Road vibration isolation system for preventing underground spatial structure vibration and construction method thereof

A vibration isolation system and space structure technology, applied in the direction of roads, roads, climate change adaptation, etc., can solve the problems of difficult construction and maintenance, poor vibration isolation effect, low service life, etc., and achieve smooth longitudinal stability without sudden change, vertical stability. The effect of smooth deformation and no sudden change, isolation of low-frequency vibration and structure noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

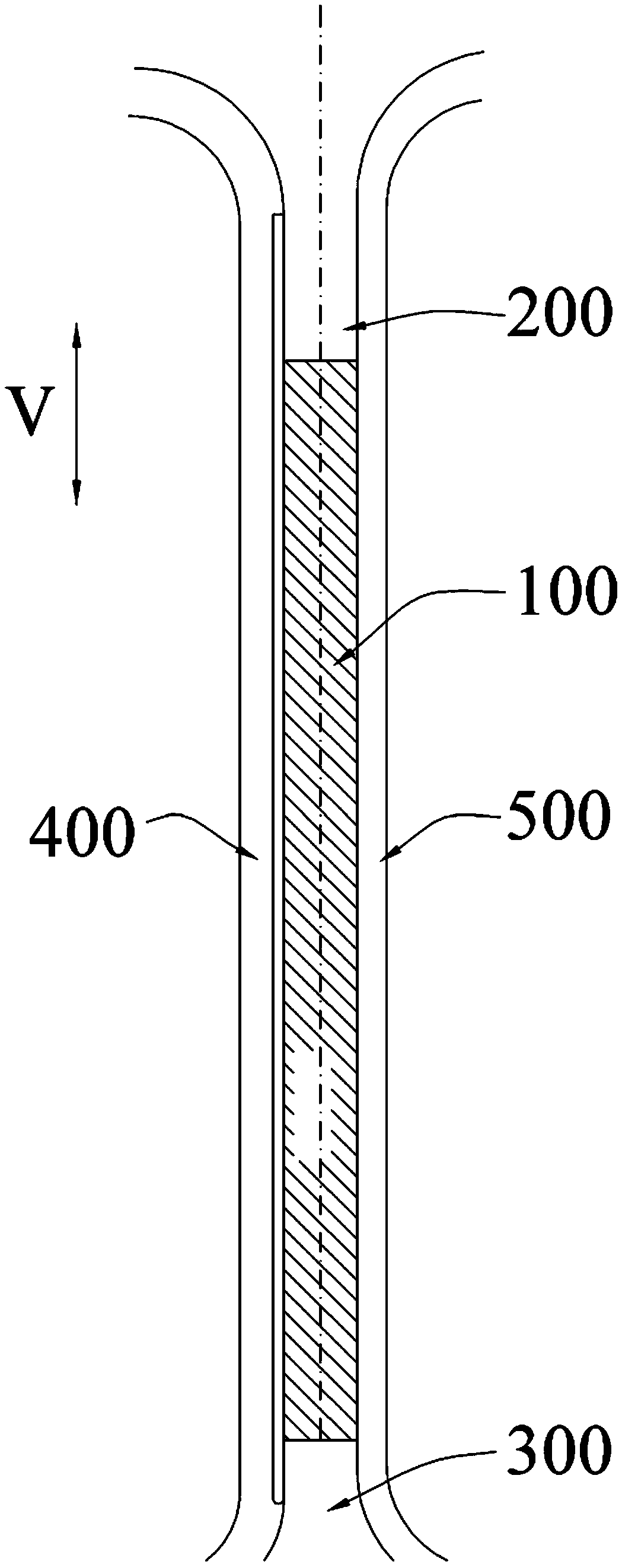

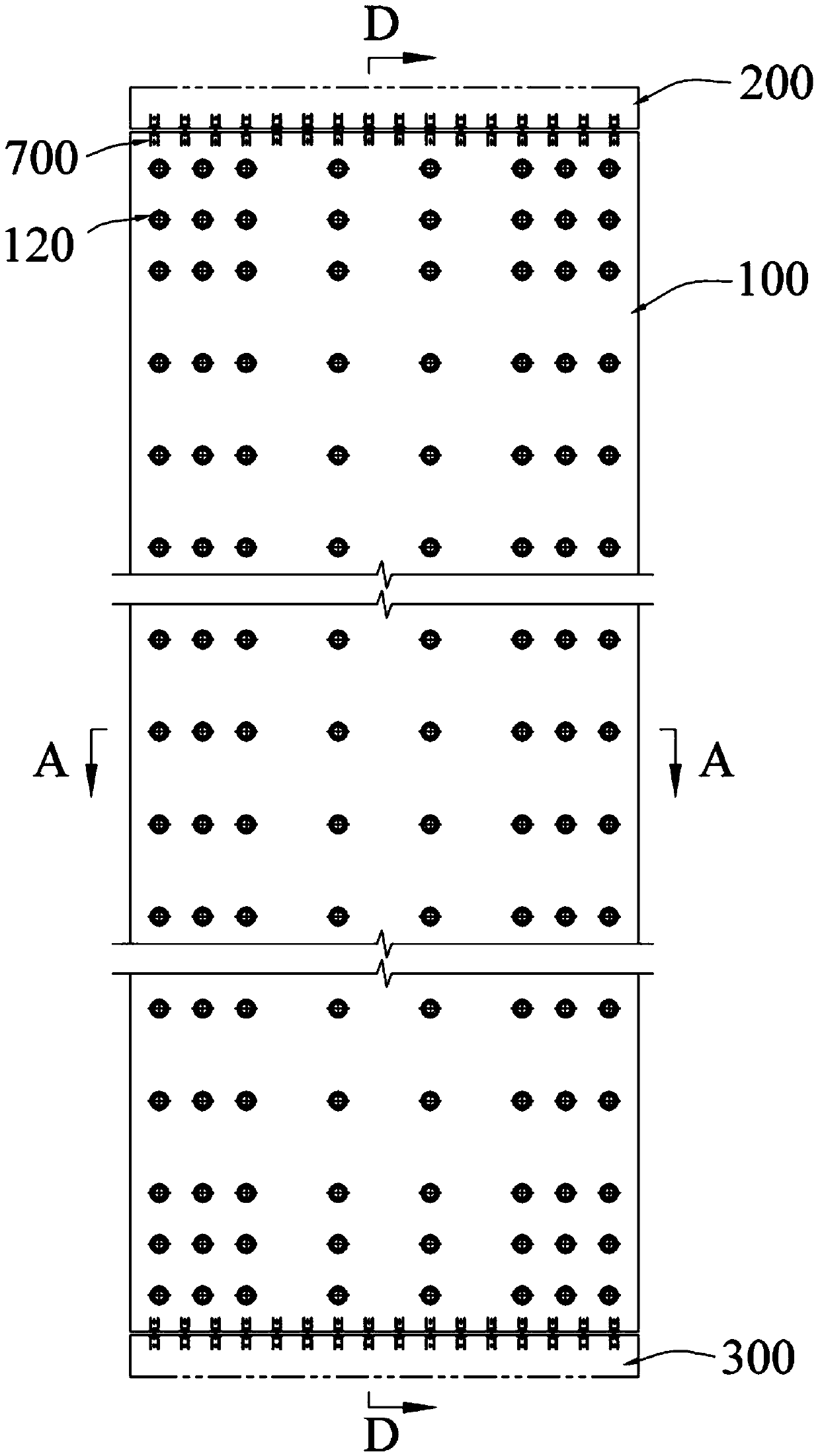

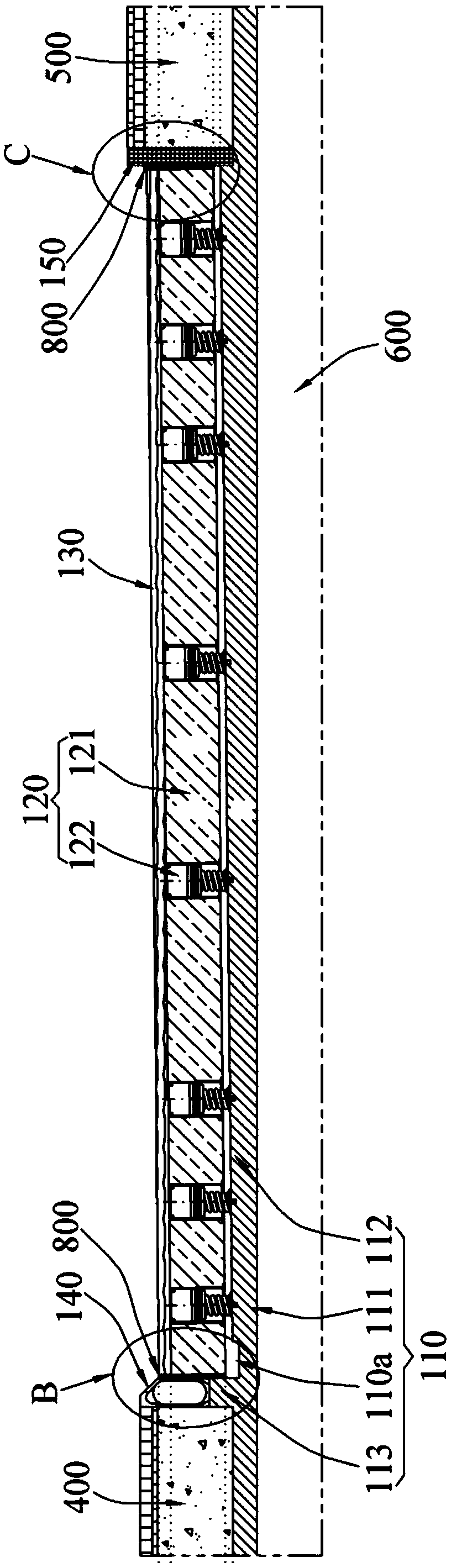

[0046] Such as Figure 1 to Figure 9 As shown, the road vibration isolation system of Embodiment 1 of the present invention includes a vibration-isolated roadway 100 and a front roadway 200 located around it, a rear roadway 300, a left non-traffic road 400 and a right non-vehicle roadway. The roadway 500, wherein the vibration-isolated roadway 100 is located above the underground space; the vibration-isolated roadway 100 includes a concrete cushion 110, steel spring floating slabs 120, asphalt pavement 130, curb stones 140 and roadside stones 150.

[0047] Above-mentioned concrete pad 110 is made up of paving layer 111, slope surface layer 112 and boss 113, and paving layer 111 is laid on the roof slab 600 of the building in underground space, and slope surface layer 112 and boss 113 are all arranged on paving. The upper surface of the layer 111 and between them form a longitudinal drainage ditch 110 a extending along the driving direction V of the vibration-isolated roadway 1...

Embodiment 2

[0068] The road vibration isolation system of the second embodiment of the present invention is basically the same as that of the first embodiment, and their difference is that in the second embodiment, the concrete cushion 110 is also provided with a horizontal drain perpendicular to the driving direction V of the vibration-isolated roadway 100 The culvert, slope layer 112 also has an aspect towards the lateral drainage culvert.

Embodiment 3

[0070] The road vibration isolation system of Embodiment 3 of the present invention is basically the same as Embodiment 1 or Embodiment 2, and their difference lies in that the slope of the slope layer 112 towards the horizontal drainage ditch is 0.47°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com