Junction box diode sucking device

A suction device and diode technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve problems such as affecting production efficiency, increasing labor costs, affecting the utilization rate of butt welding equipment, etc., to improve work efficiency and ensure position accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing of description and embodiment:

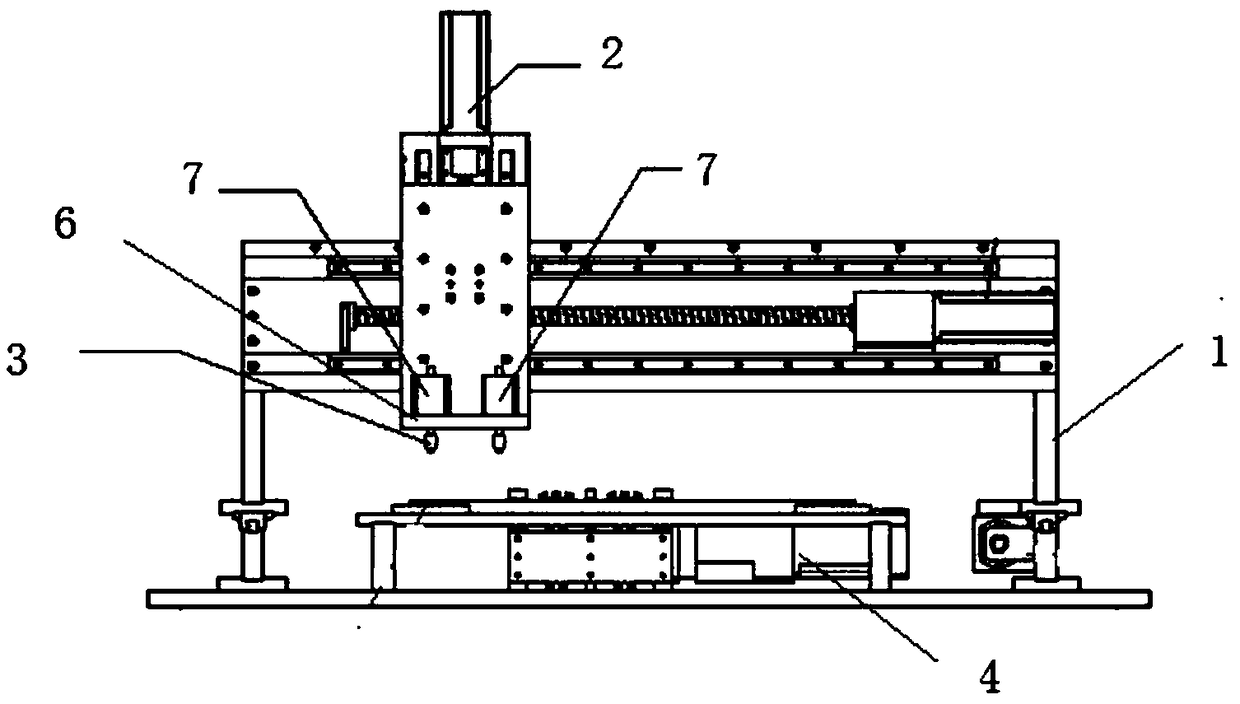

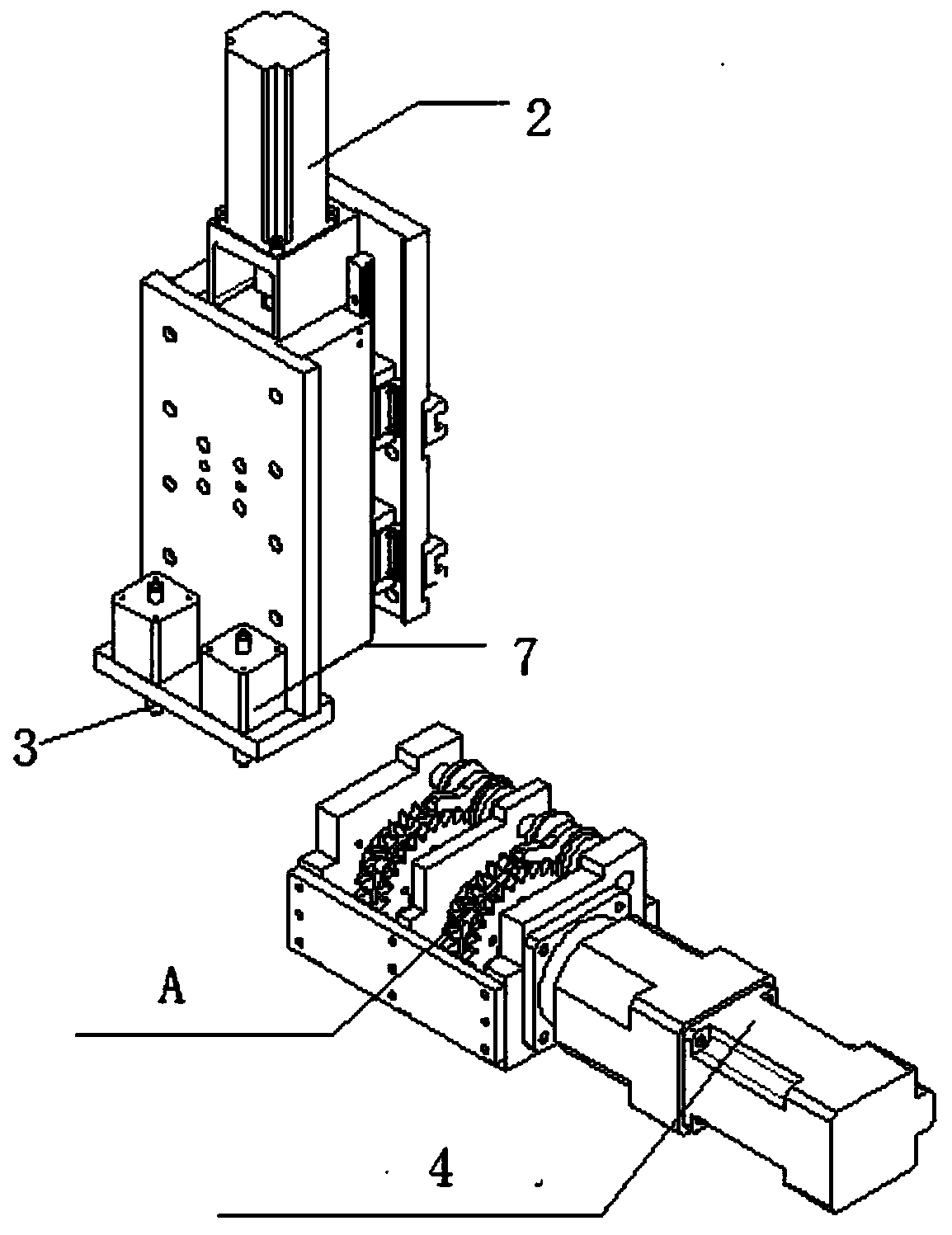

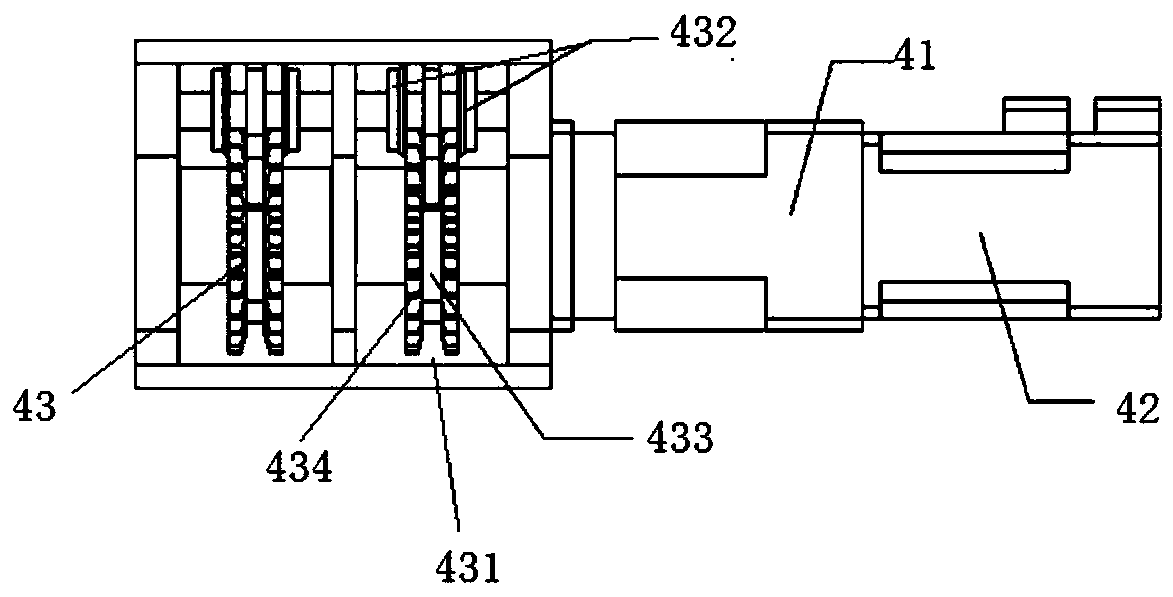

[0015] A junction box diode suction device as shown in the figure includes a frame 1, a suction nozzle driving mechanism 2, a suction nozzle 3 and a diode pin cutting mechanism 4, and the suction nozzle can be operated under the action of the suction nozzle driving mechanism. Mobilely arranged on the upper part of the frame, specifically, the suction nozzle driving mechanism 2 includes a Y-axis moving mechanism, an X-axis moving mechanism and a Z-axis moving mechanism connected in sequence, all of which are driven by a servo motor and a screw nut mechanism; The diode pin cutting mechanism 4 is arranged in the middle of the frame, and is used to cut the diode pins to a fixed length; the diode pin cutting mechanism includes a cutting frame 41, a driving motor 42 and at least one cutting unit 43. The driving motor is arranged on the cutting frame,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com