A combined permanent magnet with enhanced regional magnetic field strength

A technology of magnetic field strength and permanent magnets, applied in the direction of magnetic objects, magnetic materials, permanent magnets, etc., can solve the problems of occupied volume, demagnetization failure of permanent magnets, low production efficiency, etc., to solve serious demagnetization, improve power generation efficiency, and bond high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

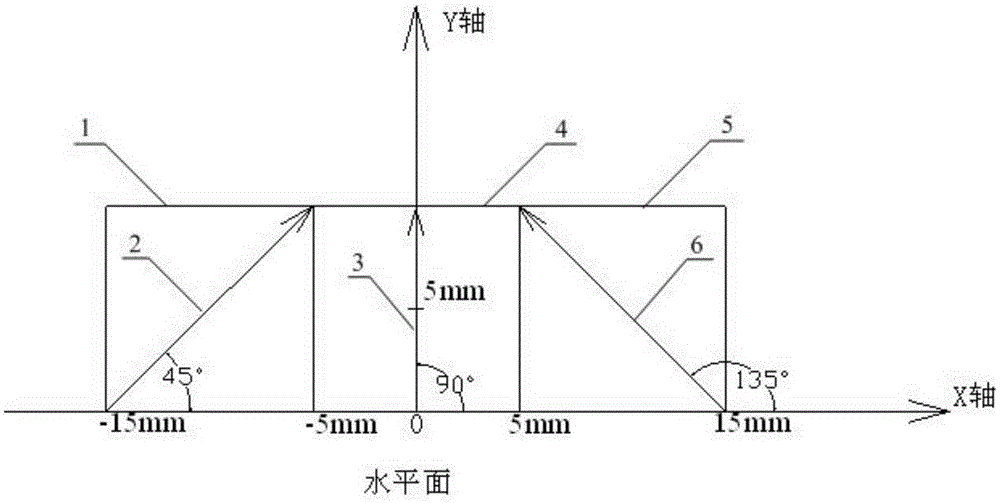

[0028] Positive combined permanent magnet: a cuboid combined permanent magnet formed by parallel welding of three sub-magnets of the same size, 10mm×10mm×10mm, cubic N50 NdFeB permanent magnets, such as figure 1 Shown: a cuboid combined permanent magnet formed by parallel welding of three cube-shaped sub-magnets 1, 4, and 5 of the same size. The combined permanent magnet is placed on a horizontal plane, and the magnetic field direction 3 of the middle sub-magnet is perpendicular to The horizontal plane is upward, the magnetic field direction 2 of the left terminal magnet is parallel to the direction where the welding seam on the upper surface of the left terminal magnet 1 forms an angle with the horizontal plane at an angle of 45°, and the magnetic field direction 6 of the right terminal magnet is parallel to the upper surface of the right terminal magnet 5 The direction where the diagonal surface where the weld is located and forms an angle of 135° with the horizontal plane; ...

Embodiment 2

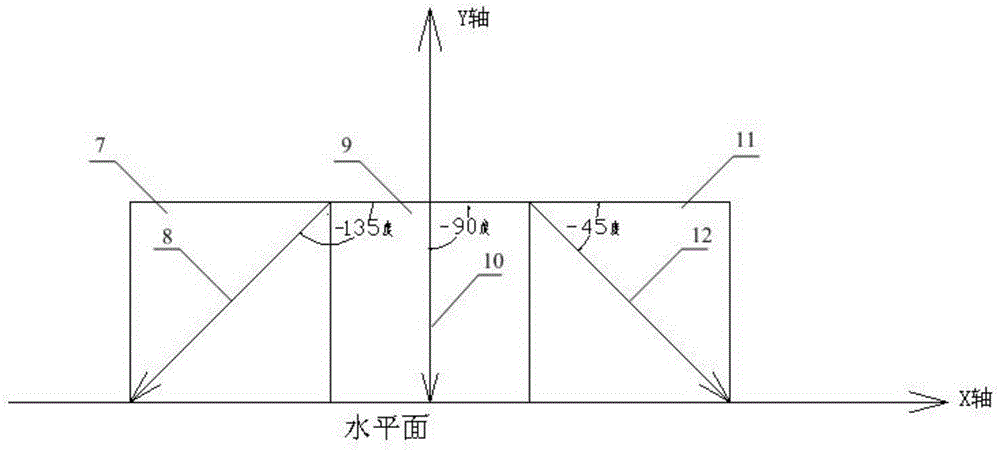

[0032] Negative combined permanent magnet: a cuboid combined permanent magnet formed by parallel welding of three sub-magnets of the same size 10mm×10mm×10mm cubic N50 NdFeB permanent magnets 7, 9 and 11, such as figure 2 As shown: when the combined permanent magnet is placed on a horizontal plane, the magnetic field direction 10 of the middle sub-magnet is perpendicular to the horizontal plane downward, and the magnetic field direction 8 of the left terminal magnet is parallel to the diagonal plane where the welding seam on the upper surface of the left terminal magnet 7 is located. In the direction of a negative 135° angle with the horizontal plane, the magnetic field direction 12 of the right terminal magnet is parallel to the diagonal surface where the welding seam on the upper surface of the right terminal magnet 11 is located and is at a negative 45° angle with the horizontal plane.

[0033] The welding is electron beam welding, laser welding or ion beam welding; the wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com