Assembly structure of motor

An assembly structure and motor technology, applied in electromechanical devices, manufacturing motor generators, electrical components, etc., can solve problems such as complicated installation methods, achieve the effects of reducing vibration, reducing length and space, and avoiding instant shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

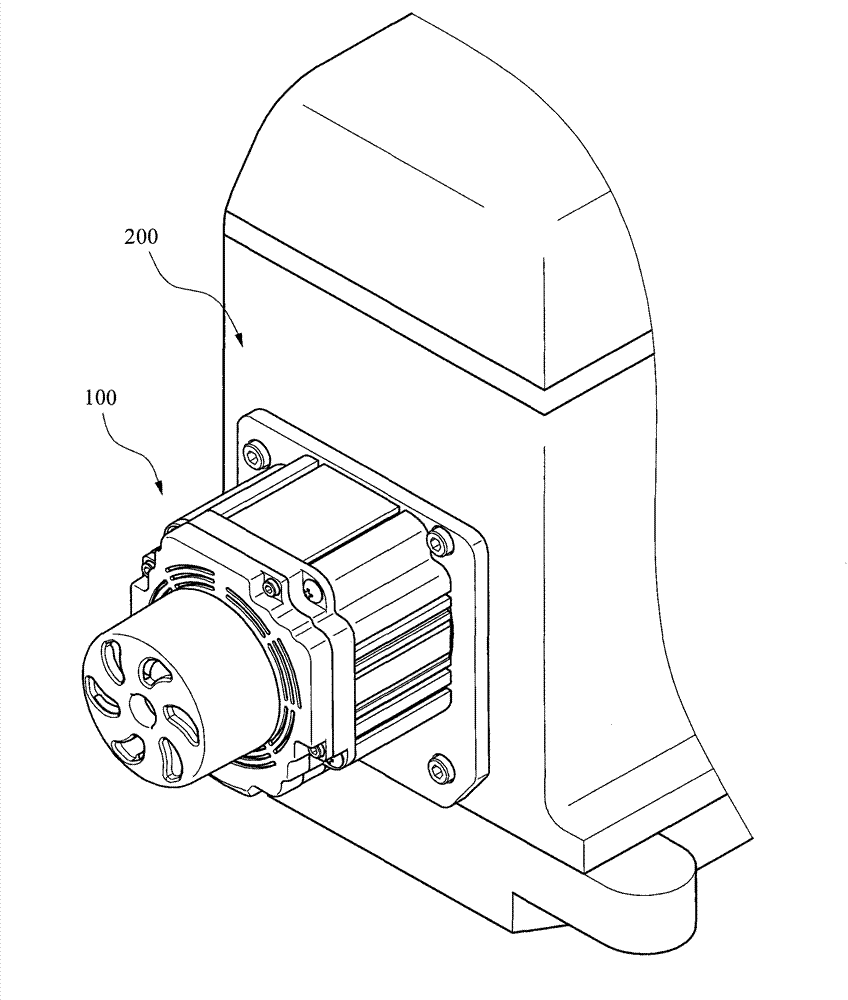

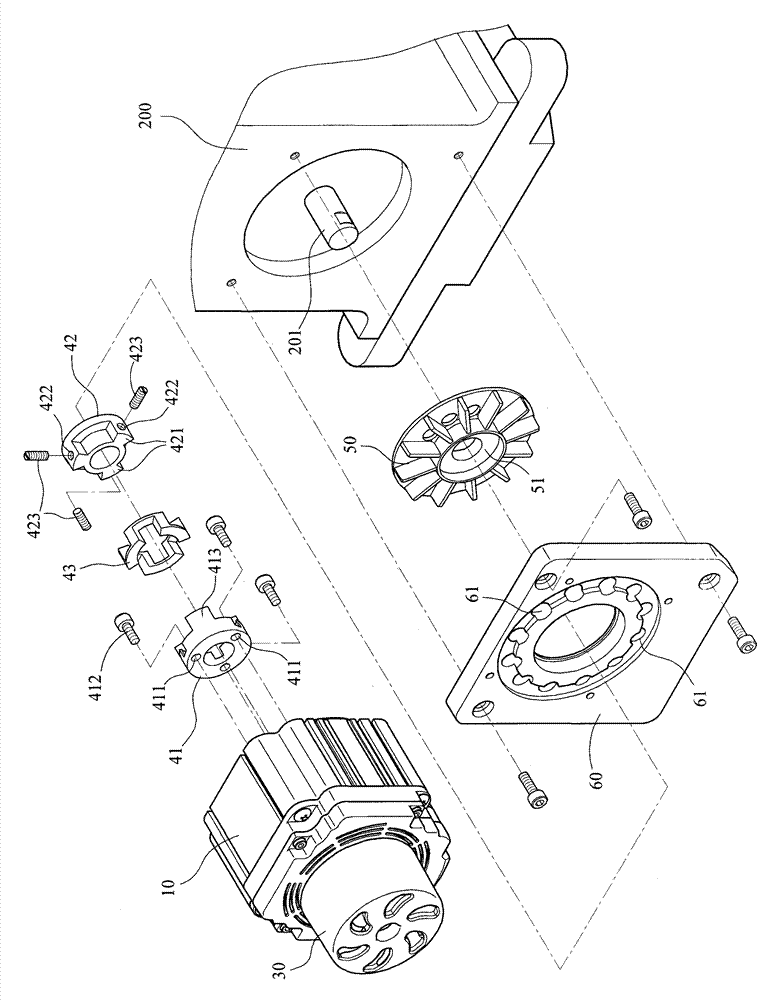

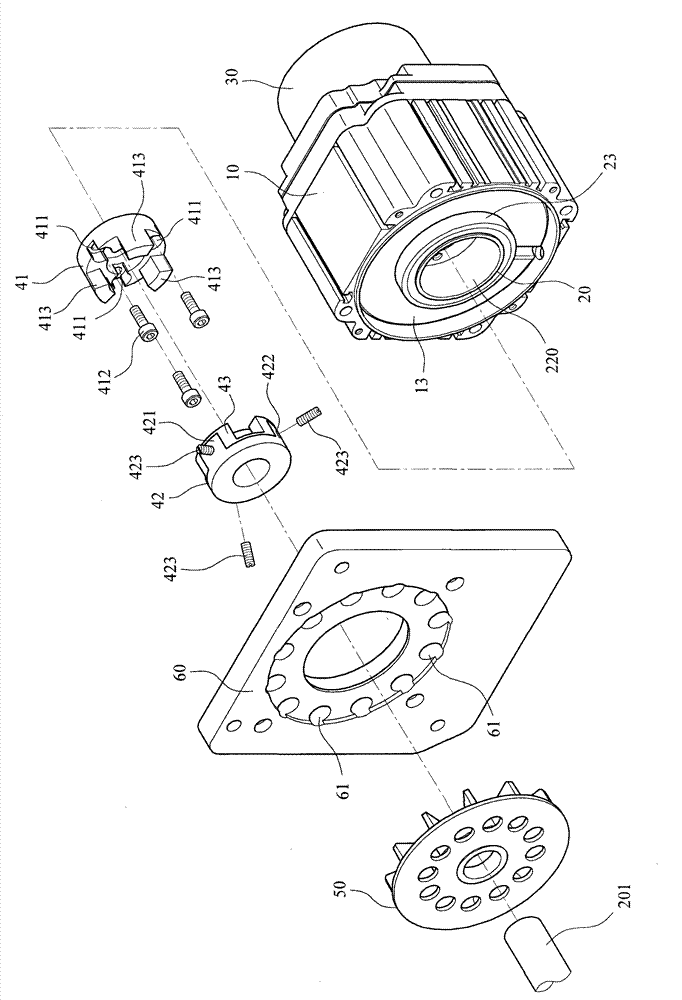

[0041] see Figure 1 to Figure 3 , is a perspective view, an exploded schematic diagram and an exploded schematic diagram in another direction of the first embodiment of the present invention. A motor 100 is directly assembled on the side of a machine base 200, and a mandrel 201 protrudes from the side of the machine base 200, and is mounted on the body 10 of the motor 100. There is a drive shaft 20 inside, and a stator and a rotor (not shown) are arranged between the drive shaft 20 and the body 10 .

[0042] Same reference Figure 4 , Figure 5 As shown in , one end of the drive shaft 20 is a small-diameter portion 21 long enough to pass through the body 10 of the motor 100. The small-diameter portion 21 passes through the part of the motor 100 to provide a handwheel 30. The selective threading device is fixed on the body of the motor 100. 10; while the other end of the drive shaft 20 expands to form a large-diameter portion 22, the large-diameter portion 22 is recessed wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com