Lamp bulb of LED lamp filament structure

A technology of LED filaments and LED light strips, which is applied to the components of lighting devices, lighting devices, light sources, etc., can solve the problems of unfavorable mass production, inconvenient welding of LED filaments, and small power boards, etc., to achieve mass production The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

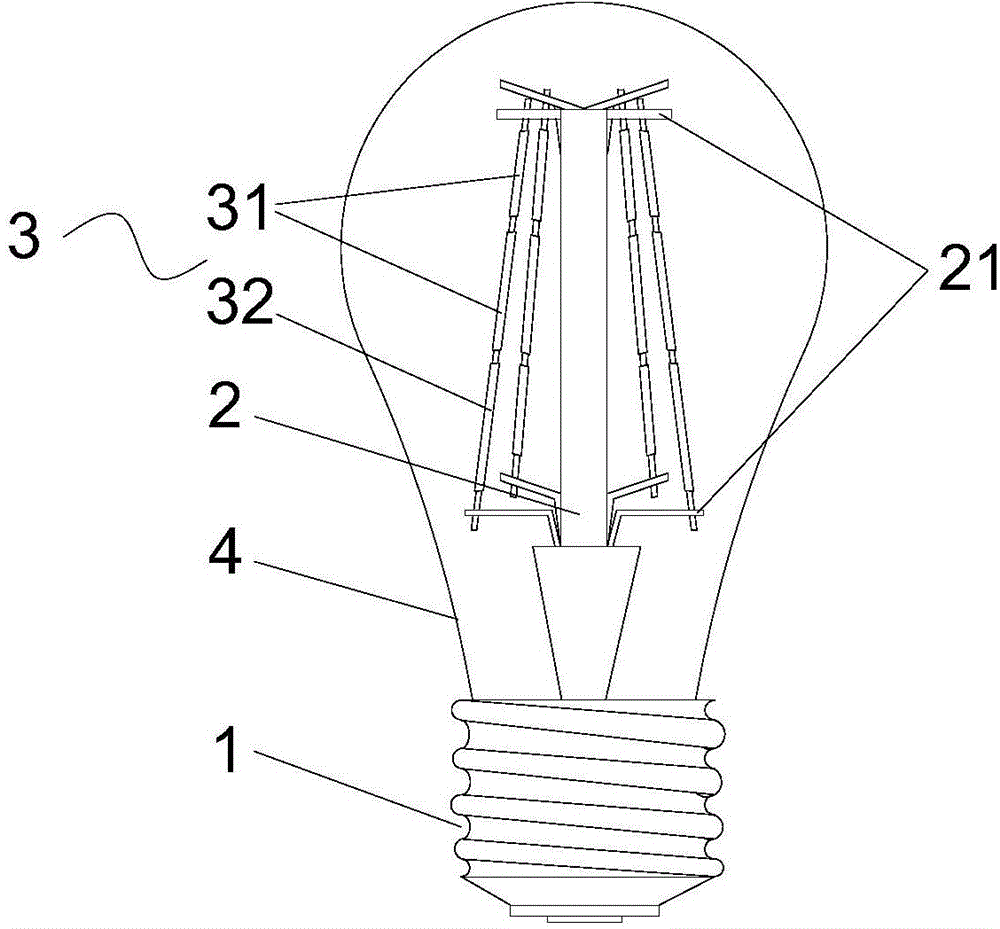

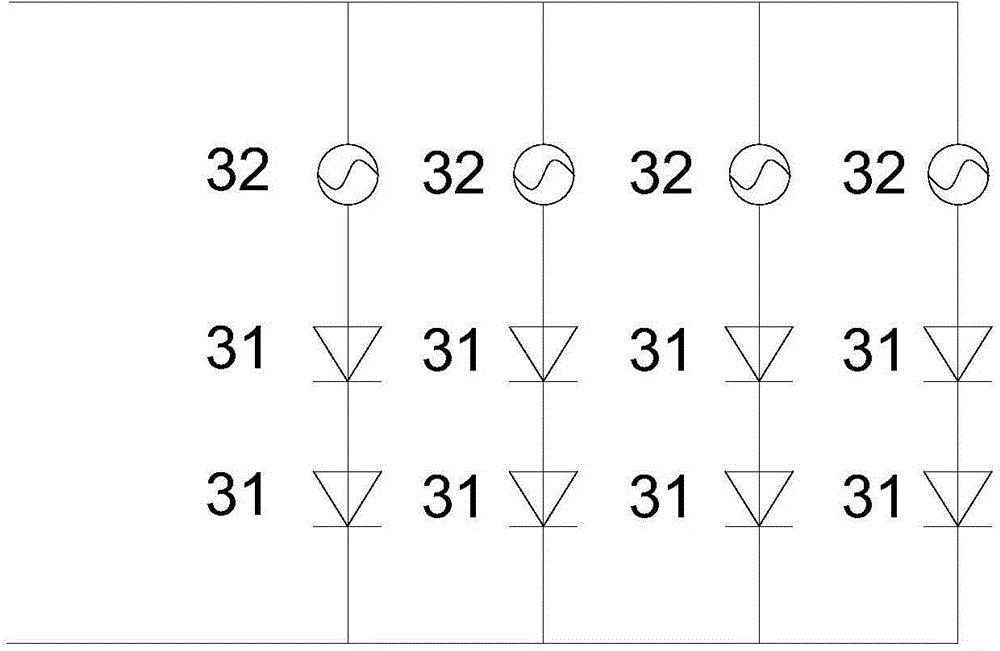

[0016] Such as figure 1 or 2, the present invention includes a lamp cap 1, a stem 2, more than two LED light bars 3, and a lampshade 4; Sealed by the lampshade 4, more than two LED light bars 3 are arranged around the core column 2, and the core column 2 is provided with more than two electrodes 21, and the two ends of each LED light bar 3 are respectively connected to the core. One end of an electrode 21 on the column 2 is connected by butt welding, the other end of the electrode 21 is connected to the lamp cap 1, and is connected to an external AC or DC circuit through the lamp cap 1, and each LED light bar 3 includes a filamentary LED 31 and The LED driving power supply 32 is connected in series with the filamentary LED 31 and drives the filamentary LED 31 to work.

[0017] The LED light bar 3 is a flexible LED light bar.

[0018] There are two LED light bars 3 .

[0019] The LED light bar 3 has more than two filamentary LEDs 31, and the LED light bar 3 has one LED drivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com