Open-cast coal mine and mining method thereof

A technology of open-pit coal mines and mining methods, applied in ground mining, earth drilling, underground mining, etc., can solve the problems of repeated stripping in internal dumps, failure to arrange transportation systems at junctions, reduce transportation costs, etc., and achieve improved Economic efficiency and safety, ensuring integrity and smoothness, and reducing transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings. Wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

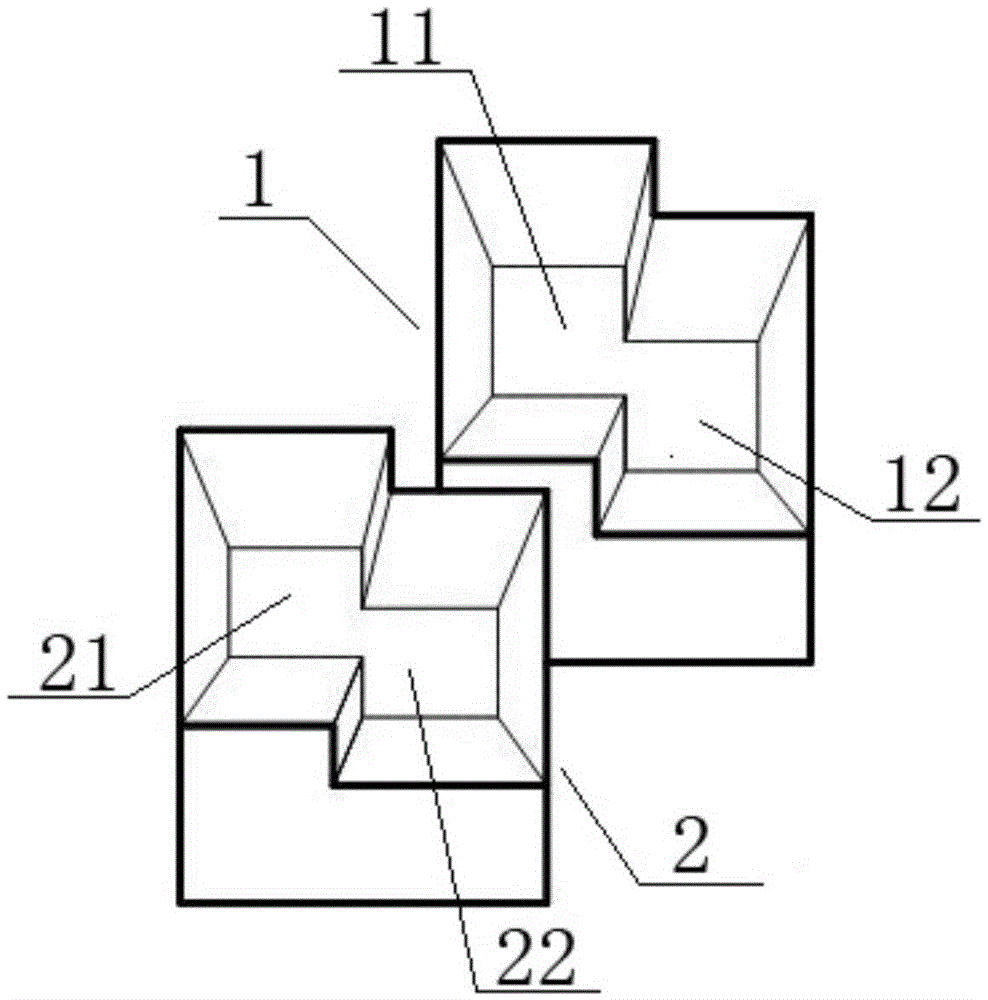

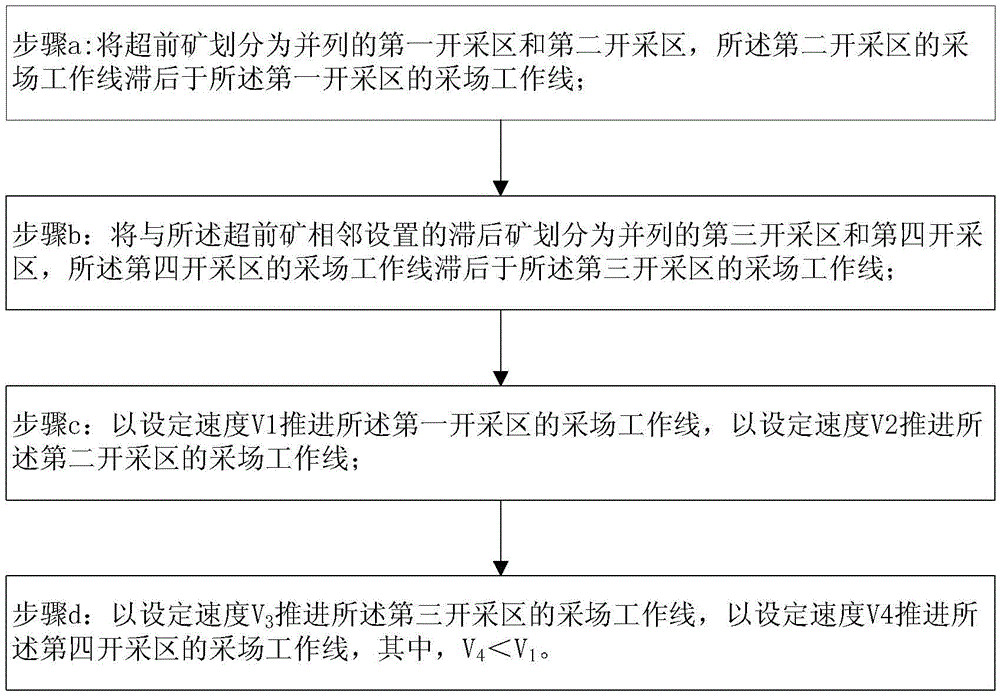

[0024] like figure 1 As shown, the open-pit coal mine provided by the present invention includes adjacent advanced mines 1 and lagging mines 2, and those skilled in the art should note that the leading mines 1 and the lagging mines 2 are all advancing in parallel in the same direction, as figure 1 As shown, the lagging mine 2 is located at the rear of the advanced mine 1, that is, the stope working line of the lagging mine 2 is adjacent to the inner dump working line of the adva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com