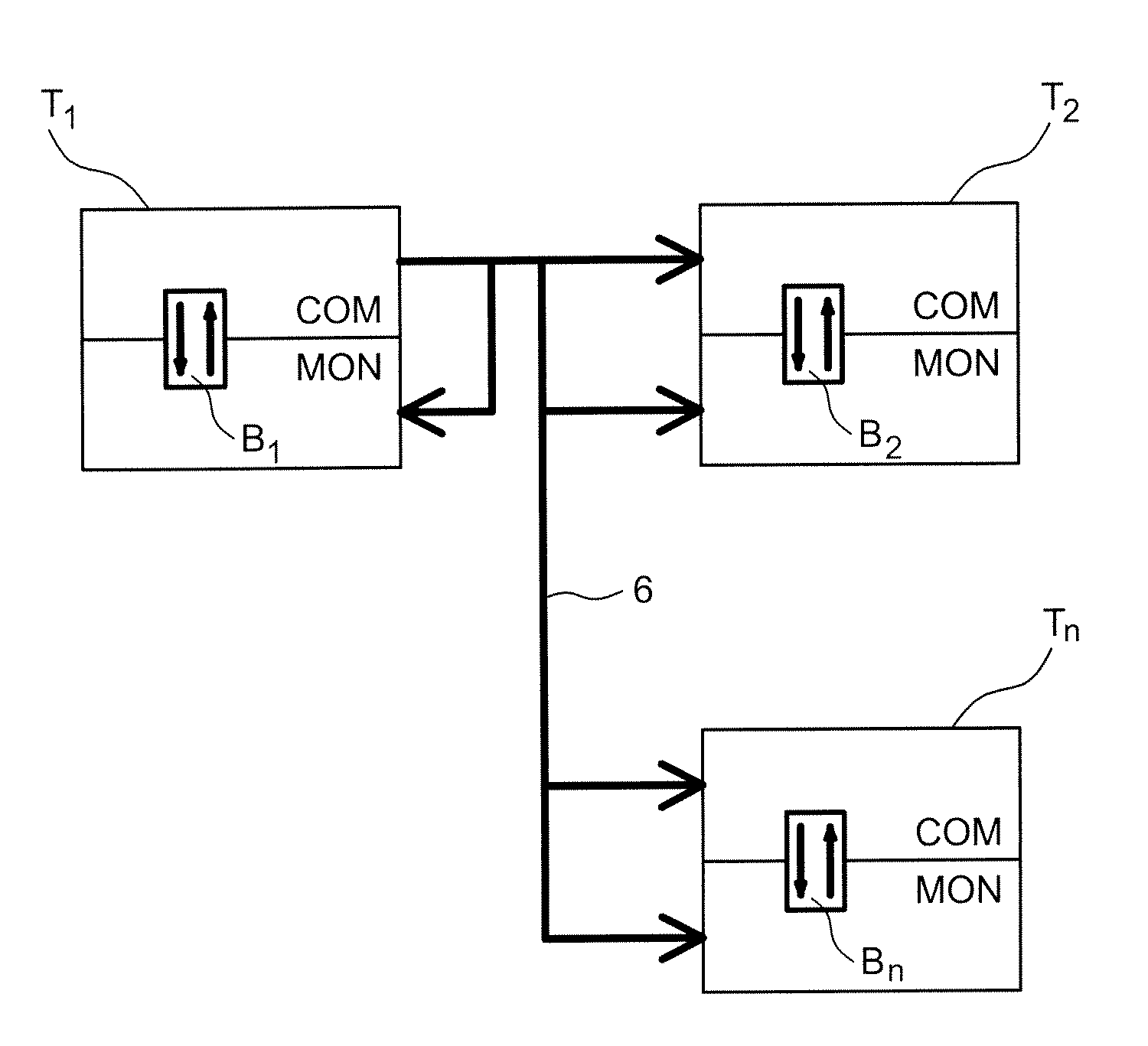

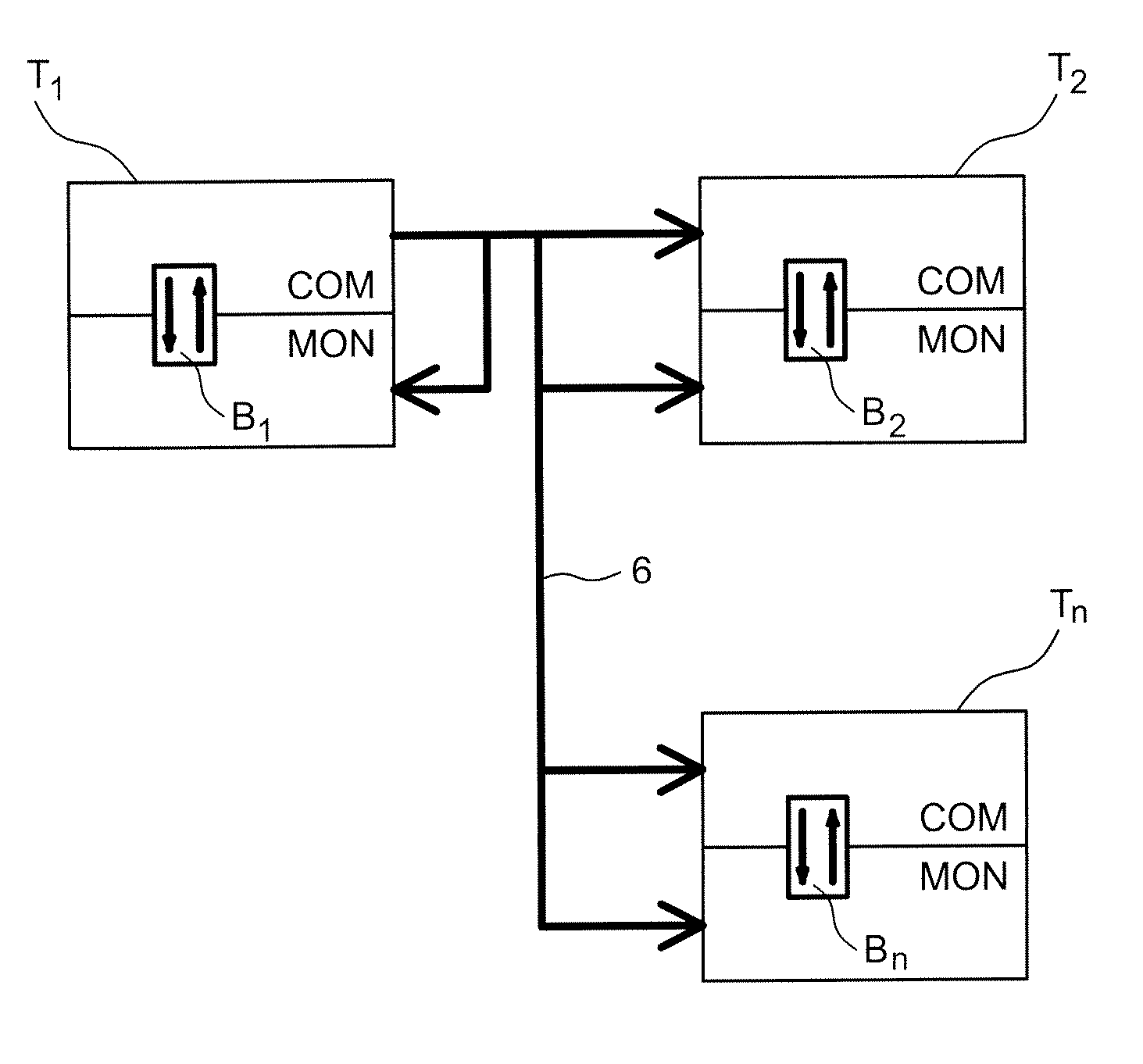

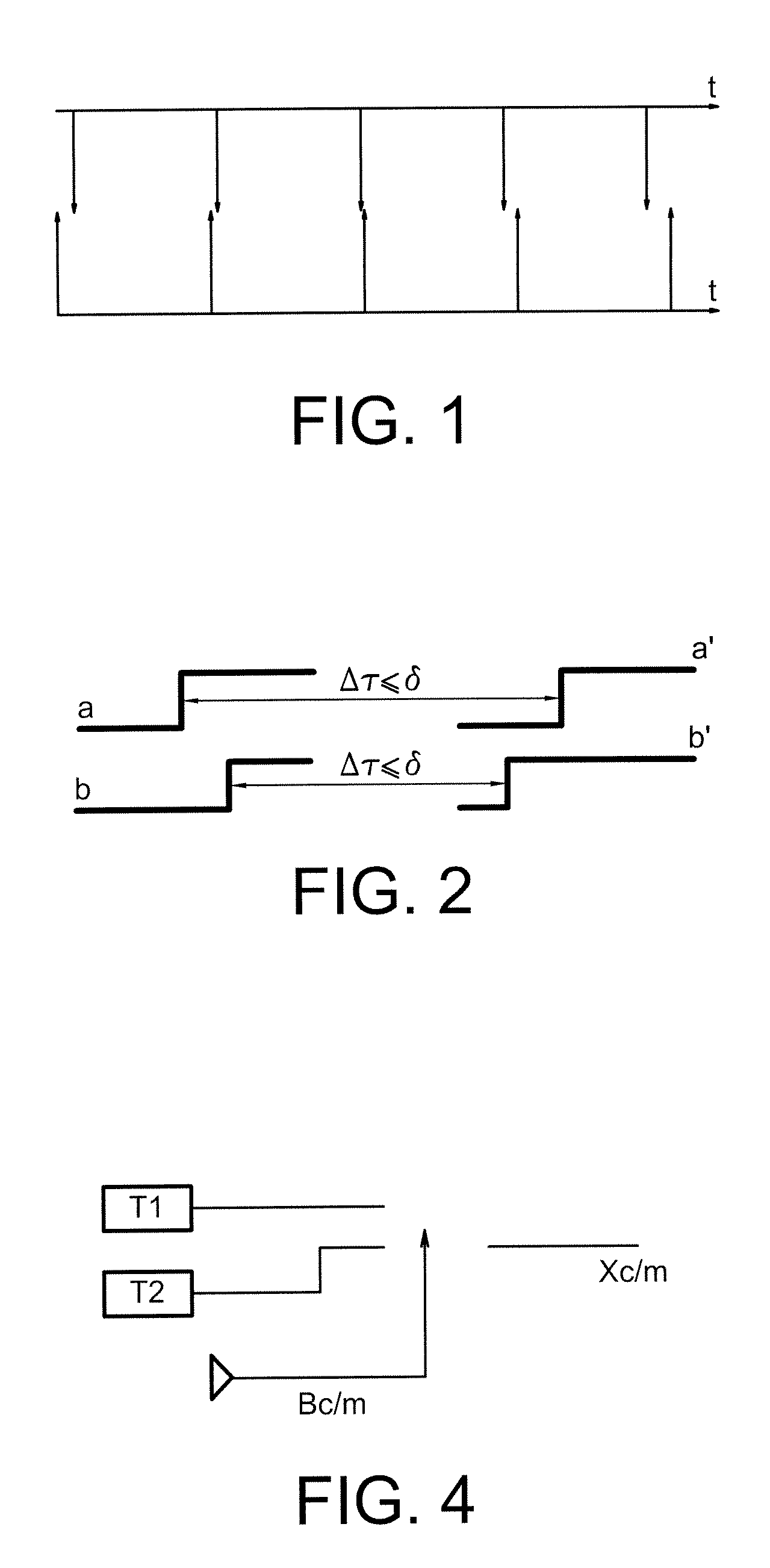

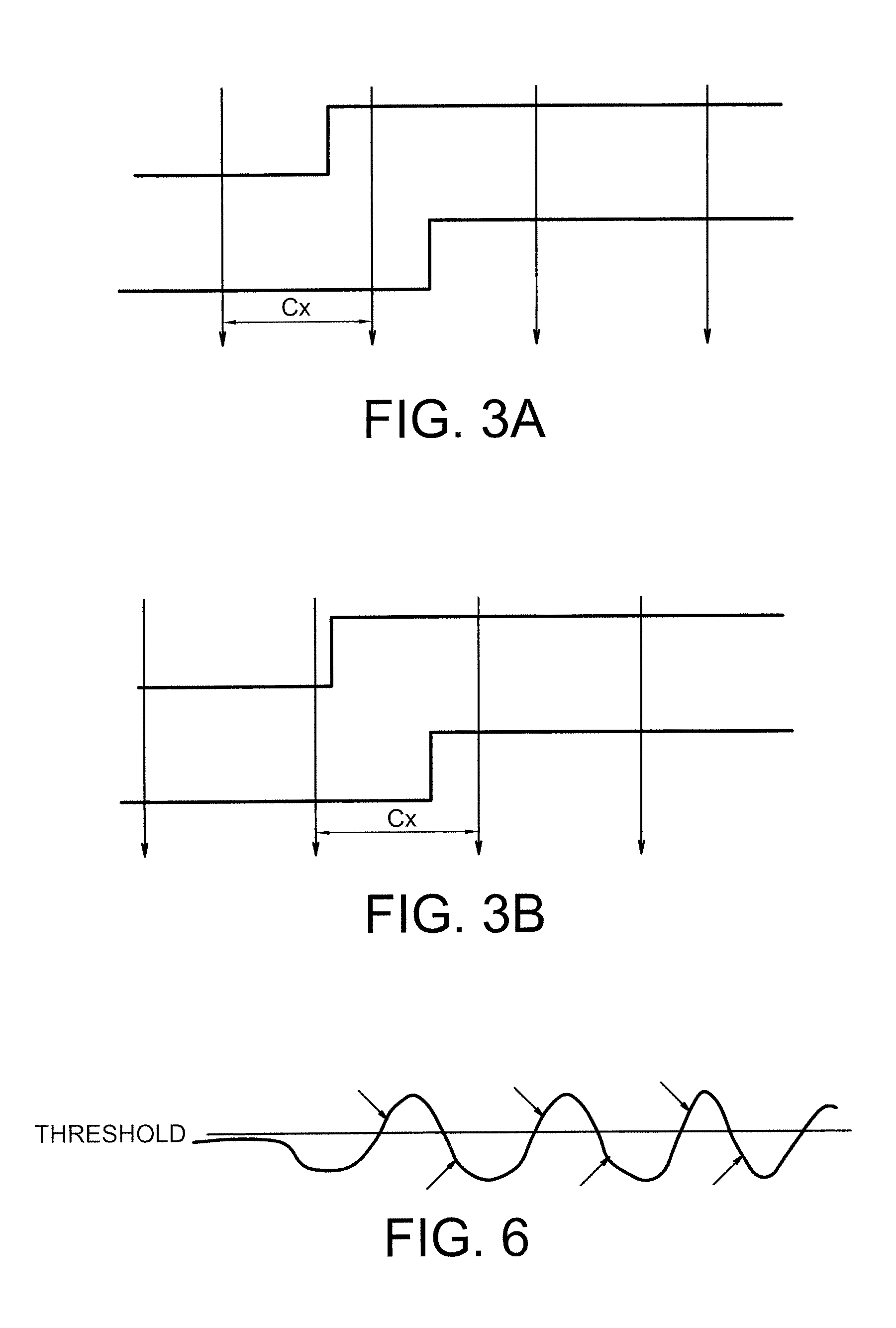

Method and device for consolidation by software synchronisation in flight control computers

InactiveUS7890221B2Ensure smoothnessAnalogue computers for trafficError detection/correctionIsochronous signalComputer software

A method for synchronising two asynchronous control and monitoring units of a computer, wherein each of these units comprises a computation unit. The method includes a computation of independent local Boolean signals, each having a Boolean inertia greater than the temporal uncertainties, due to the latencies in transmission between computers and the precision of the sampling controlled by the clock cycle of each unit, capable of affecting them. The method also includes an exchange, between the two units, of local signals, with each unit sending a locally computed value to the other unit, the generation of a pair of synchronised signals, in each unit, based on the local value and the value received from the other unit, and the formation of a consolidated signal based on the pair of synchronised signals.

Owner:AIRBUS OPERATIONS (SAS)

Method and device for consolidation by software synchronisation in flight control computers

InactiveUS20070271010A1Ensure smoothnessAnalogue computers for trafficError detection/correctionMonitor unitReal-time computing

This invention relates to a method for synchronising two asynchronous control and monitoring units of a computer, wherein each of these units comprises a computation unit, which method comprises: a computation of independent local Boolean signals, each having a Boolean inertia greater than the temporal uncertainties, due to the latencies in transmission between computers and the precision of the sampling controlled by the clock cycle of each unit, capable of affecting them, an exchange, between the two units, of local signals, with each unit sending a locally computed value to the other unit, the generation of a pair of synchronised signals, in each unit, based on the local value and the value received from the other unit, the formation of a consolidated signal based on the pair of synchronised signals.

Owner:AIRBUS OPERATIONS (SAS)

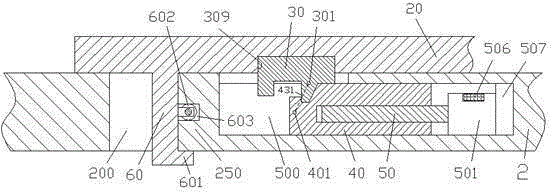

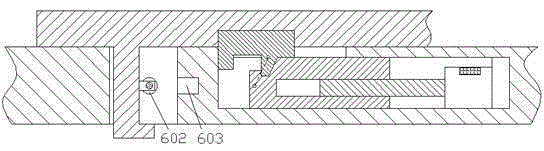

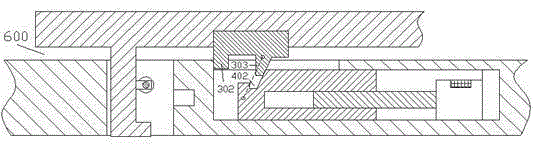

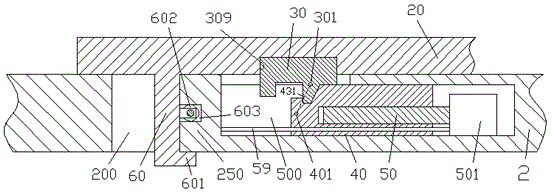

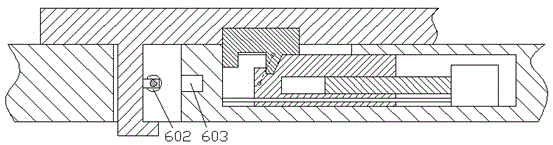

Adjustable computer cabinet with solar energy to provide power

InactiveCN105430974AAchieve mechanical lockingEasy mechanical lockingCasings/cabinets/drawers detailsEngineeringMechanical engineering

The invention discloses an adjustable computer cabinet with solar energy to provide power, which comprises a cabinet body (2) and a door cover (20), wherein the door cover (20) removably covers the opening of the cabinet body (2); the inner side, facing the cabinet body, of the door cover (20) is provided with a locking hook (60) in an integrated mode to pass through a through hole (200) in the wall part of the cabinet body and to be connected with the inner side of the wall part via a hook tail end (601) to realize to lock the door cover (20) on the cabinet body; the inner side of the door cover (20) is also provided with a driving concave part (309) for being connected with a driving block (30) so as to enable the driving block (30) to drive the driving concave part along the direction parallel to the plane of the wall part and the direction vertical with the plane of the wall part to further enable the locking hook (60) to be unlocked; and the inner side of the driving block (30) is provided with a driving connection convex part (303) for being matched with a connection concave part (402) in an inner thread sliding block (40) in screw driving by a screw rod (50).

Owner:吴琼

Yarn sizing device for spinning

InactiveCN106968068AGuaranteed parallelismReasonable structural designTextile treatment containersTextile treatment machine arrangementsSizingYarn

The invention discloses a textile yarn sizing device, which comprises a workbench, a sizing assembly and a material receiving assembly. The sizing assembly includes a sizing tank, a sizing device and a height adjustment device. The sliding cover plate is arranged on the adjusting plate, and the sliding cover plate is connected with the height adjustment device. The height adjustment device includes a moving column, a slider assembly and a limit rod. A limit rod is arranged on the right end surface of the clamping slide block, and the clamping slide block moves up and down along the moving column, and is limited and fixed by the limit rod. The present invention has strong practicability, simple structure, convenient installation, and improves the uniformity of yarn sizing, so that the quality of yarn after sizing is better. Phenomena such as fracture and wear occur, which is more convenient for actual operation and use, and improves the comprehensive utilization rate.

Owner:嵊州市靖洁纺织机械有限公司

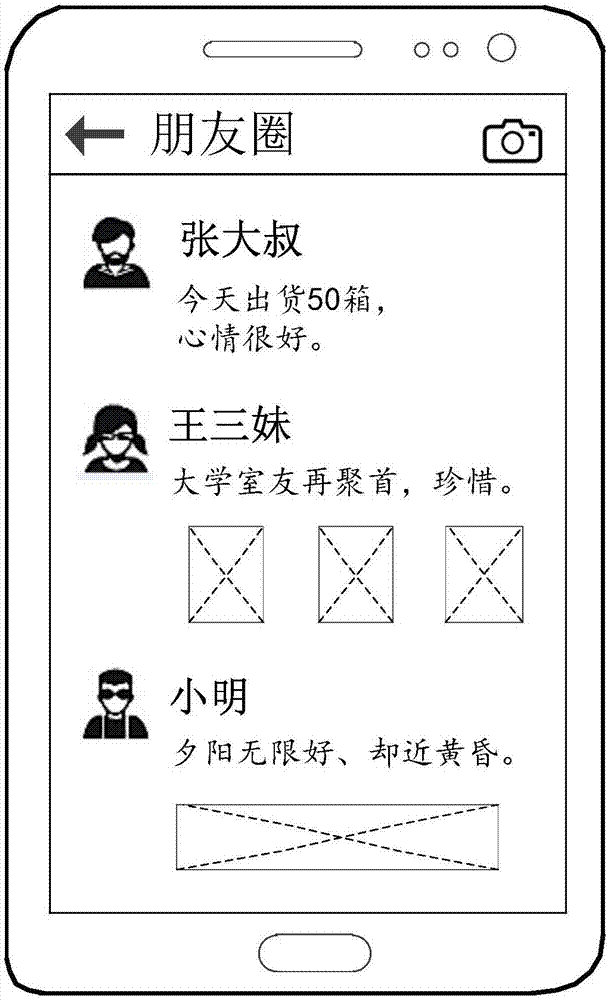

List display device and list display method

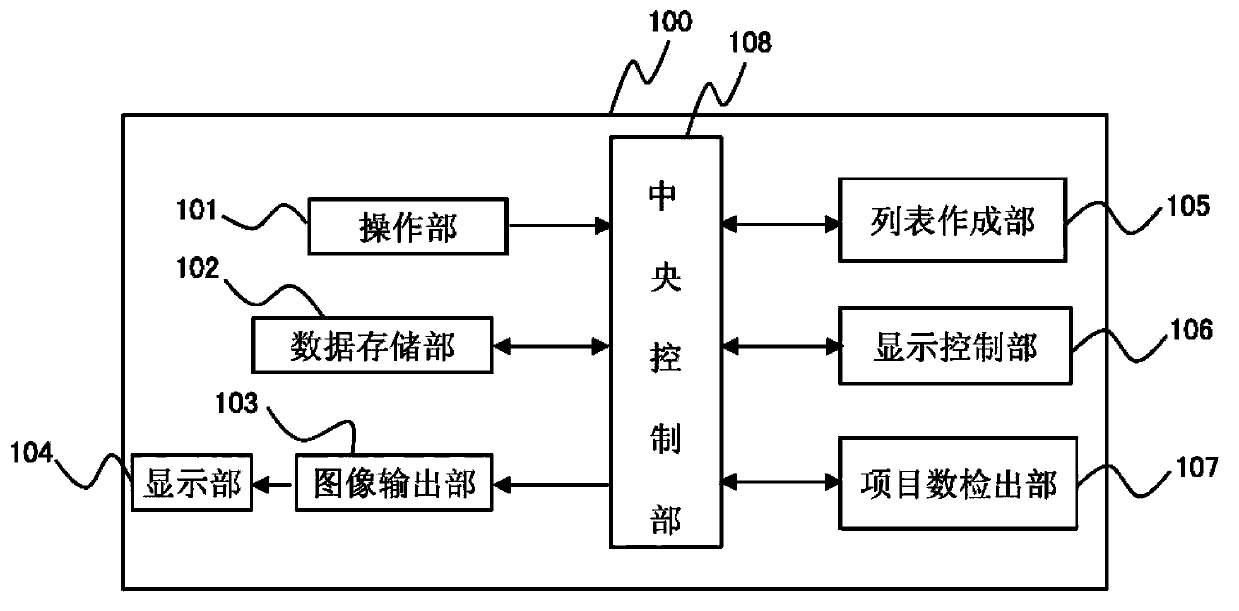

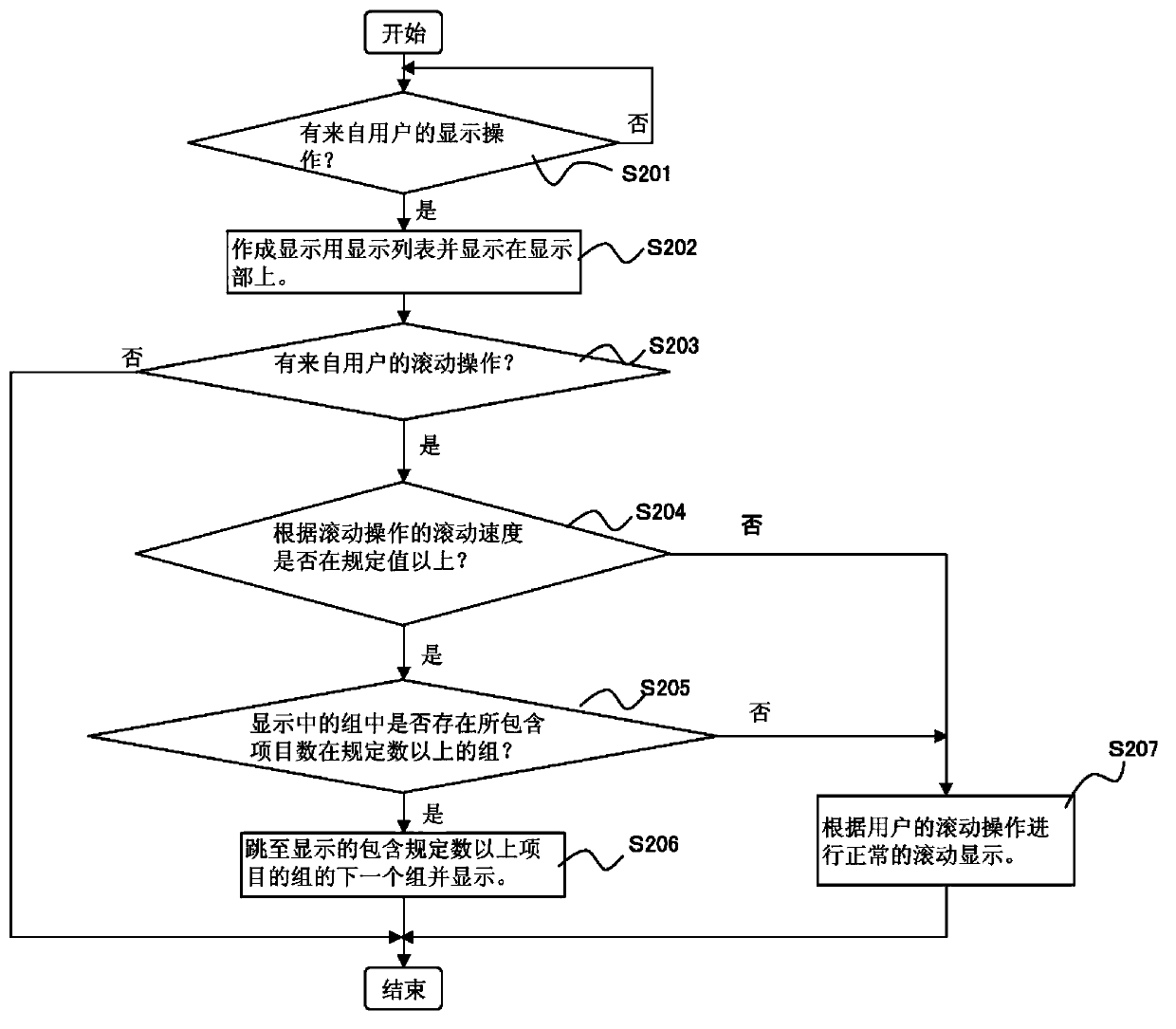

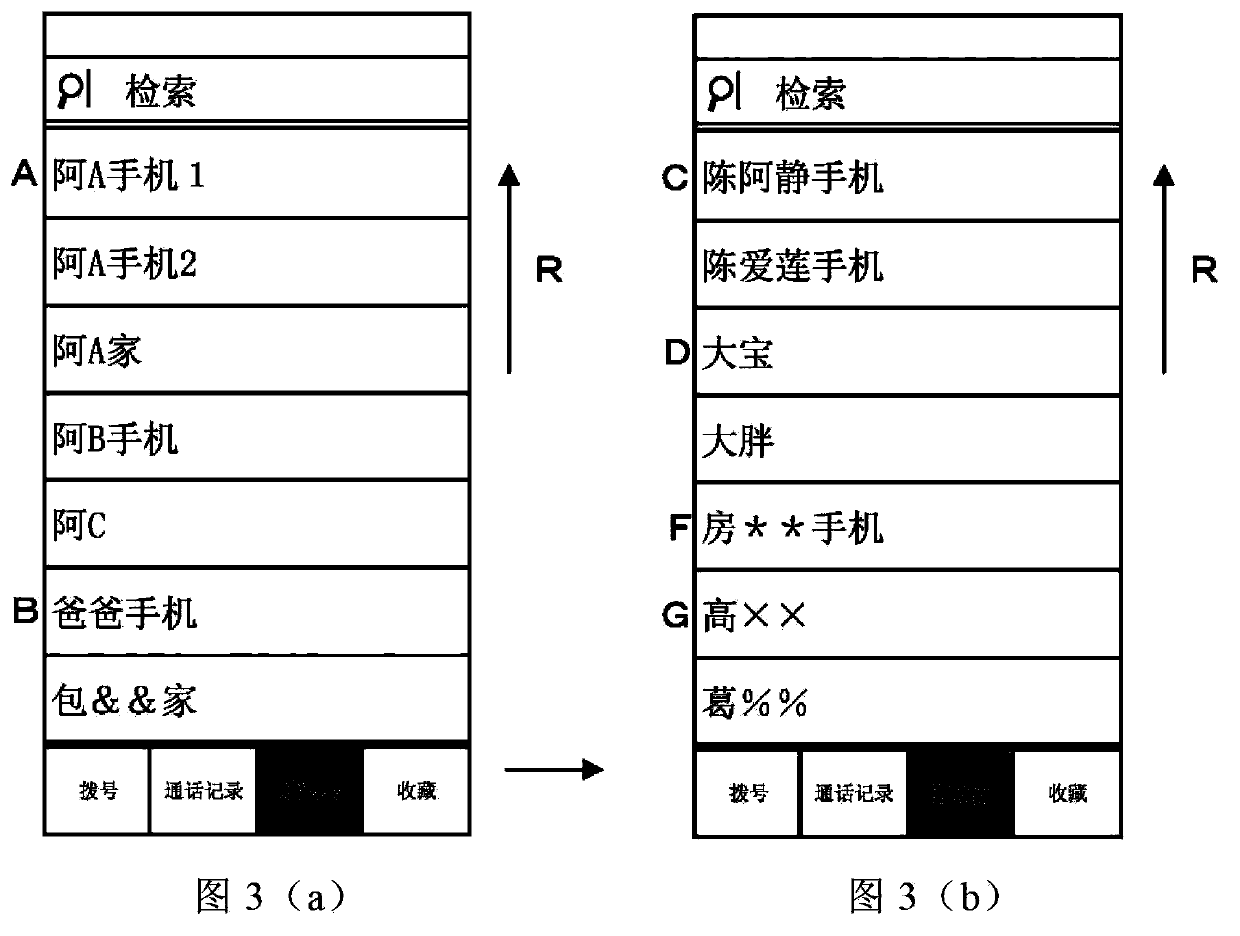

ActiveCN103995655AImprove satisfactionQuick display/retrievalSpecial data processing applicationsInput/output processes for data processingDisplay deviceRolling speed

The invention provides a list display device and a list display method. List display can be controlled according to the rolling operation of a user and the number of items in an item set existing in a list displayed in the operation process. The list display device is provided with a data storage part, an operation part, a list workout part, a display part, a display control part and an item number detection part, wherein the display control part controls the list displayed on the display part to be displayed in a rolling mode according to the rolling speed generated by the rolling operation, received by the operation part, of the user; the item number detection part detects out the number of items belonging to a set displayed by the display part in the rolling operation process. When the rolling speed is above the specified speed and the number, detected out by the item number detection part, of the items is above the specified number, the display control part carries out control in the mode that the next set in the rolling direction of the set displayed on the display part currently in the rolling operation process is displayed in a jumping mode, wherein the set displayed on the display part currently is provided with the items of the number above the specified number.

Owner:ALPINE ELECTRONICS INC

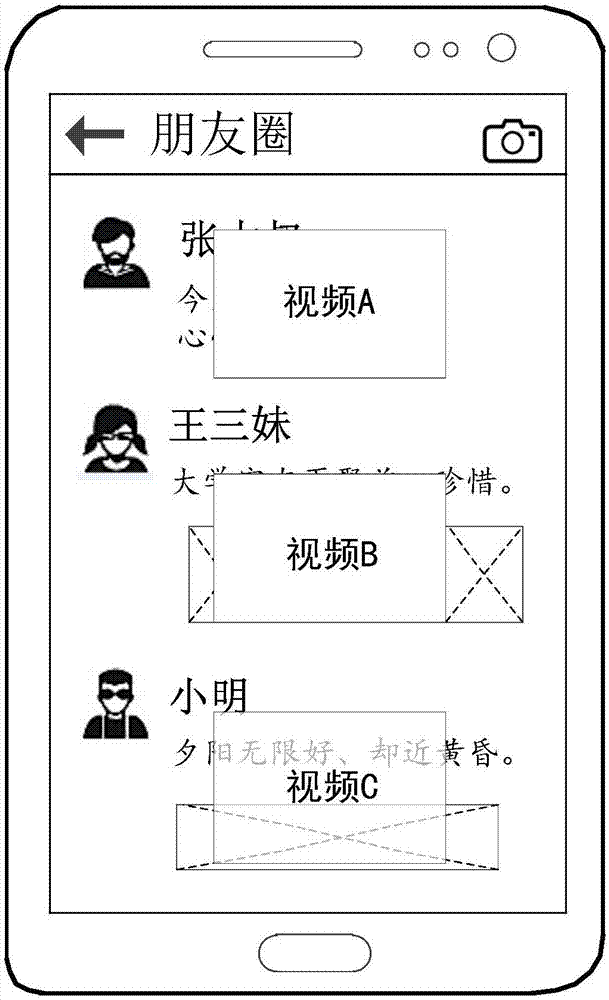

Information processing method and processing program device

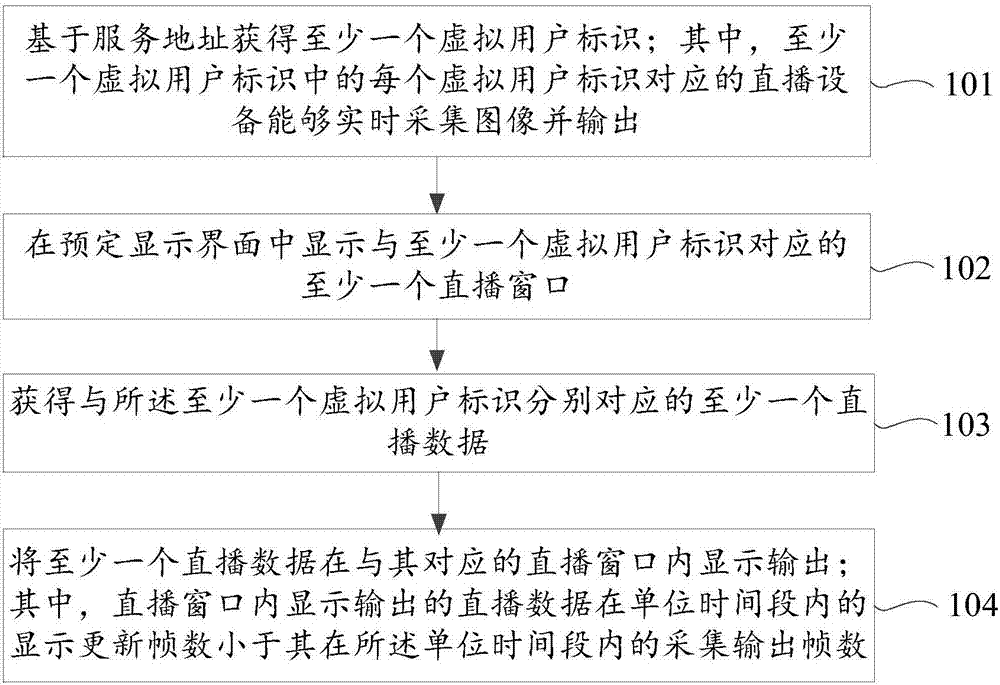

InactiveCN106993215AMeet real-time live broadcast viewing needsImprove acquisitionSelective content distributionInformation processingData display

The invention discloses an information processing method and a processing program device, aiming at solving the technical problem that the current video live-broadcasting sharing mechanism is defective and cannot meet the real-time live-broadcasting viewing demands of users. The method comprises the following steps: obtaining at least one virtual user identity based on a service address, wherein the live-broadcasting equipment corresponding to each virtual user identity in the at least one virtual user identity can real-timely acquire images and output the images; displaying at least one live-broadcasting window corresponding to the at least one virtual user identity in a predetermined display interface; obtaining at least one live-broadcasting data separately corresponding to the at least one virtual user identity; and displaying and outputting the at least one live-broadcasting data in the corresponding live-broadcasting window, and ensuring that the display update frame number of the live-broadcasting data displayed and output in the live-broadcasting window in a unit time period is smaller than the acquisition output frame number of the live-broadcasting data in the unit time period.

Owner:LENOVO (BEIJING) CO LTD

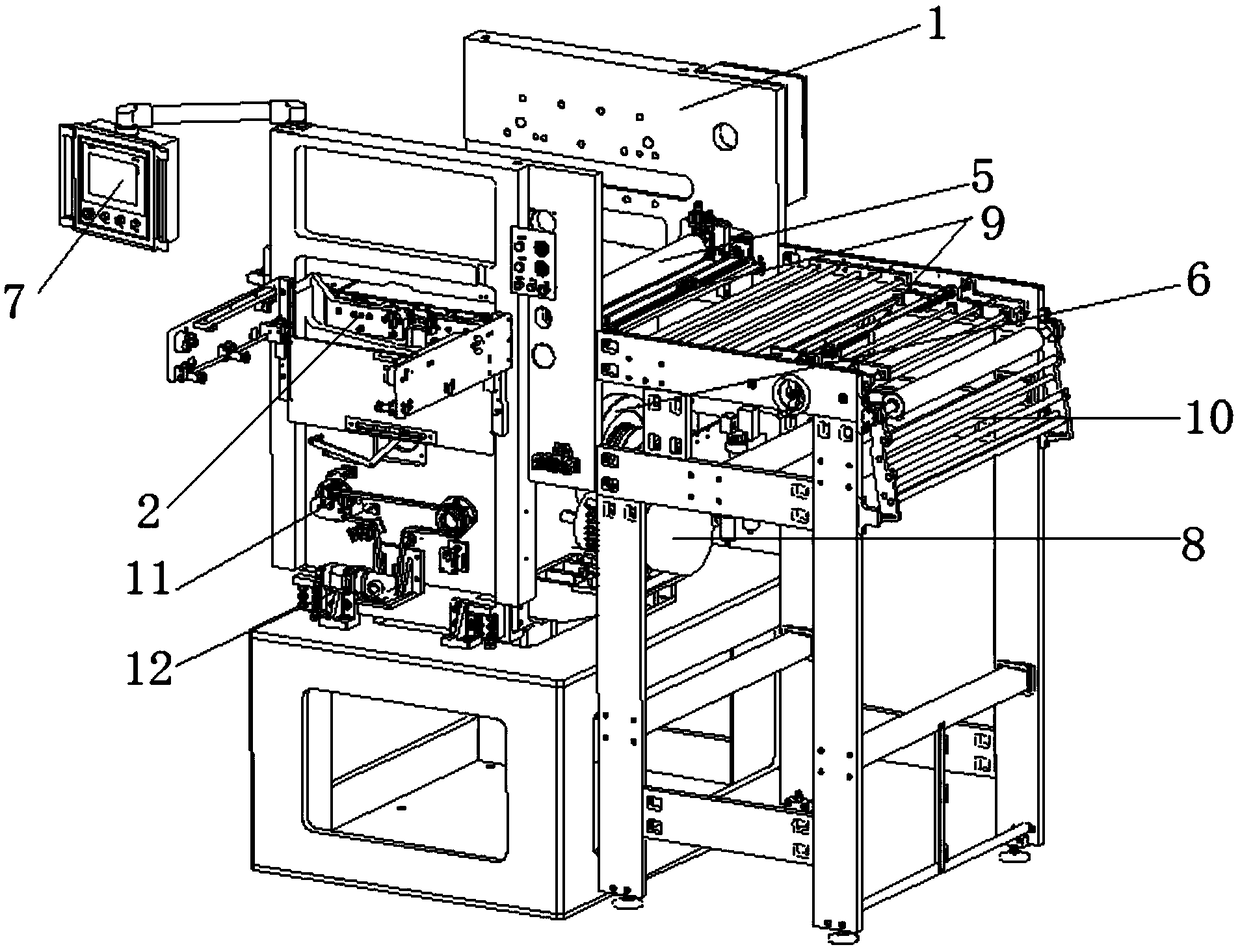

Mold table device of uncoiling die cutting machine

InactiveCN108789638AStable torque characteristicsEnsure smoothnessMetal working apparatusFeed driveEngineering

The invention relates to an all-servo mold table device of an uncoiling die cutting machine. The device comprises a mold table main body frame, an upper die cutting platform, a lower die cutting platform, a feed driving mechanism for guiding products to enter a die cutting station, and a discharge driving unit for guiding the products to shift out of the die cutting station; the feed driving mechanism and the discharge driving mechanism are both fixedly mounted on the lower die cutting platform; the lower die cutting platform is connected with a mold table driving unit; the die table driving unit controls the lower die cutting platform to move up and down; and the lower die cutting platform and the upper die cutting platform are pressed for die cutting of the products. Compared with the prior art, the device adopts an all-servo control and stick clamping mode to simplify mechanical structure and to improve the die cutting speed and the production efficiency; and through arrangement ofthe lower die cutting platform capable of moving, a lower mold is always bonded with the products during die cutting, and conveyed papers and the mold table are always maintained on the same plane, sothat the floating in the mold table is reduced, the up-down travel of the mold table is reduced, and the die cutting frequency can be greatly improved.

Owner:SHANGHAI ZIDAN FOOD PACKAGING & PRINTING CO LTD

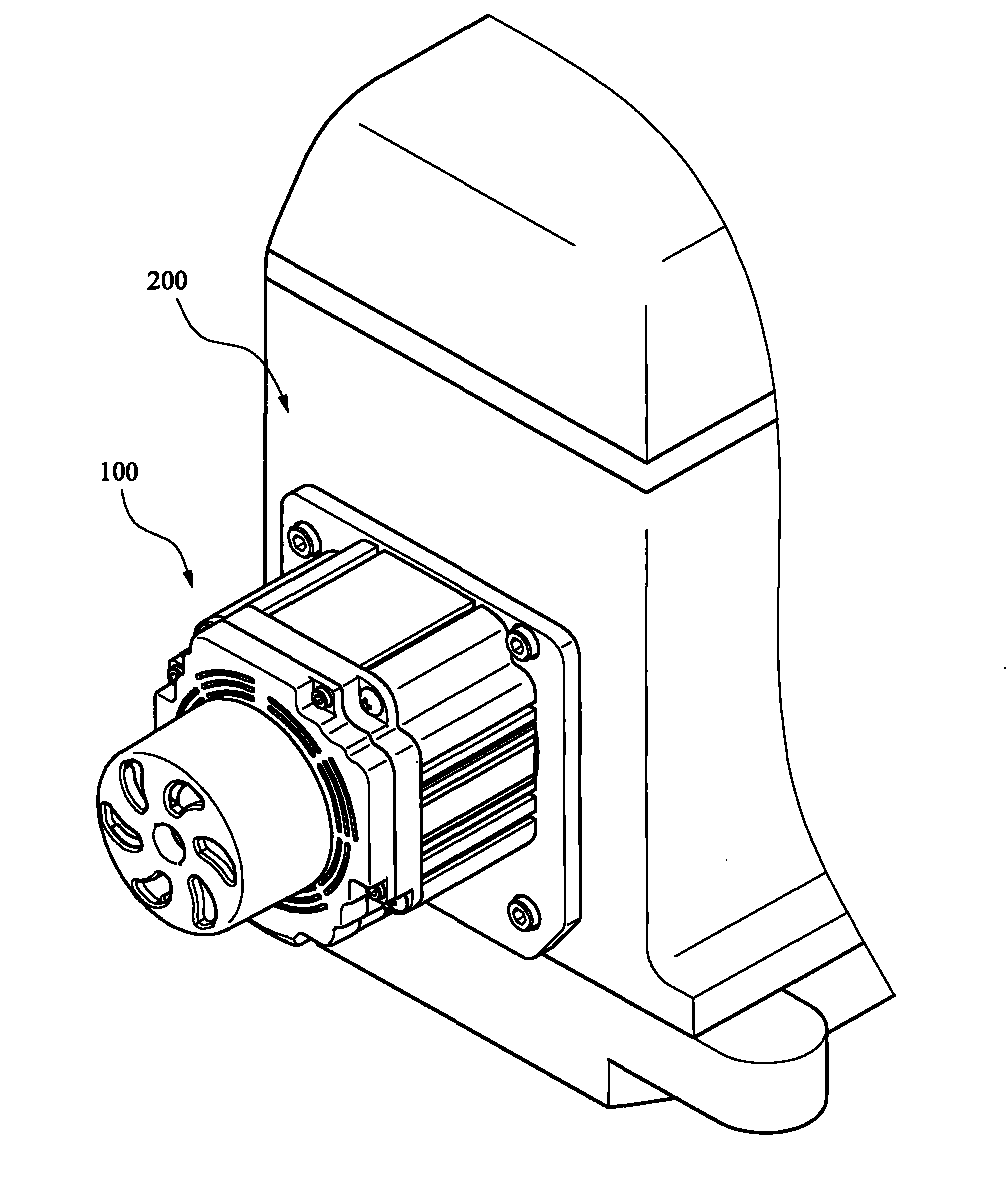

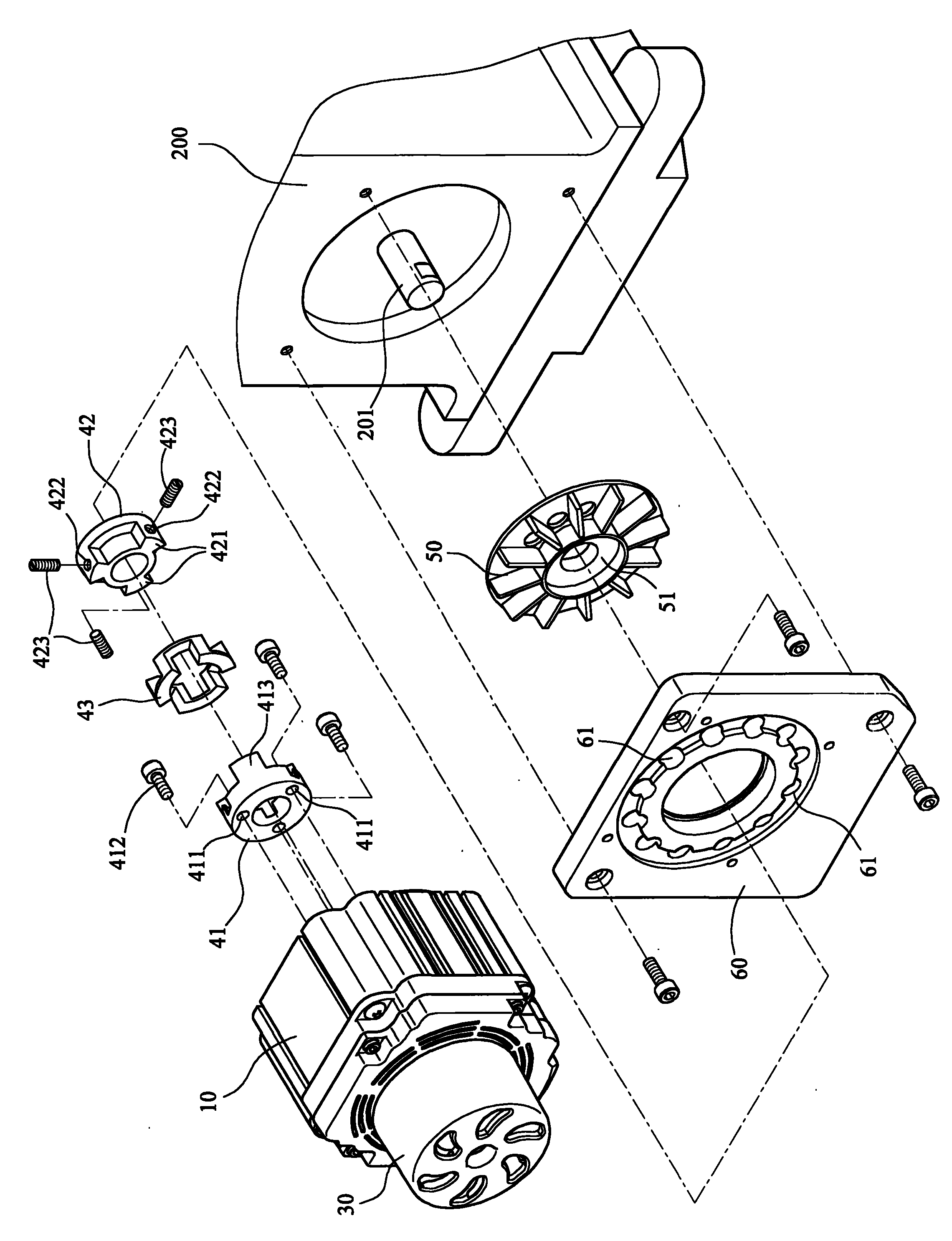

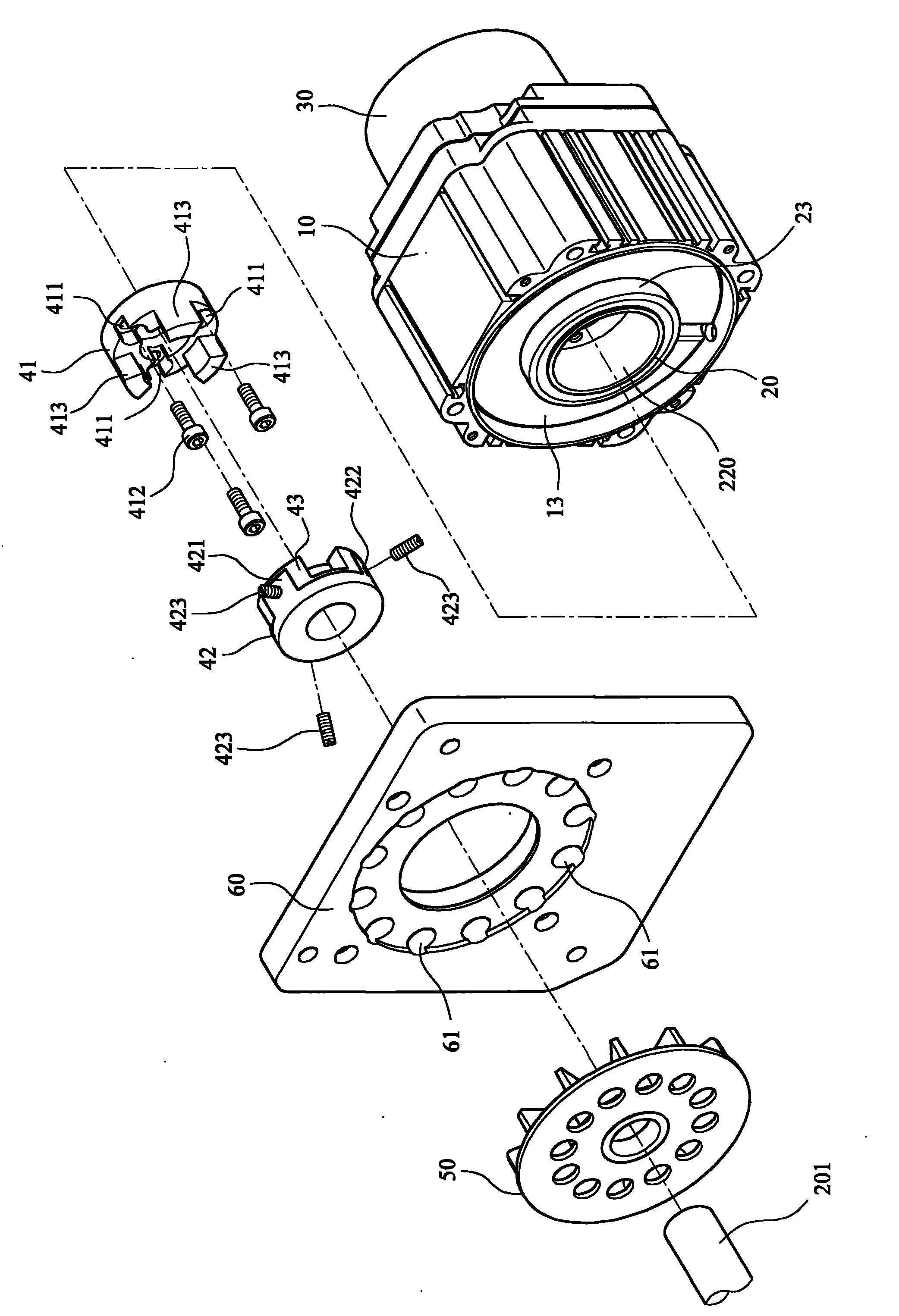

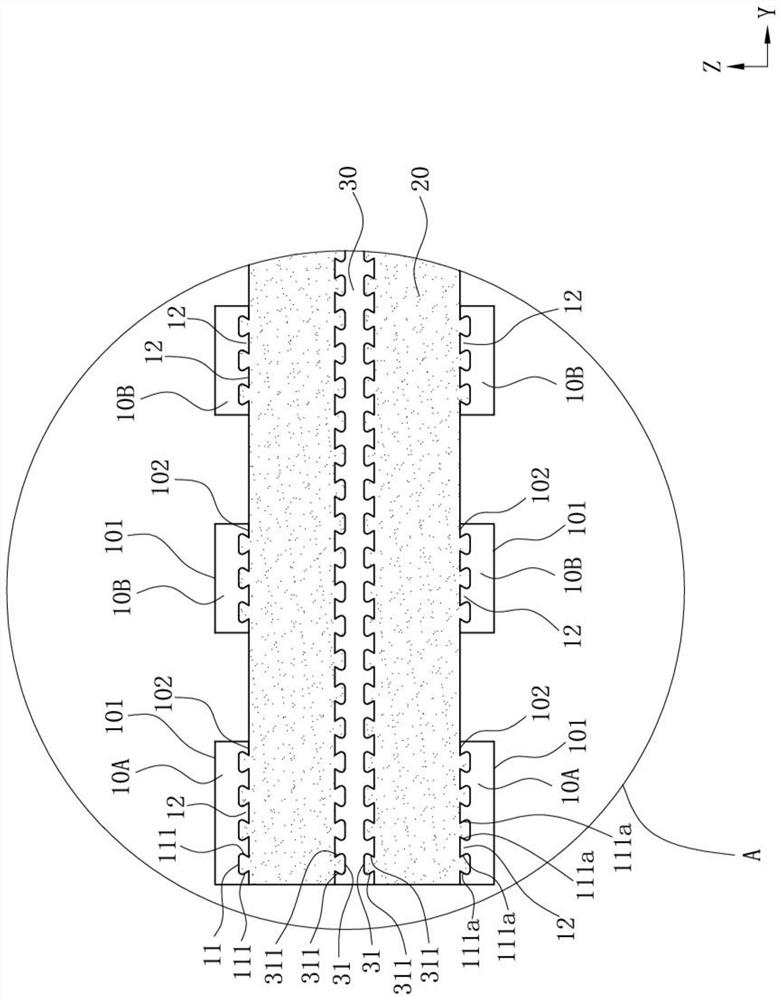

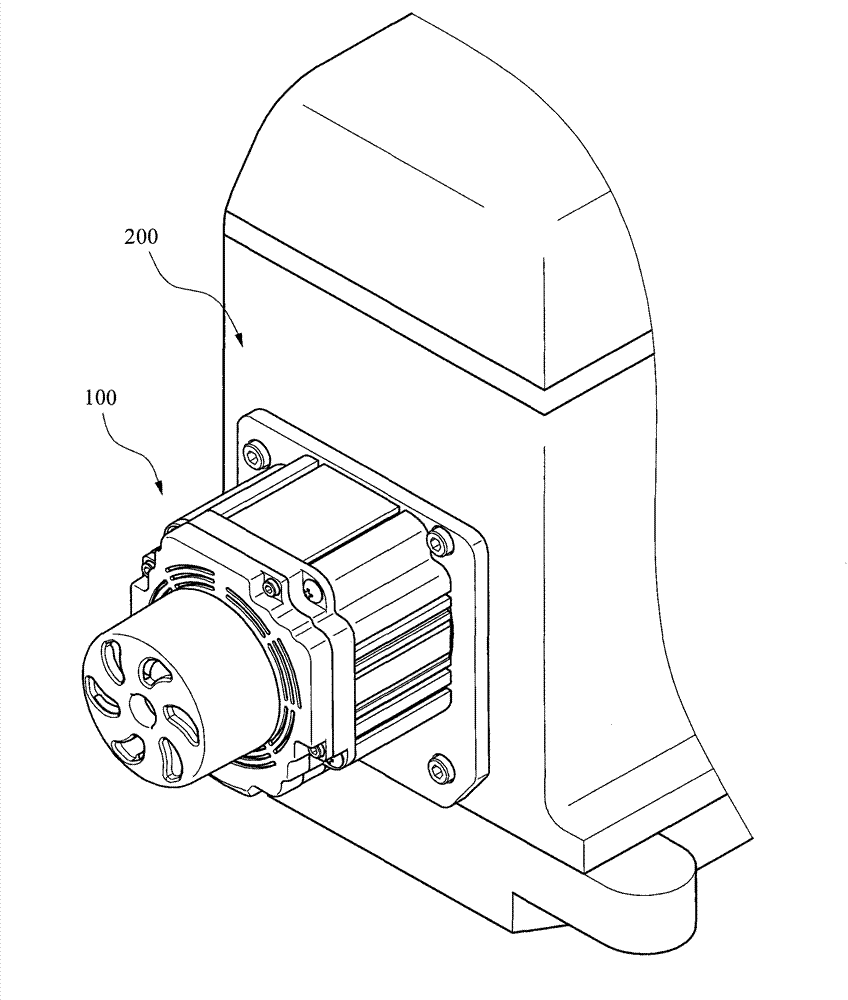

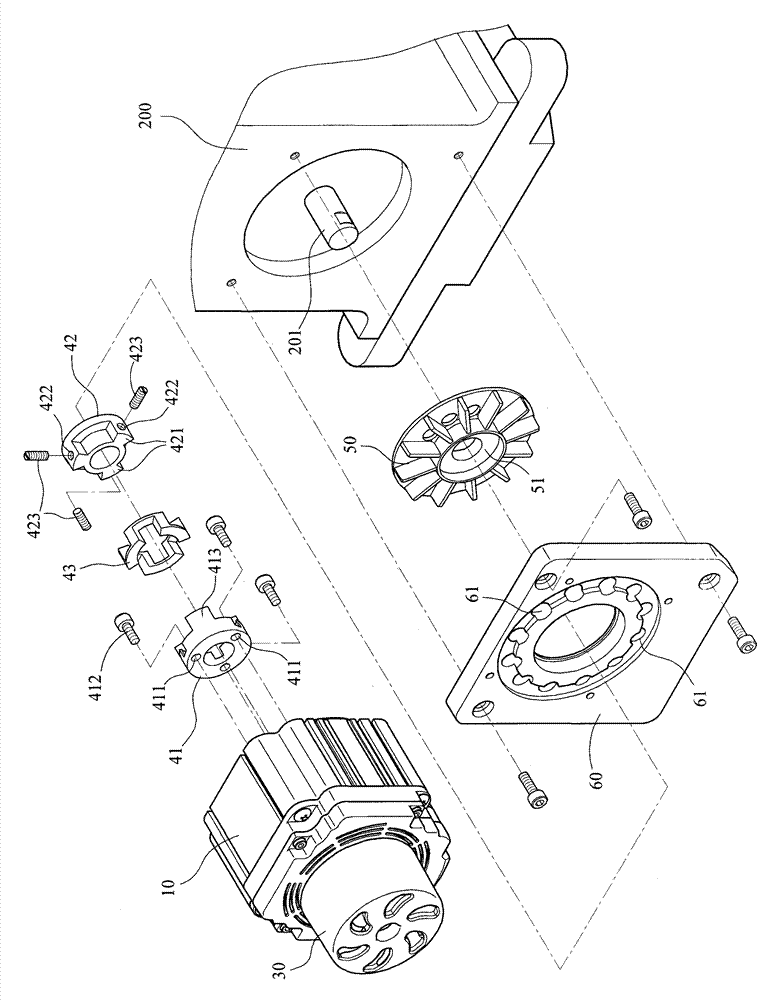

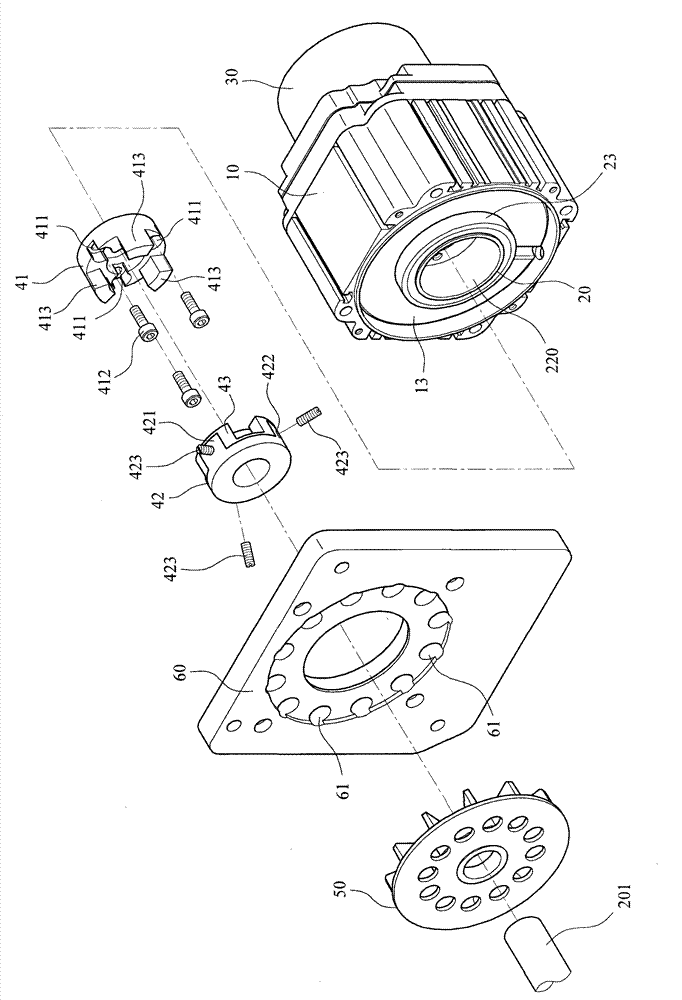

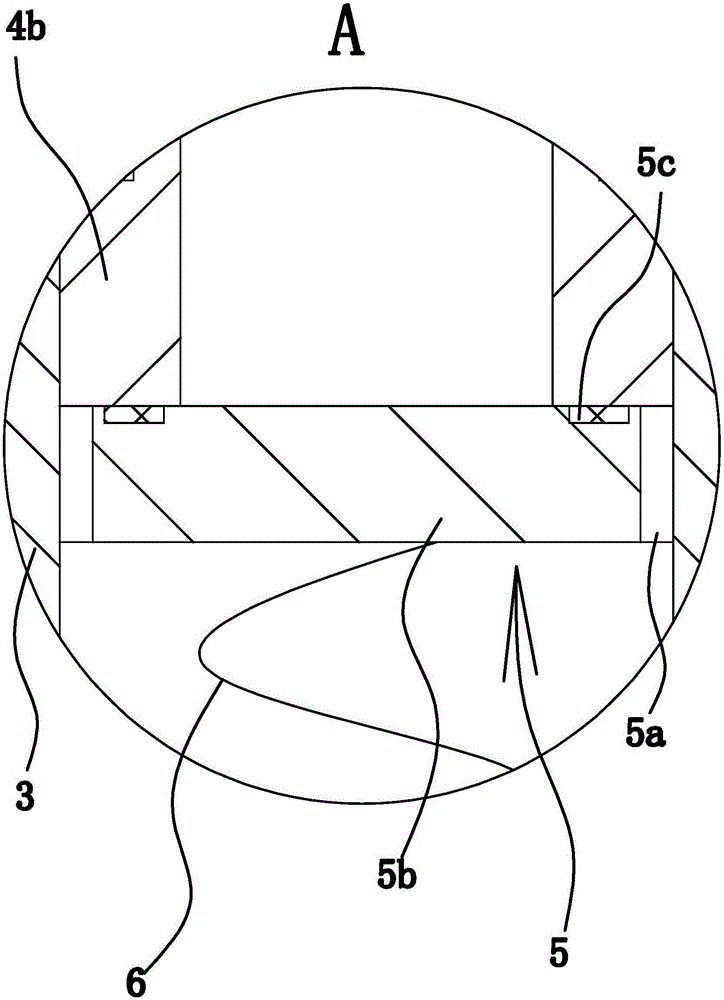

Assembly structure of motor

ActiveCN102075037ASave length spaceSmall footprintManufacturing dynamo-electric machinesCouplingDrive shaft

The invention discloses an assembly structure of a motor, which can directly assemble the motor on the side of an engine base. The motor is provided with a driving shaft, wherein a large-diameter part is arranged on a first end of the driving shaft; a small-diameter part is arranged on a second end of the driving shaft; a first accommodating space of a coaxial core is convexly formed in the large-diameter part and is used for fixedly arranging a first transmission part; and a second transmission part is fixedly arranged on a mandrel on the side of the engine base. The driving shaft of the motor, the first transmission part, the mandrel of the engine base and the second transmission part on the mandrel are radially and coaxially assembled in the large-diameter part of the driving shaft through the mutual corresponding coupling transmission of the second transmission part on the mandrel and the first transmission part on the driving shaft, so that the motor directly drives the mandrel of the engine base.

Owner:H S MASCH CO LTD

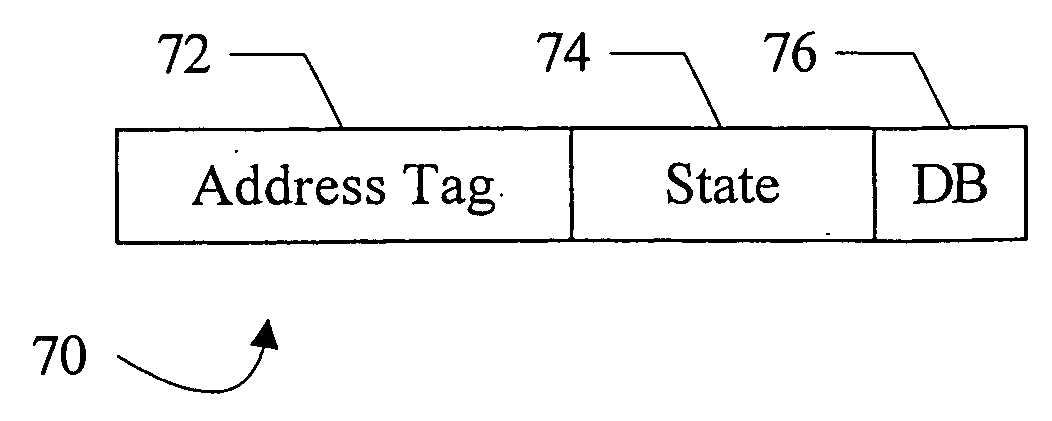

System and method enabling efficient cache line reuse in a computer system

A system permits unacknowledged write backs in a computer. The computer has a plurality of processors and a shared memory. The shared memory stores data in terms of memory blocks, and each processor has a cache. Associated with each cache line is a tag containing the address of the block at that line, and its state. A duplicate copy of the tag information (DTAG) for each processor cache is also provided, and each section of the DTAG that corresponds to a given processor is organized into a primary DTAG region and a secondary DTAG region. The secondary DTAG region preferably stores tag information for a dirty version of a block, while the write back of the block is in flight to memory. This frees the primary DTAG region to store tag information for a block other than the dirty block, but using the same cache line.

Owner:SAMSUNG ELECTRONICS CO LTD

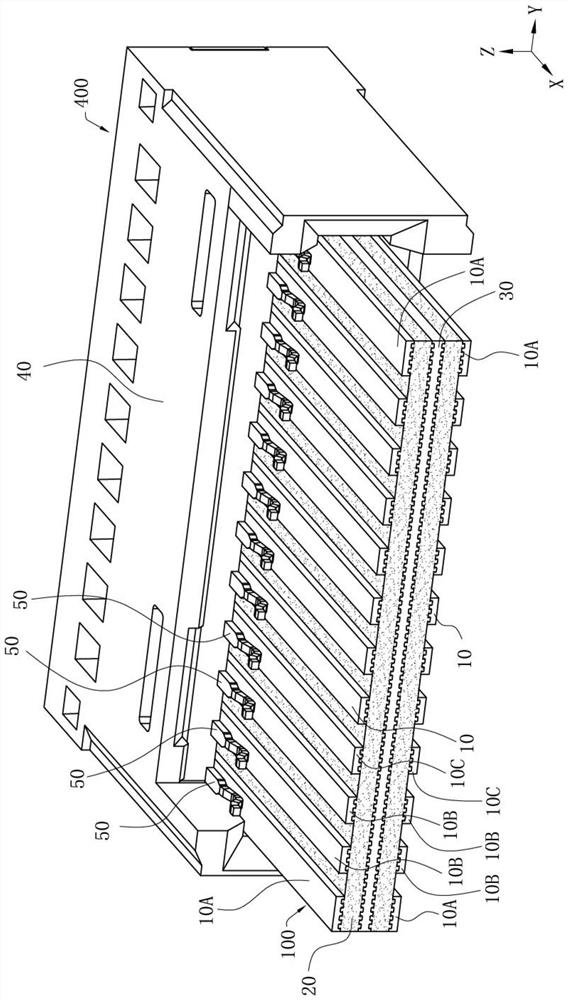

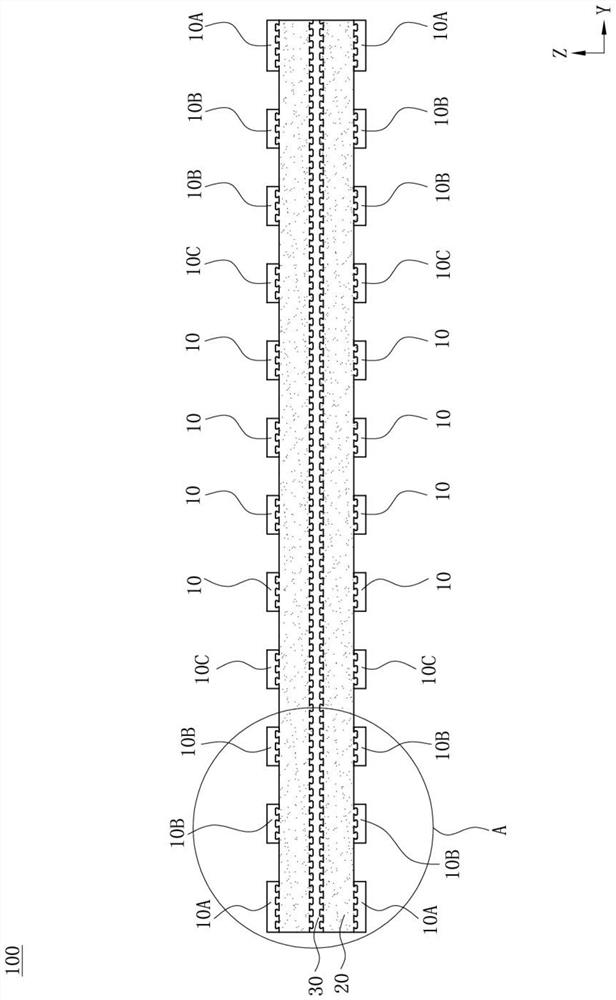

Electronic substrate, connector assembly and manufacturing method of electronic substrate

ActiveCN111986837AImprove binding tightnessGuaranteed uniformityCoupling device connectionsCommunication cablesConductive materialsMechanical engineering

The invention discloses an electronic substrate. The electronic substrate comprises a polytetrafluoroethylene base layer and a plurality of conductive strips arranged on the polytetrafluoroethylene base layer, each conductive strip is provided with a first surface and a second surface which are opposite up and down, wherein at least one groove is concavely formed from the second surface to the first surface; the grooves do not penetrate through the conductive strips in the vertical direction; the grooves extend along the front-back direction, the polytetrafluoroethylene base layer partially fills the grooves, the groove walls of the grooves are provided with at least one stopping surface, the stopping surface prevents the part, filling the grooves, of the polytetrafluoroethylene base layerfrom being separated from the conductive strips in the direction opposite to the concave direction of the grooves, and a conductive path of the conductive strip is defined to transmit signals in thefront-back direction. Compared with the prior art, the polytetrafluoroethylene material and the conductive material in the electronic substrate are tightly combined, loss can be reduced when signals are transmitted on the conductive strip, and transmission is stable.

Owner:DEYI PRECISION ELECTRONIC IND CO LTD PANYU

Assembly structure of motor

ActiveCN102075037BSave length spaceSmall footprintManufacturing dynamo-electric machinesCouplingDrive shaft

The invention discloses an assembly structure of a motor, which can directly assemble the motor on the side of an engine base. The motor is provided with a driving shaft, wherein a large-diameter part is arranged on a first end of the driving shaft; a small-diameter part is arranged on a second end of the driving shaft; a first accommodating space of a coaxial core is convexly formed in the large-diameter part and is used for fixedly arranging a first transmission part; and a second transmission part is fixedly arranged on a mandrel on the side of the engine base. The driving shaft of the motor, the first transmission part, the mandrel of the engine base and the second transmission part on the mandrel are radially and coaxially assembled in the large-diameter part of the driving shaft through the mutual corresponding coupling transmission of the second transmission part on the mandrel and the first transmission part on the driving shaft, so that the motor directly drives the mandrel of the engine base.

Owner:H S MASCH CO LTD

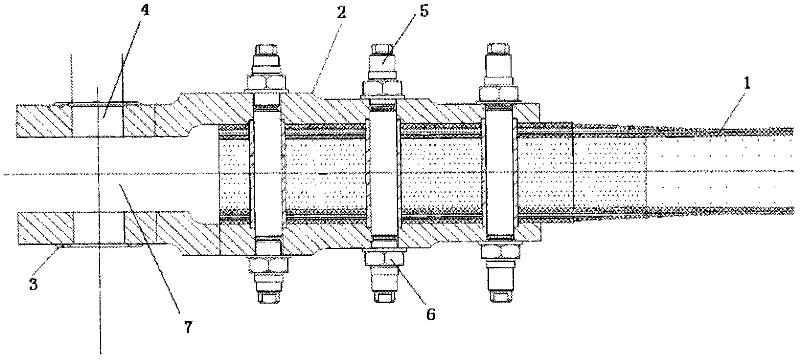

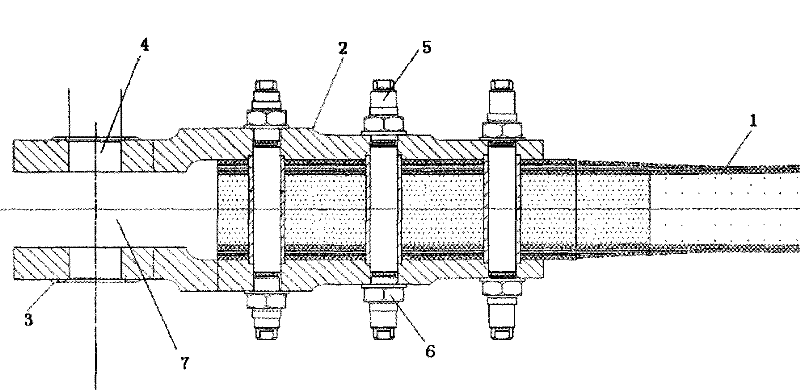

Road vibration isolation system for preventing underground spatial structure vibration and construction method thereof

ActiveCN105369702ATo achieve the effect of vibration reductionEnsure smoothnessPaving gutters/kerbsClimate change adaptationSurface layerSpatial structure

The invention discloses a road vibration isolation system for preventing underground spatial structure vibration and a construction method thereof. A steel spring floating plate is arranged between the roof of a building in an underground space and an asphalt pavement as a travelling pavement above the roof, through spring shear stiffness of spring vibration isolators and compression stiffness of flexible water stopping materials at left and right sides of the floating plate, floating plate vertical support and lateral support stiffness is formed, through a shear hinge and the flexible water stopping materials at front and rear ends of the floating plate, floating plate vertical deformation and smooth longitudinal stability without mutation are realized, and the flexible water stopping materials, kerb drainage ditches and longitudinal drainage ditches are arranged so that accumulation of rainwater in gaps between the floating plate and a slope surface layer is avoided and rainwater-caused corrosion damage to the spring vibration isolators is prevented. The road vibration isolation system can prevent road traffic-caused underground spatial structure vibration, has good vibration isolation effects, can reliably work in an outdoor environment for a long time and is convenient for construction.

Owner:ARCHITECTURAL DESIGN RES INST OF GUANGDONG PROVINCE +1

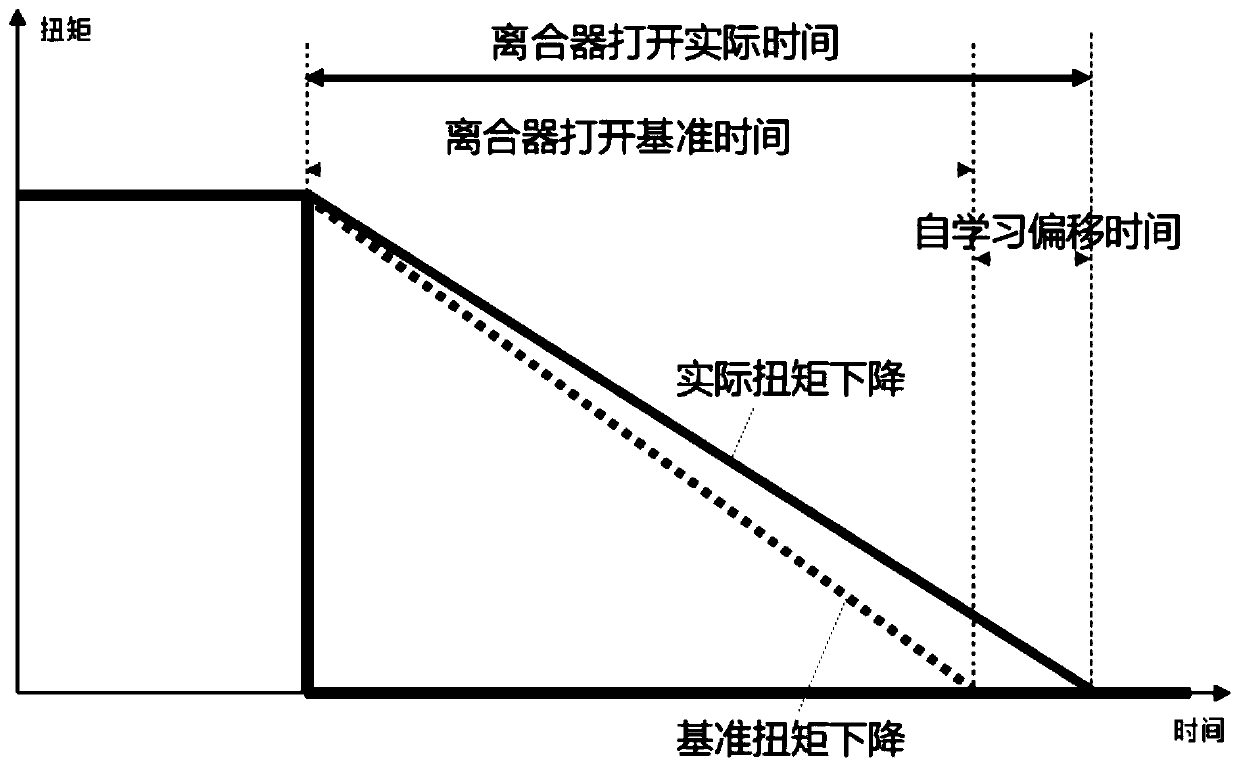

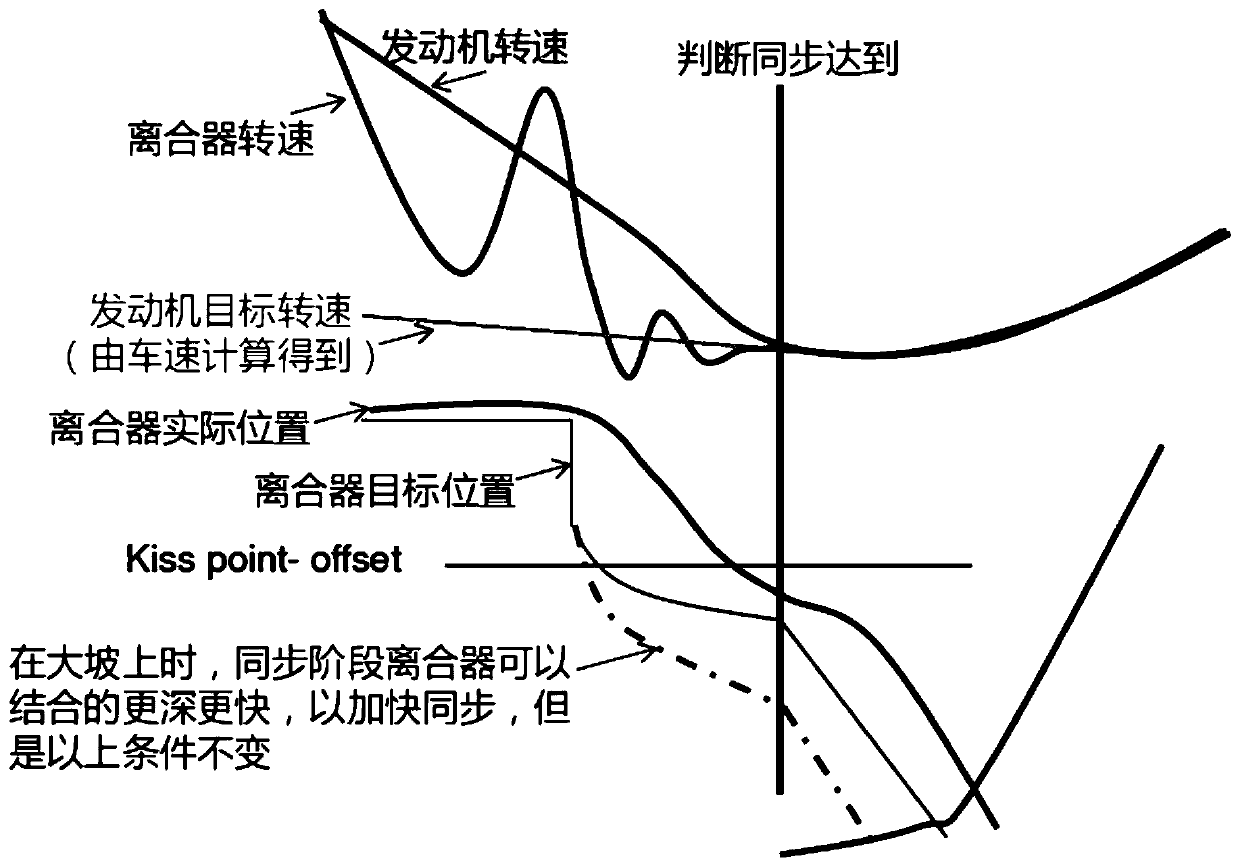

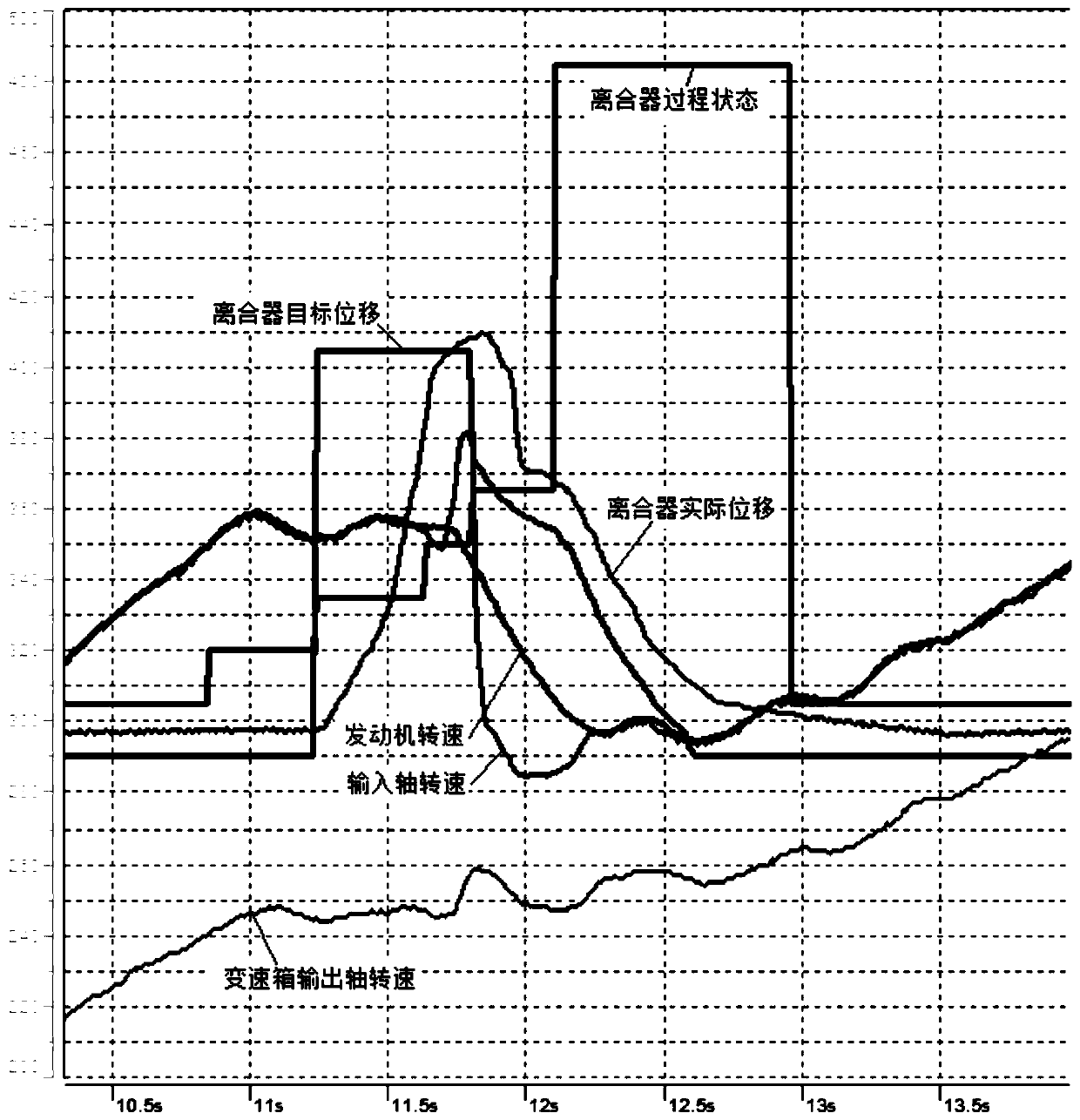

Heavy duty vehicle AMT engine and clutch self-adaption coordination control method

ActiveCN110159743AOptimal separation pointEasy to separateMechanical actuated clutchesGearing controlEngineeringControl theory

The invention relates to a heavy duty vehicle AMT engine and clutch self-adaption coordination control method. The heavy duty vehicle AMT engine and clutch self-adaption coordination control method comprises the following steps of firstly, the Roll off stage, wherein an engine is subjected to torque decreasing before a gear is disengaged, and then a clutch is controlled to be opened; secondly, theSpeed Contral stage, wherein the engine is subjected to speed regulation to the target rotating speed; and thirdly, the Roll On stage, wherein the clutch is engaged, after the rotating speed of the engine and the rotating speed of the clutch are synchronized, the torque of the engine is restored. The design can adaptively learn the clutch separation time and ensure the vehicle smoothness and thedynamic property.

Owner:DONGFENG COMML VEHICLE CO LTD

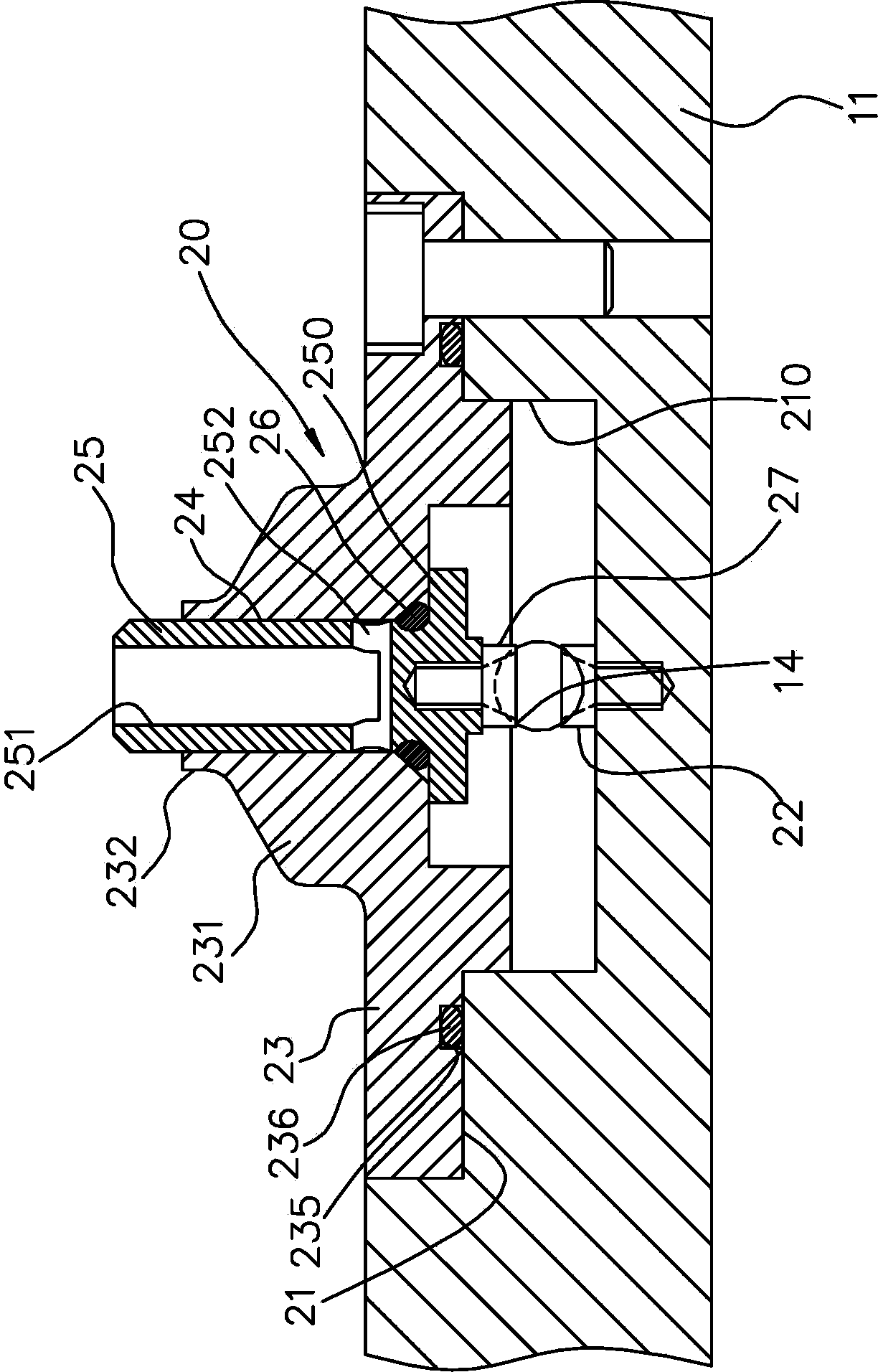

Air-valve structure and inflatable seat applying same

InactiveCN104235386AReduce generationNo elastic fatigue problemOperating means/releasing devices for valvesSemiconductor/solid-state device manufacturingEngineeringAir cavity

The invention relates to an air-valve structure and an inflatable seat applying the same, in particular to the air-valve structure with few parts involved and not easy to damage. The air-valve structure comprises a base body, a valve body and a floating piece, an inserting groove is formed in the base body, a magnetic piece is arranged on the inner bottom surface of the inserting groove, the valve body is arranged in the inserting groove of the base body in a locked manner, a through penetrating hole is formed in the center of the valve body, the floating piece is slidably arranged in the penetrating hole of the valve body, an air hole with an upward opening is formed in the center of the floating piece, at least one guide hole communicated with the air hole is formed in an annular abutted piece on the periphery of the floating piece, and another magnetic piece corresponding to the magnetic piece of the base body and repellent to the same is arranged on the bottom surface of the floating piece. By the aid of the design that the magnetic piece inside the base body is repellent to the magnetic piece of the floating piece in the valve body, the floating piece can generate power of closure relative to the penetrating hole of the valve body, the problem and trouble caused by using of elastic pieces or electromagnetic valves in the prior art are avoided, elastic fatigue is avoided, service life of the air-valve structure can be prolonged, and generation of pollutants can be decreased.

Owner:GUDENG EQUIP CO LTD

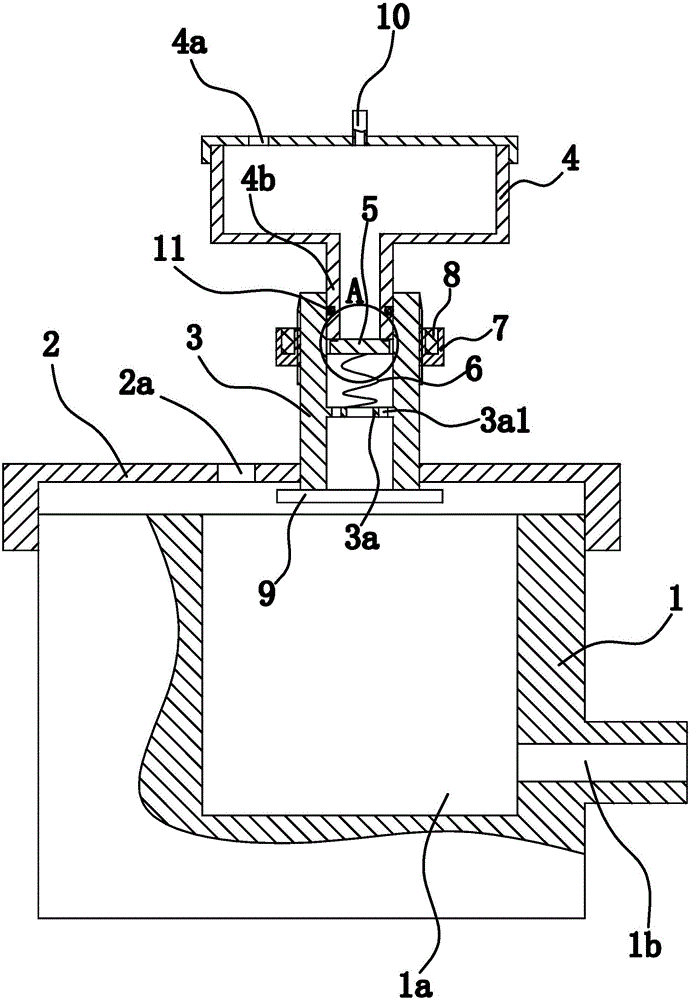

Liquid adding mechanism for pharmaceutical granulator

InactiveCN106074164AReduce distanceImprove compactnessPharmaceutical product form changeEngineeringMaterial storage

The invention provides a liquid adding mechanism for a pharmaceutical granulator, and belongs to the technical field of machinery. The liquid adding mechanism for the pharmaceutical granulator solves the problem that an existing liquid adding mechanism for the pharmaceutical granulator is loose in structure. According to the liquid adding mechanism for the pharmaceutical granulator, the granulator comprises a box body provided with a material storage cavity and a box cover arranged on the box body, and the liquid adding mechanism comprises a liquid inlet pipe and a liquid storage barrel, wherein the liquid inlet pipe and the box cover are fixed, the liquid inlet pipe is communicated with the material storage cavity, and the liquid storage barrel is located on the liquid inlet pipe; the bottom of the liquid storage barrel is provided with a connecting portion shaped like a circular tube, the connecting portion is sleeved with the upper end of the liquid inlet pipe, and the upper end of the liquid inlet pipe and the connecting portion are fixed in a sealed mode; a sealing plate is arranged in the liquid inlet pipe, the side wall of the sealing plate is attached to the inner side wall of the liquid inlet pipe, the edge of the sealing plate is provided with multiple notches, the liquid inlet pipe is sleeved with a rotary sleeve, the liquid inlet pipe and the rotary sleeve are connected in a threaded mode, the upper end face of the rotary sleeve is provided with an annular groove, and a magnet which can drive the sealing plate to slide in the axial direction of the liquid inlet pipe so as to control the lower end opening of the connecting portion to be opened or closed is fixed in the annular groove. The liquid adding mechanism for the pharmaceutical granulator has the advantage of being compact in structure.

Owner:郭根松

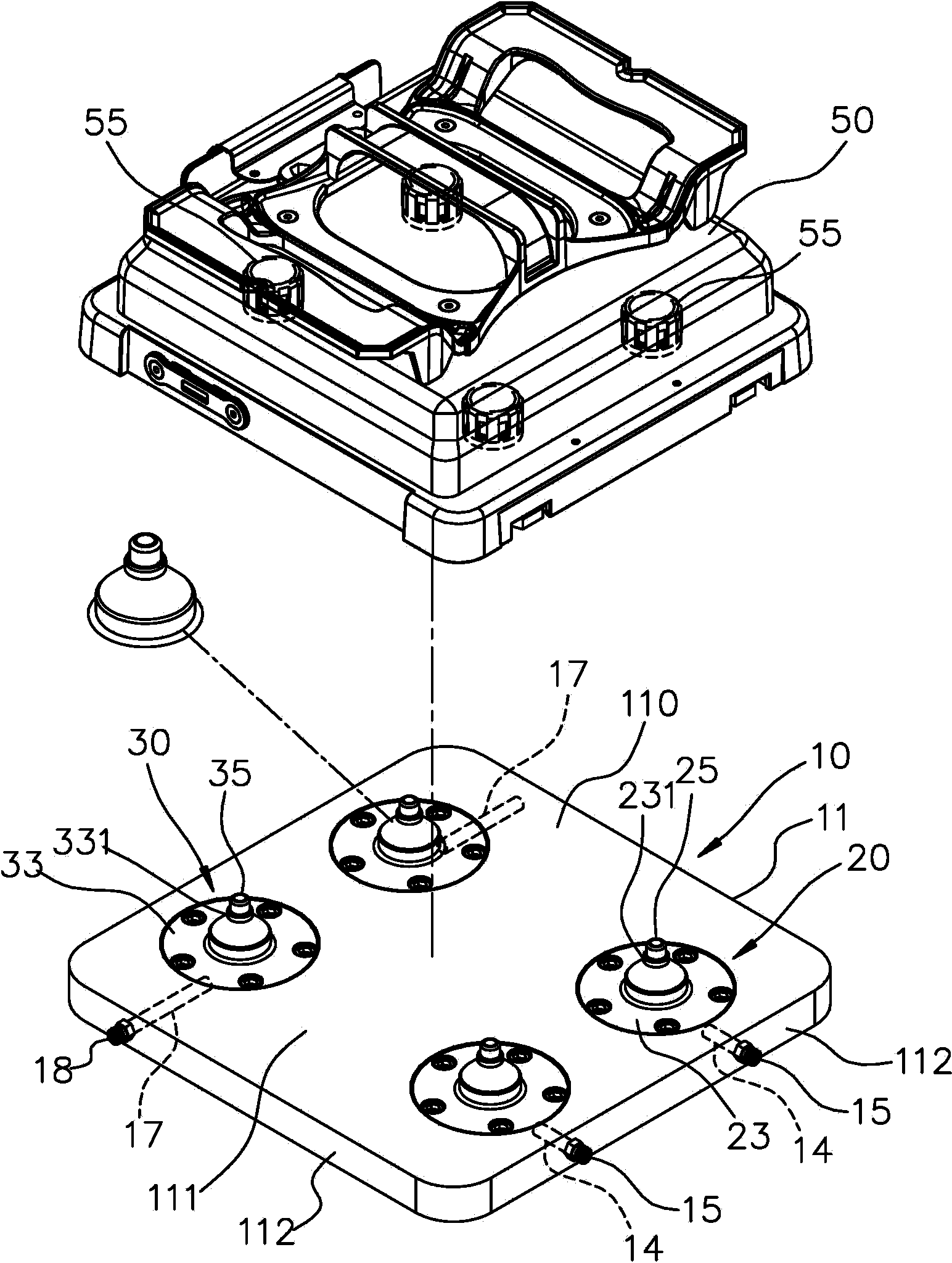

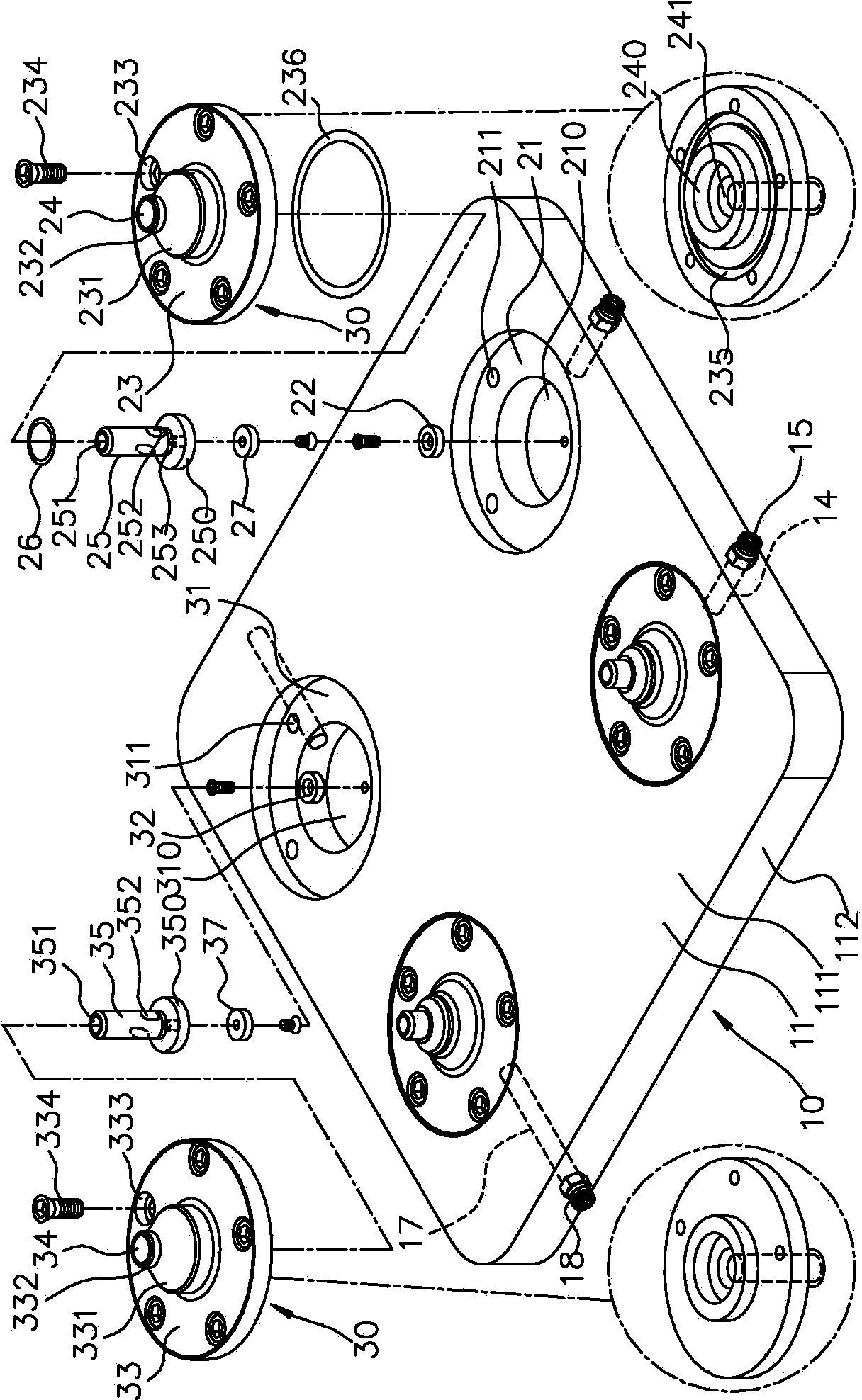

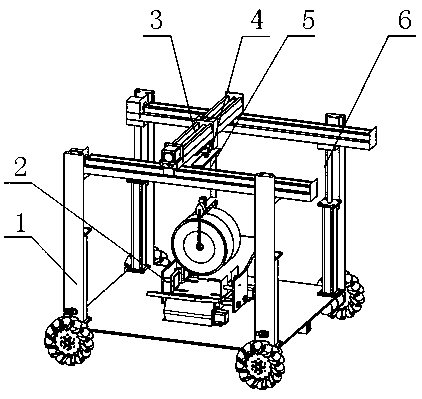

Automatic wheel carrying device

ActiveCN111169926ASave human effortImprove work efficiencyMechanical conveyorsObstacle avoidanceEngineering

The invention discloses an automatic wheel carrying device, and belongs to the field of carrying equipment. The automatic wheel carrying device comprises a trolley frame, a wheel fixing device, a translation device, a rotating device, a hooking device and a lifting device, the whole device takes the trolley frame as a main structure, the wheel fixing device is fixedly connected to the middle position of the bottom of the trolley frame, the lifting device and the bottom of the trolley frame are fixedly connected to the four corners through bolts, the translation device comprises an x-axis translation device and a y-axis translation device, the x-axis translation device is connected with the lifting device and can rise and fall along with the lifting device, the y-axis translation device isperpendicular to and slidably connected with the x-axis translation device, the y-axis translation device is connected with the rotating device, the rotating device is connected with the hooking device, a sensor and an observation device are arranged on the trolley frame, and automatic obstacle avoidance can be achieved in the carrying process. According to the automatic wheel carrying device, automatic carrying, loading and unloading of wheels between a storehouse and a station are achieved, the wheels are protected against damage in the carrying process, safety is improved, the structure issimple, and production efficiency can be remarkably improved.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

Mobile computer cabinet guided by guide rod

InactiveCN105407668AAchieve mechanical lockingEasy mechanical lockingCasings/cabinets/drawers detailsEngineeringMechanical engineering

A mobile computer cabinet guided by a guide rod is disclosed. The mobile computer cabinet comprises a cabinet body (2) and a door cover (20) that removably covers the opening of the cabinet body (2); a shifting mechanism is arranged at the bottom of the cabinet body (2); the shifting mechanism comprises a supporting frame (6) and a moving wheel (7) fixedly arranged on the supporting frame (6); the supporting frame (6) is fixedly connected with the cabinet body (2); a locking hook body (60) is integrally arranged on the inner side, facing to the cabinet body, of the door cover (20), wherein the locking hook body is used for penetrating through a through hole (200) in the wall part of the cabinet body to lock the door cover (20) on the cabinet body through joint between a hook part tail end (601) and the inner side of the wall part; a driving concave part (309) is further formed in the inner side of the door cover (20); the driving concave part is jointed with a driving block (30), so that the driving block (30) drives the door cover in a direction parallel to the plane of the wall part and in a direction perpendicular to the plane of the wall part so as to enable the locking hook body (60) to be unlocked.

Owner:余炳强

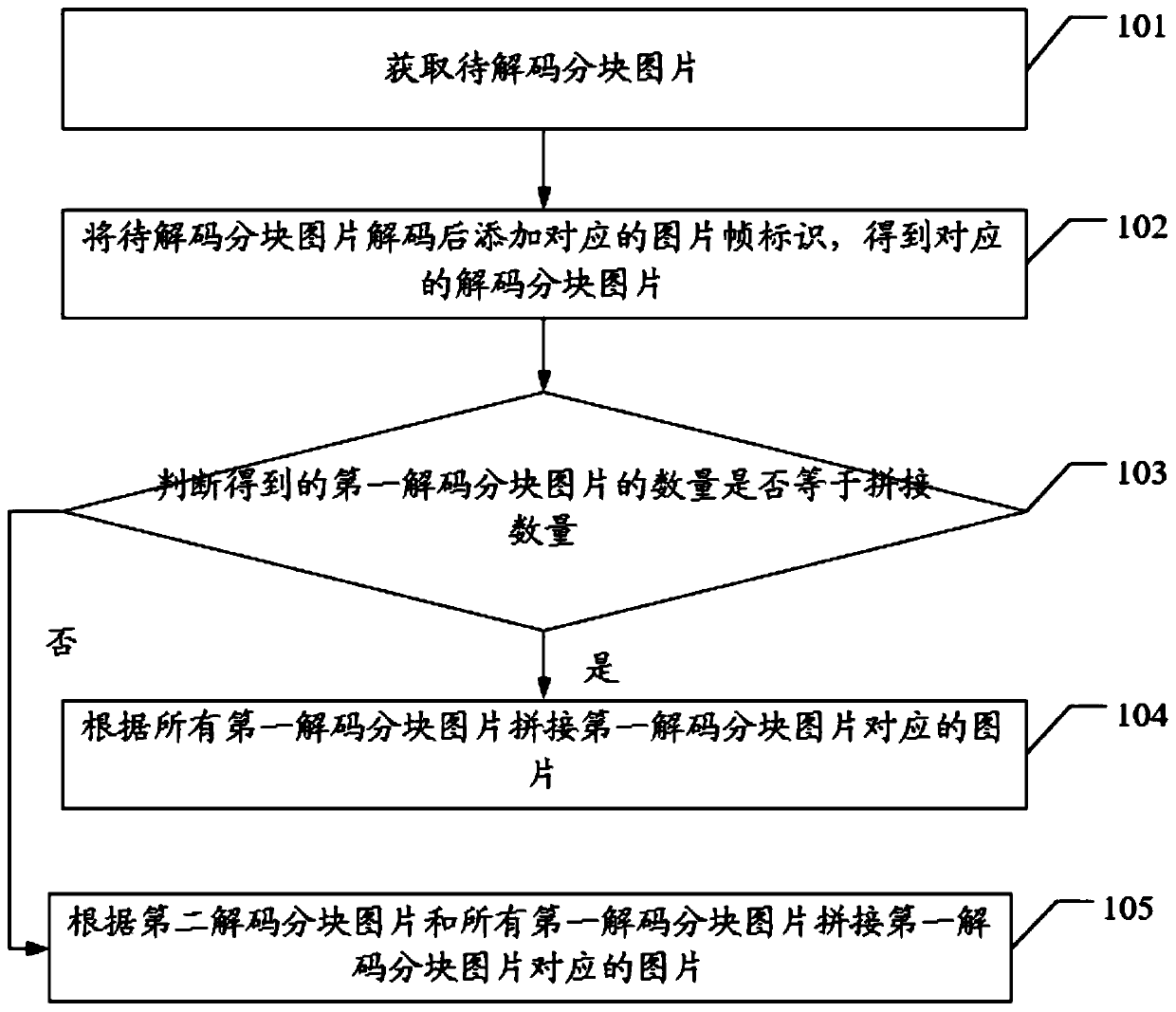

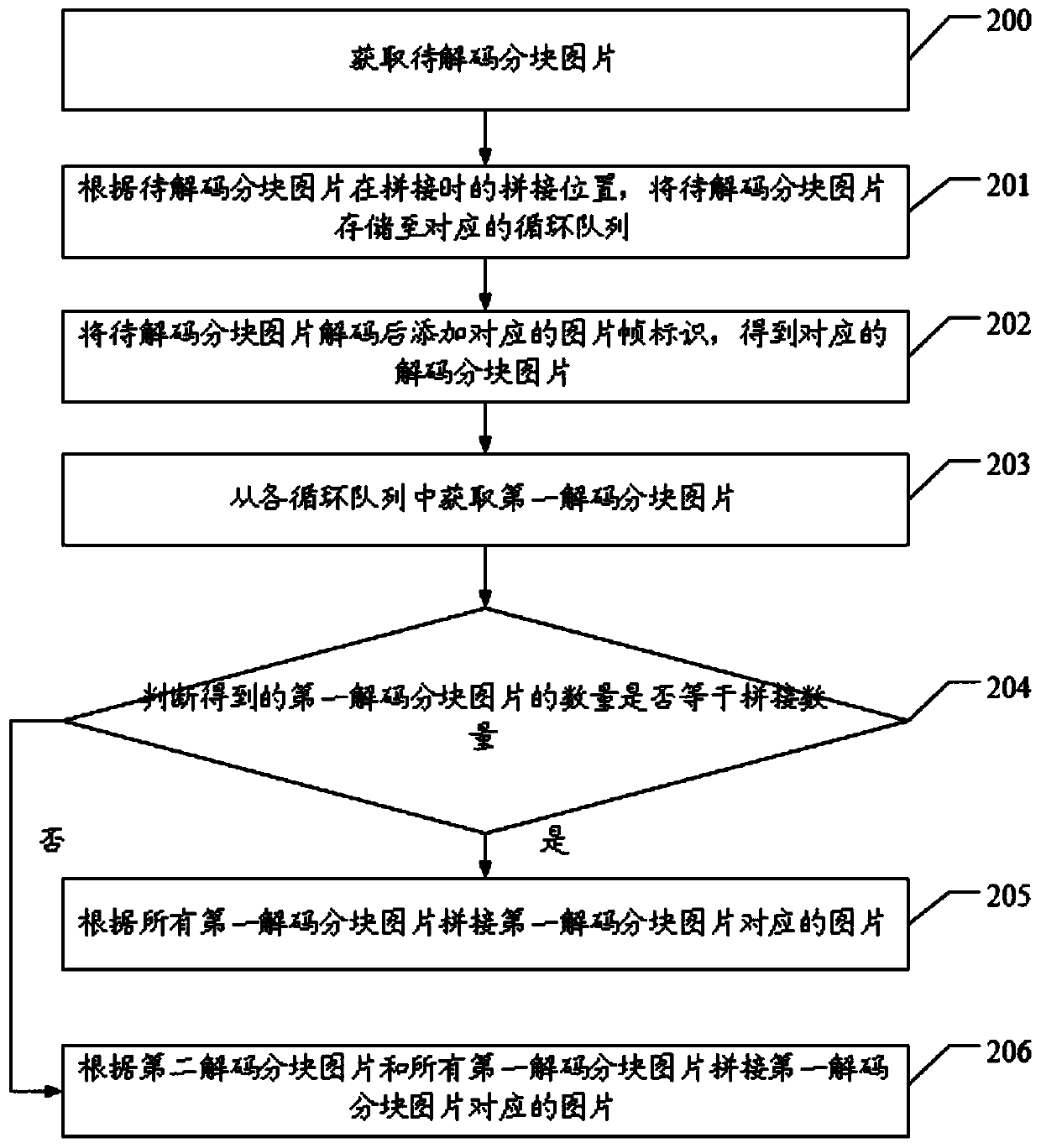

Image splicing processing method, device and equipment and computer storage medium

ActiveCN110072144AEnsuring Synchronization and FluencyHigh cost of solutionDigital video signal modificationSelective content distributionComputer engineeringImage splicing

The invention discloses an image splicing processing method, device and equipment, and a computer storage medium. The method comprises the steps of obtaining a to-be-decoded partitioned image; decoding the partitioned picture to be decoded, and adding a corresponding picture frame identifier to obtain a corresponding decoded partitioned picture; judging whether the number of the obtained first decoded block pictures is equal to the splicing number or not; if yes, splicing pictures corresponding to the first decoded block pictures according to all the first decoded block pictures, if not, splicing pictures corresponding to the first decoded block pictures according to the second decoded block pictures and all the first decoded block pictures, wherein the first decoded block picture is a decoded block picture with the picture frame identifier being the first picture frame identifier, and the second decoded block picture is a decoded block picture adjacent to the missing first decoded block picture, so that the technical defects of high cost, image delay and non-synchronization of the existing image splicing processing method are solved.

Owner:GUANGDONG VTRON TECH CO LTD

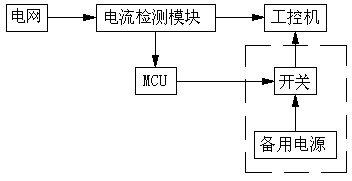

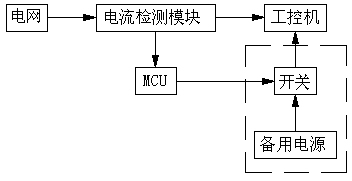

Power supply system of industrial personal computer

InactiveCN102437638AUninterrupted powerEnsure smoothnessEmergency power supply arrangementsPower gridStandby power

The invention discloses a power supply system of an industrial personal computer, which comprises a mains power grid. The mains power grid is connected with the industrial personal computer. The power supply system also comprises a standby power supply module, an MCU (micro control unit) and a current detection module, and the current detection module is connected between the mains power grid and the industrial personal computer and is used for detecting current signals and transmitting the current signals to the MCU; and the MCU is connected with the standby power supply module and is used for controlling communication of the standby power supply module and the industrial personal computer for supply of power to the industrial personal computer when no current signals are detected by the current detection module. By adopting the power supply system, uninterrupted power supply can be realized for the industrial personal computer, and the production stability can be ensured.

Owner:苏州洽成电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com