Patents

Literature

59results about How to "Beautiful craftsmanship" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

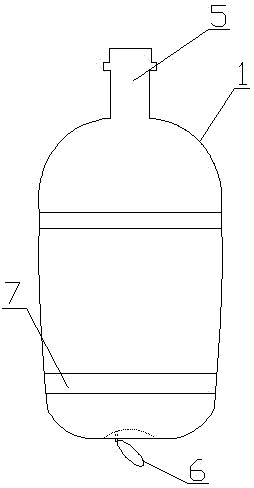

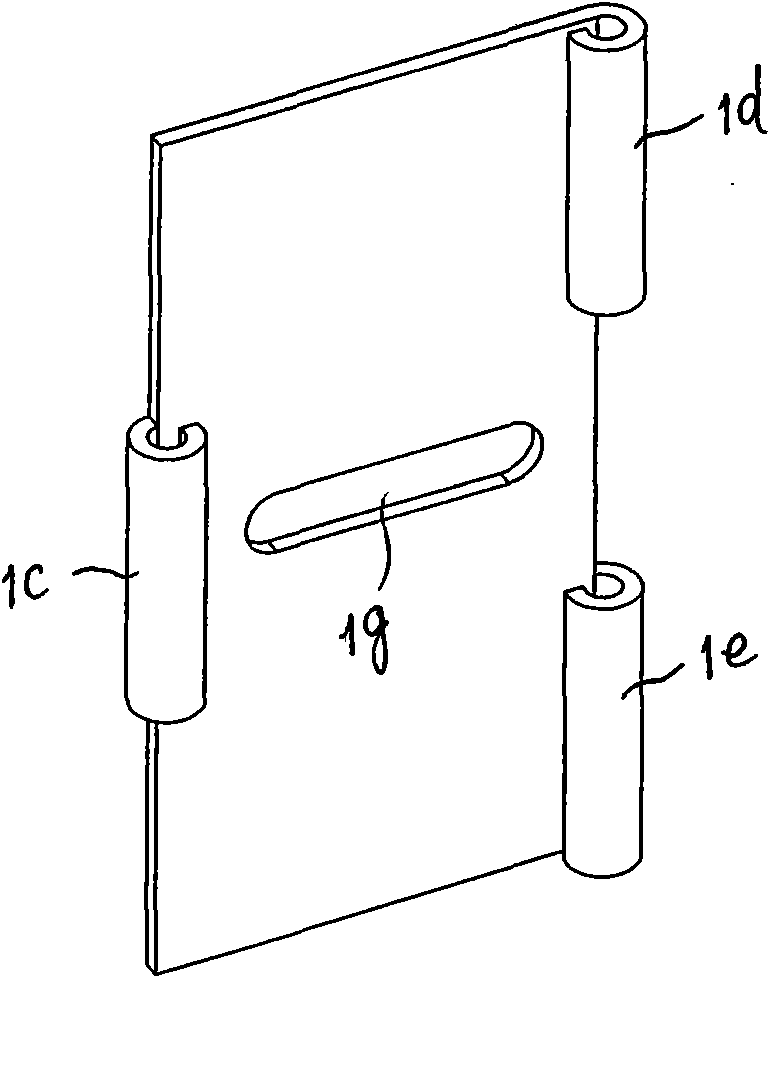

Three-layer medical infusion bag and manufacturing method thereof

InactiveCN103893012AImprove oxygen barrierImprove water resistanceInfusion devicesPharmaceutical containersPolypropyleneBiomedical engineering

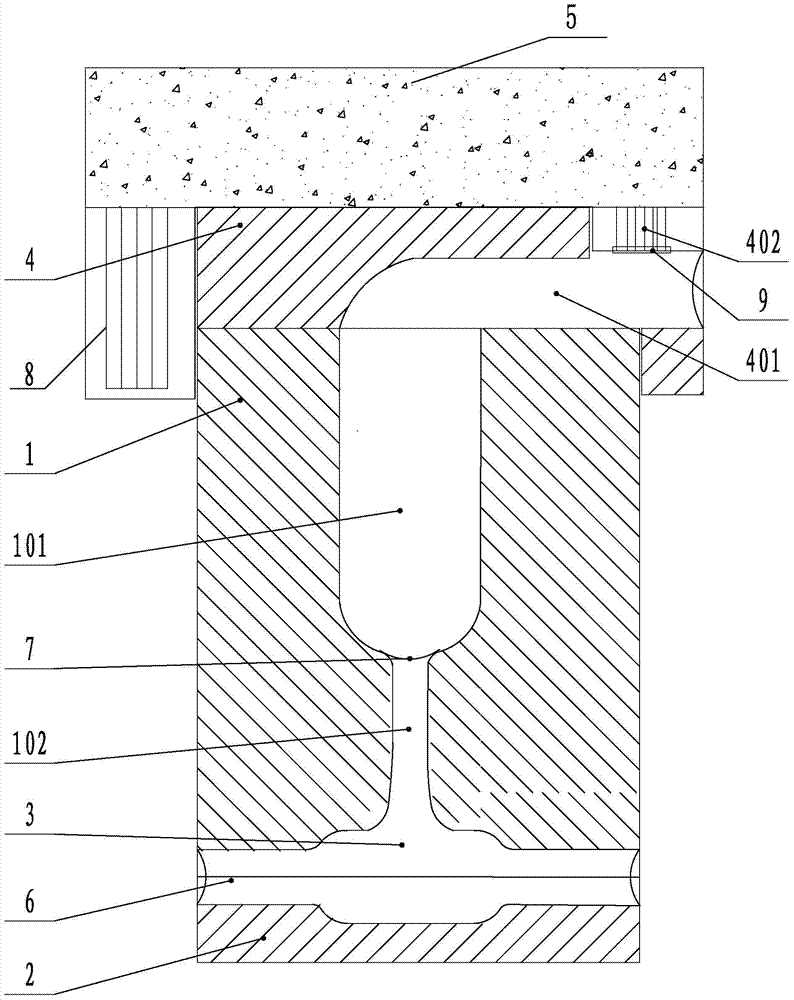

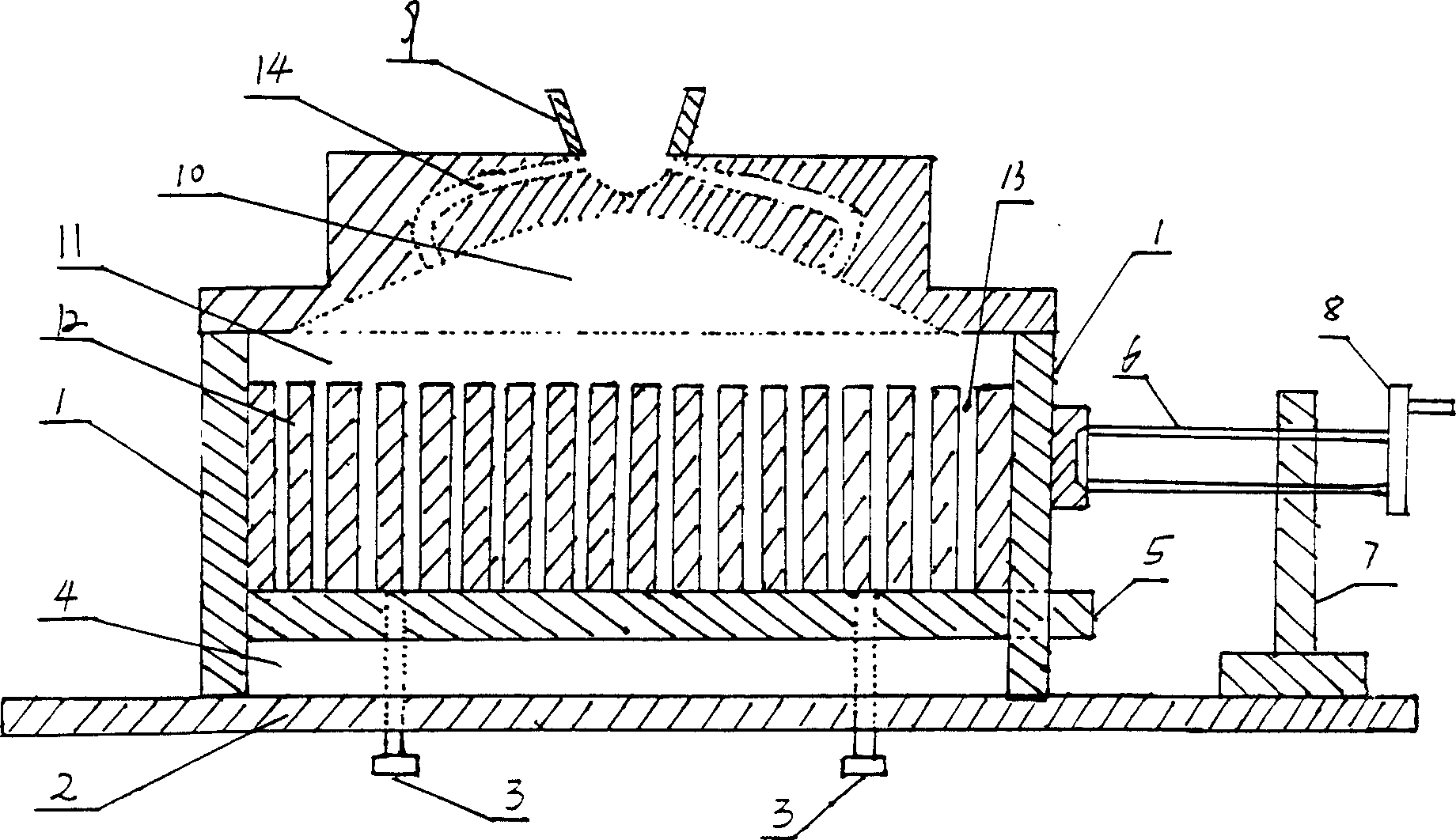

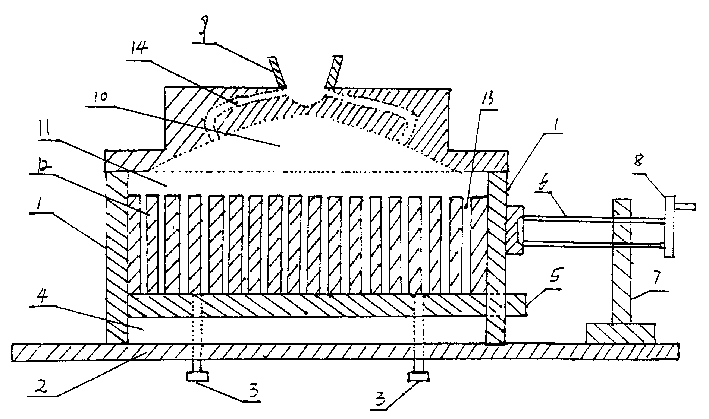

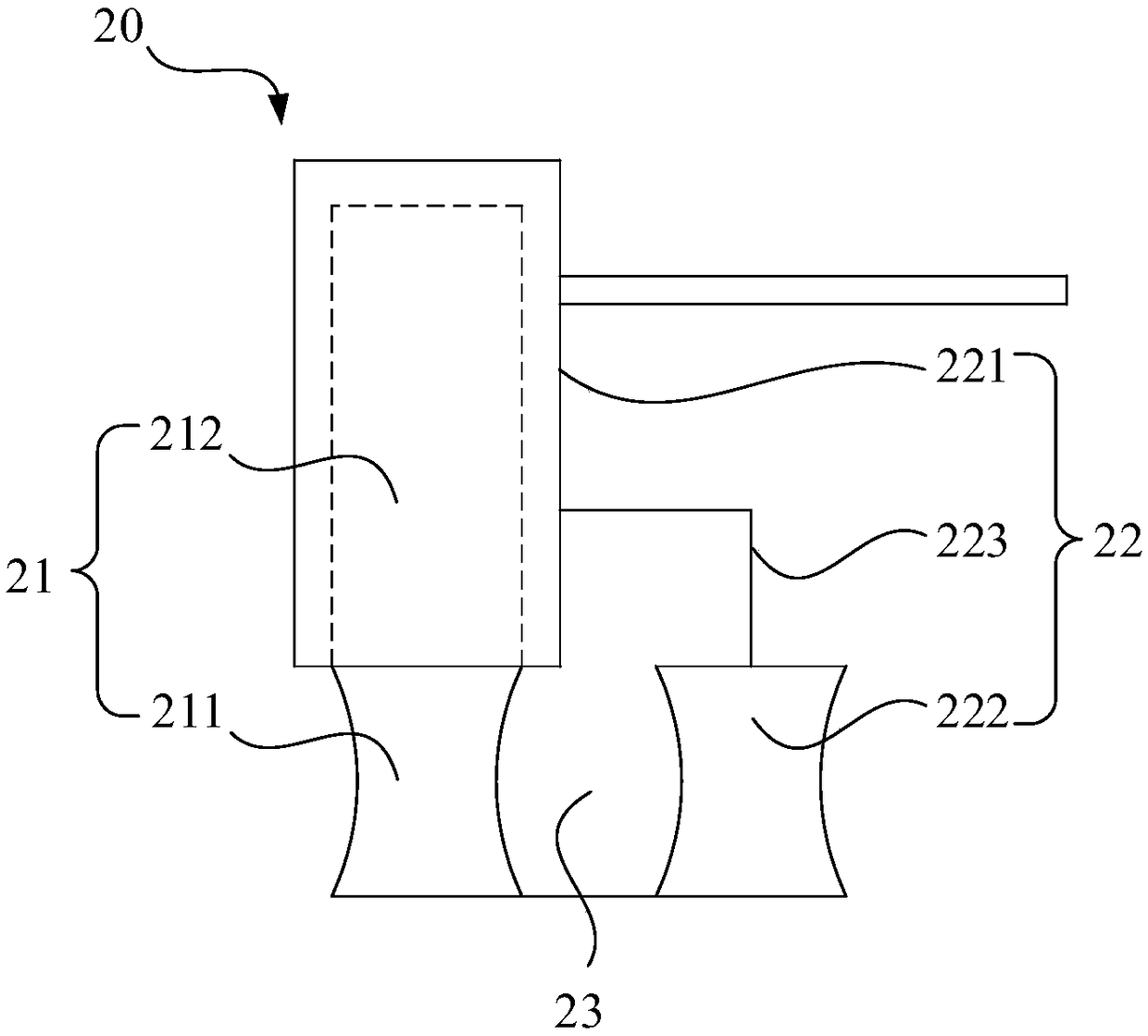

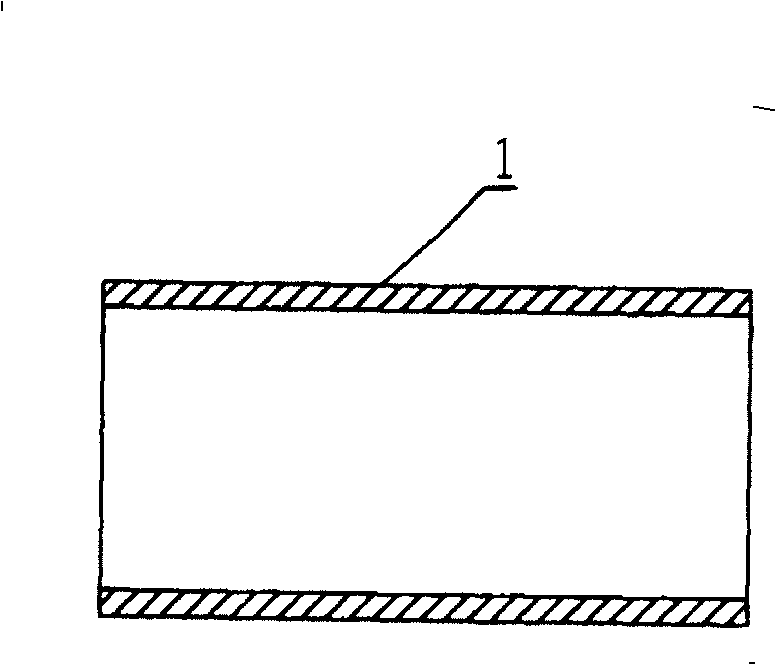

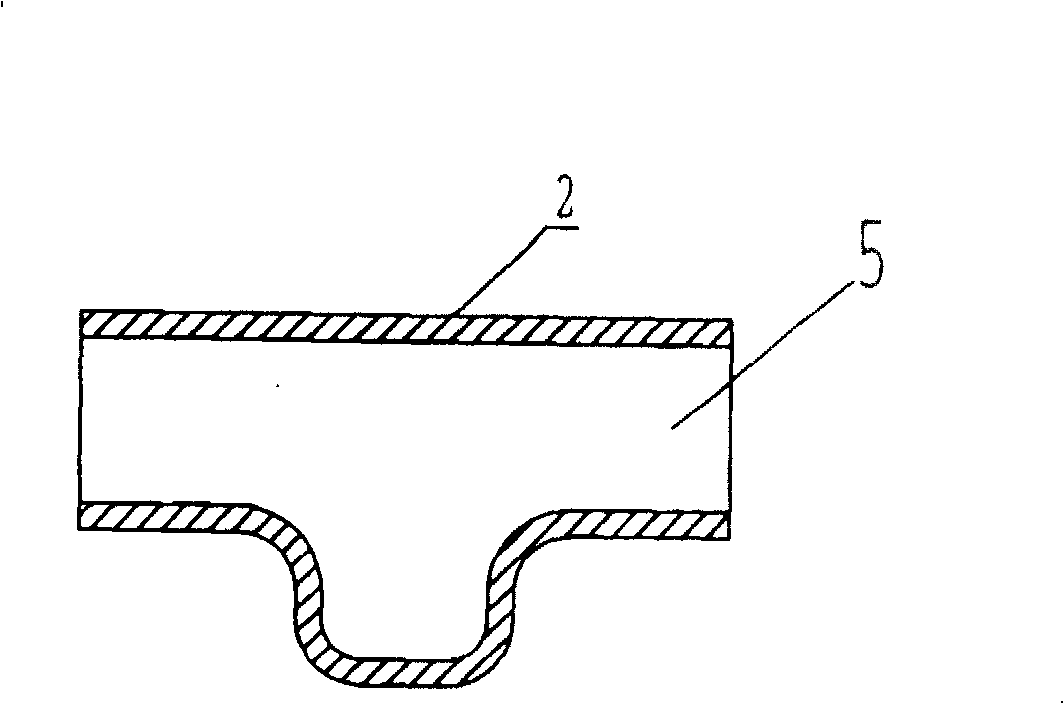

The invention aims to provide a three-layer medical infusion bag. The three-layer medical infusion bag comprises a flat infusion bag body of a three-layer structure. The three-layer structure comprises an inner bag layer made of polyethylene material, a middle bag layer made of polypropylene and styrene-ethylene / butylene-styrene segmented copolymer material and an outer bag layer which is a blended layer of polypropylene, carboxylated styrene-ethylene / butylene-styrene segmented copolymer and anionic polymerization nylon nanocomposite. The barrier performance of the anionic polymerization nylon nanocomposite of the outer bag layer is excellent. Air inlet is not needed in the infusion process and medicine liquid can automatically flow and is completely drained through the design of the thickness and the width of the infusion bag body, and therefore the whole infusion bag is good in safety, barrier property and infusion performance. The invention further provides a manufacturing method of the three-layer medical infusion bag. One-time injection molding and air blowing are conducted through a three-die-head injection molding die, the whole process is simple and advanced, one-time forming is achieved, the method is suitable for production of the infusion bag, and the manufactured infusion bag meets the infusion requirement.

Owner:ANHUI DOUBLE CRANE PHARMA

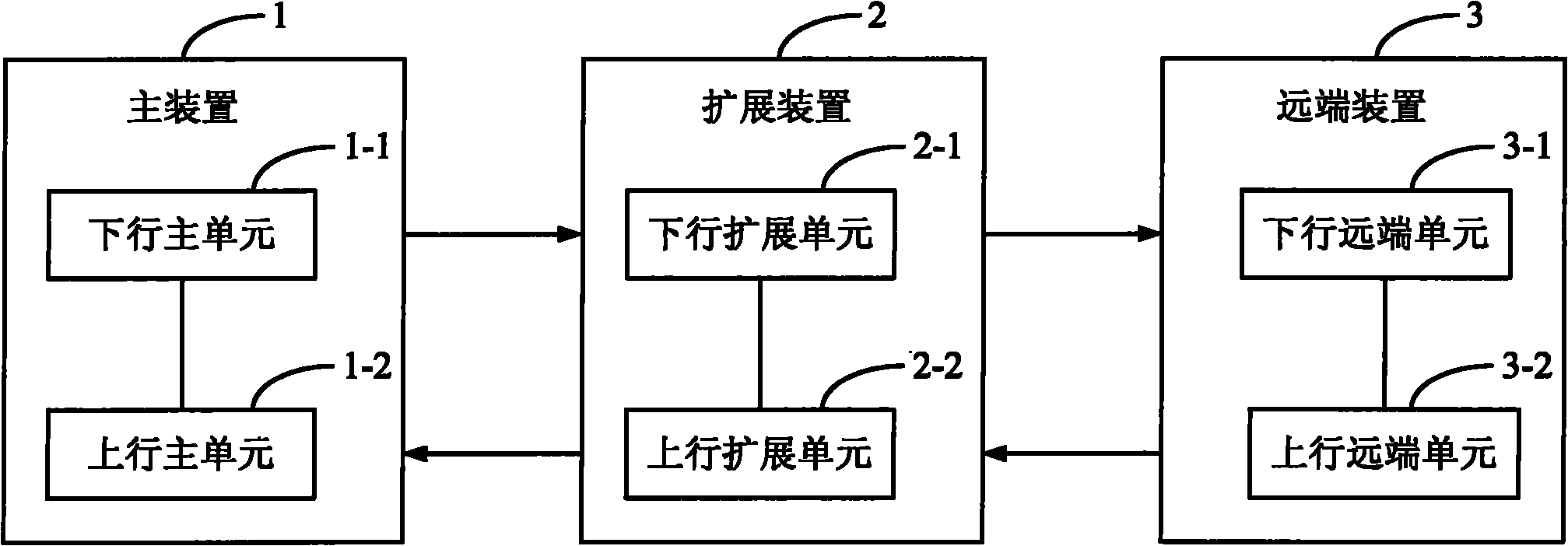

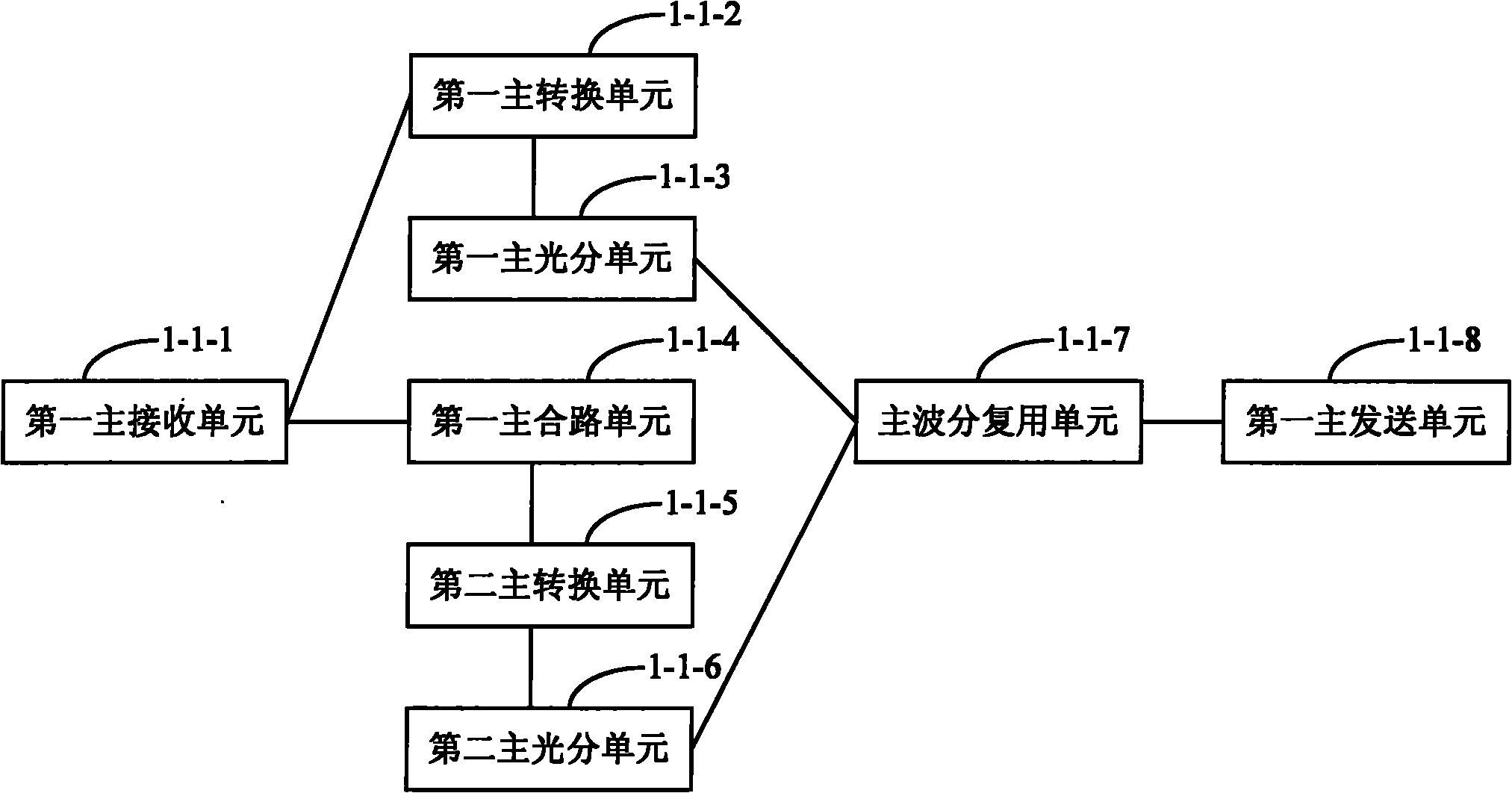

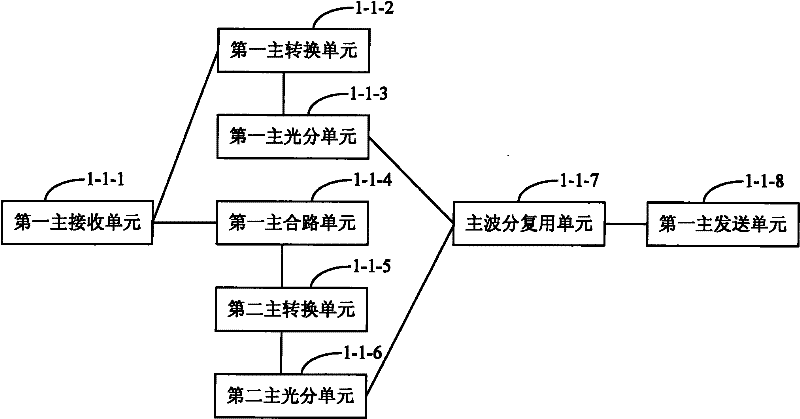

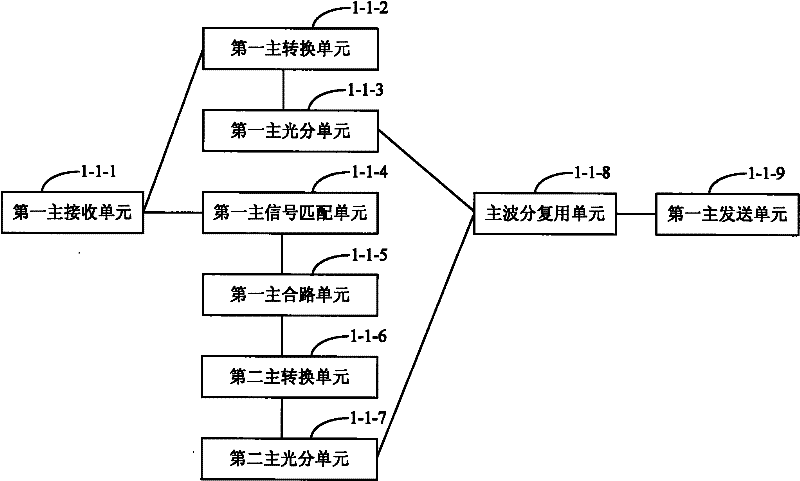

Main device for wireless communication multi-network integration, expansion device and remote device

InactiveCN102137406AImprove stabilityImprove reliabilityNetwork topologiesNetwork planningMultiplexingCarrier signal

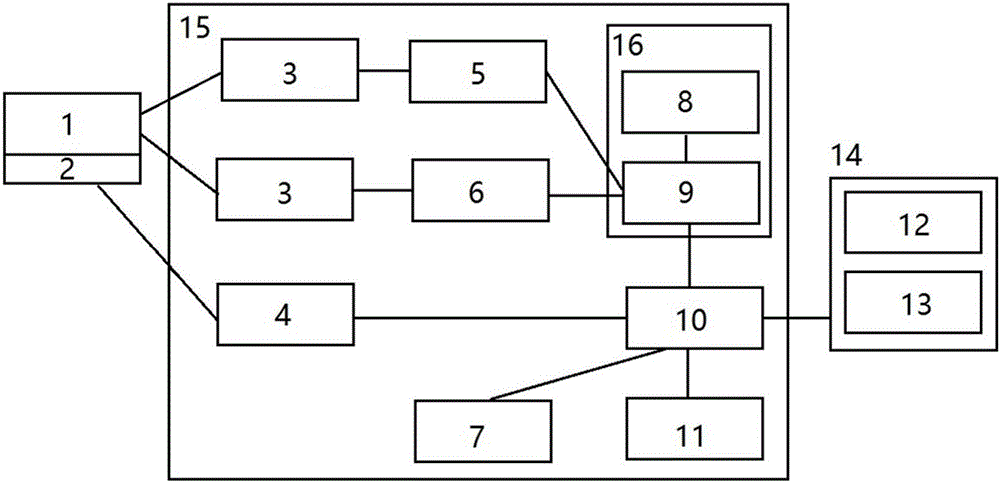

The invention provides a main device for wireless communication multi-network integration, an expansion device and a remote device, wherein the main device comprises an uplink main unit and a downlink main unit, wherein the downlink main unit is used for receiving main unit Internet access signals and mobile communication signals, respectively converting the main unit Internet access signals and the mobile communication signals into downlink network optical signals modulated by a first optical carrier and downlink optical signals modulated by a second optical carrier, carrying out wavelength division multiplexing on the downlink network optical signals and the downlink optical signals to form downlink multiplexing optical signals, and transmitting each path of downlink multiplexing optical signals to a downlink network element; and the uplink main unit is used for uplink multiplexing optical waves, decomposing the multiplexing optical waves into network optical signals modulated by the first optical carrier and uplink optical signals modulated by the second optical carrier, converting the network optical signals modulated by the first optical carrier into main unit Internet outputsignals and outputting the main unit Internet output signals through a network access interface, and converting uplink optical signals modulated by the second optical carrier into electric signals and outputting the electric signals through a radio frequency access interface. A distributed system is formed by adopting three devices so that multi-network signal fusion of Internet, mobile communication and the like is directly realized, and therefore, network operation stability and reliability are effectively enhanced.

Owner:北京裕源大通科技股份有限公司

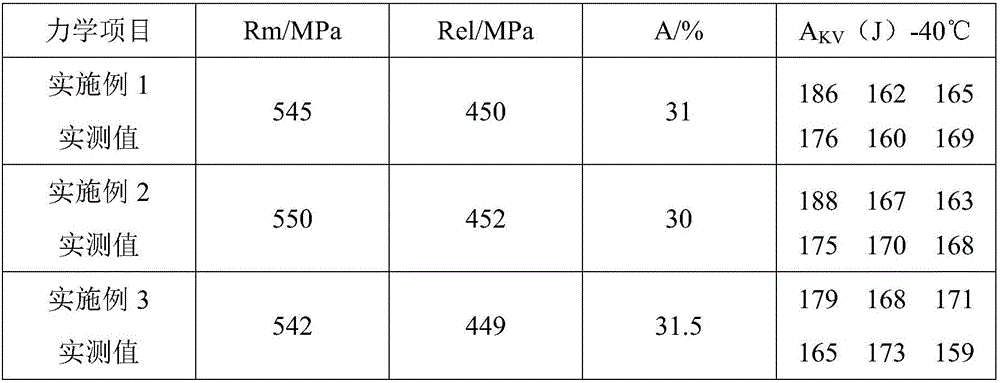

Ship-building steel small-groove submerged-arc welding agent and preparation method thereof

InactiveCN106736044ALow hygroscopicityLow costWelding/cutting media/materialsSoldering mediaSlagRutile

The invention discloses a ship-building steel small-groove submerged-arc welding agent and a preparation method thereof. The ship-building steel small-groove submerged-arc welding agent comprises the following raw materials, by weight, of 15-28% of magnesite, 15-30% of white corundum, 10-25% of grammite, 10-20% of fluorite, 10-20% of rutile, 1-10% of manganese ores and 1-7% of silicon iron. The sum of the weight percentage of the components is 100%. The ship-building steel small-groove submerged-arc welding agent has low hygroscopicity; electric arc welding is stable; the slag detachability of the welding agent after welding is good; the appearance of a welded joint is attractive after forming; slag shells can automatic cock after welding; and no defects such as undercuts exist. The production efficiency is high, the comprehensive cost is low, the welding quality is good, and the welding agent is quite suitable for submerged arc welding under the condition of small grooves of ship-building steel.

Owner:SHANGHAI HULIN HEAVY IND +2

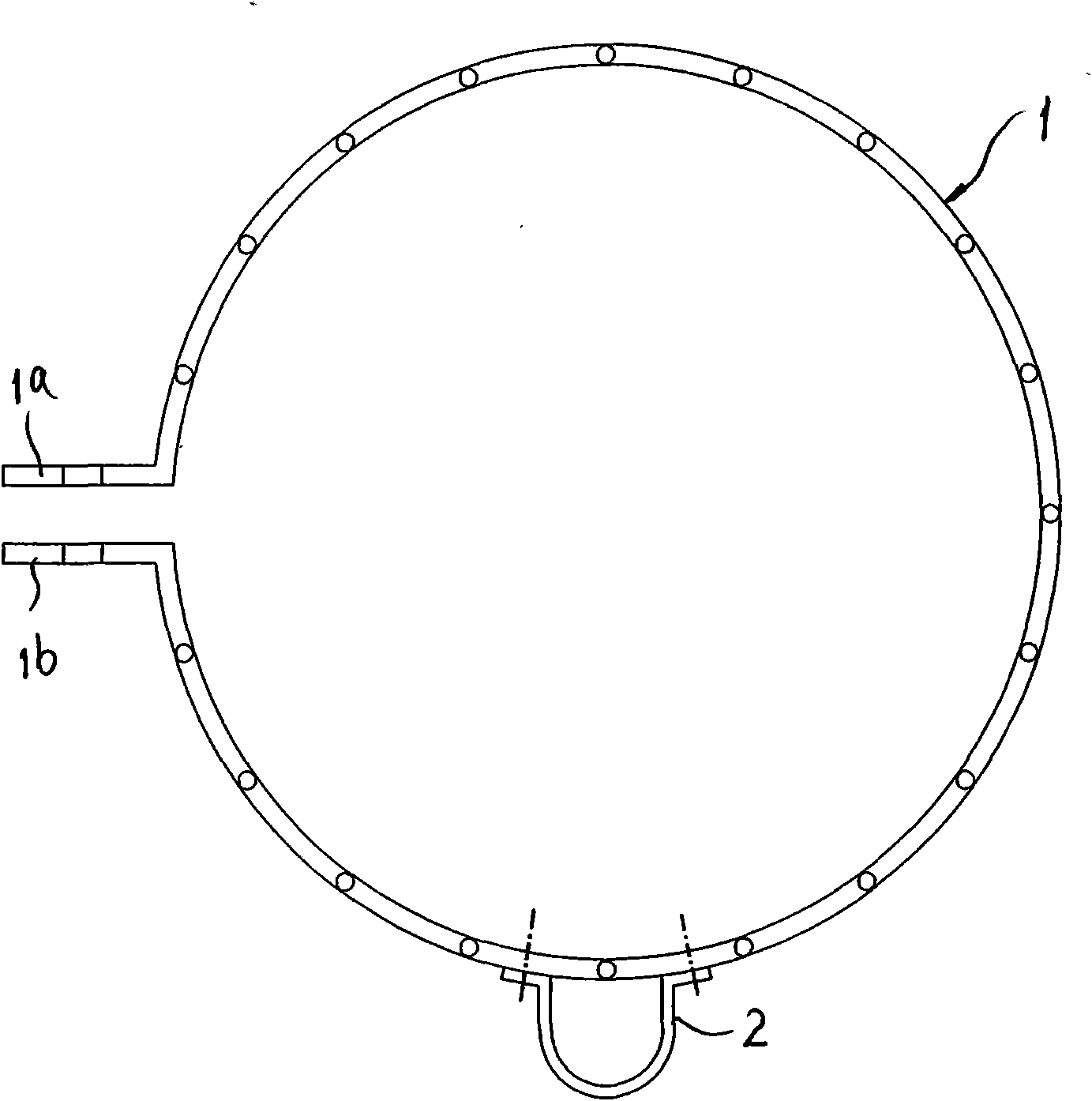

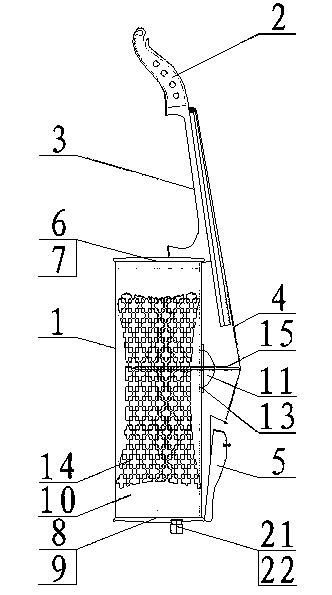

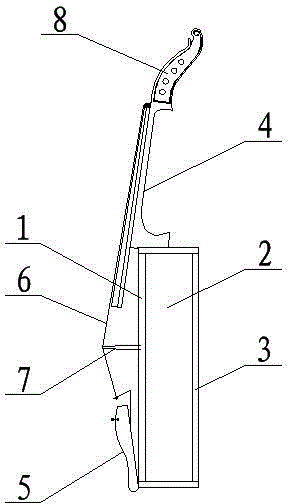

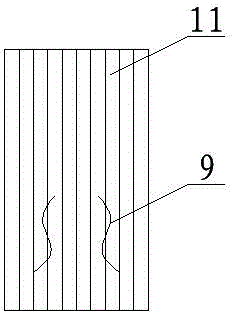

Device for cable conduits in urban distribution networks

ActiveCN101982912AEasy constructionGuaranteed uptimePipe supportsApparatus for overhead lines/cablesEngineeringDistribution networks

A device for cable conduits in urban distribution networks belongs to the appliance for fixing the cable conduits on the poles. The device comprises a hinged hoop fixed on the poles by bolts and more than one U-shaped hoops fixed on the outer side of the hinged hoop by bolts. The device can be especially used on the poles in different specifications and types and has the characteristics of simple and convenient use, aesthetic process, low possibility of being damaged, etc.

Owner:达州电业局

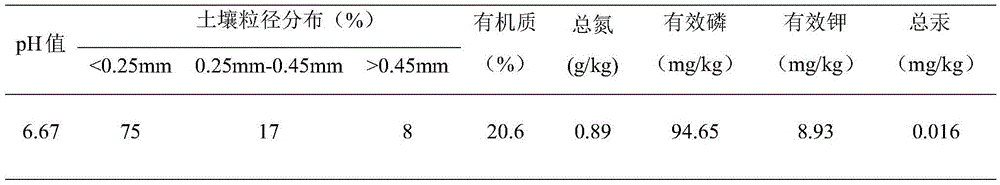

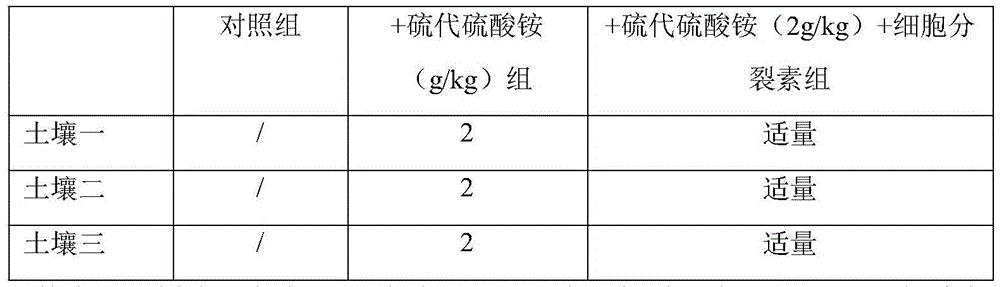

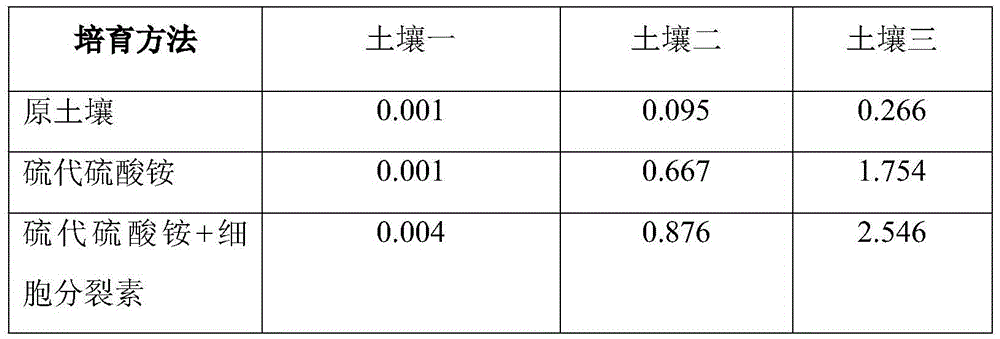

Method for remediating mercury-contaminated soil by combining byproduct ammonium thiosulfate with calendula officinalis

The invention discloses a method for remediating mercury-contaminated soil by combining a byproduct ammonium thiosulfate with calendula officinalis. The method comprises the following steps: planting calendula officinalis on the mercury-contaminated soil, fertilizing and watering in a planting process; when the calendula officinalis enters a flowering stage, applying a dilute solution prepared by the byproduct ammonium thiosulfate generated in steelmaking wastewater treatment process by many times, harvesting plant at the mature period of the calendula officinalis, thereby remediating the mercury-contaminated soil. At the stage of applying the solution prepared by the ammonium thiosulfate, a cytokinin solution is sprayed to the calendula officinalis plant. According to the method, the plant calendula officinalis has enrichment effect on mercury in the soil; the ammonium thiosulfate is used as a nitrogen fertilizer and a sulfur fertilizer, so that plant growth can be promoted; and mercury in the mercury-contaminated soil is activated by the ammonium thiosulfate, so that the mercury in the soil is greatly absorbed to the ground part by the calendula officinalis root system easier. The method has the advantages of being environmentally-friendly, low in cost, simple and aesthetic in process, good in treatment effect, free from secondary pollution, and easy to popularize.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

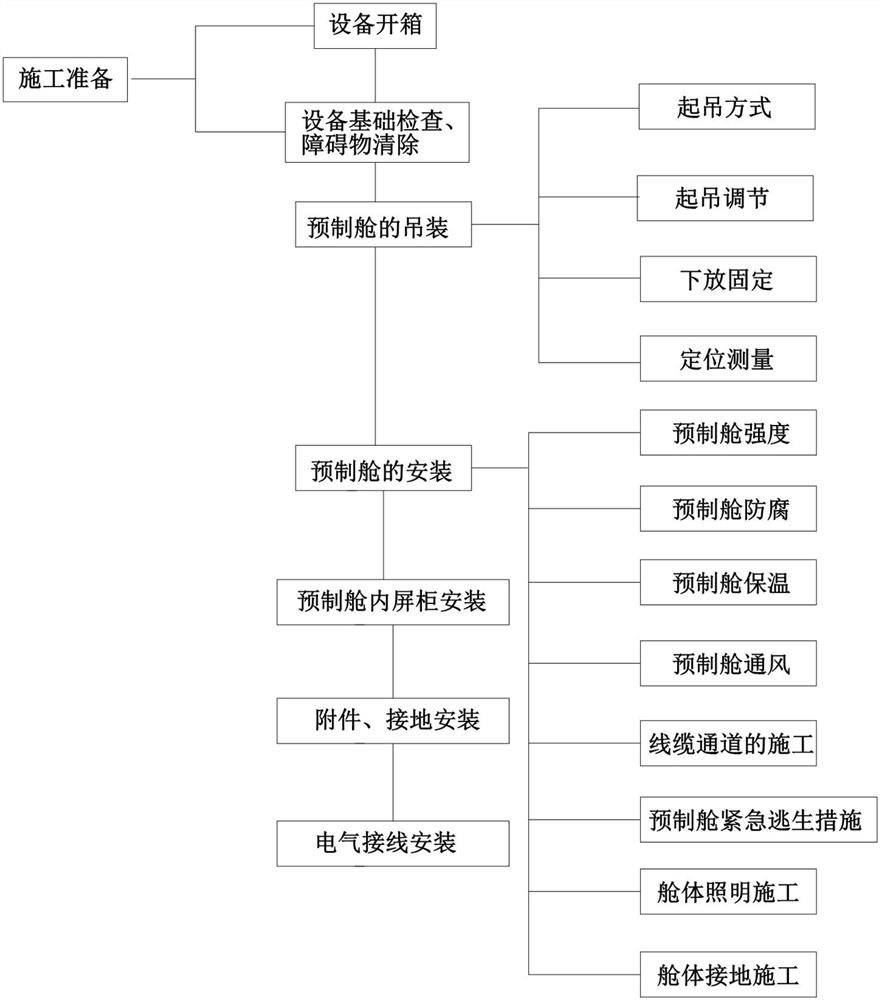

Installation and construction method for prefabricated cabin of 110-kilovolt transformer substation

PendingCN112366578AImprove construction qualityShort cycleSwitchgearTransformerArchitectural engineering

The invention discloses an installation and construction method for a prefabricated cabin of a 110-kilovolt transformer substation. The installation and construction method specifically comprises thefollowing steps of equipment unpacking; equipment basic inspection; obstacle removal; equipment hoisting and installation; equipment adjustment, fastening and inspection; accessory installation; grounding installation; and electrical wiring installation. With the installation and construction method for a prefabricated cabin of a 110-kilovolt transformer substation adopted, the situation that collision damage occurs when the prefabricated cabin is hoisted is avoided, a set of complete operation process and operation procedures are provided, the construction quality is improved, the construction period is shortened, the overall stability and safety of construction are guaranteed. The installation and construction method is easy to popularize.

Owner:国网河南省电力公司中牟县供电公司 +1

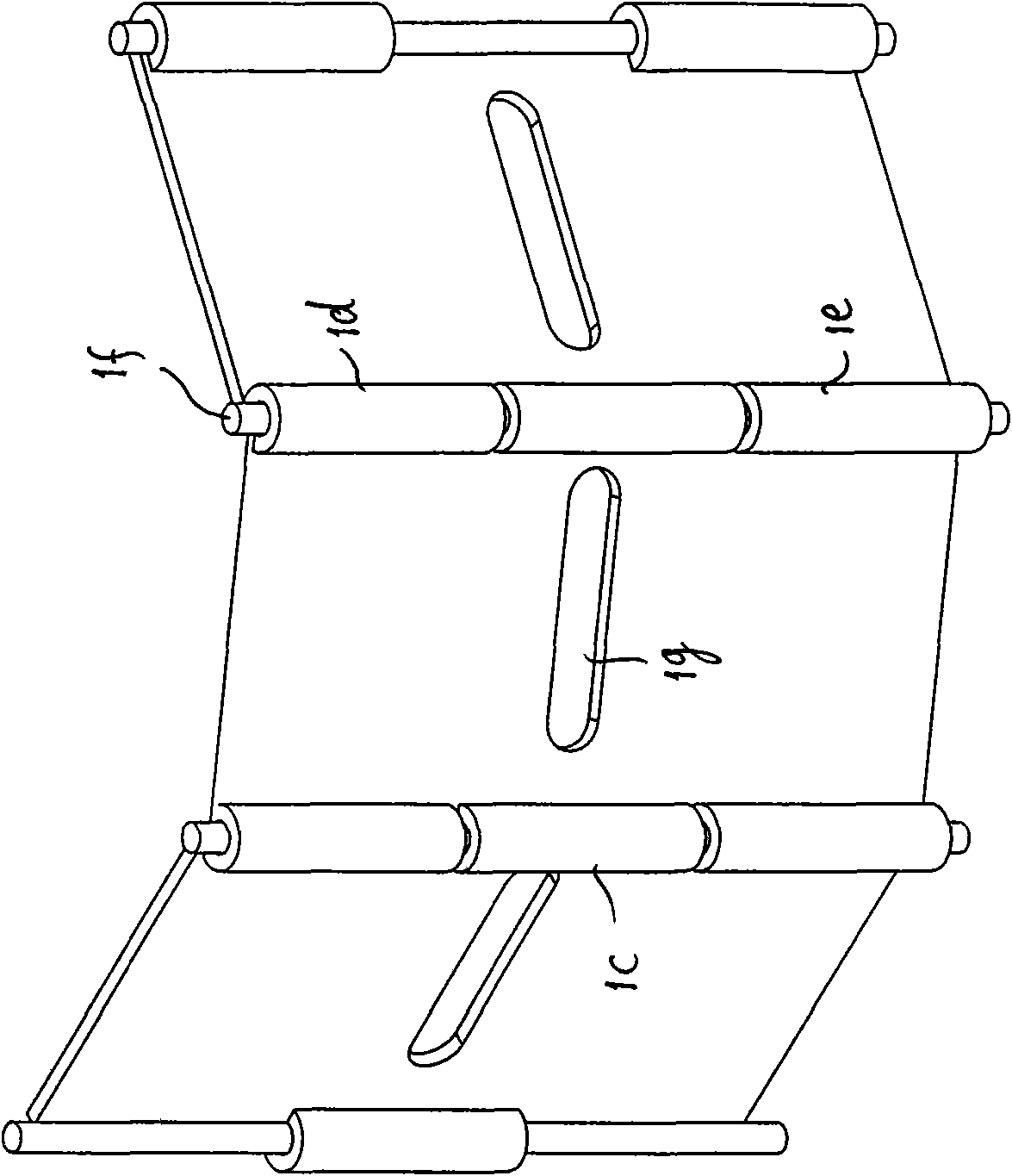

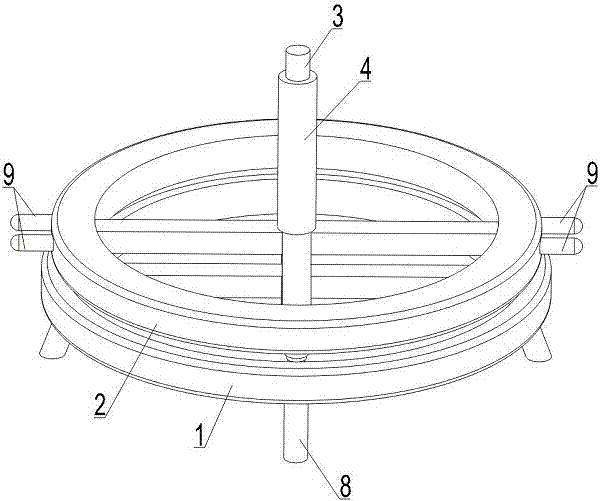

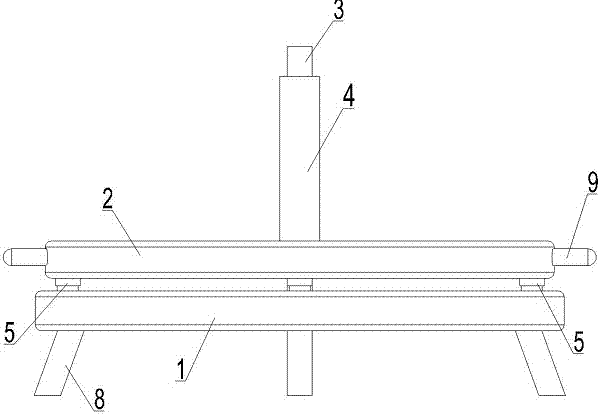

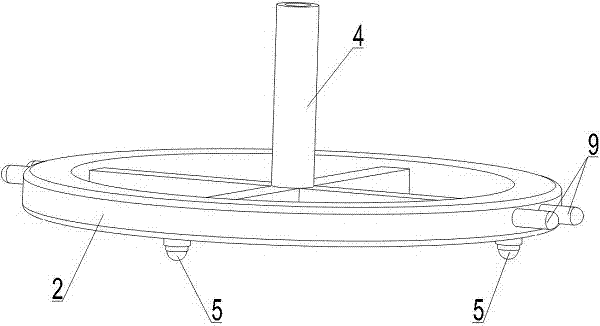

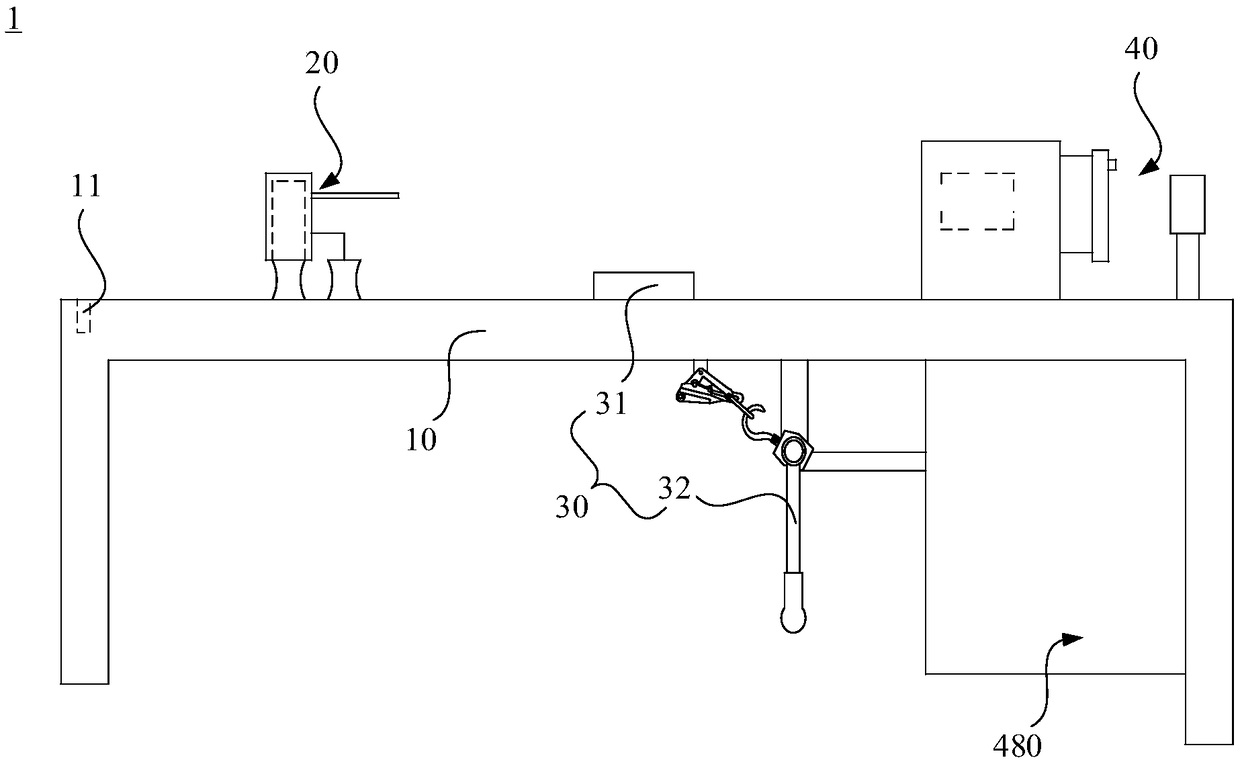

Reel cable laying tool

PendingCN107954252AThe laying and setting out work is smooth and stableSimplify the laying and setting out processFilament handlingStructural engineeringElectric cables

Owner:STATE GRID CORP OF CHINA +2

Welding process of thousand pure platinum ornaments

InactiveCN101733503AKeep the same colorFlat surfaceJewelleryGas flame welding apparatusWorking environmentWork in process

The invention discloses a welding process of thousand pure platinum ornaments, which is characterized by comprising the following steps of: horizontally placing two or more thousand pure platinum jewelry semi-finished products to be welded and aligning welding parts in the working environment with the temperature of 16-26 DEG C and the humidity of not more than 65 percent, and melting the welding parts of the thousand pure platinum jewelry semi-finished products by adopting the outer flame of a welding flame with the temperature of 1773+ / -5 DEG C to realize rapid fusion and welding, wherein the weld forming coefficient is 0.9-1.1. The welding process is adopted, thereby effectively ensuring the purity and the attractive surface of jewelries, being beneficial to energy saving and consumption reduction and improving the production efficiency.

Owner:SHENZHEN BOFOOK JEWELRY

Large-diameter metal material welding mold and welding method

ActiveCN103692048AAvoid harmReduce harmHeating appliancesMetal working apparatusPower flowDiesel engine

The invention relates to a large-diameter metal material welding mold and a welding method, which relate to the welding technology. In the field welding, the price for utilizing a diesel engine is high, the current is instable, and the welding quality is poor. The large-diameter metal material welding mold comprises an upper die and a lower die, wherein the upper die is provided with a molten powder cavity, an injection hole and an upper welding cavity, and the large-diameter metal material welding mold is characterized in that the top surface of the upper die is provided with a top cover, the bottom surface of the top cover is provided with a draught groove which is communicated with the molten powder cavity, one end of the draught groove is an ignition end, the other end is a fire guide end, the ignition end is exposed, the fire guide end is connected with the molten powder cavity, the top cover is provided with a vertical flue which is communicated with the draught groove, a flue port is provided with a filter net for preventing large particles from entering the flue, and a smoke removing device is arranged above the flue. By adopting the technical scheme, the electric energy is not needed, convenience in carrying can be realized, flexibility in field construction is realized, and the cost is low; moreover, the top of the mold is additionally provided with a smoke-dust processing device, so that dust splashing can be prevented from injuring operation personnel in the construction process, and the harm of the smoke on the human body can be reduced.

Owner:STATE GRID CORP OF CHINA +2

Method for metal type cast radiator and mould

The present invention discloses a method and metal mold for casting radiator, and features that the mold consists of side board, bottom board, sprue, clamping metal sheet, adjustable spacing strip, screw bolt, etc. The casting process includes the steps of setting radiating fins inside the clamping metal sheets, locking the side boards with the screw bolts, pouring high temperature aluminum liquid, cooling, demolding, and eliminating clamping metal sheets. By means of altering and replacing different mold parts, radiators of different types and sizes may be produced.

Owner:钟志兵 +1

Integrated low pressure monitoring device

InactiveCN106291036AIncreased sensitivityEasy and fast wiringMulti-tester circuitsComputer moduleEngineering

The invention discloses an integrated low pressure monitoring device. The front end of the device is connected with a breaker. The device comprises a voltage transformer, a current transformer, an electric power metering module, a CPU processor and a display panel. The voltage transformer, the current transformer, the electric power metering module and the CPU processor are integrated to form an integrated CT module. The display panel and the integrated CT module are detachably connected. The breaker is connected with the voltage transformer and the current transformer separately. The voltage transformer and the current transformer are both connected with the CPU processor through the electric power metering module. The display panel is connected with the CPU processor. The beneficial effects are as follows: wiring is simple and fast; the device does not need to be connected with an external current loop; the device is beautiful in look; only the integrated CT module needs to be installed; the device is high in stability and improves the work efficiency; the check content is not much; the error test rate is reduced; the running status can be directly reflected; and background monitoring, remote monitoring and remote maintenance can be achieved.

Owner:HANGZHOU SHIBANG ELECTRIC TECH CO LTD

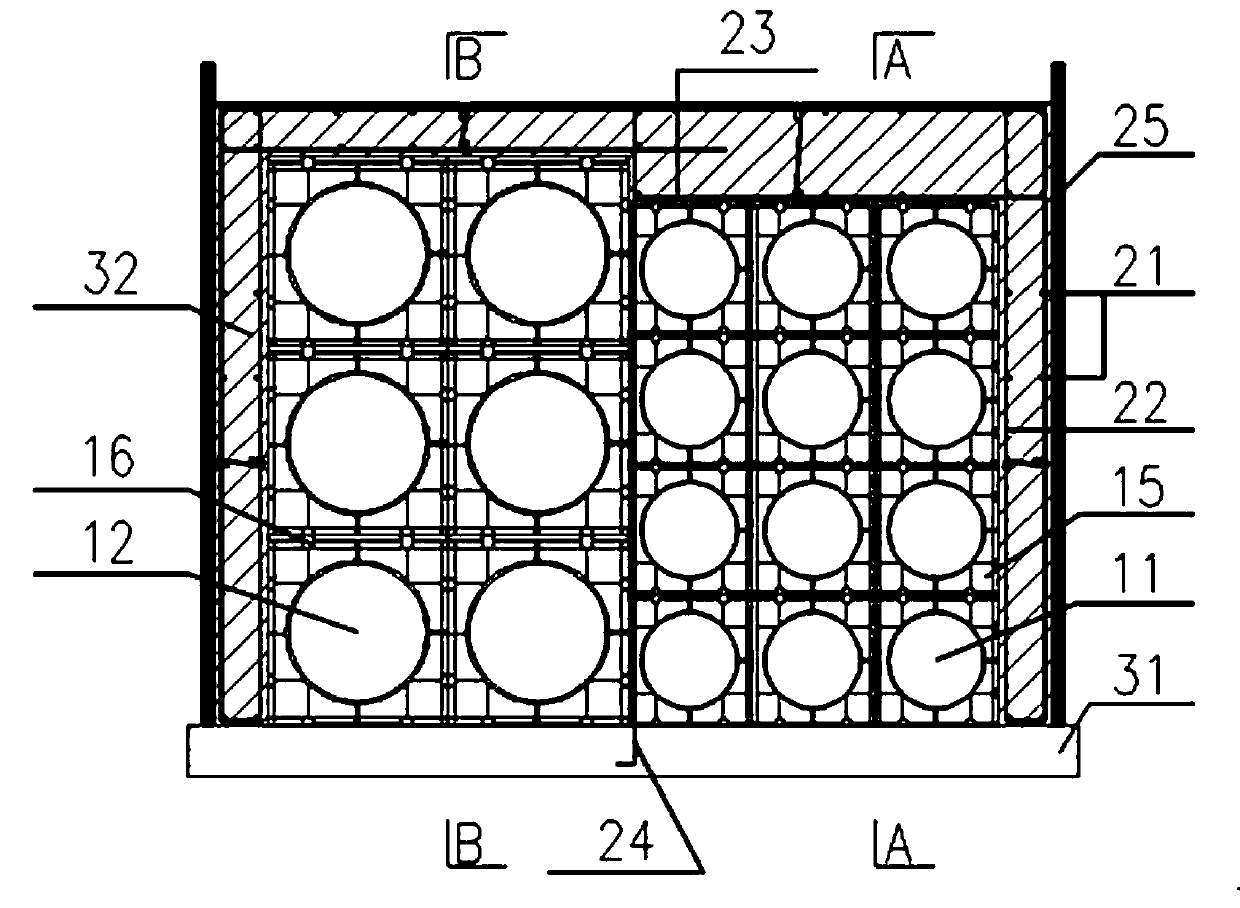

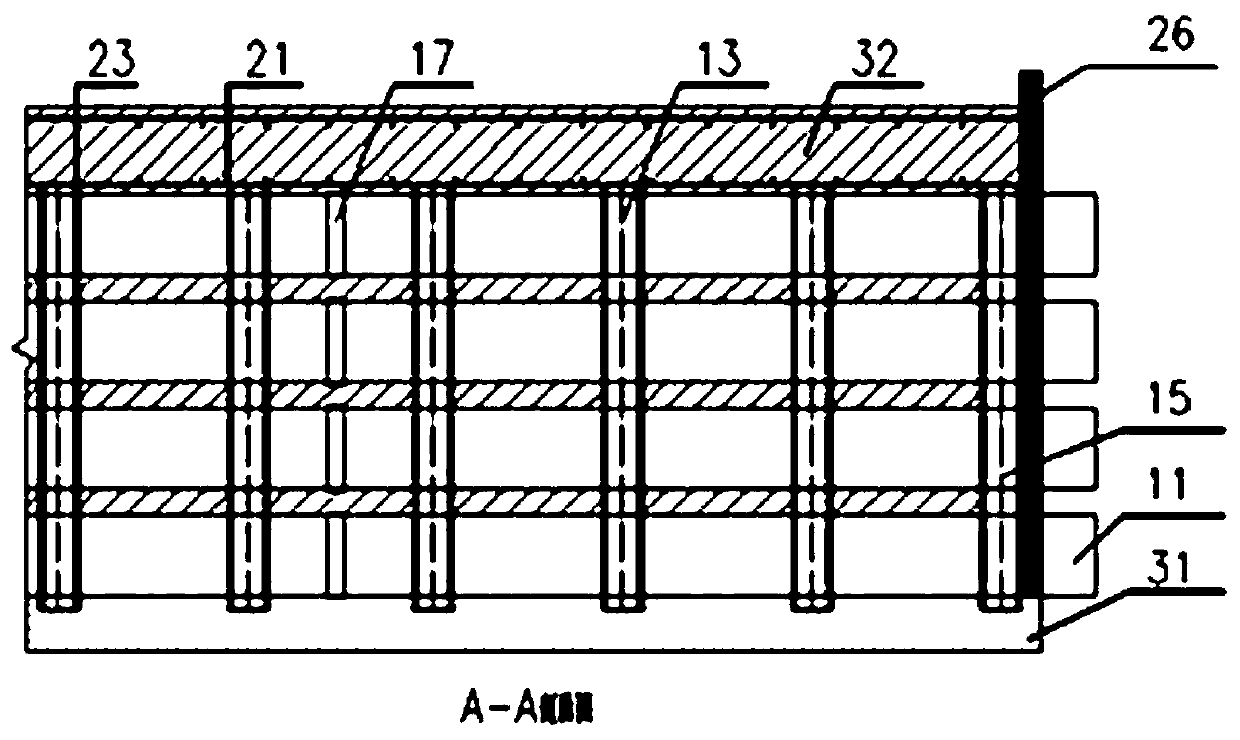

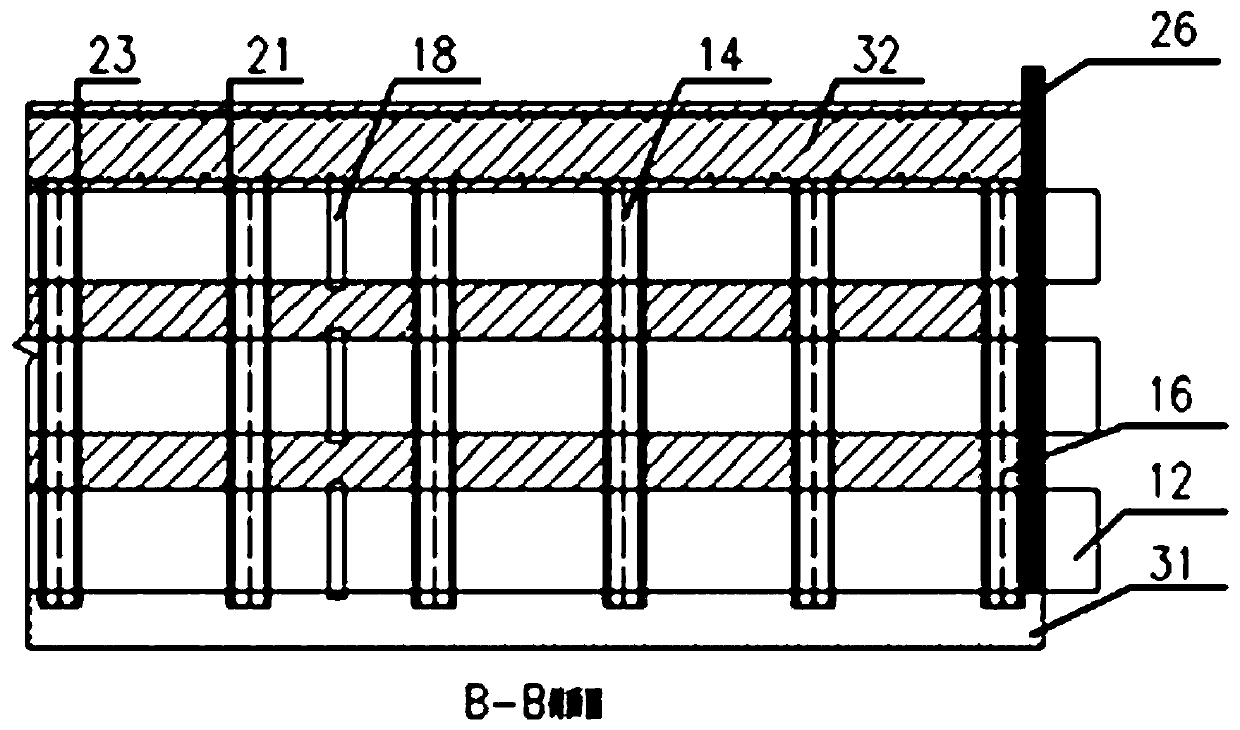

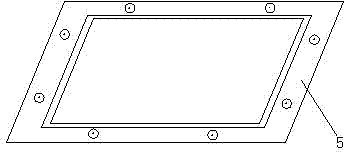

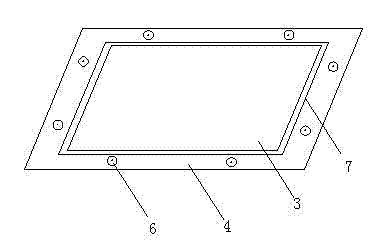

Duct bank array installation and encapsulation construction method

ActiveCN111064155ASimple structureEasy constructionArtificial islandsProtective foundationCompressive resistancePower cable

The invention discloses a duct bank array installation and encapsulation construction method. After cushion concrete is constructed, a cushion layer is used as an operation platform to install first duct banks and second duct banks into two duct bank arrays through matched first middle pipe pillows, second middle pipe pillows, first end pipe pillows, second end pipe pillows, first casing pipes, second casing pipes, distribution reinforcing bars, vertical reinforcing bars and anti-floating reinforcing bars, the two duct bank arrays are effectively connected into a whole, then downward-pressingreinforcing bars, side formworks and end formworks are combined, and encapsulating concrete is continuously poured in a layered mode after concealed project acceptance. The construction method is suitable for installation of power cable MPP duct banks of different specifications in open cut construction on most urban roads, and has the advantages of being low in manufacturing cost, high in construction speed, attractive in technology, high in compressive strength, high in adaptability and the like.

Owner:GEZHOUBA GRP ELECTRIC POWER COMPANY

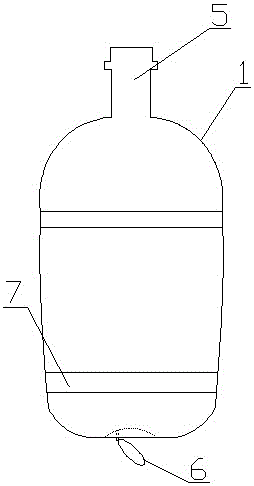

Preparation method of highly transparent liquid silica gel protective glass container

InactiveCN106431002AImprove securitySimple processBottlesSynthetic resin layered productsOrganic solventProtective glasses

The present invention provides a preparation method of a highly transparent liquid silica gel protective glass container. The method comprises the steps of preparing a glass container, cleaning the outer surface of the glass container, preparing a highly transparent liquid silica gel, diluting the highly transparent liquid silica gel to be 100 Pas by using a high-boiling organic solvent, spraying the diluted highly transparent liquid silica gel onto the surface of the glass container by a spray gun, standing for 8-10 minutes, baking for 100 minutes at the temperature of 180-220 DEG C, volatizing the solvent to completely vulcanize and mold the silica gel, and adding a layer of high-brightness light silica gel hand-feel oil on the outer surface of the vulcanized and molded silica gel. According to the technical scheme of the invention, the highly transparent liquid silica gel protective glass container is simple in preparation process and beautiful in appearance. The liquid silica gel is sprayed on the surface of the glass container, so that the safety of the glass can be effectively improved. In this way, glass chips are prevented from splashing. The temperature-sensing or non-temperature-sensing color paste is added into the silica gel, so that the indication function of a product is improved. Therefore, the color of the product is enriched.

Owner:SHENZHEN BANGJIA IND CO LTD

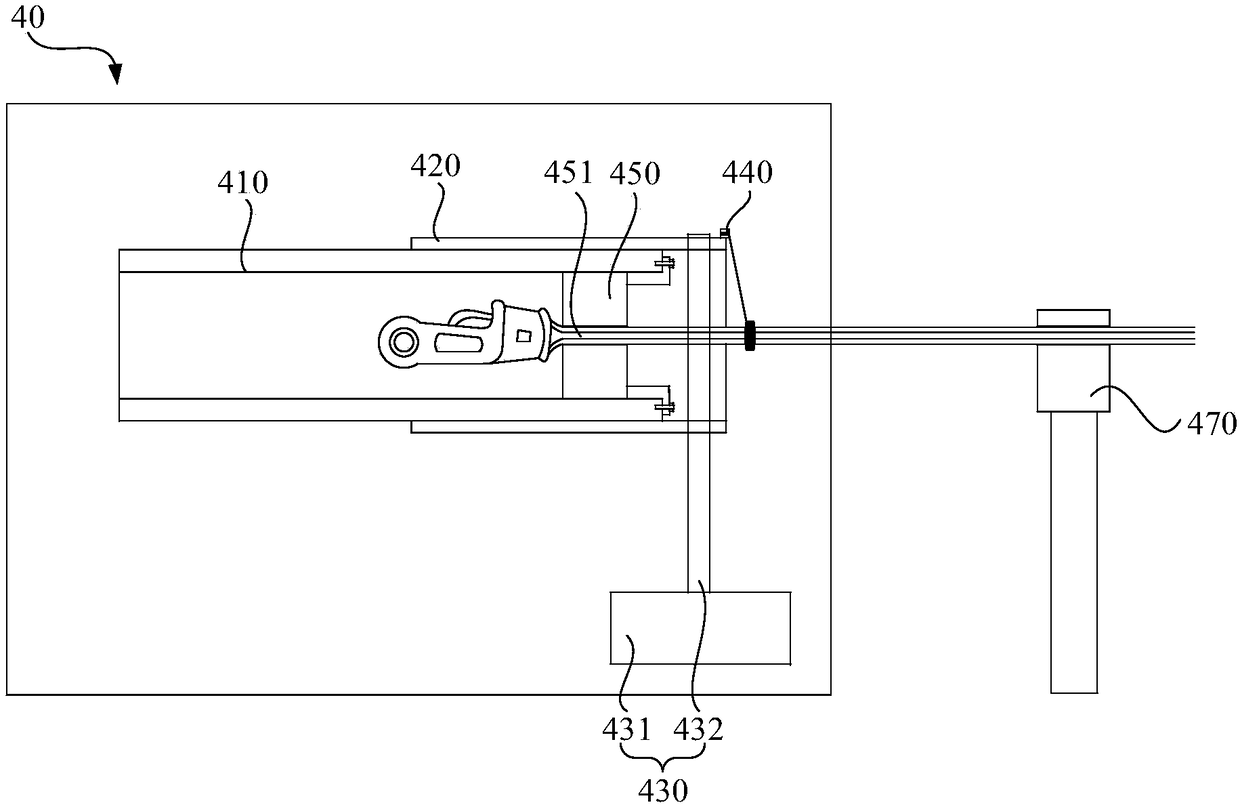

Pull wire manufacturing device

Owner:CREC RAILWAY WUHAN ELECTRIFICATION BUREAU GRP GUANGZHOU BRANCH

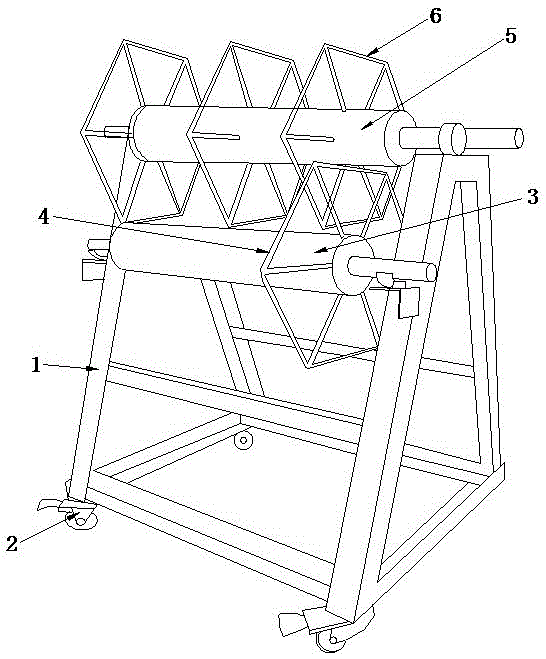

Micro bi-directional multi-household paying-off device

The invention discloses a micro bi-directional multi-household paying-off device and relates to the technical field of distribution circuits. Braking trundles are installed at four corners of the bottom of a rack respectively. The two ends of a lower wire rotating shaft are installed at the lower side of the rack through bearings. A lower rotating hand wheel is installed at one side of the lower wire rotating shaft. The two ends of an upper wire rotating shaft are installed at the upper end of the rack through bearings. A plurality of upper rotating hand wheels are installed on the upper wire rotating shaft. The device saves time, labor and strength, improves the technology quality, and is simple, convenient to move and easy to master.

Owner:国网山东莒县供电公司 +1

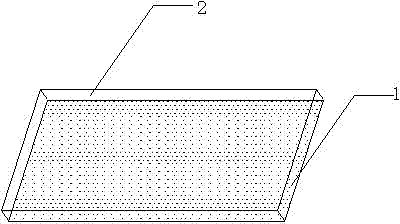

Fireproof flame-retardant wall plate and manufacturing method thereof

The invention discloses a fireproof flame-retardant wall plate and a manufacturing method thereof. The fireproof flame-retardant wall plate includes a glass-fiber reinforced body and a polymer substrate, wherein the polymer substrate wraps an external surface of the glass-fiber reinforced body. The glass-fiber reinforced body is waste glass fiber long wires or short fibers and the polymer substrate is waste fibers or rope nets. The fireproof flame-retardant wall plate is simple in moulding technology, is low in cost, is high in product strength and is strong in stability.

Owner:TAIAN ROPE NET PLASTIC

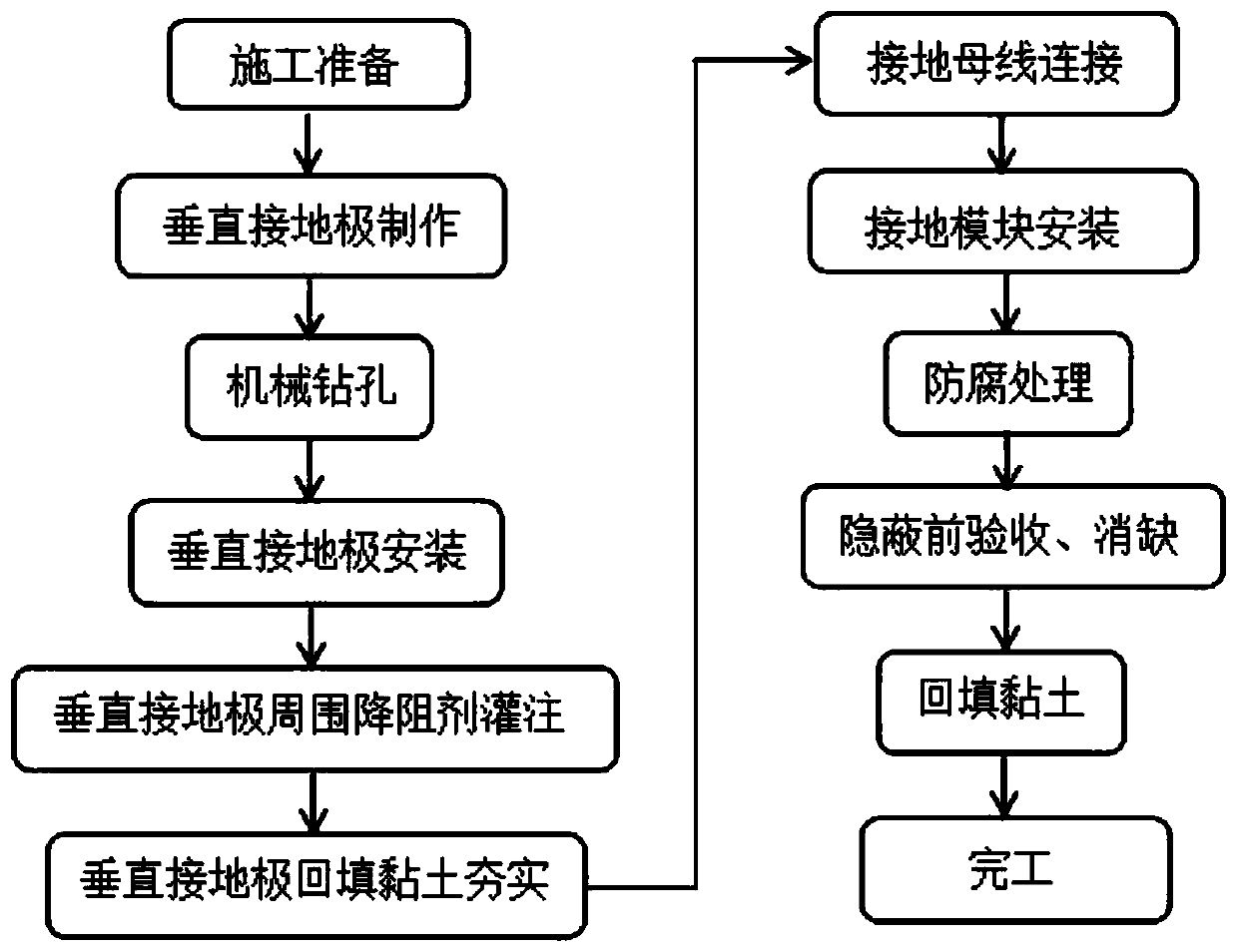

Construction method of large power station grounding grid under rock geological conditions

InactiveCN109755839AGood resistance reduction effectSimple construction methodLine/current collector detailsConnection contact member materialGrounding gridElectrical resistance and conductance

The invention discloses a construction method of a large power station grounding grid under rock geological conditions. The construction method includes the following steps: production of a vertical grounding electrode; mechanical drilling; installation of the vertical grounding electrode; proportioning, stirring and pouring of a resistance reducing agent; clay backfilling and tamping of the grounding electrode; connection between grounding buses and grounding buses, and connection between the grounding buses and the grounding electrode; connection and installation of a grounding module; corrosion prevention at welding places; and clay backfilling and tamping of the grounding buses. The construction method of the invention adopts an advanced grounding construction process, reasonably selects a product combination for reducing the resistance value, and has obvious resistance reduction effects on areas with difficult resistance reduction construction such as mountainous areas, areas withhigh soil rate and arid areas in North China; for the installation of the vertical grounding body, only the prepared grounding electrode and a physical resistance reducing agent need to be inserted and poured into holes after mechanical drilling, so that the construction method is simple and convenient; and the construction method combines the physical resistance reducing agent and the groundingmodule, and the vertical grounding body with high construction difficulty is replaced by a horizontal grounding body, so that the construction workload is effectively reduced, materials are saved, pollutions are reduced, and obvious economic efficiency is realized.

Owner:中能建建筑集团有限公司

Manufacturing process of electric heating kneecap

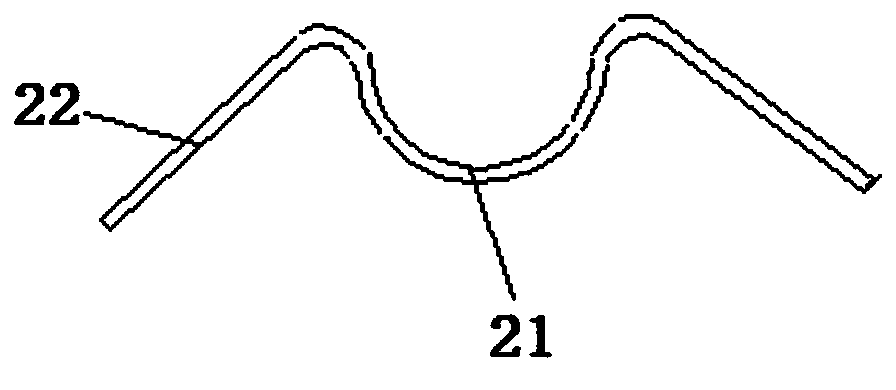

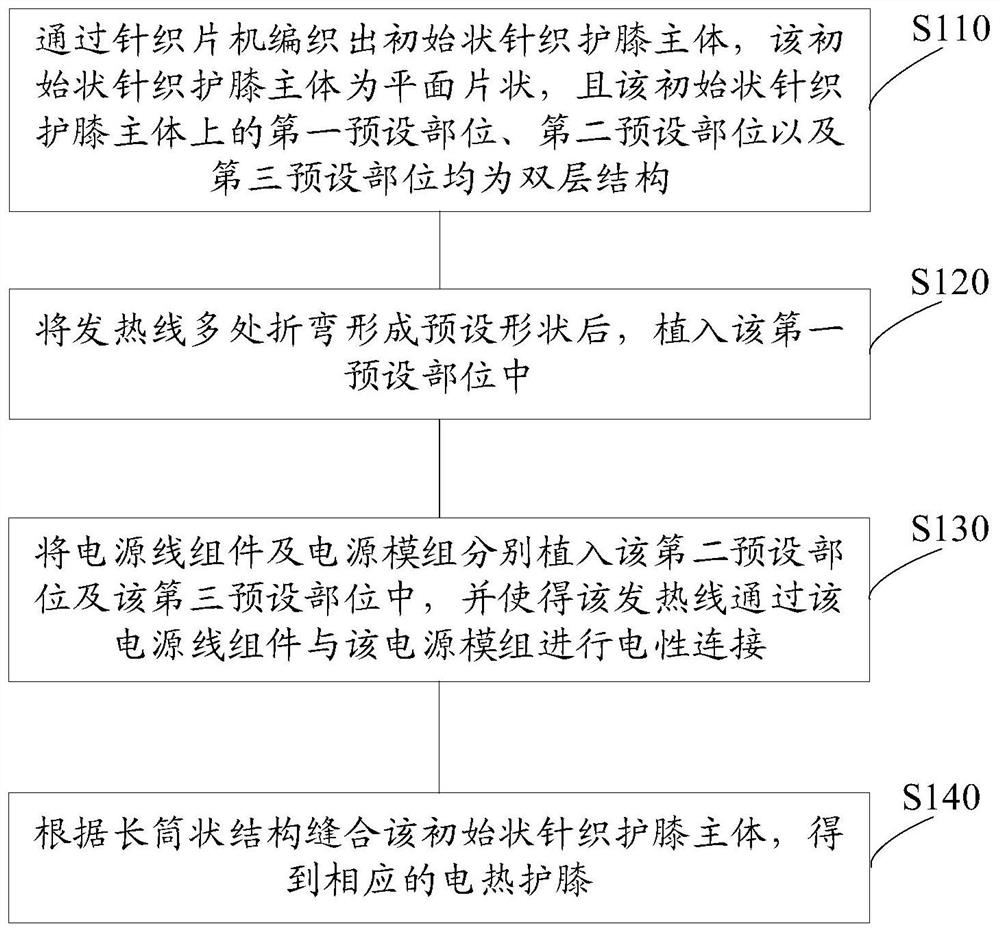

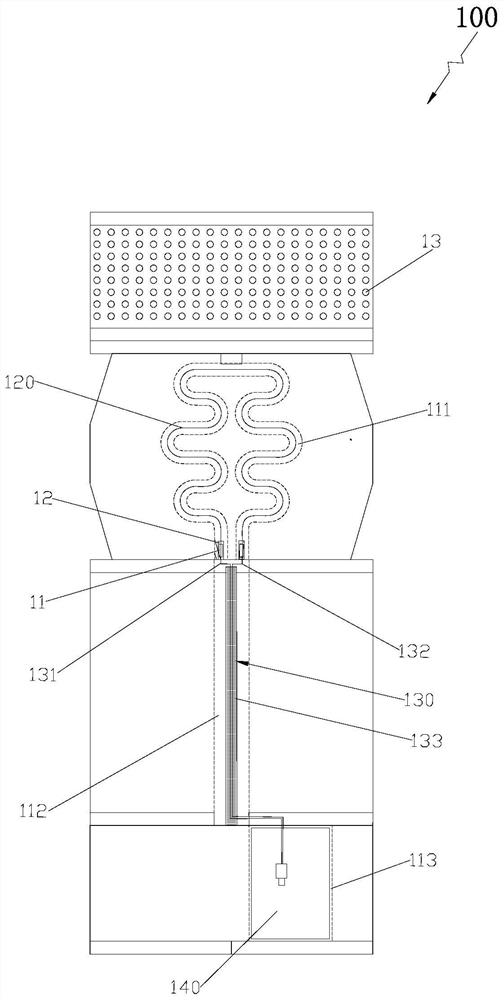

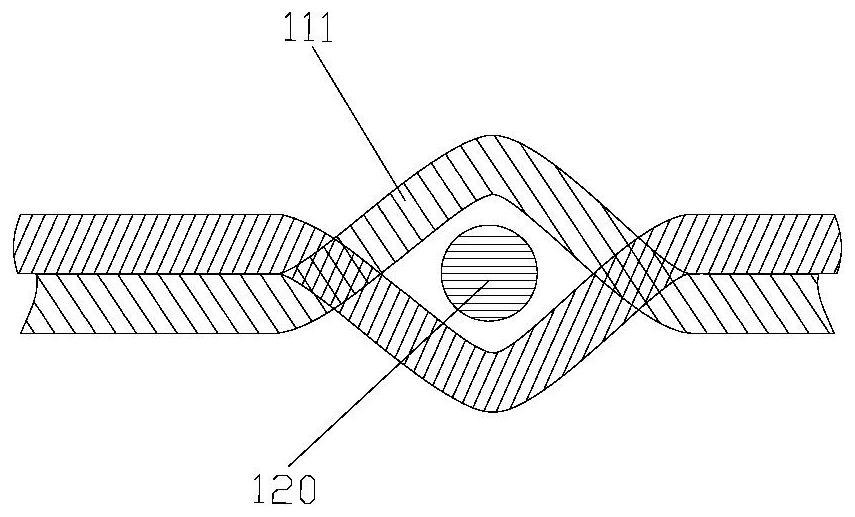

InactiveCN112315051ABeautiful craftsmanshipRealize the heating functionGarment special featuresHeating element materialsProcess engineeringBandage

The invention provides a manufacturing process of an electric heating kneecap, and belongs to the technical field of electric heating products. The process comprises the following steps: knitting an initial knitted kneecap main body in a plane sheet shape by using a sheet knitting machine, and the first preset part, the second preset part and the third preset part on the initial knitted kneecap main body are of double-layer structures; bending a plurality of parts of the heating wire to form a preset shape, and implanting the heating wire into a first preset part; respectively implanting the power line assembly and the power supply module into the second preset part and the third preset part, and enabling the heating line to be electrically connected with the power supply module through the power line assembly; and sewing the initial knitted kneecap main body according to the long cylindrical structure to obtain the corresponding electric heating kneecap. According to the technical scheme, the technical problem that an existing electric heating kneecap is poor in wearing experience due to the fact that the existing electric heating kneecap only can adopt a bandage type sheet structure through heating of the heating sheet can be effectively solved.

Owner:深圳市嘉良合科技有限公司

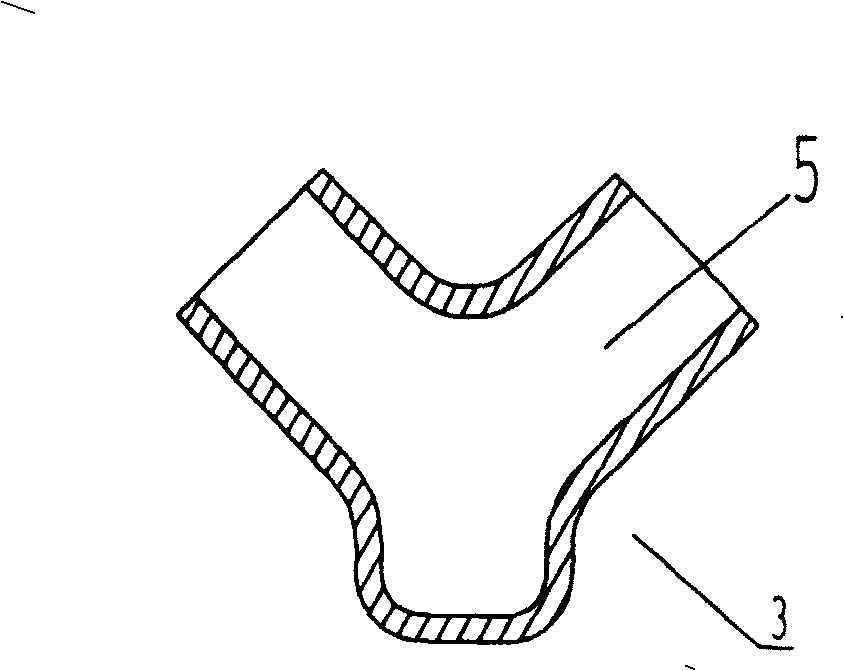

Preparation method of Y-shaped hot-pressed three-way pipe fitting

ActiveCN100445627CReduce manufacturing costSimple appearanceBranching pipesPipe fittingMaterials science

The invention relates to a method for producing Y-shape thermal compress three-way, belonging to the metallic tube processing technique. Said method is formed by blank selecting, thermal compressing, bending and machining, etc. wherein, the thermal compressing step comprises: first heating and compressing the blank into T-shape three-way blank; the bending step comprises: heating and bending the main tube of said T-shape blank to form the Y-shape three-way blank. The invention can be used to product the metallic tube Y-shape three-way whose Dn is 100-1000mm and diameter / thickness is less than 14 / . The invention has lower cost, simple process, easy operation and it can use standard three-way and short-radius bent moulds. The invention can reach relative standards as size, allowance, detection and physicochemical test.

Owner:HEBEI HONGRUN NUCLEAR EQUIP SCI & TECH CO LTD

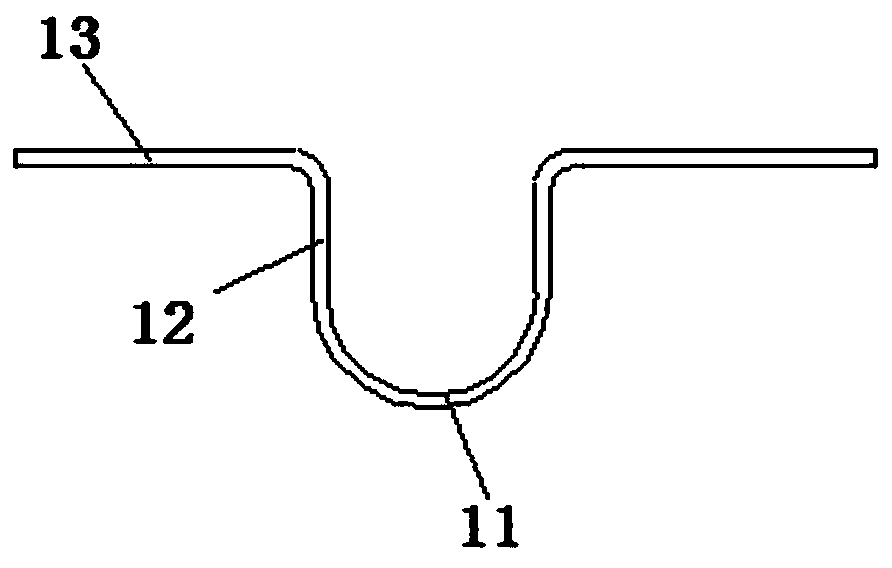

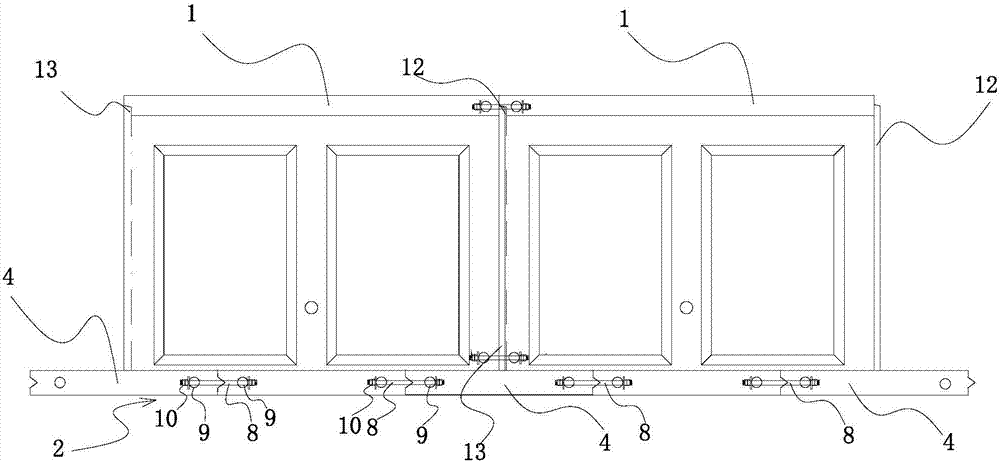

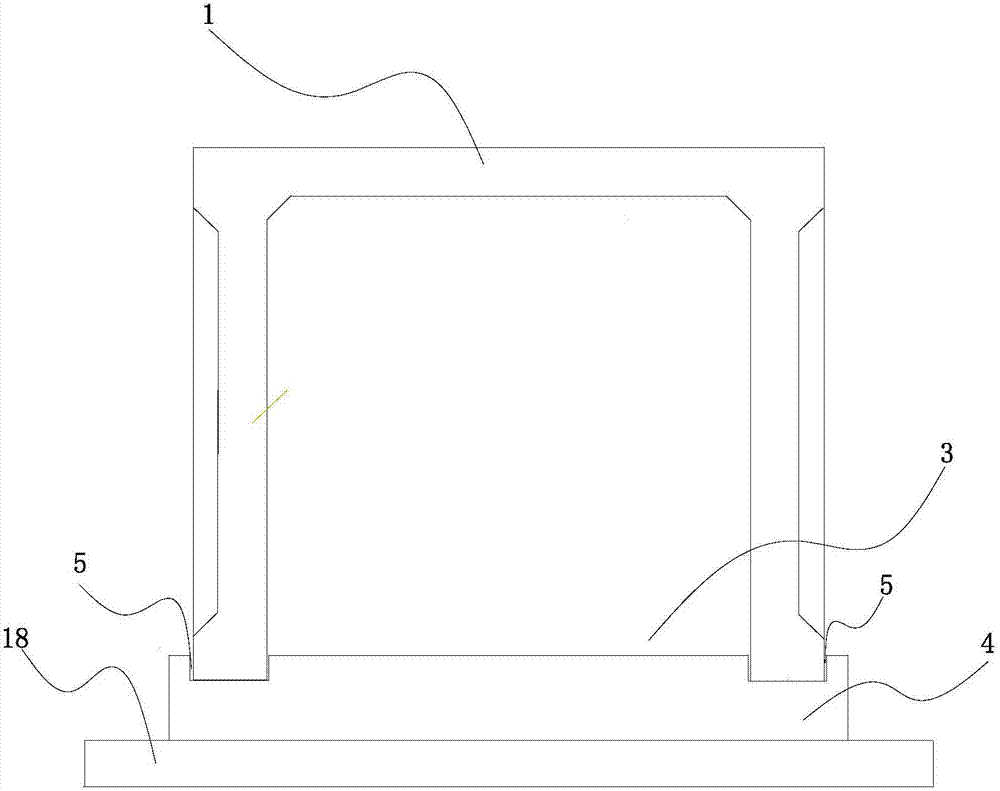

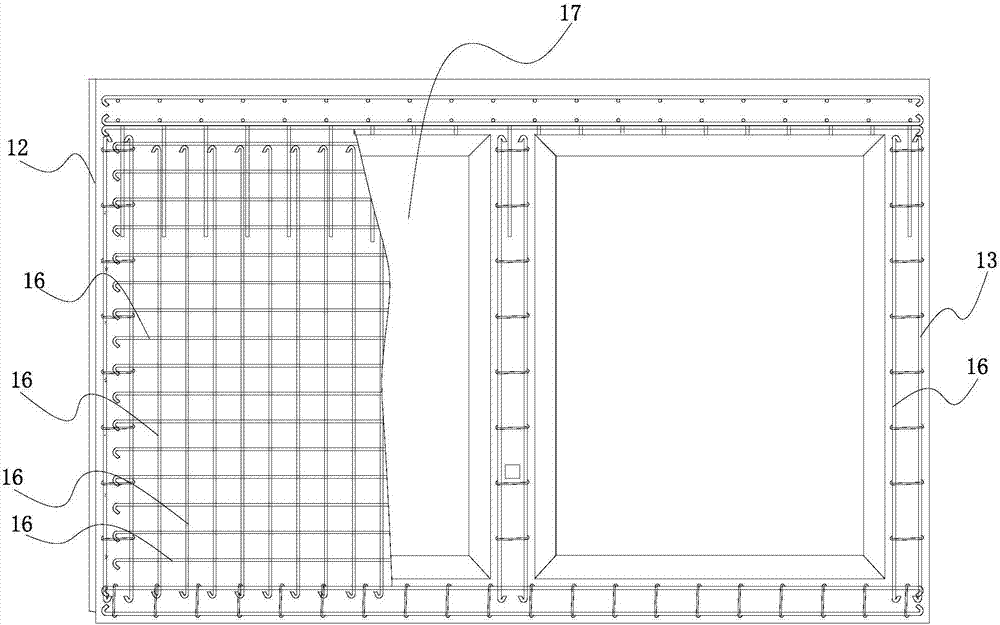

Cable trench assembly

ActiveCN107276002AEasy maintenanceEasy to replaceElectrical apparatusEngineeringMechanical engineering

The invention discloses a cable trench assembly which includes at least two cable trenches and a base plate assembly. The adjacent cable trenches are horizontally and detachably fixed together by means of butt joint sealing. The base plate assembly is detachably fixed to the ground or a mounting surface. The lower part of each cable trench is detachably fixed to the upper part of the base plate assembly by means of sealing and inserting. Each cable trench has a trench opening at the bottom. The upper middle part of the base plate assembly is disposed in the trench openings. The cable trench assembly of the invention is simple in structure, convenient to install and disassemble and easy to transport, and is installed by means of splicing on an installation site. The cable trench assembly can be used in renovation of old cable channels or old cable lines. The cable trench assembly can be directly used in a channel with unmovable equipment, and can be installed without moving the original equipment. Thus, time is saved. The cable trench assembly is inclusive. There is no need to reinstall the original cable and other lines.

Owner:宁夏众力管廊科技有限公司

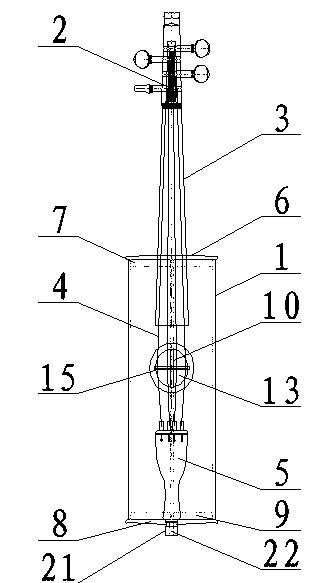

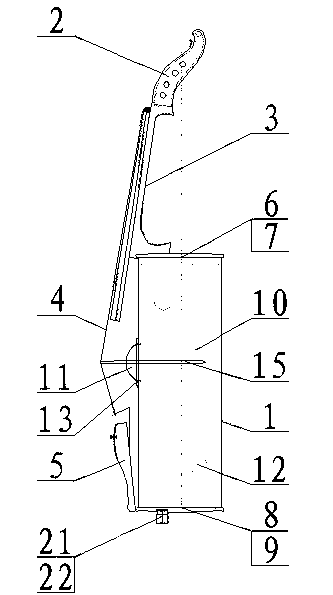

Bamboo string pulling qin manufacturing process

InactiveCN103198813AShort cycleIncrease productionStringed musical instrumentsMechanical engineering

The invention relates to a bamboo string pulling qin manufacturing process which comprises the following steps: selecting fresh bamboo tubes having corresponding apertures according to the standard of a string pulling qin, processing bamboo tiles, cooking, drying and resurging; manufacturing a sound-emitting middle board and resonance holes; manufacturing a bridge and longitudinal opening clamp grooves; manufacturing an liner board and a package board; combining two bamboo tiles into one tube and manufacturing sound holes communicated with the cavity of the tube body; placing a sound-emitting middle board into the tube body and packaging the sound-emitting middle board through the liner board and the package board; manufacturing hollow holes in one position, on one side of the sound-emitting middle board, of the tube body; installing a qin head, a finger board, a string pulling board and strings on the outer wall of the tube body; and installing the bridge across the sound-emitting middle board. The process integrates bamboo and wood, material is drawn conveniently, cost is low, forest resources can be effectively protected, and the manufactured string pulling qin is simple and compact in structure, convenient to use, and long in service life, and has good high, middle and low sound-emitting effects.

Owner:江苏凤灵乐器文化产业有限公司

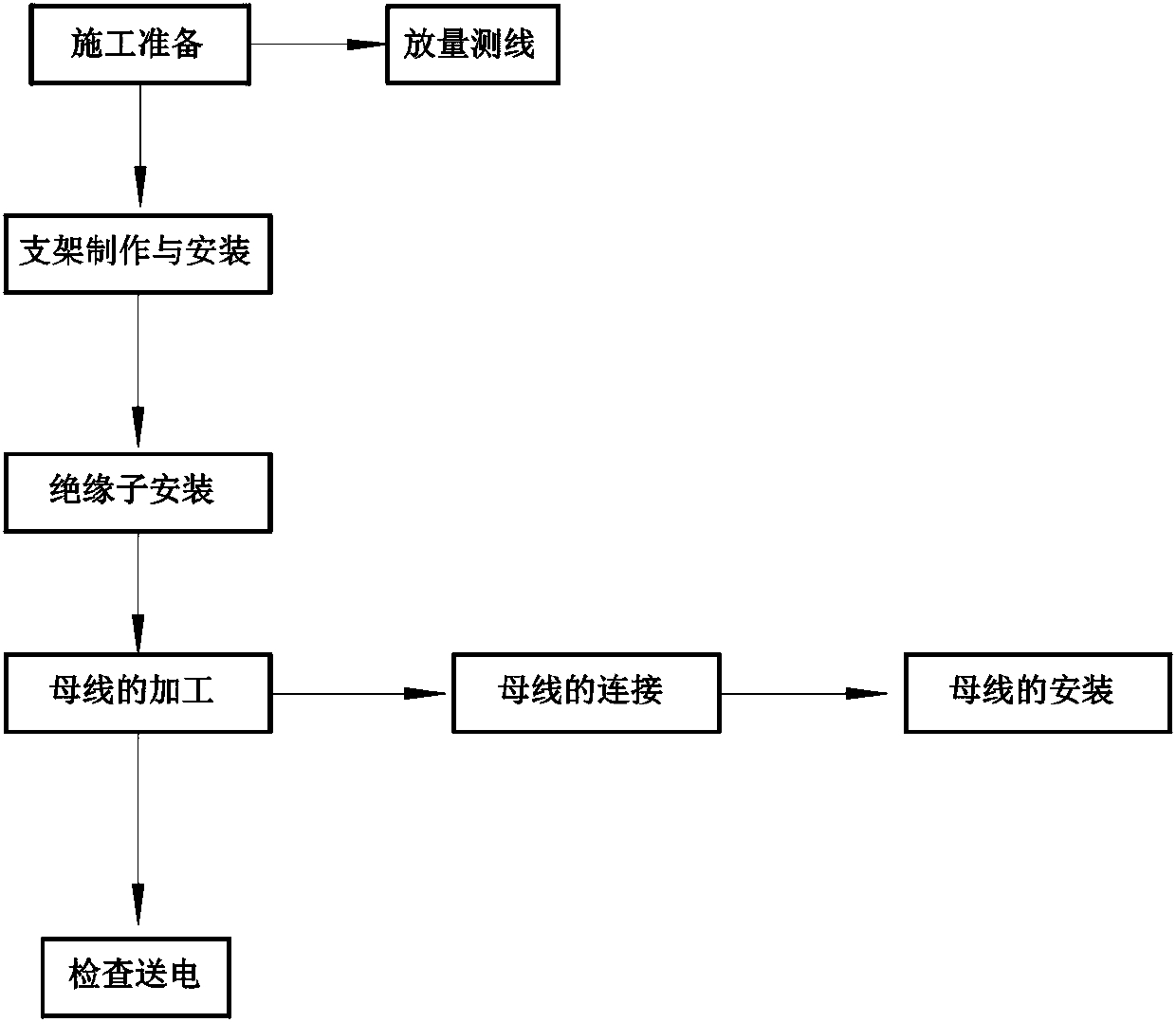

Method for constructing rectangular busbar for generator outlet of large substation

InactiveCN110718888ALarge carrying capacitySimple structureTotally enclosed bus-bar installationsBusbarMachining

The invention discloses a method for constructing a rectangular busbar for a generator outlet of a large substation, which specifically includes the following steps: 1) pay-off measurement, 2) insulator installation, 3) busbar machining, 4) busbar connection, 5) busbar installation, 6) inspection and power transmission. The generator outlet is connected by a rectangular busbar structure, has the advantages of large current carrying capacity, simple structure, convenient installation and maintenance and the like, has attractive appearance and simple structure, and helps to later operation and maintenance. It improves construction efficiency to machine the busbar with the method.

Owner:POWER CHINA HENAN ENG CO LTD

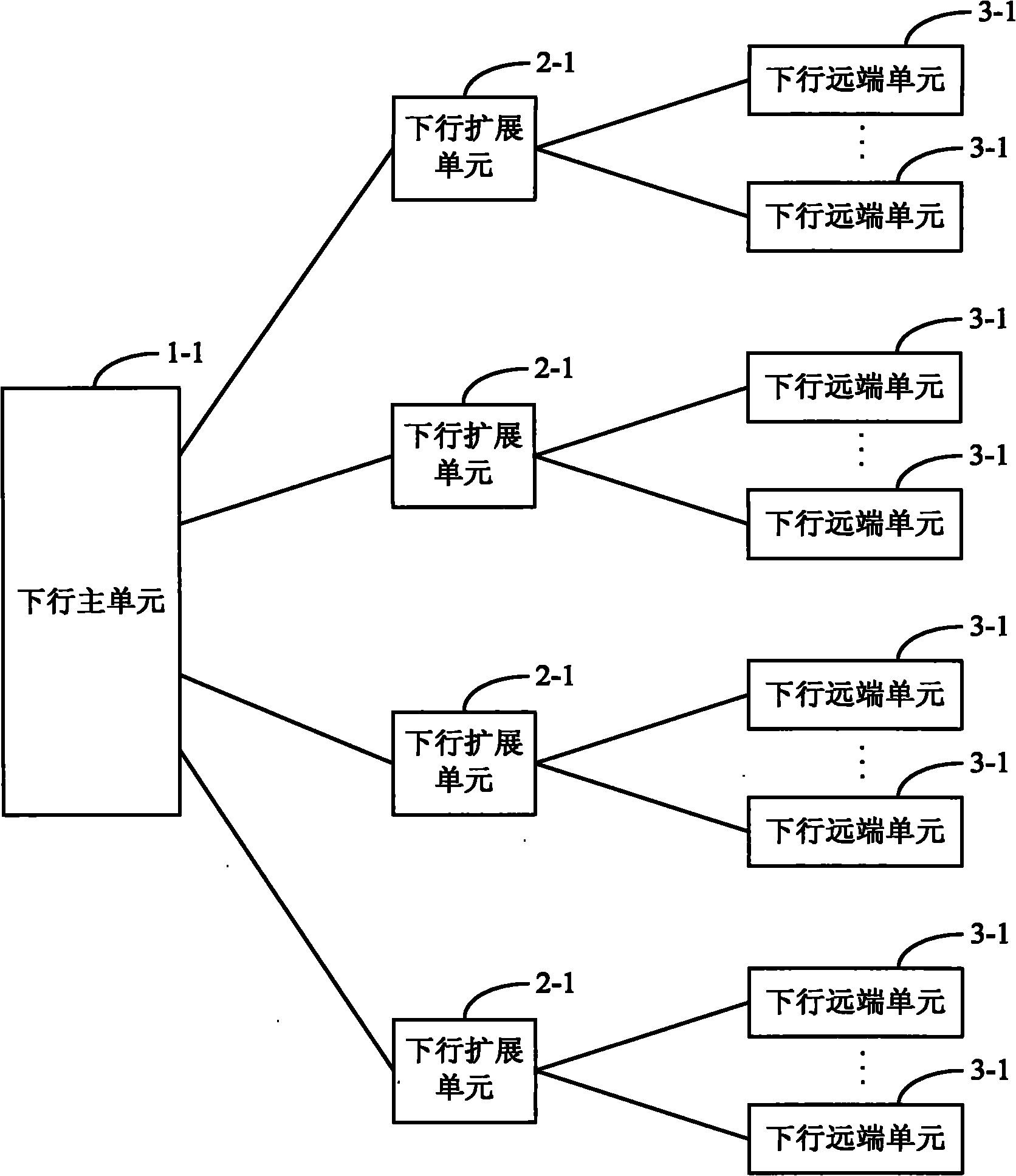

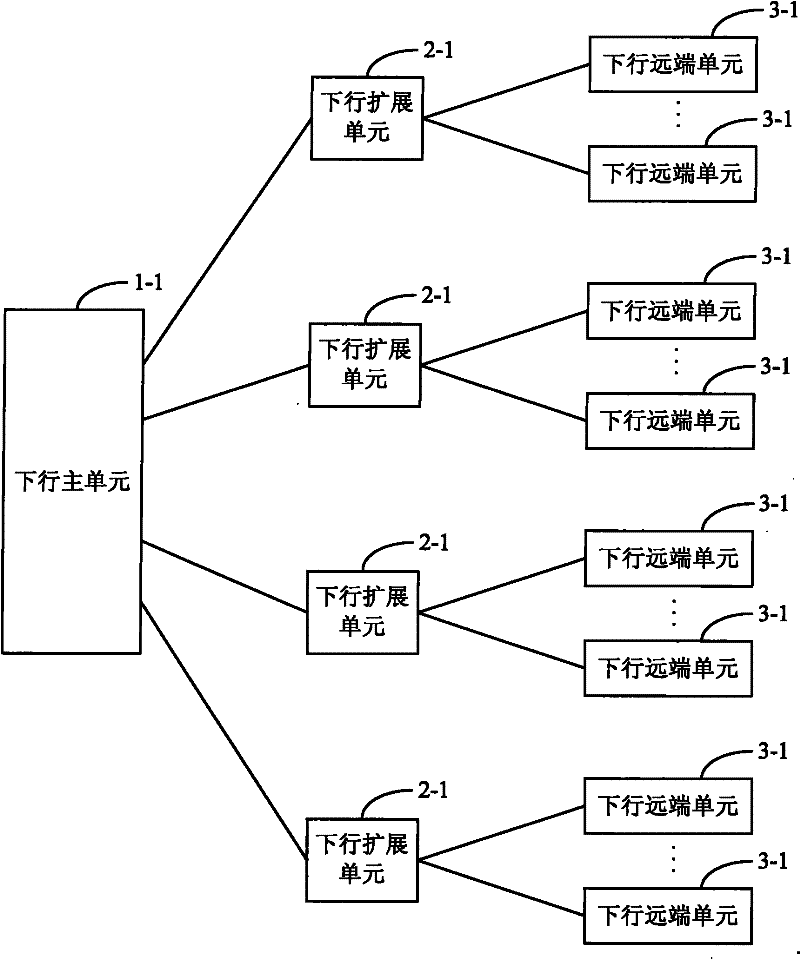

Wireless communication multi-network integrated downlink system

InactiveCN102196323AImprove stabilityImprove reliabilityMultiplex system selection arrangementsNetwork planningTTEthernetThe Internet

The invention provides a wireless communication multi-network integrated downlink system, which comprises a downlink main unit, a plurality of downlink extension units corresponding to the downlink main unit and a plurality of downlink far-end units corresponding to each of the downlink extension units; data are transmitted between the downlink main unit and the downlink extension units by using optical cables; and data are transmitted between the downlink extension units and the downlink far-end units by using optical cables and cable lines. Multi-network signal fusion of internet wireless signals and mobile communication signals and the like is directly realized by adopting a distributed system, a combiner is not needed for external combination, and stability and reliability of operation of a wireless communication downlink information network are effectively improved.

Owner:北京裕源大通科技股份有限公司

Preparation method of goat milk synthetic soap

InactiveCN107828561ATight textureSimple textureSkin careAlkali/ammonium soap compositionsHydrolysisMachining

A preparation method of goat milk synthetic soap is disclosed. The invention provides a preparation technology for preparing goat milk synthetic soap by using goat milk as the main raw material. goatmilk, caustic soda powder and mixed plant oils which are used as raw materials successively undergo steps of goat milk concentration, goat milk hydrolysis, plant oils mixing, oil-milk mixing, productmoulding and the like, so as to prepare the goat milk synthetic soap product. The technology is simple and easy to realize; machining production efficiency is high; production cost is low; and the prepared product has beautiful appearance, uniform texture, long preservation time and long service time.

Owner:XIXIA JIANYANG ANIMAL HUSBANDRY

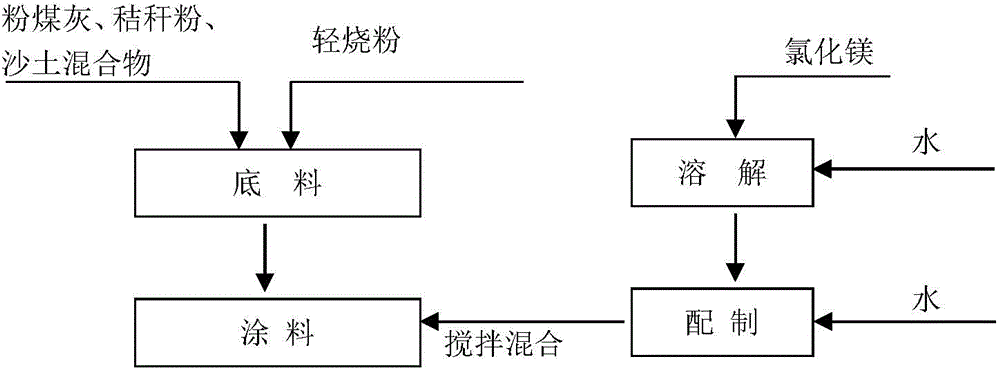

Magnesium oxychloride cement coating for exterior walls and preparation method of coating

ActiveCN104446320ASolving housing exterior wall coating problemsNice appearanceSolid waste managementThermal insulationMass ratio

The invention relates to the technical field of coatings, in particular to a preparation method of a magnesium oxychloride cement coating for exterior walls. The method comprises steps as follows: evenly mixing light-burned powder, fly ash or silica fume, straw or sawdust as well as a sand and soil mixture in the mass ratio of 100:(5-20):(10-70):(20-110) to form a base material; adding a magnesium chloride aqueous solution with the mass percent ranging from 20 to 25 to the base material, and evenly mixing the mixture to form the coating for coating the exterior walls, wherein the mass ratio of the light-burned powder to the magnesium chloride aqueous solution is in a range of 1:(1-2.6). The coating for the exterior walls is good in fireproof performance, good in cold resistance, simple in process, convenient to construct and operate, low in cost and quite suitable for popularization and application in northwest regions and has a certain thermal insulation effect.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

A kind of three-layer medical infusion bag and its manufacturing method

InactiveCN103893012BImprove securityAdvanced technologyInfusion devicesPharmaceutical containersPolypropyleneBiomedical engineering

Owner:ANHUI DOUBLE CRANE PHARMA

A kind of ceramic container and its preparation process

InactiveCN104193291BHard textureNot perishableCeramic materials productionClaywaresMetallurgyKaolin clay

The invention provides a ceramic vessel and a preparation process thereof. The inner part of the ceramic vessel is a porcelain liner which is made from a porcelain material while the outer part of the ceramic vessel is a ceramic jacket which is made from a ceramic material. The protein material consists of 93-97 parts of kaolin and 3-7 parts of water in parts by weight and the ceramic material consists of 80-90 parts of yellow river bottom mud, 7-13 parts of fine sands and 3-7 parts of water in parts by weight. The preparation method is unique and pottery and porcelain are skillfully combined, and moreover, the obtained ceramic vessel is free from cracking. The inner protein and the outer ceramic of the obtained ceramic vessel are tightly attached by virtue of arrangement of special ceramic material, protein material and shrinkage ratio, so that the ceramic vessel is attractive in craft.

Owner:天津感光空间现代雕塑艺术研究院 +1

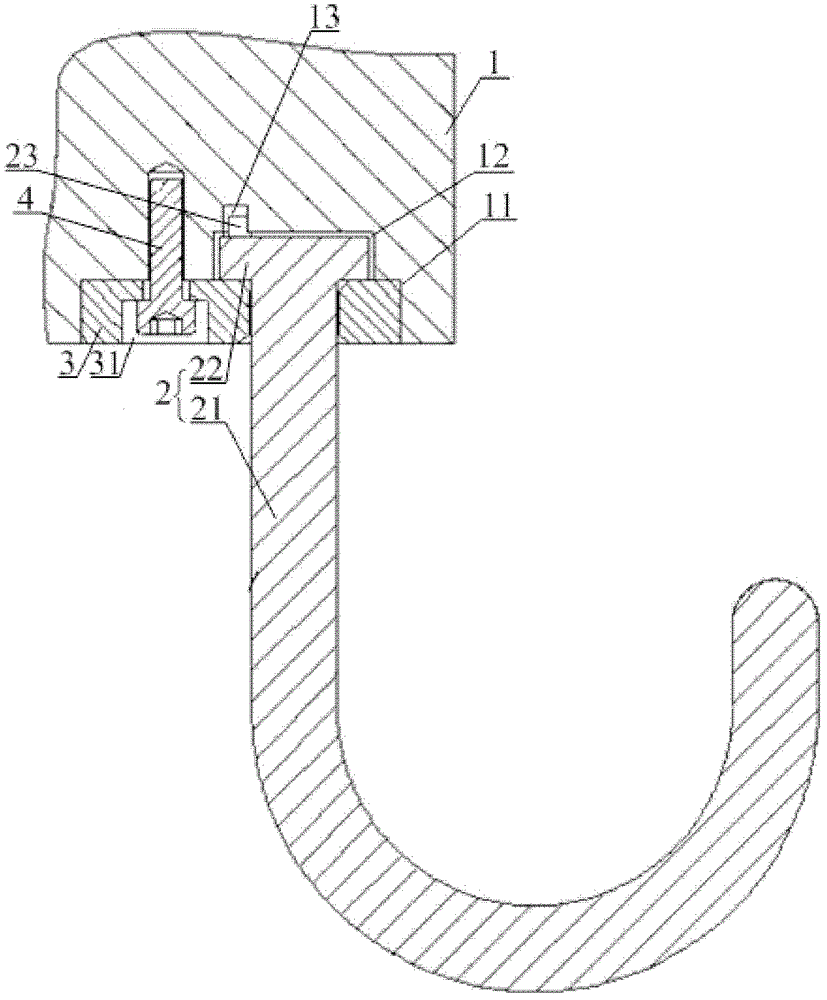

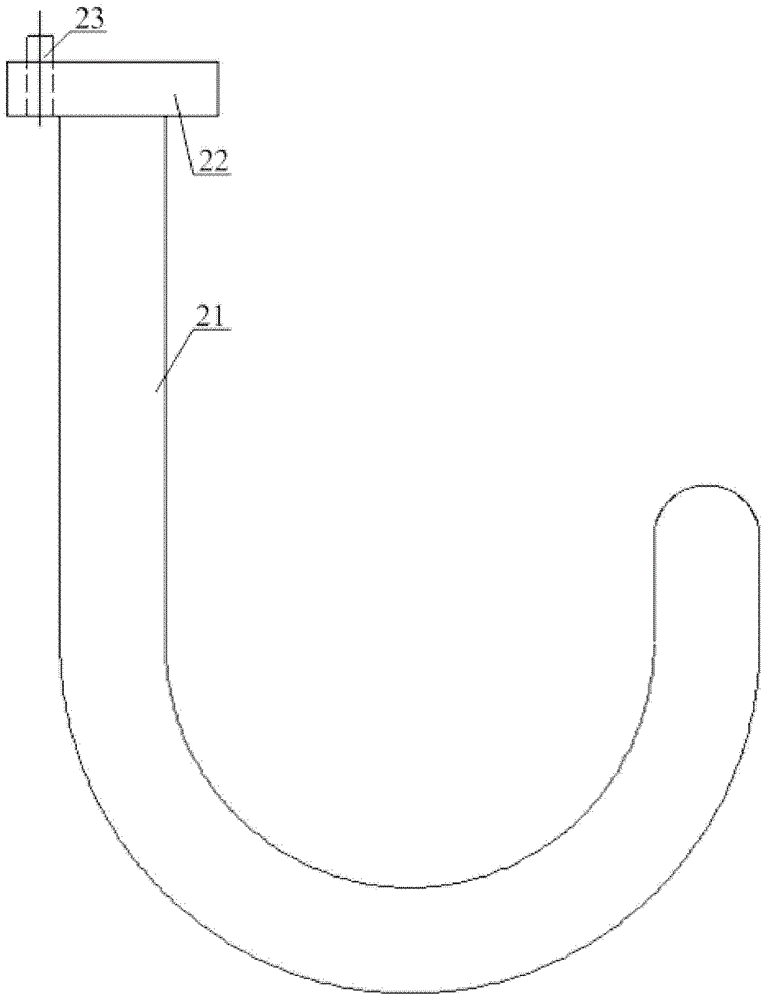

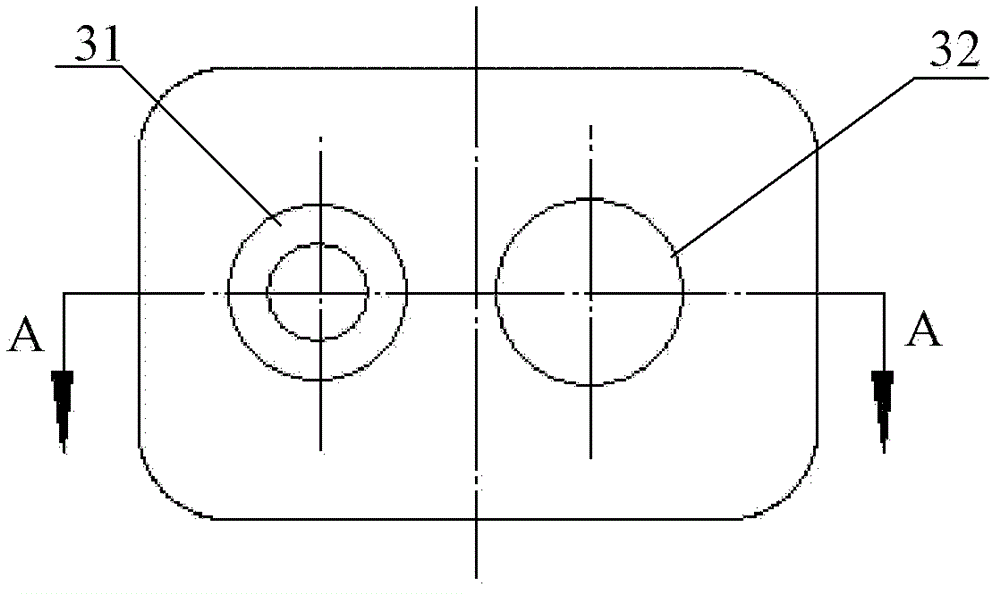

Limit hook device

Owner:BEIJING AEONMED

A kind of manufacturing process of bamboo violin

ActiveCN103258525BIncrease productionEasy to get materialsViolinsManufacturing technologyEngineering

The invention relates to manufacturing technology for a bamboo violin. A violin face board, a violin base board, violin side boards and a violin head are made of bamboo. The bamboo is easy to take and the bamboo violin is convenient to manufacture, low in cost, capable of effectively reducing wood resource consumption and protecting natural environment, good in sound effect and long in service life.

Owner:江苏凤灵乐器有限公司

Ceramic vessel and preparation process thereof

InactiveCN104193291AHard textureNot perishableCeramic materials productionClaywaresMetallurgyKaolin clay

The invention provides a ceramic vessel and a preparation process thereof. The inner part of the ceramic vessel is a porcelain liner which is made from a porcelain material while the outer part of the ceramic vessel is a ceramic jacket which is made from a ceramic material. The protein material consists of 93-97 parts of kaolin and 3-7 parts of water in parts by weight and the ceramic material consists of 80-90 parts of yellow river bottom mud, 7-13 parts of fine sands and 3-7 parts of water in parts by weight. The preparation method is unique and pottery and porcelain are skillfully combined, and moreover, the obtained ceramic vessel is free from cracking. The inner protein and the outer ceramic of the obtained ceramic vessel are tightly attached by virtue of arrangement of special ceramic material, protein material and shrinkage ratio, so that the ceramic vessel is attractive in craft.

Owner:天津感光空间现代雕塑艺术研究院 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com