Copper aluminum heat exchanger of gas water heater and connecting method thereof

A technology for gas water heaters and heat exchangers, applied in heat exchange equipment, indirect heat exchangers, fluid heaters, etc., can solve the problems of low mechanical strength performance of aluminum heat exchangers, difficult welding, and scarcity of copper materials, etc. Ensure smooth flow and corrosion resistance, reduce production costs, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0029] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings.

[0030] The copper-aluminum heat exchanger of the gas water heater according to the embodiment of the first aspect of the present invention will be described in detail below with reference to the accompanying drawings.

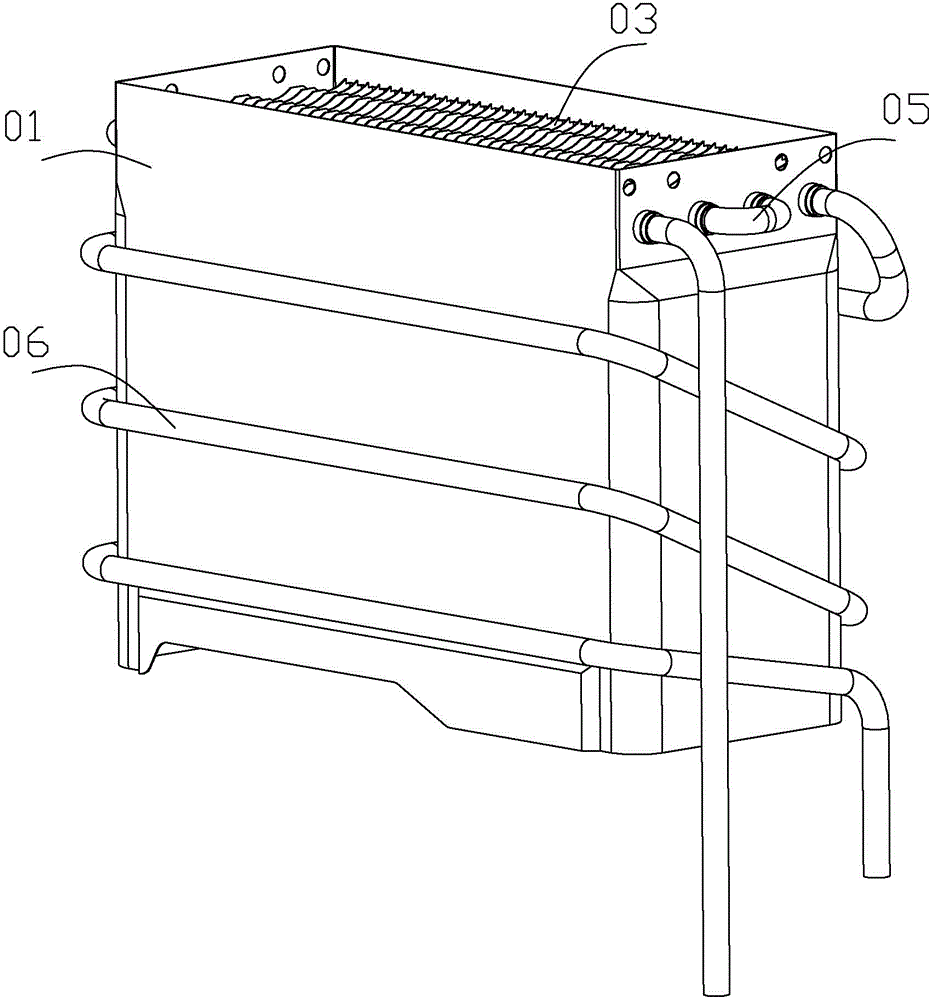

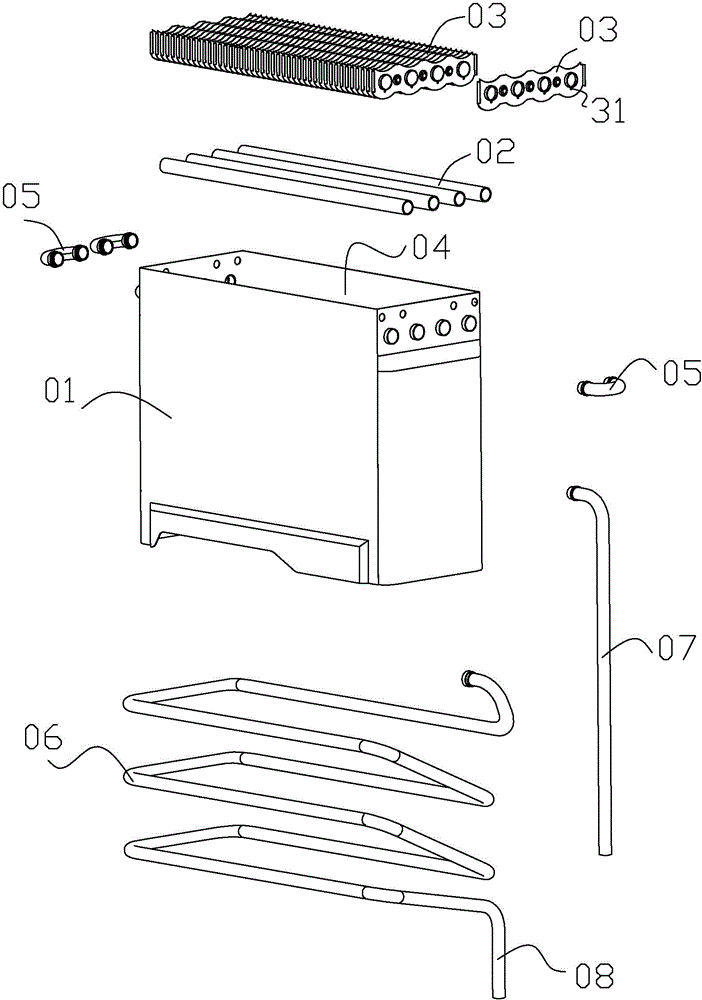

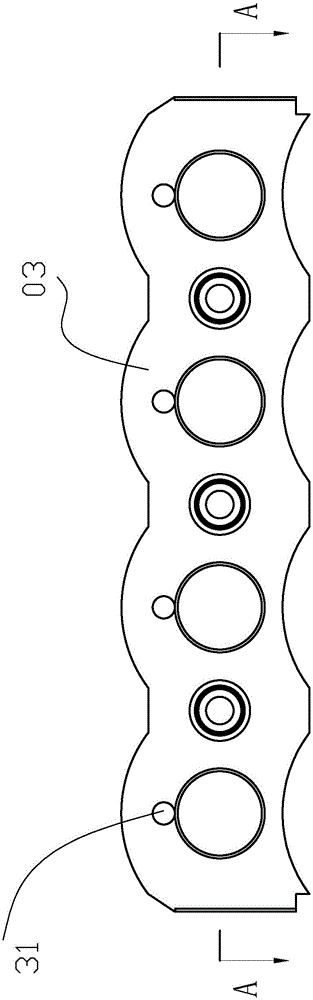

[0031] See figure 1 , figure 2 , the heat exchanger in this embodiment includes a shell 01, a straight pipe 02, a heat exchange fin 03, a U-shaped pipe 05, a coil pipe 06, a water inlet pipe 07, and a water outlet pipe 08.

[0032] The shell 01 encloses the flue gas channel 04 to collect high-temperature flue gas; the straight tubes 02 are arranged in an array and cross the flue gas channel 04, and the heat exchange fins 03 are arranged in the flue gas channel 04 and are stacked and passed through the straight tubes in sequence. On 02, the heat exchange fins 03 are used to absor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com