Large-diameter metal material welding mold and welding method

A metal material and welding mold technology, applied in the field of welding technology, can solve the problems of high cost of diesel generators, decreased welding quality, unstable current, etc., and achieve the effects of reducing human injury, stable welding quality and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

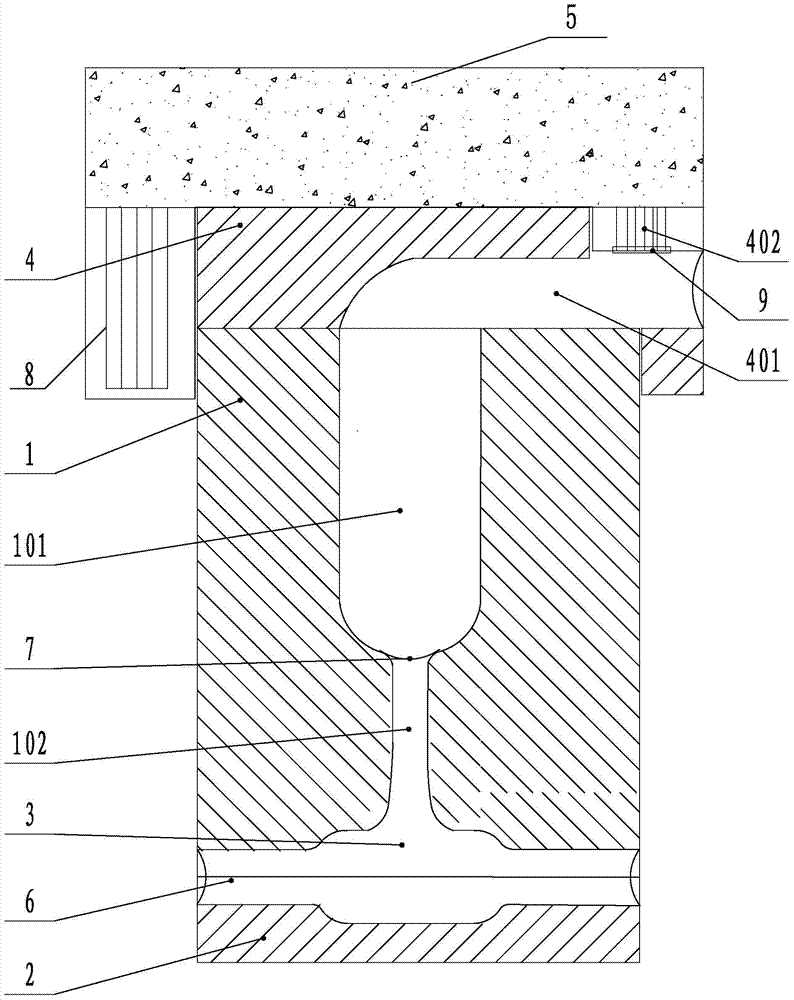

[0023] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0024] As shown in Figure 1, the present invention includes an upper mold 1 and a lower mold 2, the upper mold 1 is provided with a molten powder cavity 101, an injection hole 102 and an upper welding cavity 3, and the described injection hole 102 is located in the molten powder cavity Between 101 and the upper welding cavity 3, the lower mold 2 is provided with a lower welding cavity 3 opposite to the upper welding cavity 3, and the upper welding cavity 3 and the lower welding cavity 3 are combined to form the welding cavity 3. The upper mold 1 The top cover 4 is provided on the top surface, and the bottom surface of the top cover 4 is provided with a guide groove 401 communicating with the melting powder chamber 101. One end of the guide groove 401 is an ignition end, and the other end is a fuse end. The ignition end is exposed, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com