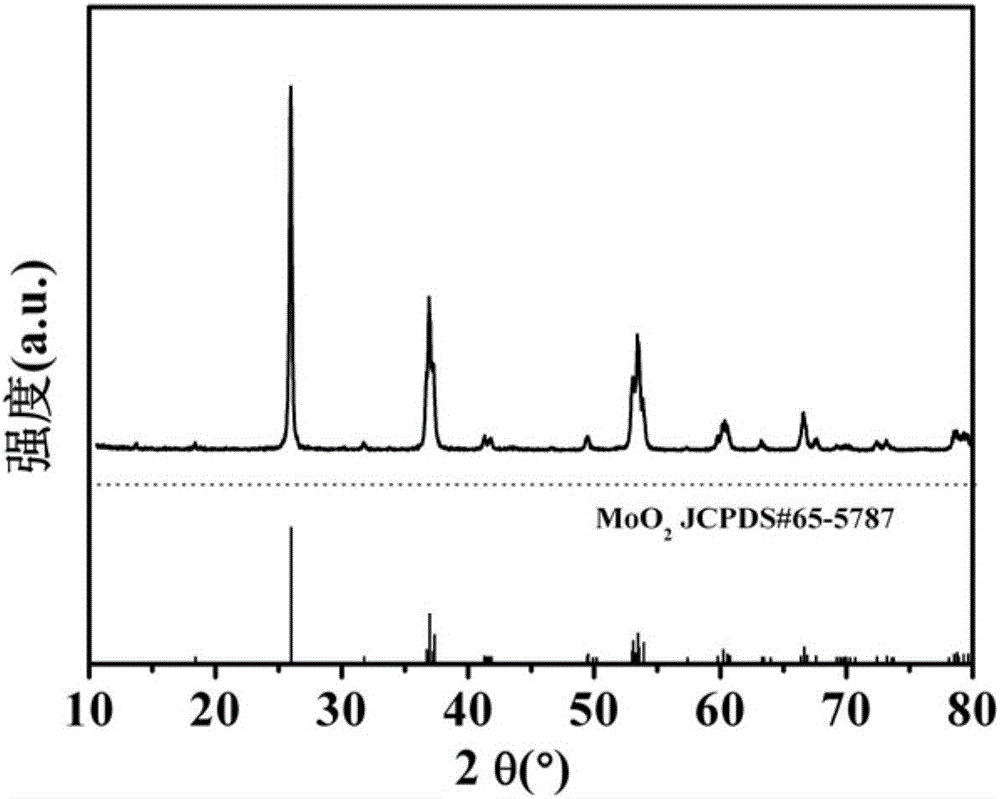

Preparation method of octahedral porous molybdenum dioxide and application of octahedral porous molybdenum dioxide in lithium-ion battery

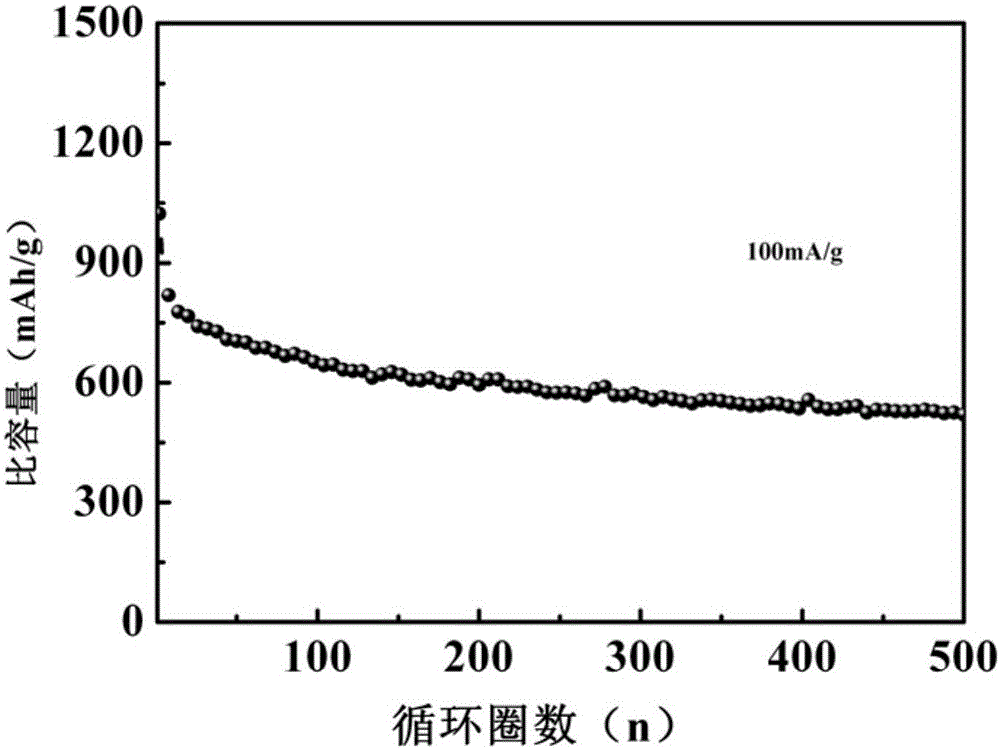

A molybdenum dioxide and octahedral technology, which is applied in the field of new energy materials, can solve the problems of difficult control of synthesis conditions, difficult control of morphology and structure, and difficulty in mass production, so as to reduce structural changes and performance deterioration, improve cycle stability, Beneficial to industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] According to the molar ratio of copper source and molybdenum source being 9:1, 1 mmol of copper nitrate and 0.11 mmol of phosphomolybdic acid were weighed respectively, and added to 10 mL of deionized water successively, and 1 mmol of trimesic acid and 1 mmol of tetramethylene tricarboxylic acid were continuously added under magnetic stirring conditions. Methylammonium hydroxide, after fully stirring for 0.5h, transfer the mixed solution into a hydrothermal reaction kettle, conduct a hydrothermal reaction at 180°C for 48h, wash the product with distilled water, dry it in an oven, and place it In a quartz crucible, argon gas was introduced to conduct high-temperature heat treatment at 850°C for 8 hours. The product was washed with ferric chloride solution and dried to obtain an octahedral porous molybdenum dioxide material.

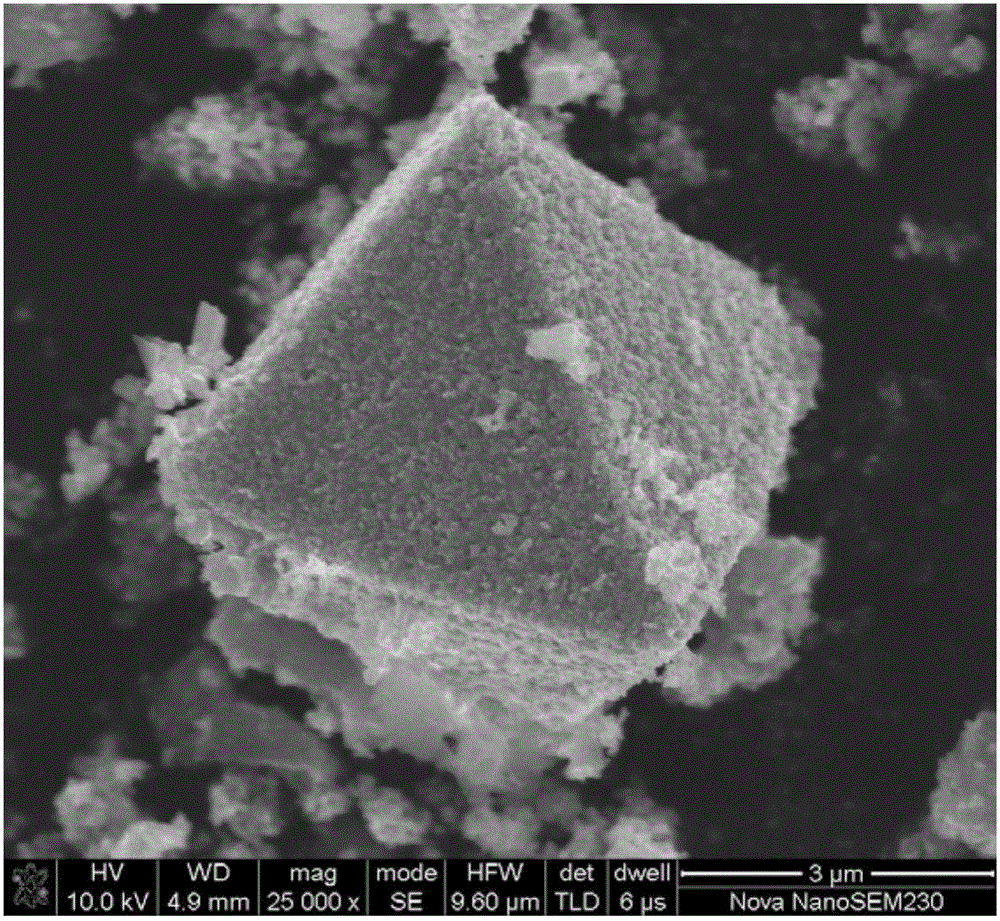

[0037] Using the octahedral porous molybdenum dioxide material prepared in this embodiment, the molybdenum dioxide nanoparticles are constructed to ...

Embodiment 2

[0044] According to the molar ratio of copper source and molybdenum source as 8:1, 1 mmol of copper nitrate and 0.125 mmol of phosphomolybdic acid were weighed respectively, and added to 10 mL of deionized water successively, and 0.5 mmol of trimesic acid and 0.5 mmol tetramethylammonium hydroxide, after fully stirring for 0.5h, transfer the mixed solution into a hydrothermal reaction kettle, carry out a hydrothermal reaction at 180°C for 36h, wash the product with distilled water, place it in an oven and dry it. It is placed in a quartz crucible, fed with argon gas for high-temperature heat treatment at 800°C for 6 hours, washed with ferric chloride solution, and dried to obtain an octahedral porous molybdenum dioxide material.

[0045] Using the octahedral porous molybdenum dioxide material prepared in this example, molybdenum dioxide nanoparticles are constructed to form a uniform octahedral structure rich in pores, and the particle size is 5-7 μm.

[0046] The electrode co...

Embodiment 3

[0048] According to the molar ratio of copper source and molybdenum source being 8:1, 1 mmol of copper nitrate and 0.125 mmol of phosphomolybdic acid were weighed respectively, and successively added to 10 mL of deionized water, and 1 mmol of trimesic acid and 1 mmol of tetramethylene tricarboxylic acid were continuously added under magnetic stirring conditions. Methylammonium hydroxide, after fully stirring for 0.5h, transfer the mixed solution into a hydrothermal reaction kettle, conduct a hydrothermal reaction at 180°C for 48h, wash the product with distilled water, dry it in an oven, and place it In a quartz crucible, argon gas is introduced to conduct high-temperature heat treatment at 800°C for 10 hours. The product is washed with ferric chloride solution and dried to obtain an octahedral porous molybdenum dioxide material.

[0049] Using the octahedral porous molybdenum dioxide material prepared in this embodiment, the molybdenum dioxide nanoparticles are constructed to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com