Heavy duty vehicle AMT engine and clutch self-adaption coordination control method

A Technology of Coordinated Control and Clutch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

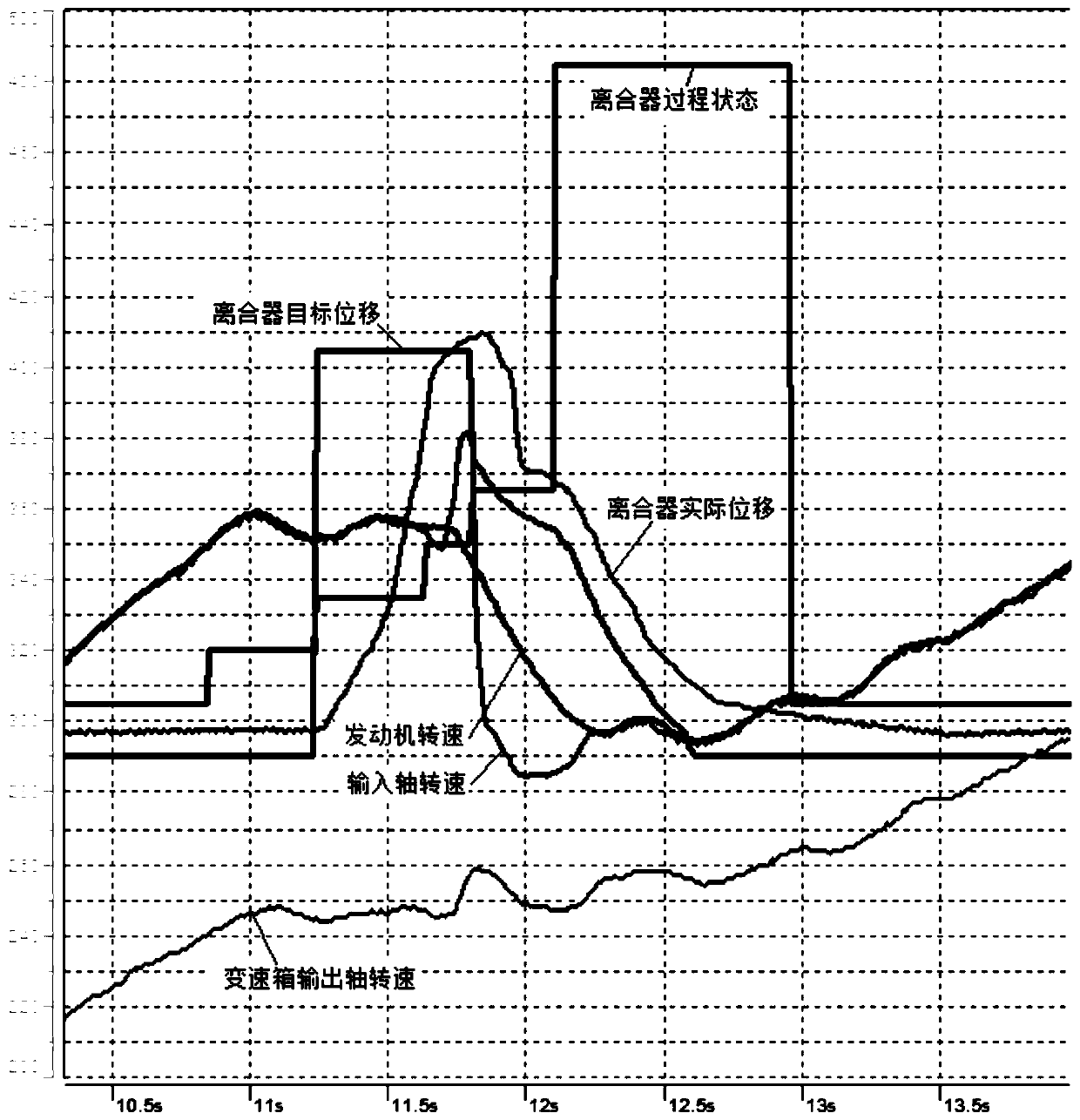

[0029] see Figure 1 to Figure 3 , a heavy-duty vehicle AMT engine and clutch adaptive coordinated control method, the coordinated control method includes the following steps:

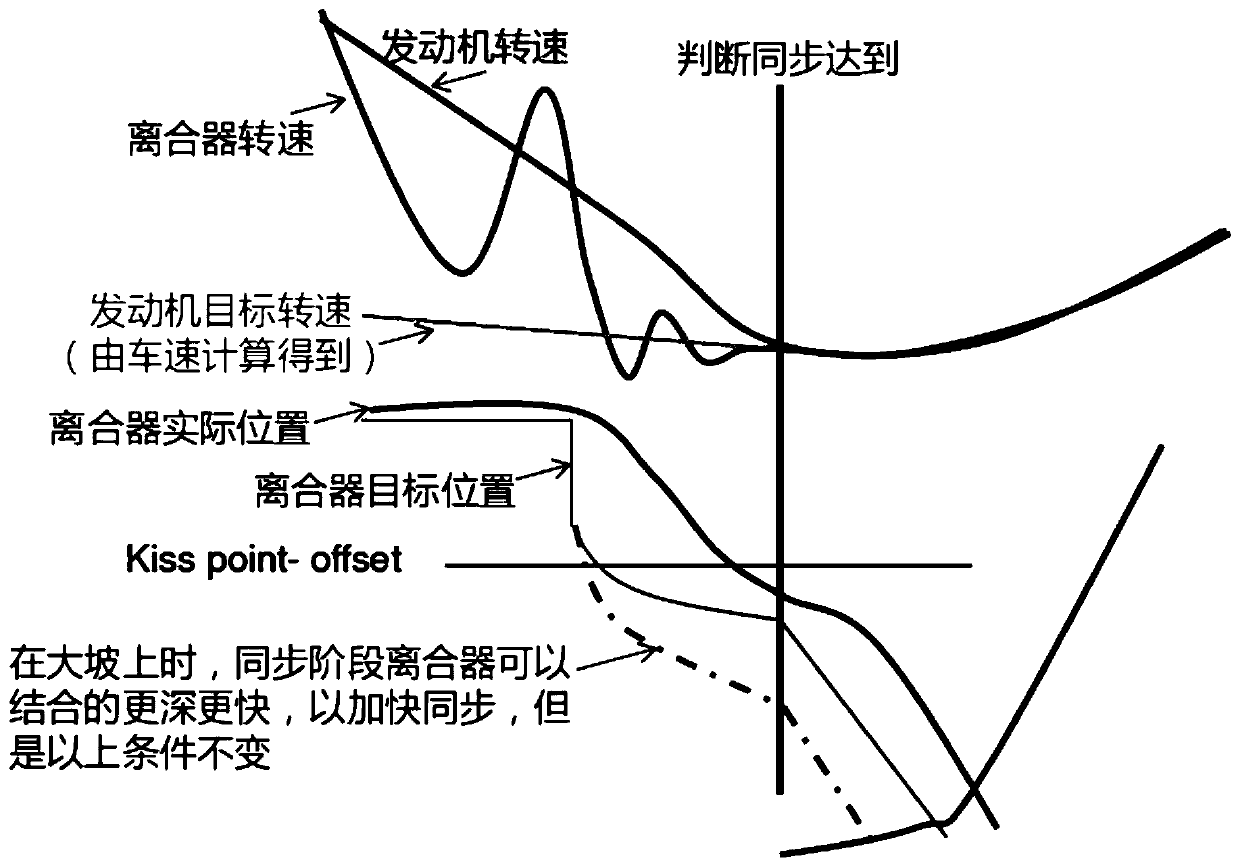

[0030] Step 1: In the Roll off stage, before the gear is removed, the engine reduces torque and then controls the clutch to open. The gearbox sends a speed torque limit request to the engine through a TSC1 message, and sends a specific engine torque request value. The torque request value is based on the quality, ramp Obtained by looking up the table, the rate of change of the engine torque and the separation rate of the clutch are corrected according to the mass, ramp, and throttle parameters, and the correction amount is obtained by looking up the table according to the mass, ramp, and throttle parameters;

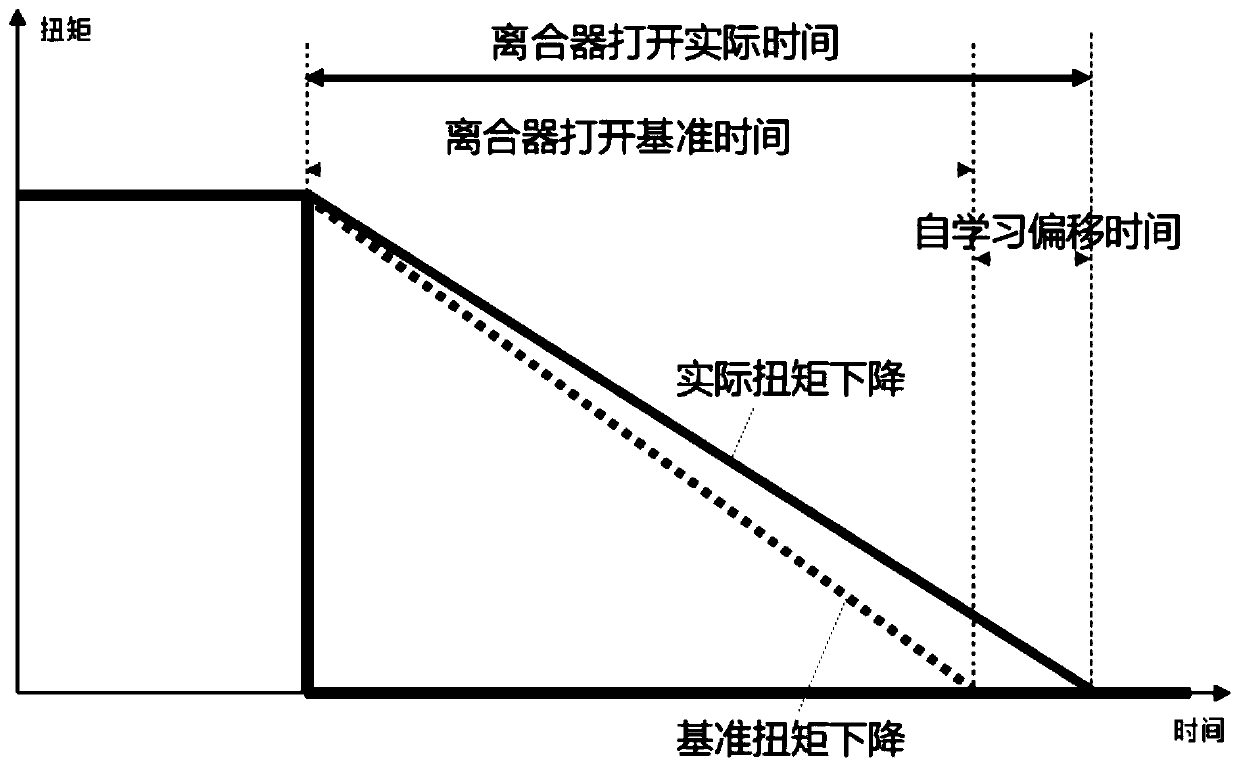

[0031]Clutch opening time self-learning: record the time from the start of clutch action in the Roll off phase to the end of Roll off, and judge with the original value of EEPROM after subtractin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com