Method for manufacturing complex intersecting line hot rolling steel tube joint

A production method and technology of intersecting lines are applied in the field of production of complex intersecting line hot-rolled steel pipe joints to achieve the effects of improving efficiency, solving welding problems, and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

[0026] The manufacturing method of the steel pipe node of the present embodiment comprises the following steps:

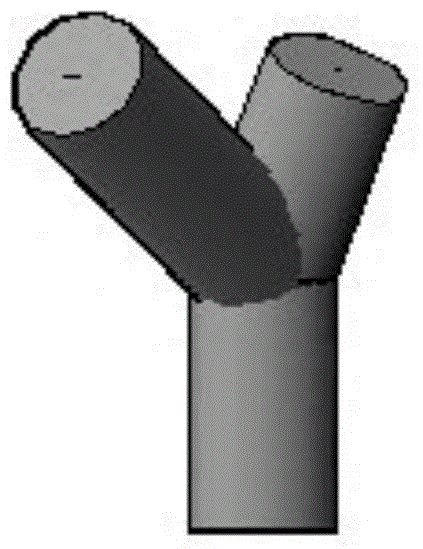

[0027] (1) if figure 1 As shown, the specification of the three branch steel pipes of the three-pipe intersecting node is Φ1050*70, the material is Q390GJC, and each branch steel pipe is unfolded and cut;

[0028] The ratio of the diameter Ф of the branch steel pipe to the wall thickness t of the steel pipe satisfies 15≤Ф / t≤20, and the wall thickness of the steel pipe is 50mm≤t≤100mm.

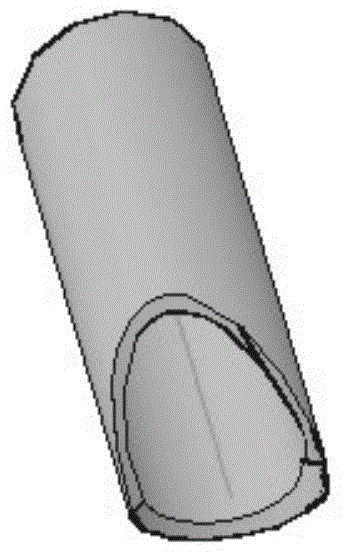

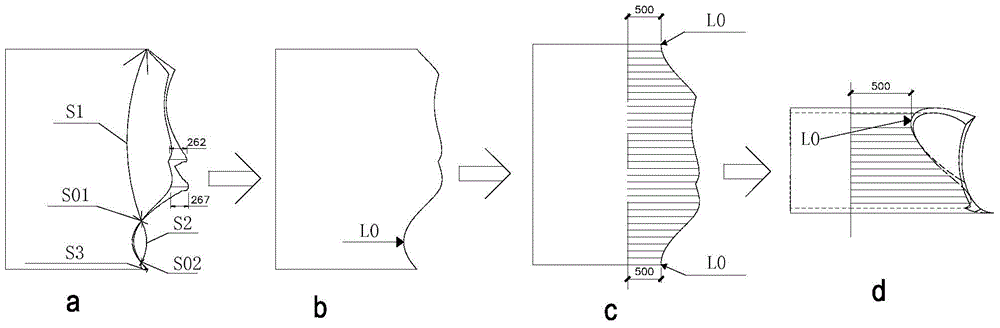

[0029] The specific unfolding method is as follows:

[0030] (11) Through solid modeling, the three-pipe intersecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com