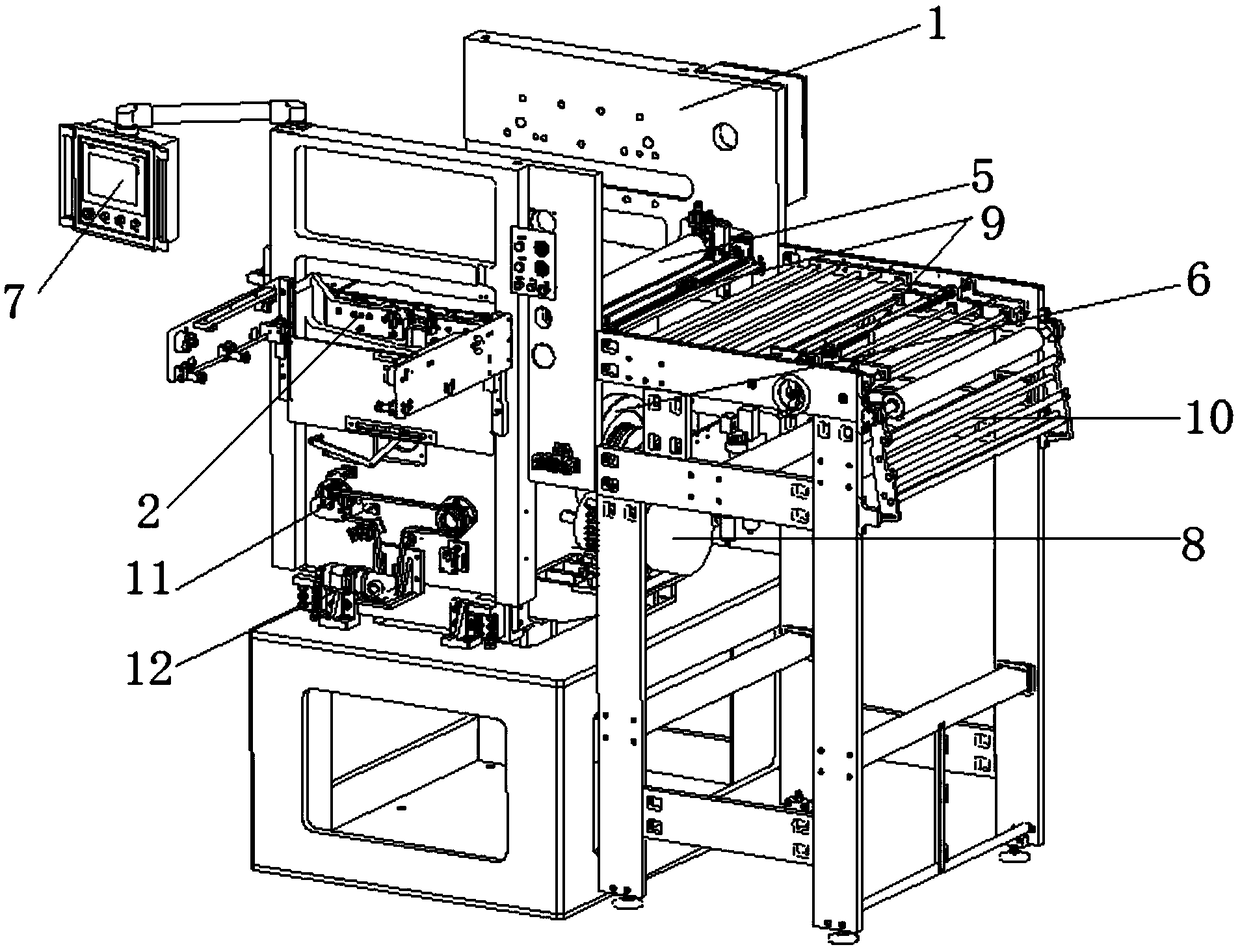

Mold table device of uncoiling die cutting machine

A die-cutting machine and die-table technology, applied in metal processing and other directions, can solve the problems of high machining and installation requirements, inaccurate die-cutting, low die-cutting efficiency, etc., to improve the running speed and die-cutting accuracy, space The effect of short opening period and reduced maintenance complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

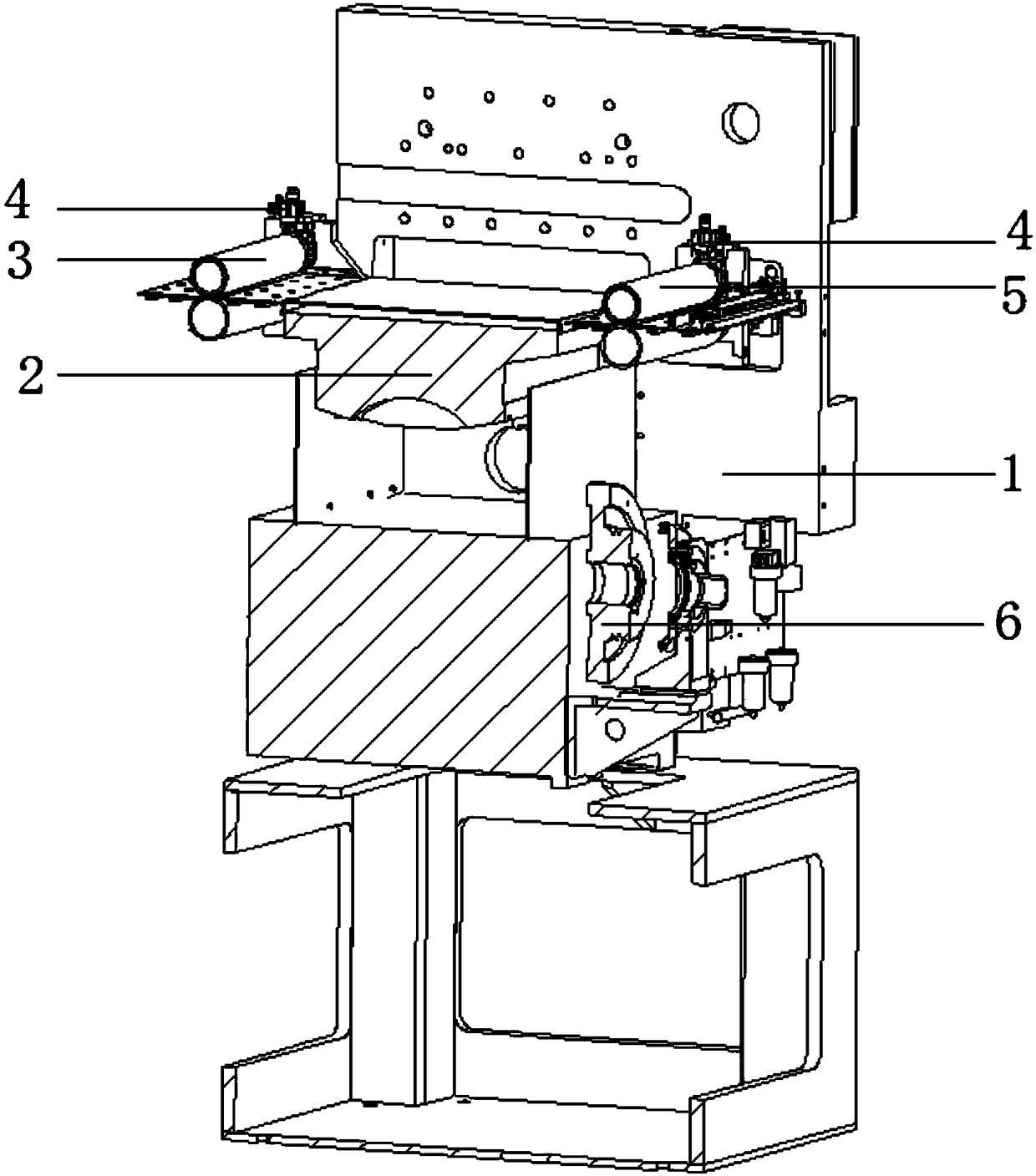

[0024] A full-servo mold table device for an unwinding die-cutting machine, such as figure 1 , 2 As shown, it includes the main body frame 1 of the mold table, the upper die-cutting platform fixed on the main body frame 1 of the mold table, the lower die-cutting platform 2 which is located at the lower part of the upper die-cutting platform and can move up and down, and guides the product to enter the die-cutting station. The feeding drive mechanism and the output driving mechanism that guides the product to move out of the die-cutting station. The feeding drive mechanism includes the die-cutting feed nip set 5 and the roller set driving unit 4 that drives it to roll. The output driving mechanism includes the die-cutting output The pinch roller group 3 and the roller group driving unit 4 that drives it to roll; the feeding driving mechanism and the discharging driving mechanism are fixedly installed on the lower die-cutting platform 2, and the lower die-cutting platform 2 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com