Fireproof flame-retardant wall plate and manufacturing method thereof

A fire-retardant and wallboard technology, which is applied in fire prevention, building materials, building components, etc., can solve the problems of non-degradable, environmental pollution, waste of resources, etc., and achieve simple molding process, avoid environmental pollution, and reduce waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

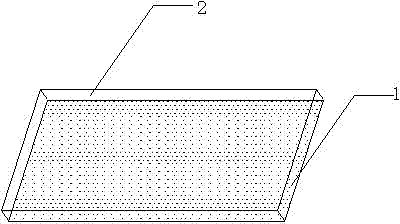

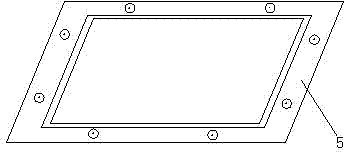

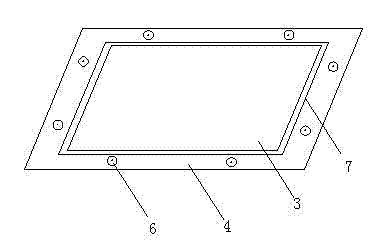

[0017] From figure 1 It can be seen from the schematic diagram of the fire-resistant and flame-retardant wallboard of the present invention that the fire-resistant and flame-retardant wallboard includes a polymer matrix 2 and a glass fiber reinforcement 1, and the polymer matrix 2 is coated on the outer surface of the glass fiber reinforcement. The glass fiber reinforcement 1 is waste glass fiber filaments or short fibers, and during the layup process of preparing wallboards, the glass fiber filaments or short fibers can be arranged and laid up according to the pattern requirements. The glass fiber reinforcement 1 and the polymer matrix 2 are laminated alternately and circularly. The polymer matrix 2 is one or a mixture of PP, PE or HDPE polymers. The PE polymer matrix adopts waste fibers and rope nets produced in the process of factory production and performance testing. During the lay-up process, the PE polymer matrix can be assigned colors and lay-up methods according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com