Ship-building steel small-groove submerged-arc welding agent and preparation method thereof

A technology for marine steel and grooves, applied in welding equipment, welding media, manufacturing tools, etc., can solve the problems of lack of weld mechanical properties, insufficient flux slag removal, and high requirements for flux particles, and achieve good slag removal. Welding process performance and mechanical properties, good effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A marine steel small groove submerged arc welding flux, its mineral raw material components account for the following weight percentages: fluorite: 20%; magnesia: 20%; rutile: 14%; white corundum: 15%; wollastonite: 18%; manganese ore: 10%; ferrosilicon: 3%. The preparation method of the flux is first to dry mix the powder weighed by weight percentage in a dry mixer, put it into a wet mixer after dry mixing evenly, add water glass with a total weight of 24% of the ingredients for wet mixing, and wet mix evenly Send the wet powder to the granulation tray through the conveyor belt for granulation, bake at 250°C to 300°C for 1 hour, and sieve the flux after removing moisture, and sieve the flux within the standard particle range at 750°C to 800°C Sinter at high temperature for 1 hour, and pass through a 10-mesh to 40-mesh sieve after cooling in the furnace to obtain the finished sintered flux.

Embodiment 2

[0038] A kind of marine steel small-groove submerged arc welding flux, its mineral raw material components account for the following weight percentages: fluorite: 10%; magnesia: 28%; rutile: 20%; white corundum: 24%; wollastonite: 10%; manganese ore: 1%; 45 ferrosilicon 7%. The preparation method of the flux is first to dry mix the powder weighed by weight percentage in a dry mixer, put it into a wet mixer after dry mixing evenly, add water glass with a total weight of 24% of the ingredients for wet mixing, and wet mix evenly Send the wet powder to the granulation tray through the conveyor belt for granulation, bake at 250°C to 300°C for 1 hour, and sieve the flux after removing moisture, and sieve the flux within the standard particle range at 750°C to 800°C Sinter at high temperature for 1 hour, and pass through a 10-mesh to 40-mesh sieve after cooling in the furnace to obtain the finished sintered flux.

Embodiment 3

[0040]A kind of marine steel small-groove submerged arc welding flux, its mineral raw material components account for the following weight percentages: fluorite: 14%; magnesia: 15%; rutile: 10%; white corundum: 30%; wollastonite: 25%; manganese ore: 5%; 45 ferrosilicon: 1%. The preparation method of the flux is first to dry mix the powder weighed by weight percentage in a dry mixer, put it into a wet mixer after dry mixing evenly, add water glass with a total weight of 24% of the ingredients for wet mixing, and wet mix evenly Send the wet powder to the granulation tray through the conveyor belt for granulation, bake at 250°C to 300°C for 1 hour, and sieve the flux after removing moisture, and sieve the flux within the standard particle range at 750°C to 800°C Sinter at high temperature for 1 hour, and pass through a 10-mesh to 40-mesh sieve after cooling in the furnace to obtain the finished sintered flux.

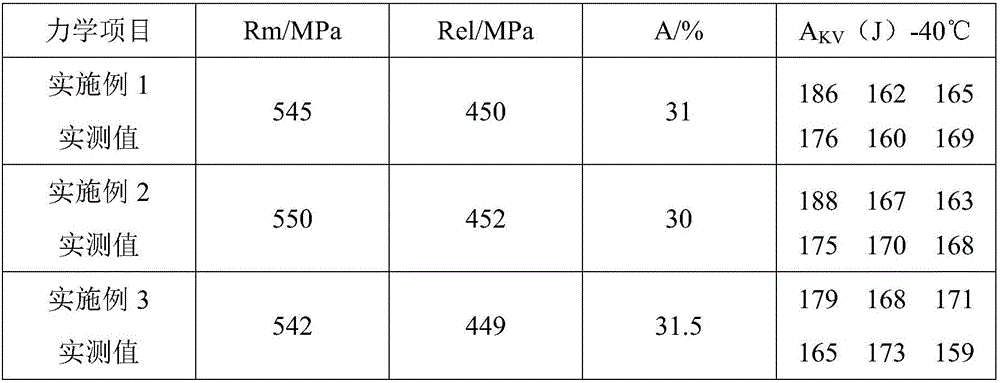

[0041] Use the above flux with GB / T H10MnSi submerged arc welding wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com