Three-step approach four-interface system-based heterogeneous material joint structure and heterogeneous material connection method

A technology of heterogeneous materials and connection methods, applied in the direction of welding/welding/cutting items, welding equipment, welding equipment, etc., can solve problems such as difficult fusion, difficult thermal conductivity, uniform heating, and inability to withstand dynamic loads, etc., to achieve Effects of eliminating performance deterioration of welded joints, improving performance of welded joints, and increasing joint strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

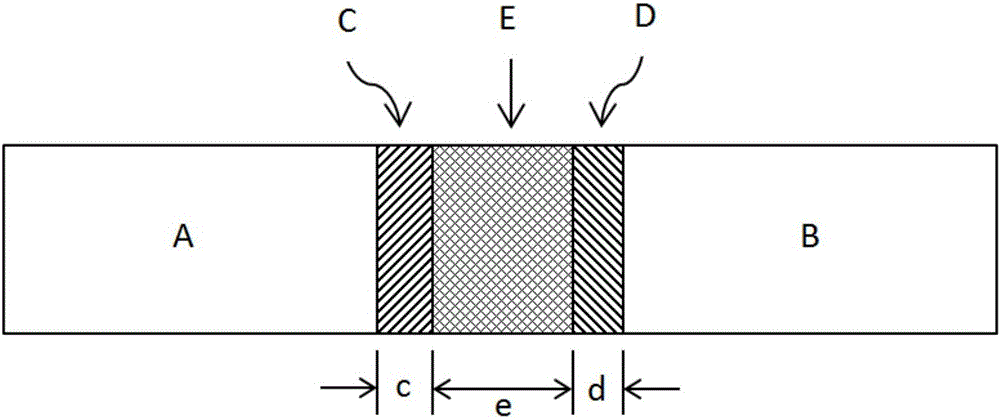

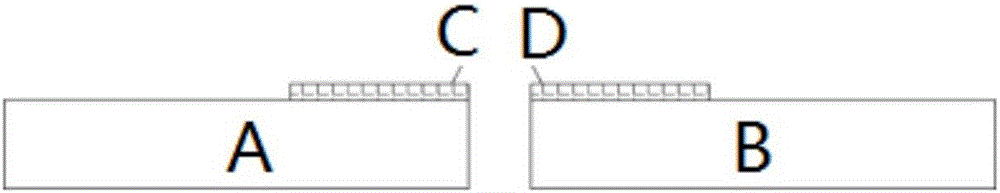

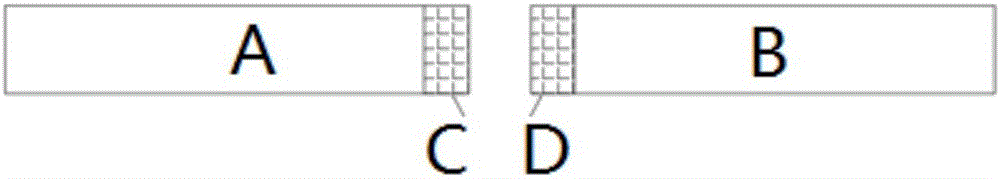

[0030] Embodiment 1: Cold spraying-brazing composite connection method of aluminum alloy 6063 / 316L stainless steel

[0031] The thickness of the aluminum alloy 6063 and 316L stainless steel plate is 4 mm, and the aluminum-silicon alloy powder with a particle size of 10-50 μm is selected as the spraying material. The surfaces of the aluminum alloy 6063 and 316L stainless steel plates to be welded were sandblasted and fixed on the fixture, and a 200 μm aluminum-silicon alloy coating was deposited on the surfaces to be welded of the two base metals by cold spraying, with a coating area of 4 ×4cm. The cold spray gun adopts laval nozzle, and the spraying parameters are: spraying distance 20mm, spray gun moving speed 40mm / s, main gas pressure 3.8MPa, gas temperature 300°C. Then use the furnace to braze the assembly, use Al12Si wire, diameter 1.5mm, brazing temperature 610 ℃, holding time 5min, and cool with the furnace.

Embodiment 2

[0032] Example 2: 316L stainless steel pipe / carbon fiber composite pipe cold spraying-laser welding composite connection method

[0033] 316L stainless steel pipe and carbon fiber composite pipe have an inner diameter of 8mm and an outer diameter of 12mm. Copper powder with a particle size of 10-50μm is used as the spraying material. The butt surface of the carbon fiber composite pipe and the stainless steel pipe was sandblasted and fixed on the fixture, and a 2mm copper coating was deposited on the surface to be welded by cold spraying. The cold spray gun adopts laval nozzle, and the spraying parameters are: spraying distance 20mm, spray gun moving speed 60mm / s, main gas pressure 4.0MPa, gas temperature 500°C. Then the 5kW laser welding method is used to join the two materials at one time.

Embodiment 3

[0034] Embodiment 3: Titanium alloy TC4 and carbon fiber plate spraying-brazing composite connection method

[0035] The length and width of the titanium alloy plate are 1000mm and 200mm respectively, and the length and width of the carbon fiber composite plate are 3000mm and 200mm. Pure titanium powder with a particle size of 10-45 μm is selected as the spraying material. The carbon fiber plate and the titanium alloy plate need to be sandblasted on the joint surface and fixed on the fixture. The cold spray method is used to deposit a 200-300 μm pure titanium layer. The coating area is the area of the lap joint. The cold spray gun adopts laval nozzle, and the spraying parameters are: spraying distance 20mm, spray gun moving speed 40mm / s, main gas pressure 5.0MPa, gas temperature 600°C. Grind the coating so that the upper and lower surfaces make the gap between the contact surfaces less than 0.5mm, and the misalignment less than 0.2mm. The assembly is then furnace brazed. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com