Improved method for connection tensioning and dismantling of adjacent tunnel pipe segments

A segment and connecting plate technology, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as inability to implement butt welding or gas cutting, hidden safety hazards for welding personnel, high-temperature cracking of segments, etc. Auxiliary welding machine and gas cutting tools, avoid welding problems, and ensure the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

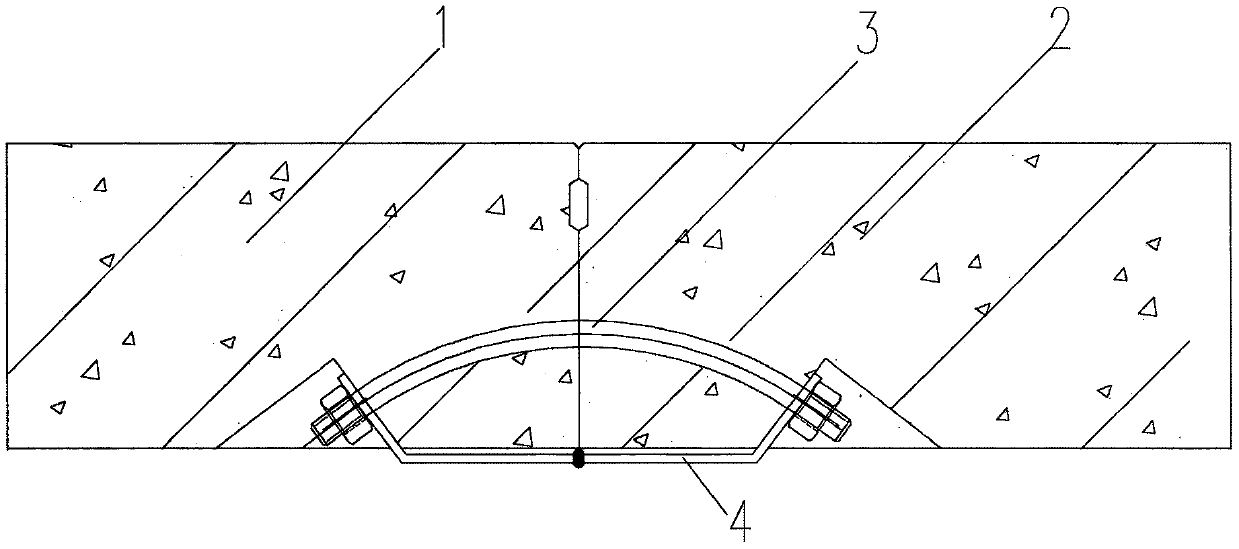

[0020] The present invention is an improved method for tightening and dismantling the connection of adjacent segments of the tunnel. The method can solve the problem of relative The difficulty of construction when the connection of adjacent segments is tightened or removed, eliminates the safety hazards caused by butt welding or gas cutting due to the humid working environment, and saves construction costs and time.

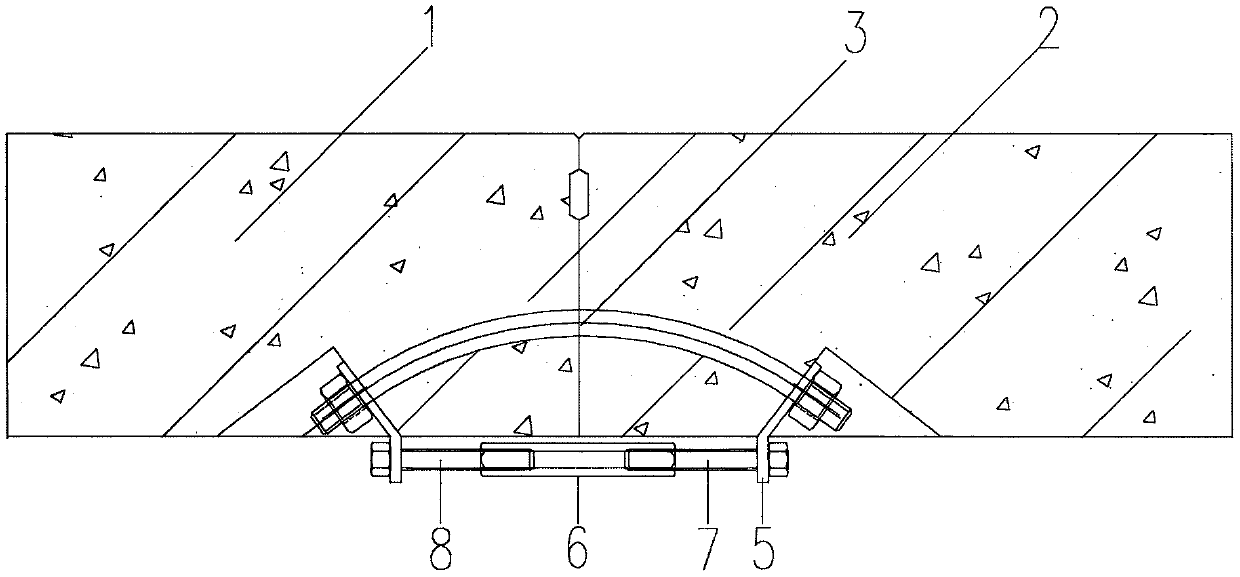

[0021] combine figure 2 , the improved method of the present invention uses the segment bolt 3, the small connecting plate 5, the hexagonal threaded sleeve 6, the normal threaded buckle cap bolt 7 and the reverse threaded buckle capped bolt 8, and the inner hole of the hexagonal threaded sleeve 6 There is a through-hole internal thread, and the outer circle of the hexagonal screw sleeve 6 is hexagonal.

[0022] For the improved method of tightening or dismantling the connection of adjacent segments in the present invention, please refer to the technical solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com