Duct bank array installation and encapsulation construction method

A construction method and array technology, which is applied in the field of pipe array installation and encapsulation construction, can solve the problems of the overall floating of the pipe array, unsightly construction joints, blockage of MPP pipes, etc., to achieve convenient construction, improve construction efficiency, The effect of high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

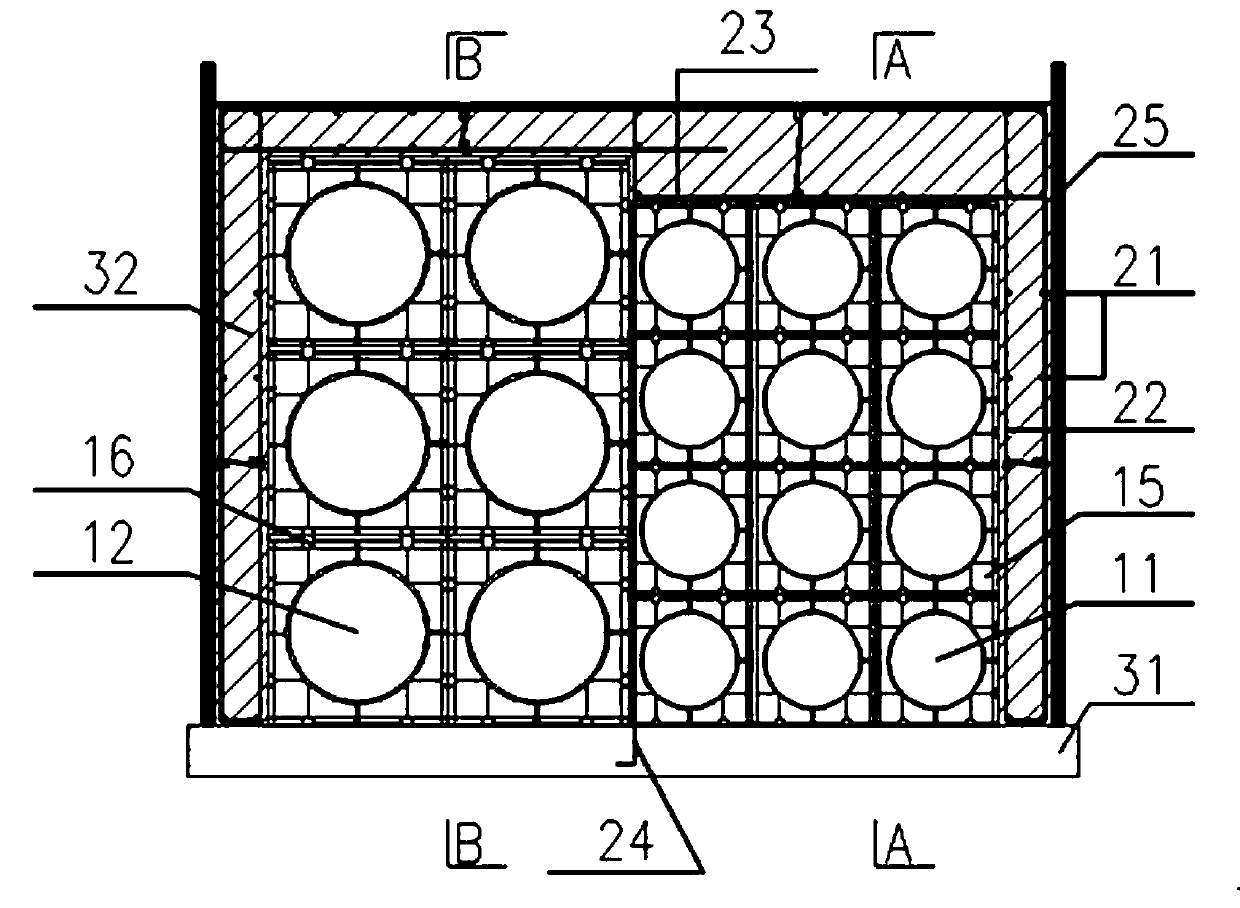

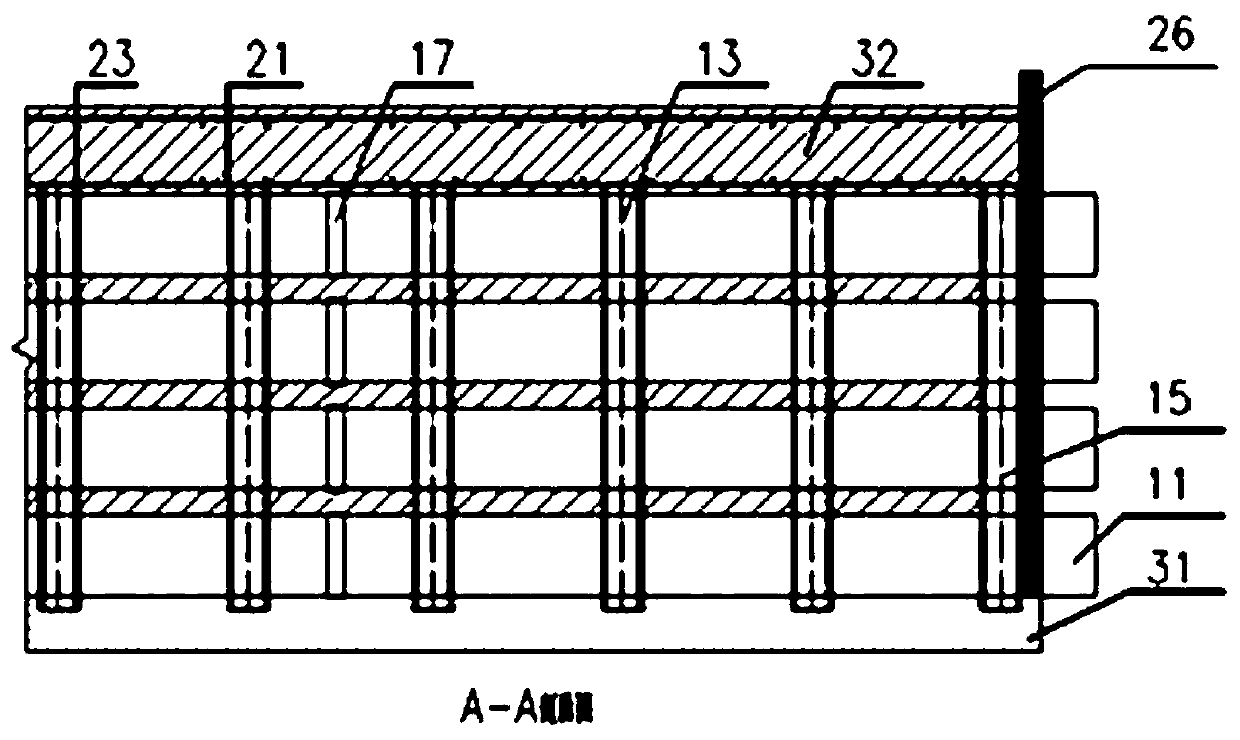

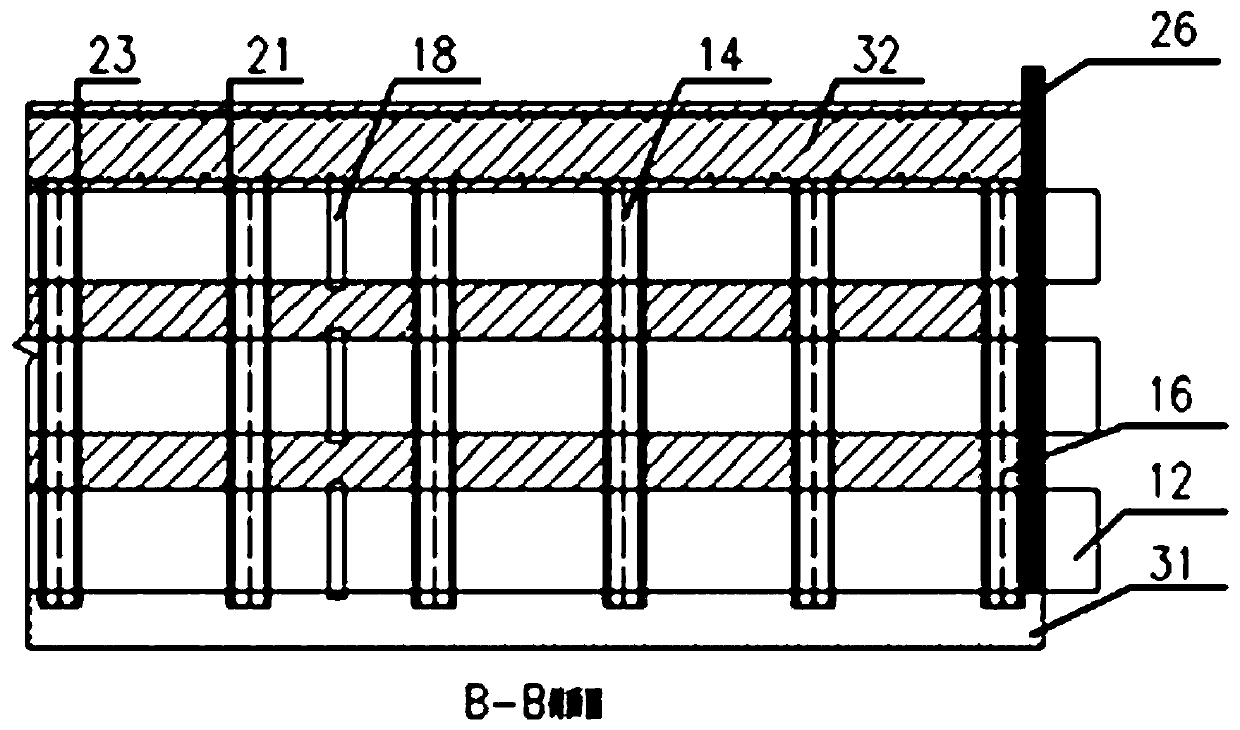

[0037] Such as Figure 1-7 Among them, a pipe array installation and encapsulation construction method includes the following steps:

[0038] 1) Pre-installation of the first row of pipes 11 and the second row of pipes 12 and their accessories, template making, steel bar processing, and preparation for measuring and setting out before construction;

[0039] 2) Level the base after excavating the foundation pit, and complete foundation pit support and dewatering measures;

[0040] 3) After installing the cushion formwork, pour the cushion concrete 31 and maintain it, and then install the anti-floating steel bars 24 on the cushion concrete 31 in sections;

[0041] 4) Use the cushion concrete 31 as the working platform to bind the vertical reinforcement 22 on both sides and the distributed reinforcement 21;

[0042] 5) Install the first intermediate pipe sleeper 13, the second intermediate pipe sleeper 14, the first casing 17, the second casing 18, the first row of pipes 11 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com