Hot air punching film and forming method thereof

A perforated film and hot air technology, applied in dressings, viscous dressings, etc., can solve the problems of destroying the flexibility of plastic films, affecting the safety of plastic films, and affecting the healing of wound surfaces, so as to achieve safety assurance, solve anxiety phenomena, and ensure The effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

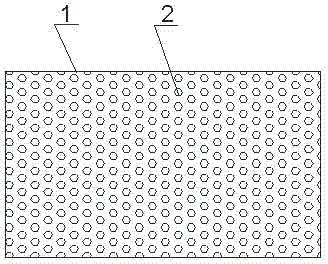

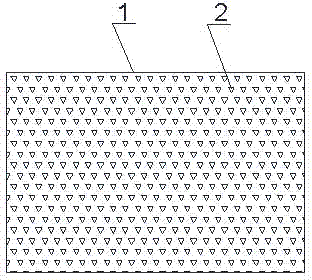

[0015] Embodiment 1: with reference to attached Figure 1-3 . A hot air perforated film, the plastic film 1 has a plurality of through holes, and the edges of the plurality of through holes 2 on the plastic film 1 surface are convex edges 3 that are naturally shrunk by hot air. There is no flame trace on the 3 sides of the hot air shrinkage flange, and the through-hole hole is a round hole or a rectangular hole or a triangular hole or a polygonal hole, and the edge of the hole is the hot air natural shrinkage flange 3, that is, the shape of the hot air natural shrinkage flange 3 Curved edges for natural shrinkage.

Embodiment 2

[0016] Embodiment 2: with reference to attached Figure 4-7 . On the basis of embodiment 1, a kind of forming method of hot-air perforated film, when plastic film 1 passes through perforated hole forming mold roll 9, plastic film 1 face is attached to the roll surface of perforated hole forming mold roll 9 in rotation, At this time, the strip-shaped high-temperature blade airflow at the upper end of the perforating hole forming die roller 9 roller faces acts on the plastic film 1 face, and the plastic film covered on the perforating hole forming die roller 9 roller faces is gas-melted and punched Holes with the same shape as the grooves on the roll surface of the hole forming die. The temperature of the strip-shaped high-temperature blade airflow is not higher than the melting point of the plastic film, so that holes can be punched by means of the pressurized airflow to form a flexible and smooth arc-shaped edge, and the scorching of the pore edge of the plastic film can be a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com