Additive welding method for large-thickness frame metal parts

A technology for metal parts and welding methods, applied in the field of additive welding, can solve the problems of poor coupling of composite welding technology, low penetration rate of laser welding technology, and difficult implementation work, so as to reduce the difficulty of implementation conditions, reduce welding defects, and solve The effect of a high power threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

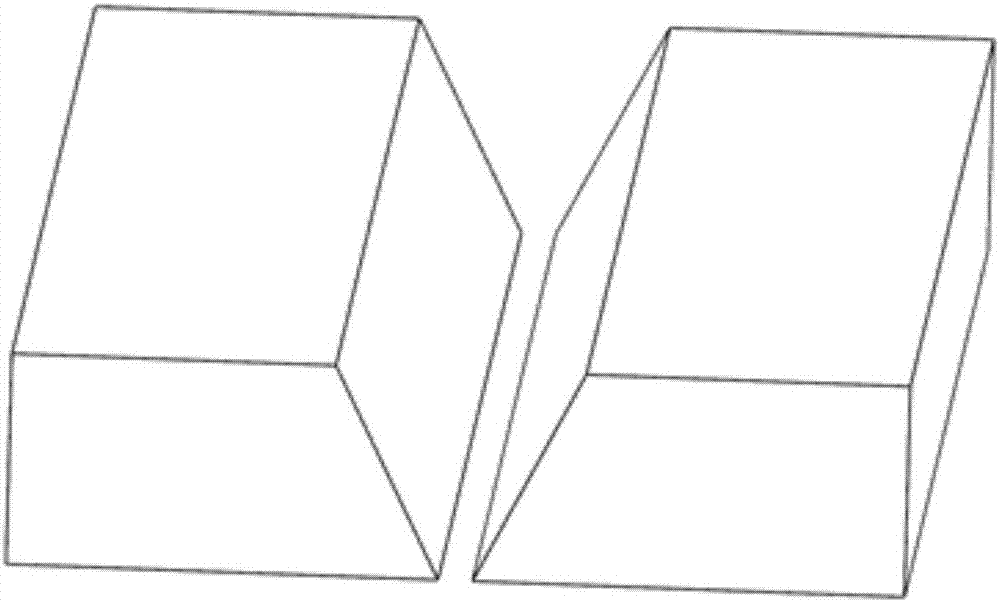

[0032] For the welding of high-performance TC4 titanium alloy parts with a thickness of 140mm, according to assembly requirements, the present invention first prepares a single-sided V-shaped groove on the parts to be welded, the groove angle is 60°, and the blunt edge size is 2-3mm, such as figure 1 As shown, the bevel is prepared by machining. Grind the beveled weldment with sandpaper, then clean it with acetone to remove surface impurities, take it out and dry it, and use the reverse deformation method to clamp the parts to be welded. The solder adopts mechanical ball milling method to prepare TC4 titanium alloy powder, and the particle diameter is 100-150 μm.

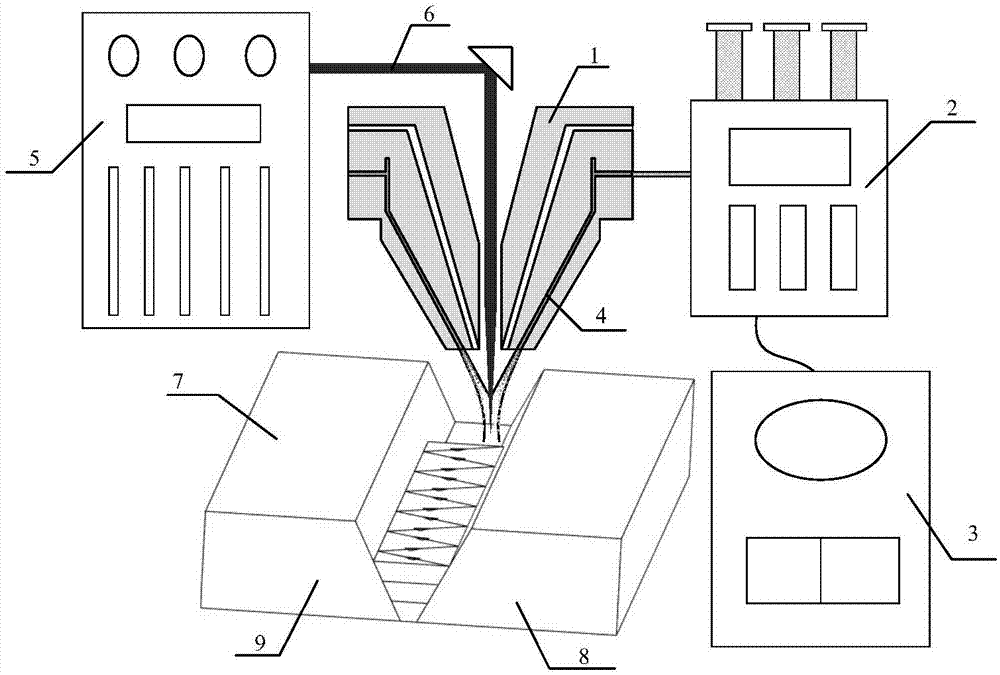

[0033] Conduct laser additive welding experiments, such as figure 2 As shown, the powder feeding head 1 is connected to the powder powder supply box 2, the powder powder supply box 2 is connected to the CNC machine tool 3 on the welding machine, and the powder feeding head transports the alloy powder 4 according t...

Embodiment 2

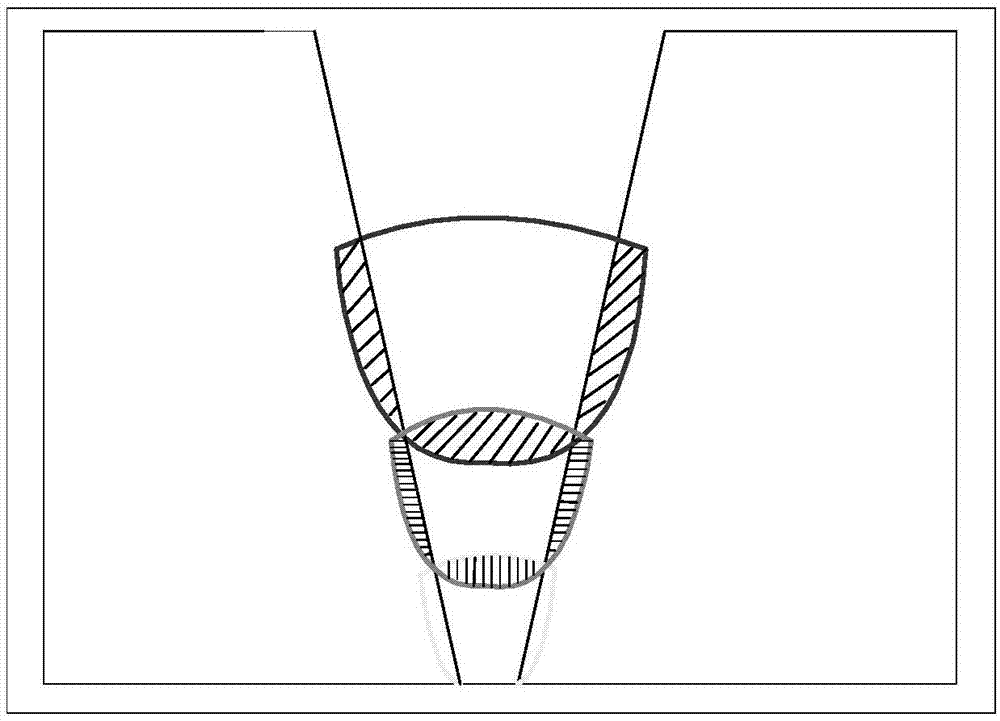

[0036] For the welding of high-performance TC4 titanium alloy parts with a thickness of 140mm, according to assembly requirements, the present invention first prepares a single-sided U-shaped groove on the parts to be welded, the root of the groove is an arc, and the bevel angles on both sides are 3-7° , the blunt edge size is 3-6mm, such as Figure 5 As shown, the bevel is prepared by machining. Grind the beveled weldment with sandpaper, then clean it with acetone to remove surface impurities, take it out and dry it, and use the reverse deformation method to clamp the parts to be welded. The solder is prepared by mechanical ball milling method to prepare TC4 titanium alloy powder, and the particle diameter is 100-150 μm.

[0037] Conduct laser additive welding experiments, such as Image 6 As shown, the powder feeding head 1 is connected to the powder powder supply box 2, the powder powder supply box 2 is connected to the CNC machine tool 3 on the welding machine, and the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com