Liquid adding mechanism for pharmaceutical granulator

A granulator and liquid inlet pipe technology, applied in the mechanical field, can solve the problems of cumbersome connection, loose structure, and large space occupied by the liquid feeding structure, and achieve the effect of improving compactness, reducing distance, and improving working stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

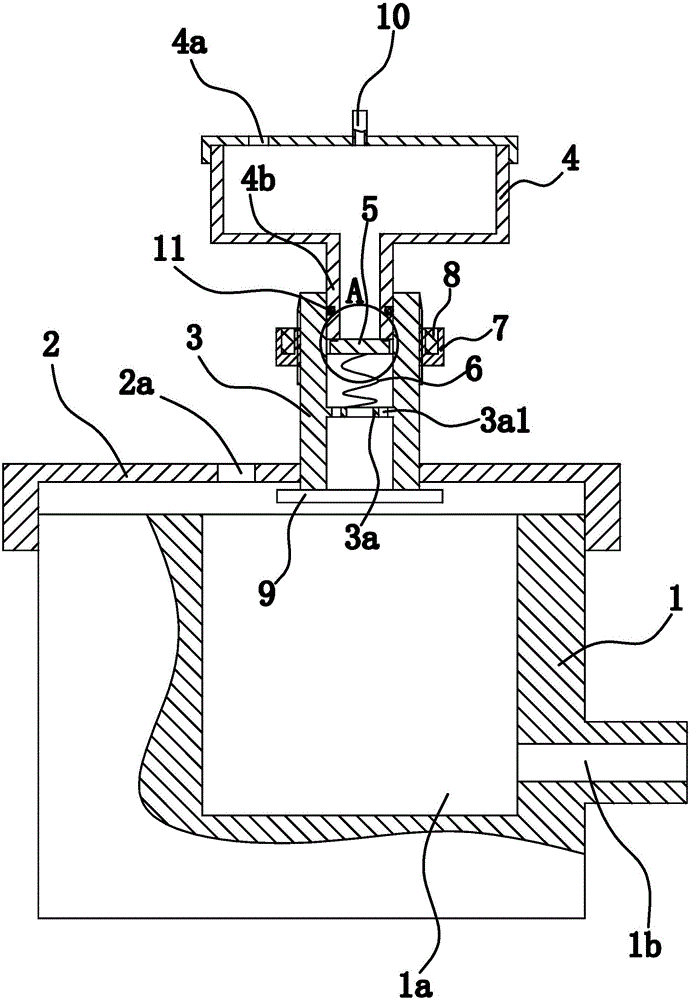

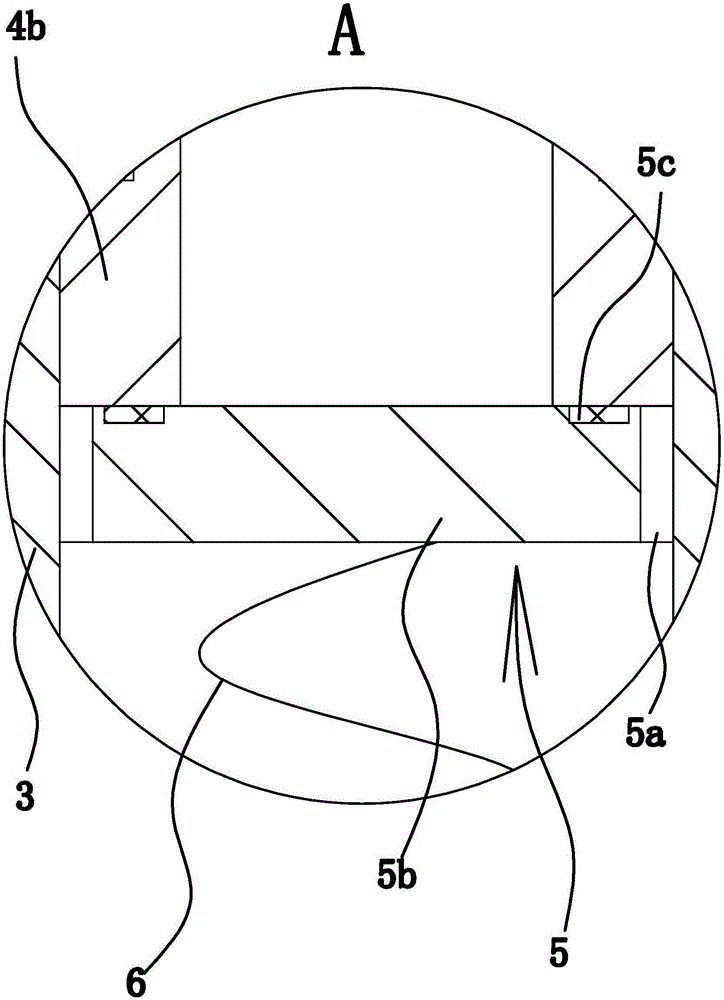

[0024] Such as figure 1 As shown, in the liquid feeding mechanism of the pharmaceutical granulator, the granulator includes a box body 1 with a material storage chamber 1a and a box cover 2 arranged on the box body 1 . Wherein, one side of the lower end of the box body 1 is provided with an outlet 1b communicating with the material storage chamber 1a, and the box cover 2 is provided with an exhaust hole 2a communicated with the material storage chamber 1a. The liquid adding mechanism is composed of a liquid inlet pipe 3, a liquid storage barrel 4, a sealing plate 5, a spring 6, a rotating sleeve 7, a magnet 8, and the like. Wherein, the sealing plate 5 is composed of a magnetically permeable material, and the magnetically permeable material can be iron or an alloy containing iron. Both the liquid inlet pipe 3 and the rotating sleeve 7 are made of non-magnetic materials, and the non-magnetic materials can be engineering plastics or brass. In this embodiment, both the priority...

Embodiment 2

[0033] The structure and principle of this second embodiment are basically the same as that of the first embodiment, except that the connecting part 4b is covered with a ring-shaped sealing gasket 2, and the inner side wall of the second sealing gasket is offset against the outer side wall of the connecting part 4b. And the two end surfaces of the sealing gasket 2 are respectively offset against the bottom wall of the liquid storage tank 4 and the upper end surface of the liquid inlet pipe 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com