Patents

Literature

31results about How to "Simple texture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Information Processing Apparatus, Information Processing Method, and Program

InactiveUS20090103814A1Easy to shapeSimple textureCharacter and pattern recognitionPattern recognitionInformation processing

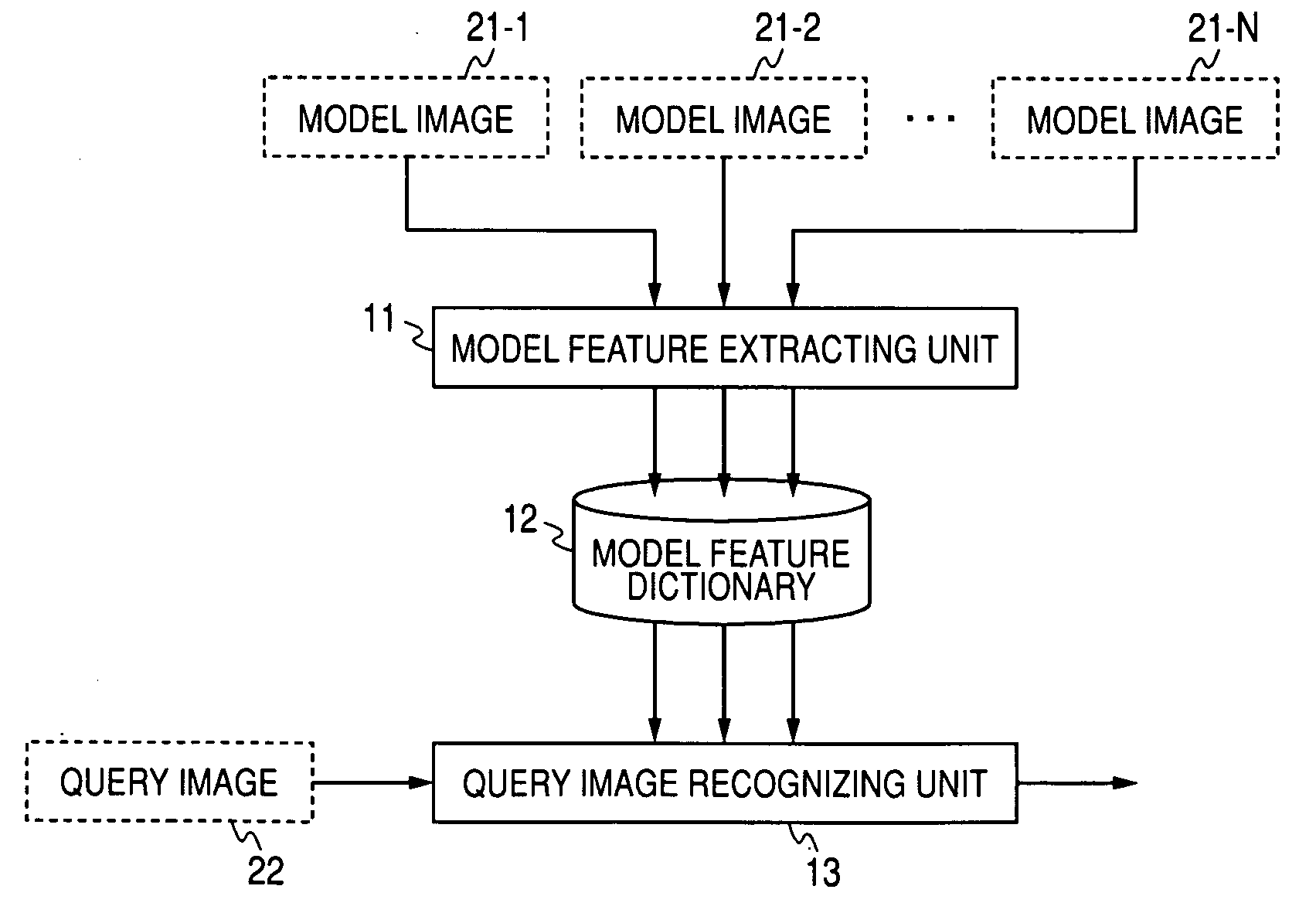

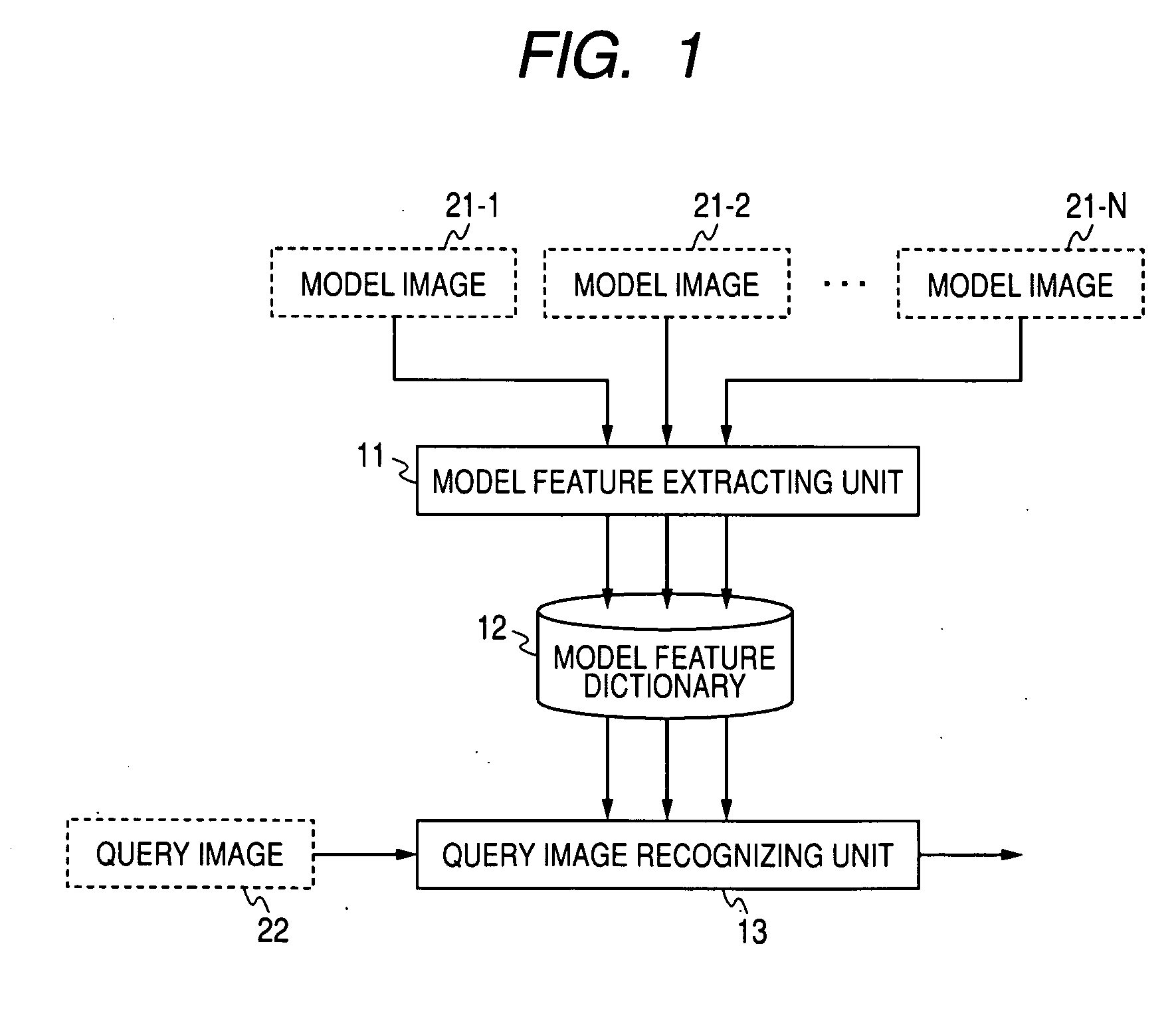

An information processing apparatus that compares a query image and a model image and provides support information for discriminating a subject of the model image from a subject of the query image is disclosed. The information processing apparatus includes: a feature point extracting means extracting one or more feature points from the model image; a feature describing means describing features of the one or more feature points extracted by the feature point extracting means; and a discrimination capability value calculating means generating correlation images among the features described by the feature describing means, the extracted model image, and one or more other model images for the one or more feature points extracted by the feature point extracting means, and calculating a discrimination capability value indicating the degree of contribution to discriminating the subject of the model image on the basis of the correlation images.

Owner:SONY CORP

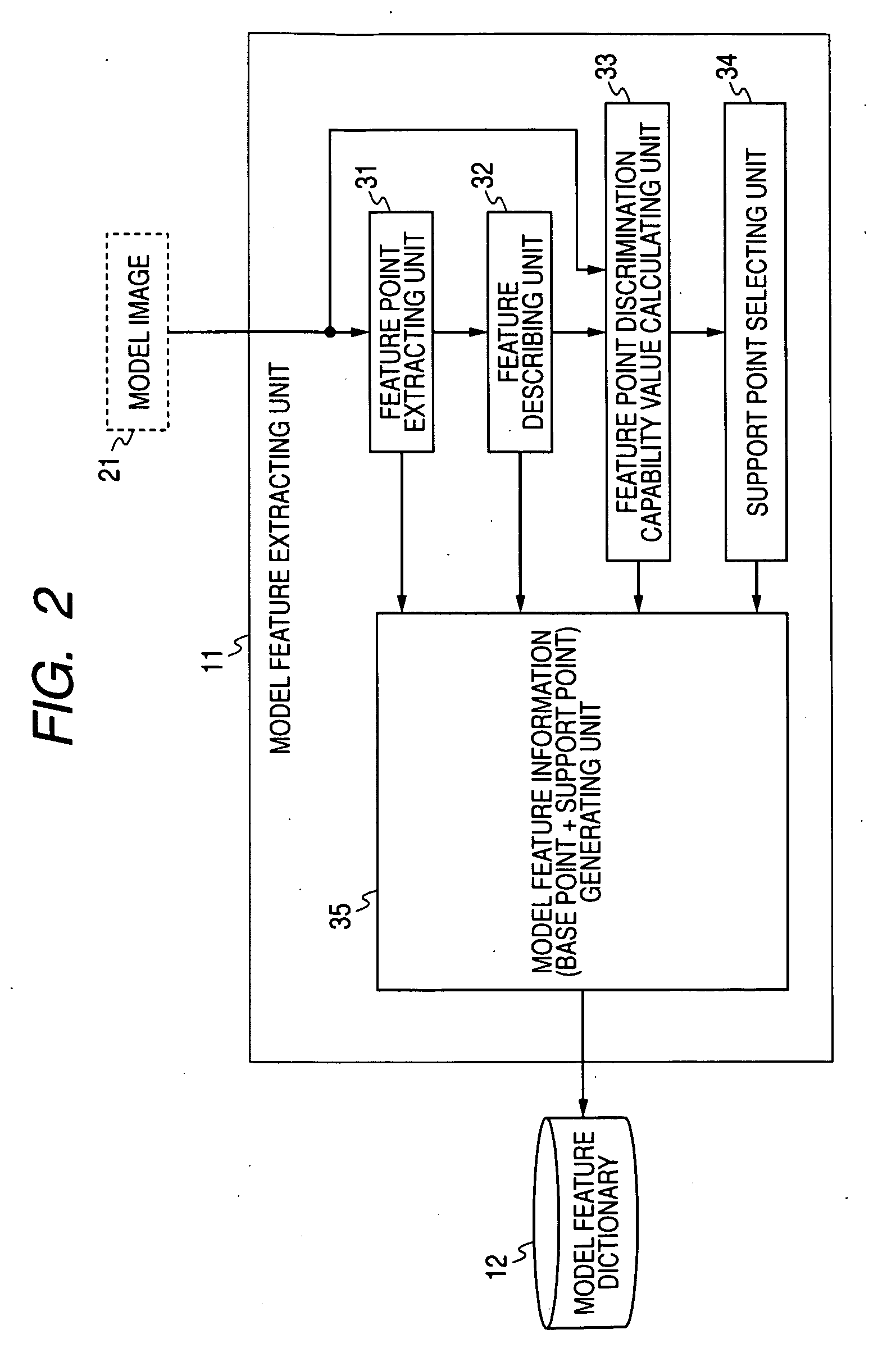

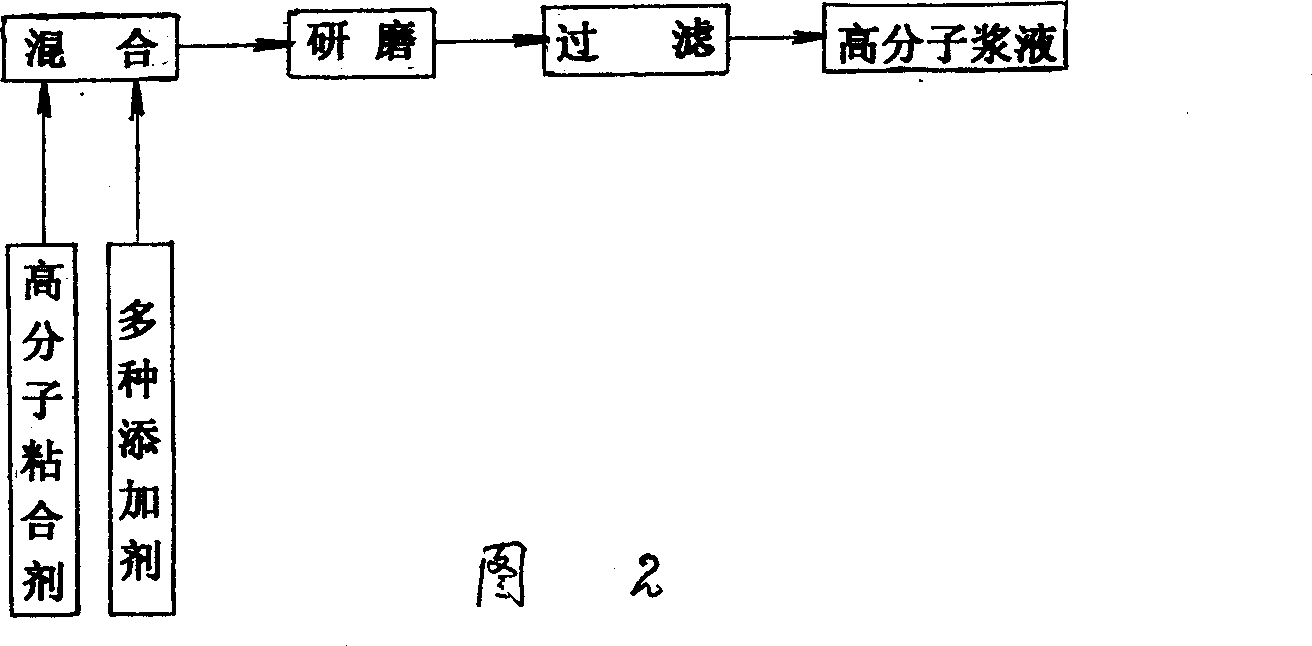

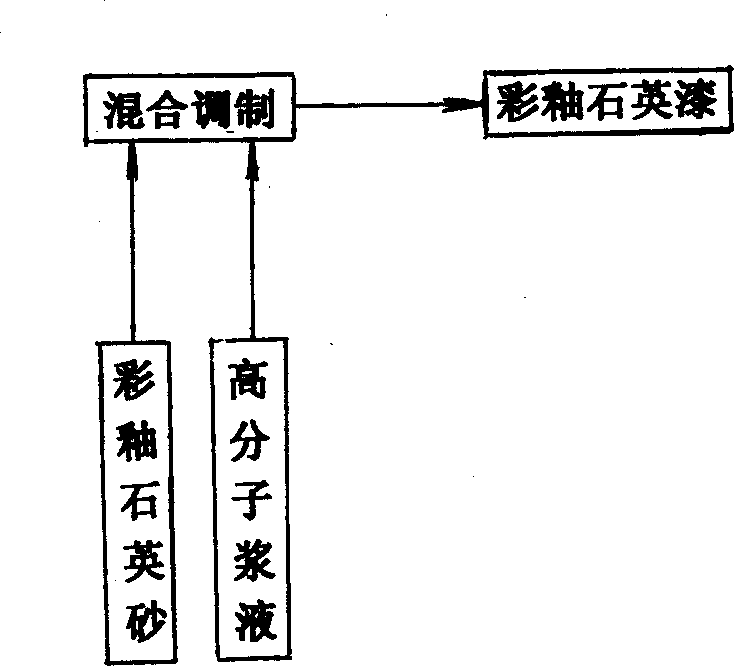

Production process of colar glaze guartz paint

The production process of color glaze quartz paint includes preparation of color glaze quartzite, preparation of polymer slurry and compounding of color glaze quartz paint. It features that during preparation of color glaze quartzite, using only two kinds of material for producing the inorganic basic pigment material and inorganic basic glaze material capable of produce the color quartzite material through mixing, sieving and middle temperature baking; and that the polymer slurry is compounded with several polymer adhesives and additives. The present invention has the advantages of simple process, easy operation, no toxicity, no environmental pollution and low cost and can produce excellent color glaze quartz paint with different required performance.

Owner:KEDA LUOKE NEW MATERIAL SICHUAN

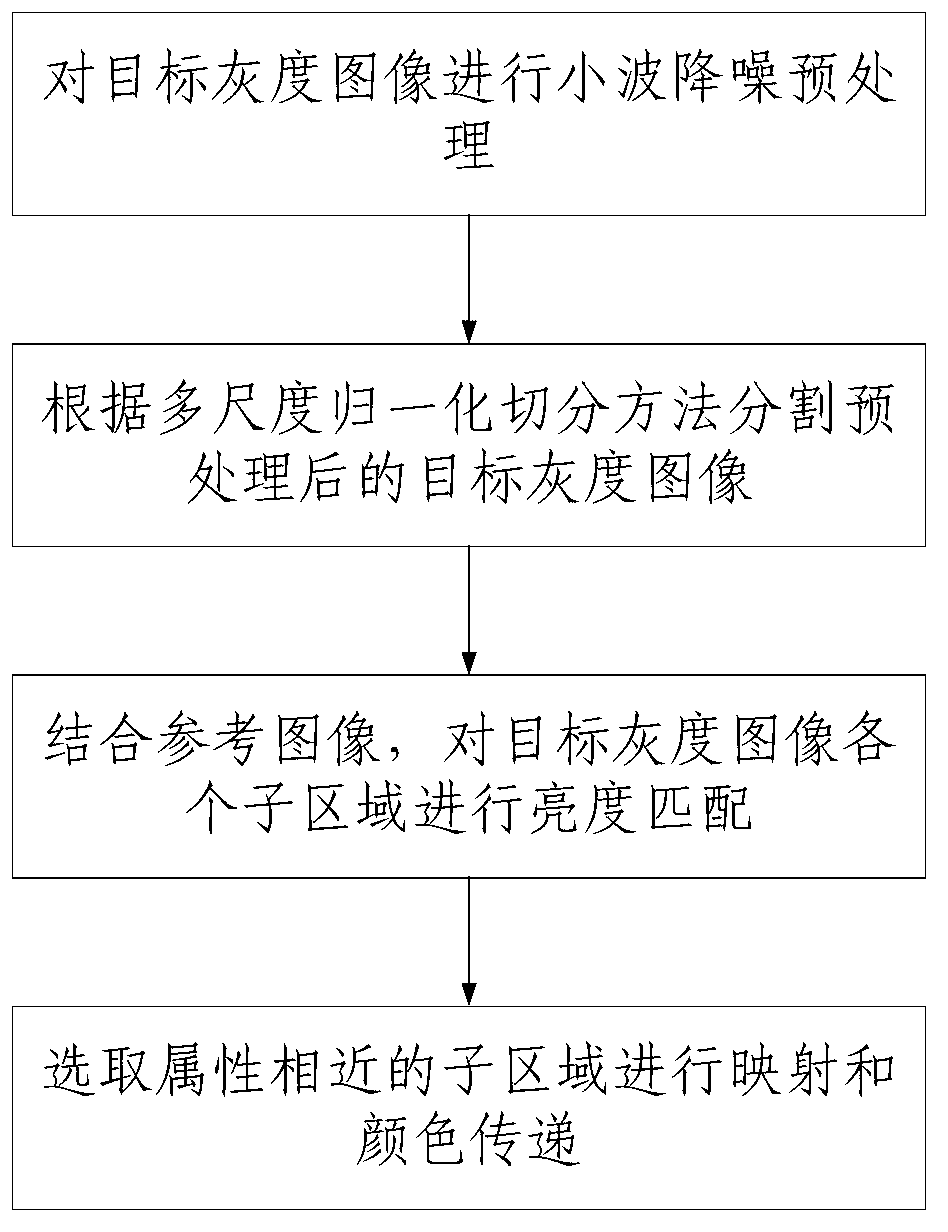

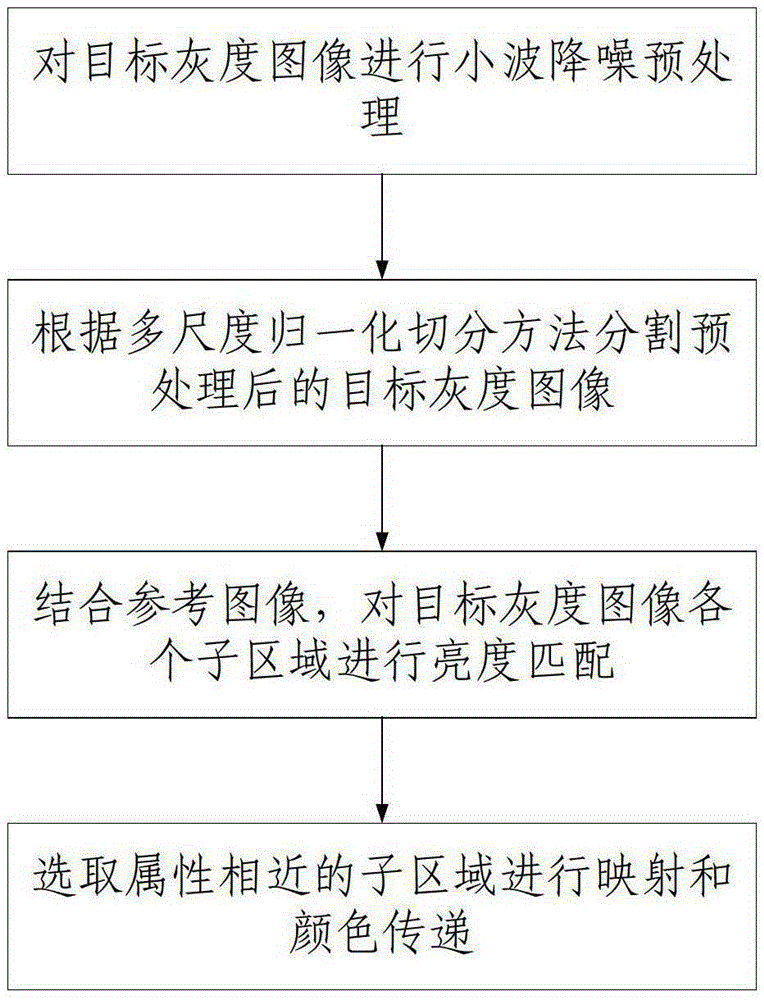

Remote sensing image color enhancing method based on multi-scale image segmentation and color transferring

InactiveCN103136733AImprove legibilityReduce color transfer errorsImage enhancementWavelet denoisingLightness

The invention relates to the technical field of remote sensing image processing, in particular to a remote sensing image color enhancing method based on multi-scale image segmentation and color transferring. The method comprises steps: S1, conducting wavelet denoising preprocessing for a target gray level image; S2, according to a multi-scale normalized segmentation method, conducting segmentation of the target gray level image after preprocessed; S3, combining a reference image, and conducting brightness matching for all sub-domains of the target gray level image; and S4, selecting a sub-domain with the similar property to conduct mapping and color transferring. Aesthetic measure and target recognized degree of a result image are obviously enhanced, under the condition that image registering is not needed, the method can achieve full-automatic color enhancing for a remote sensing image which is relatively simple in texture structure and big in brightness contrast just through a color reference image which is similar in character and style, and therefore, the remote sensing image color enhancing method provides strong technical support for remote sensing image processing.

Owner:NO 61 INST OF GENERAL STAFF +1

Cultured stone heat-insulation and decoration integrated plate and production technology thereof

The invention relates to a cultured stone heat-insulation and decoration integrated plate and a production technology thereof. The cultured stone heat-insulation and decoration integrated plate is made of the following raw materials: 42.5 silicate cement, coal ash, quartz sand, re-dispersible emulsion powder, hydroxypropyl methyl cellulose, warm water with the temperature of 35-40 DEG C, polypropylene fibers, ceramic powder, naphthalene-based superplasticizer, polyphenyl granules, closed primer and silicon-acrylic coatings. The production technology comprises the following steps of preparation of a heat-insulation layer, preparation of a surface layer, injection molding and plate making, and surface decoration. The cultured stone heat-insulation and decoration integrated plate which is produced by using the formula and the technology not only has a quite high decoration effect, but also has high heat-insulation performance.

Owner:高广银

Processing method of instant seasoning scallop

The invention relates to a processing method of instant seasoning scallop, and the method comprises the following steps that fresh and pollution-free scallop is adopted as a raw material, cleaned, soaked in salt water, stewed, shelled and cored; the internal organs and intestinal gland are removed from scallop meat, and the scallop meat is cleaned, cured and dried until the water content of the scallop meat is controlled to be 20 percent + / -2 percent; and the dried scallop meat is detected by metal and packaged, and a seasoning scallop finished product is obtained. The processing method has reasonable procedures and is simple in preparation. The seasoning for curing is mixed scientifically, so that the flavor of the product is improved, and the saline taste and sweetness are dainty. The slightly baked scallop food which is prepared through the method better maintains the appearance form and the nutrition ingredients of the scallop, has the special aroma of seafood, golden color, soft texture, unique taste, delicious taste and long storage life, and is convenient to eat.

Owner:RONGCHENG HONGWEI FOOD

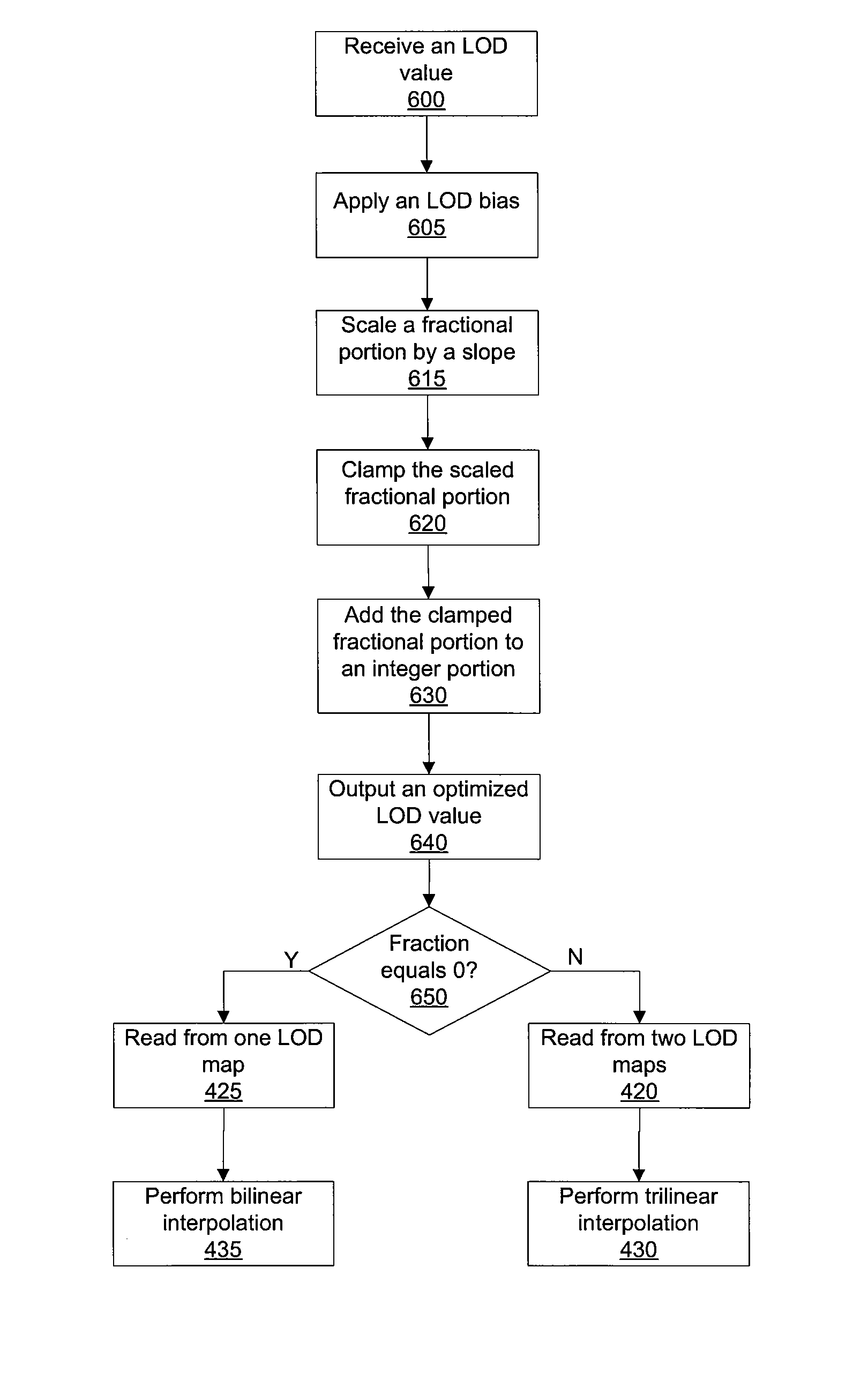

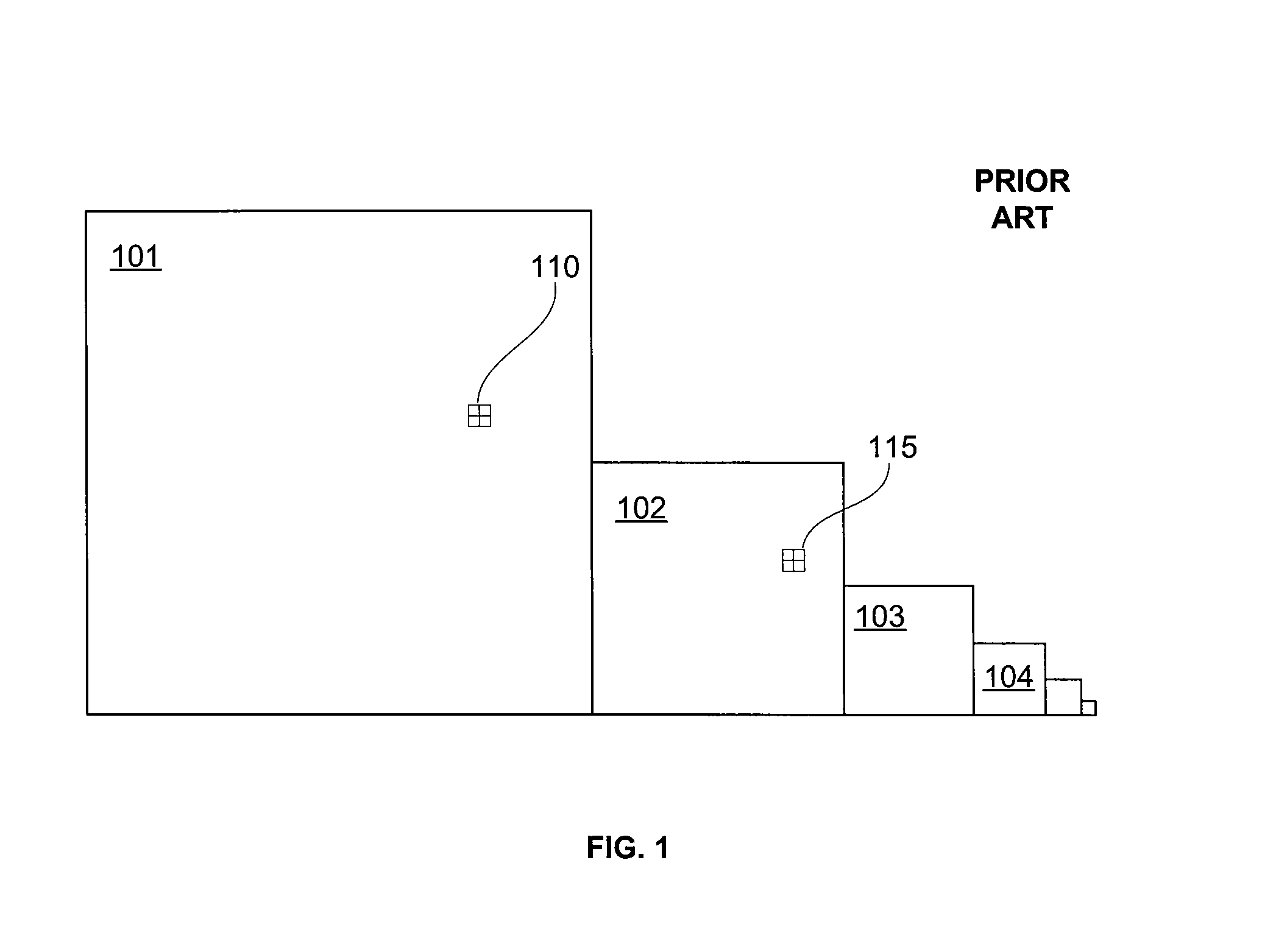

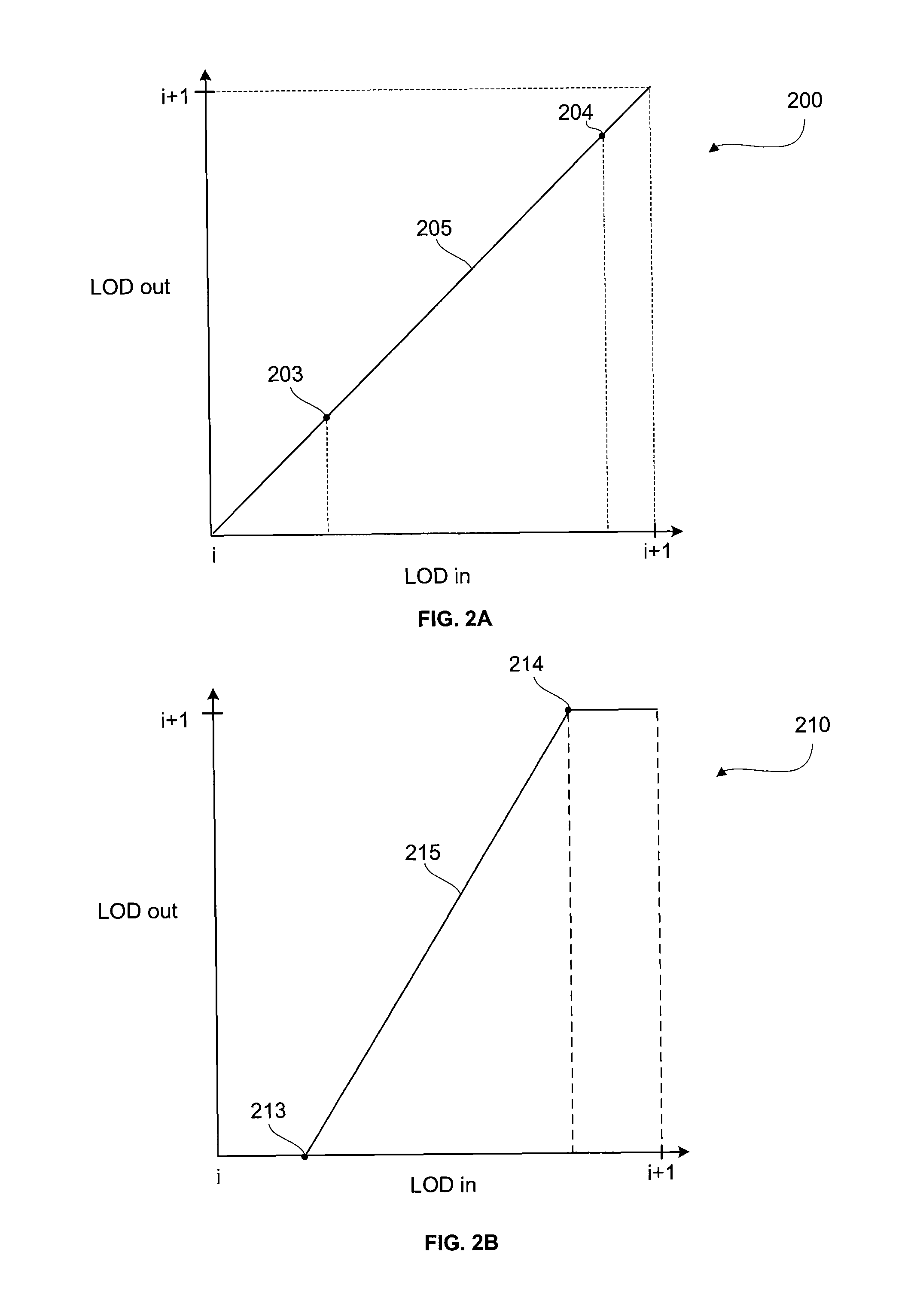

Trilinear optimization for texture filtering

InactiveUS7982745B1Reduce in quantitySimple textureDigital computer detailsCathode-ray tube indicatorsComputational scienceGraphics

Owner:NVIDIA CORP

A kind of processing method of antique wood

InactiveCN104441152BSimple textureAvoid damageWood treatment detailsWood heatingChemical preparationProcessing cost

The invention relates to a processing method of antiqued wood. The processing method comprises the following steps: (1) preparing processing pulp; (2) processing wood surface; (3) baking; (4) varnishing; and (5) sizing to obtain the antiqued wood. The antiqued wood provided by the invention is simple in process, the processed wood is primitive in texture, the corrosion resistance on the wood surface is good, and the processing cost is low, the chemical preparation dosage is small, the damage to the wood structure is little, and the method is suitable for large-scale production.

Owner:FUNAN XINGGUANG ARTS & CRAFTS CO LTD

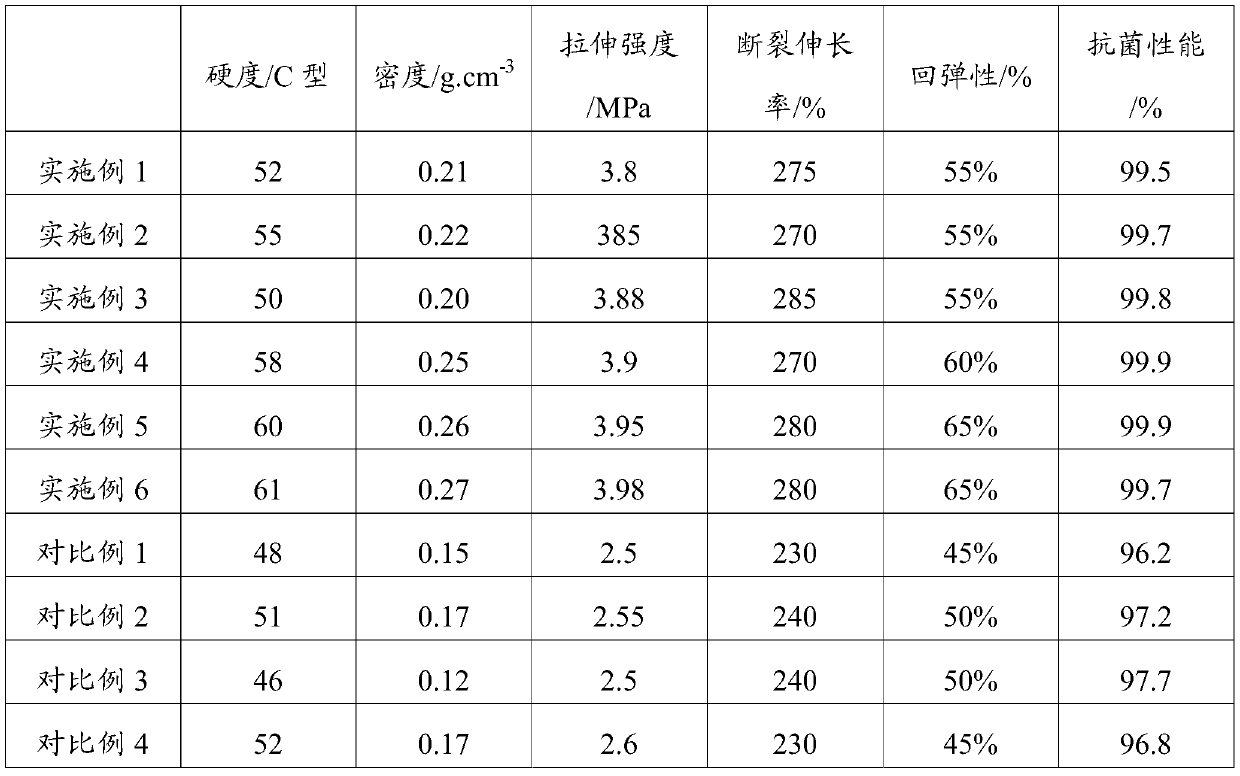

Durable elastic floating body and preparation method thereof

The invention discloses a durable elastic floating body and a preparation method thereof, and belongs to the technical field of high polymer materials. The durable elastic floating body comprises an ethylene-vinyl acetate copolymer, a thermoplastic elastomer TPE, a filler, a foaming agent, a foaming aid, a lubricant, a coupling agent modified anti-ultraviolet agent, a coupling agent modified antioxidant, a coupling agent modified antibacterial agent, a cross-linking agent and a pigment. According to the durable elastic floating body, the surfaces of the anti-ultraviolet agent, the antioxidantand the antibacterial agent are changed into hydrophobicity from hydrophilcity through modification of the coupling agent, the dispersity of an inorganic auxiliary agent in an organic material is improved, the binding force of the inorganic auxiliary agent and the organic material is enhanced, the effect of the inorganic auxiliary agent can be fully exerted, the obtained elastic floating body hasexcellent wear resistance, rebound resilience, antibacterial property and aging resistance at the same time. The preparation method is simple in step and easy to operate, and the elastic floating bodyis formed through one-time foaming, compact in texture, smooth and thorn-free in surface and excellent in quality.

Owner:福建创合新材料科技有限公司

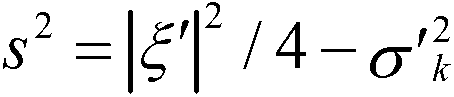

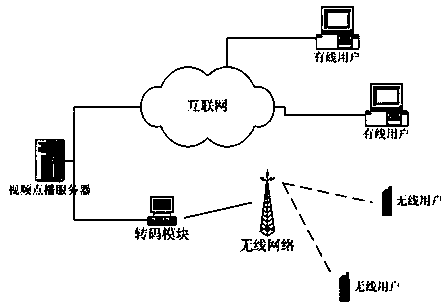

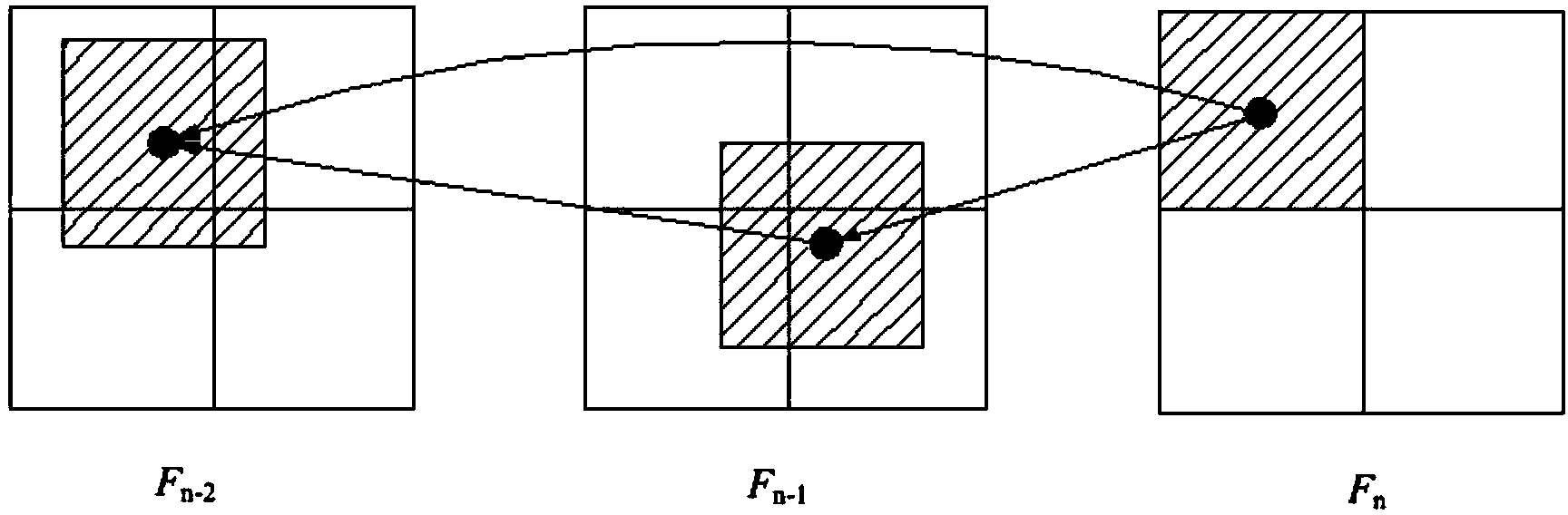

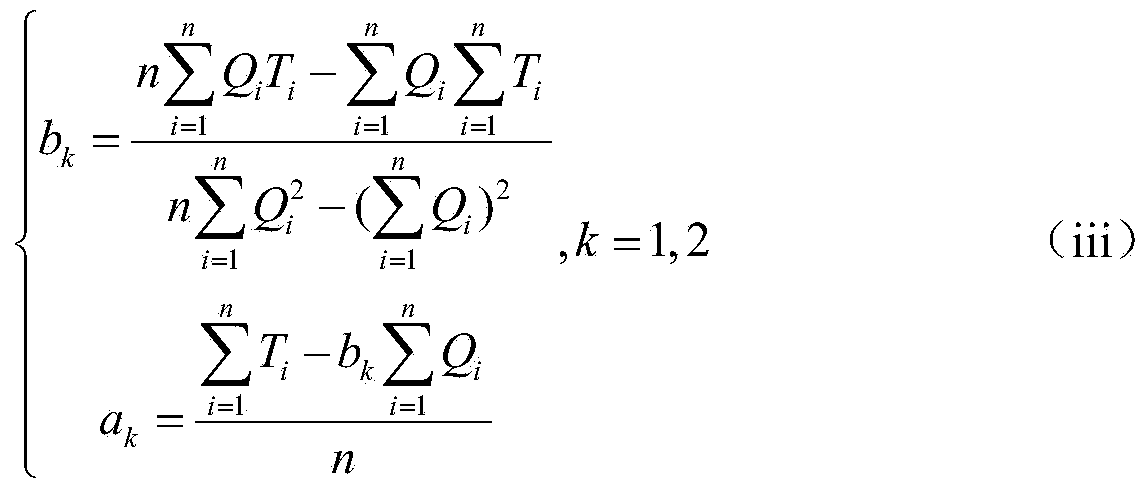

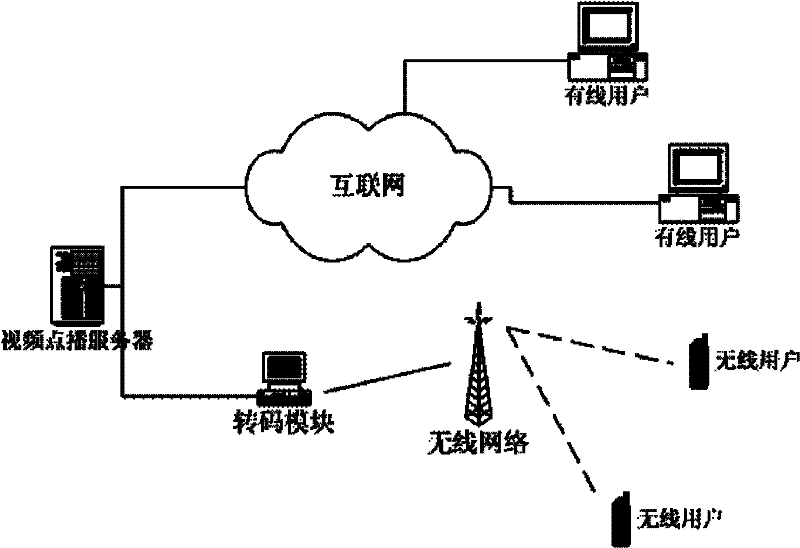

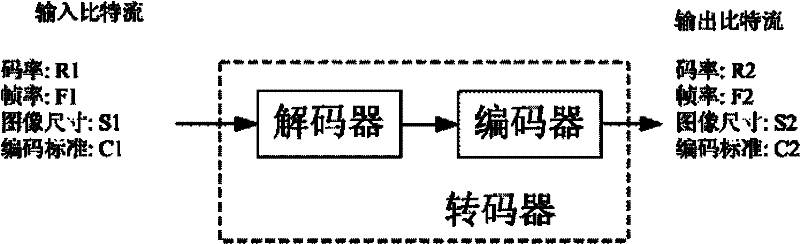

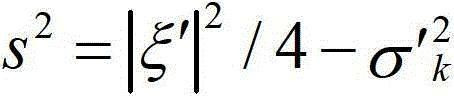

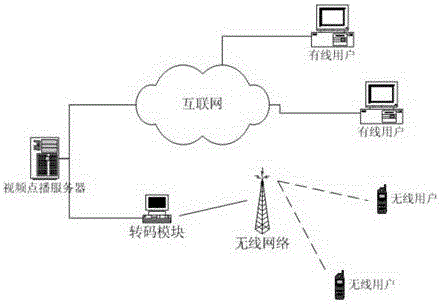

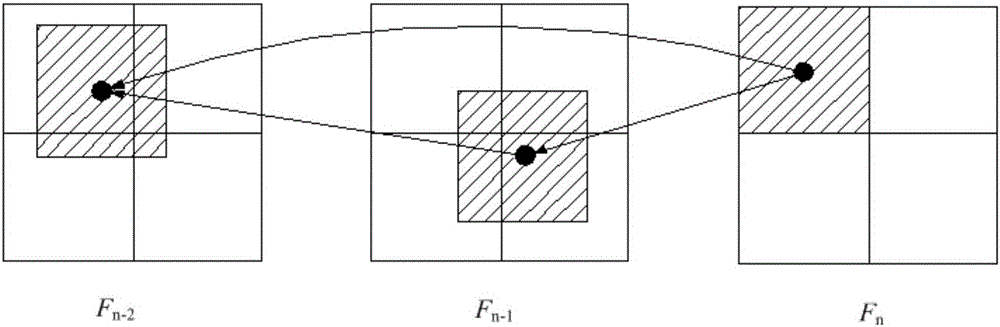

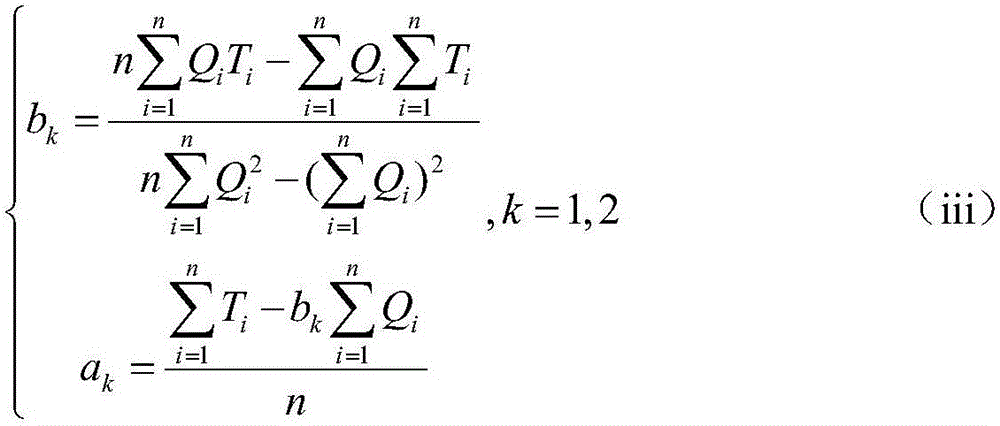

Interframe macro block type selecting method used in real-time AVS-based video frame rate transcoding

ActiveCN103596012AShort timeFast transcodingDigital video signal modificationWireless videoTranscoding

The invention discloses an interframe macro block type selecting method used in real-time AVS-based video frame rate transcoding and belongs to the field of multimedia signal processing. The method is mainly used for achieving fast macro block type selection in frame rate transcoding. The method is characterized in that macro block type selection is achieved by means of a model established with four parameters, and macro block type selection comprises the steps of parameter calculation, threshold selection and determination of the macro block type according to a threshold. According to the interframe macro block type selecting method used in real-time AVS-based video frame rate transcoding, transcoding speed can be increased remarkably, the superior macro block type in recoding is fully guaranteed, and then a quite low bit rate is obtained. The interframe macro block type selecting method used in real-time AVS-based video frame rate transcoding is suitable for fields such as wireless video monitoring, Internet video monitoring and wireless video on demand.

Owner:山东电子职业技术学院

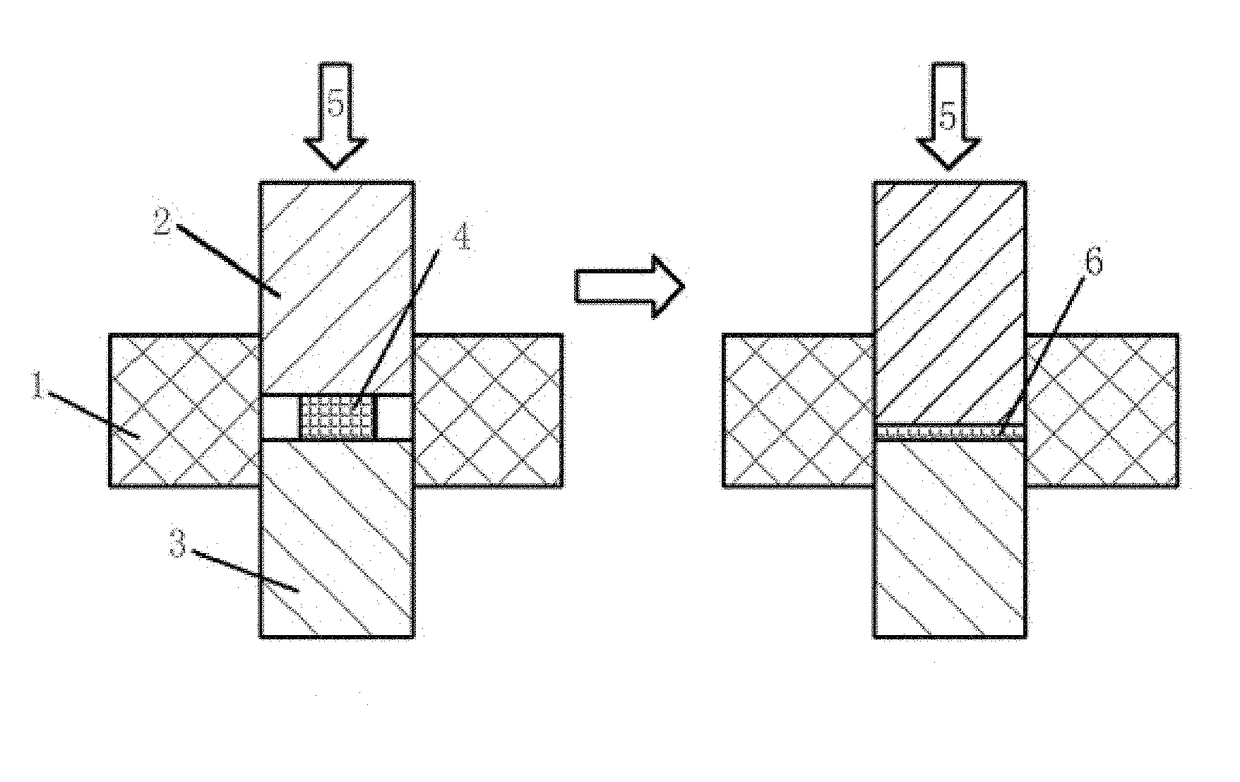

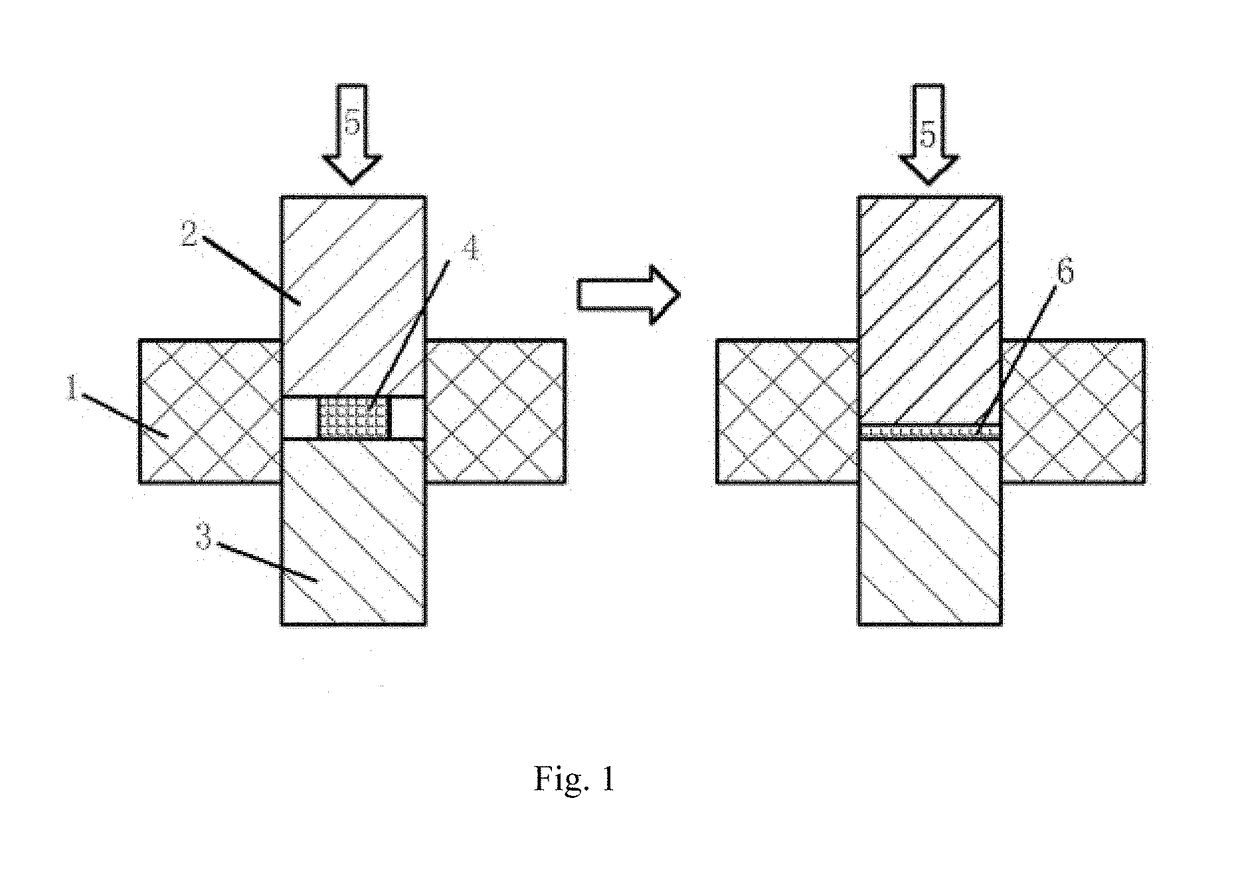

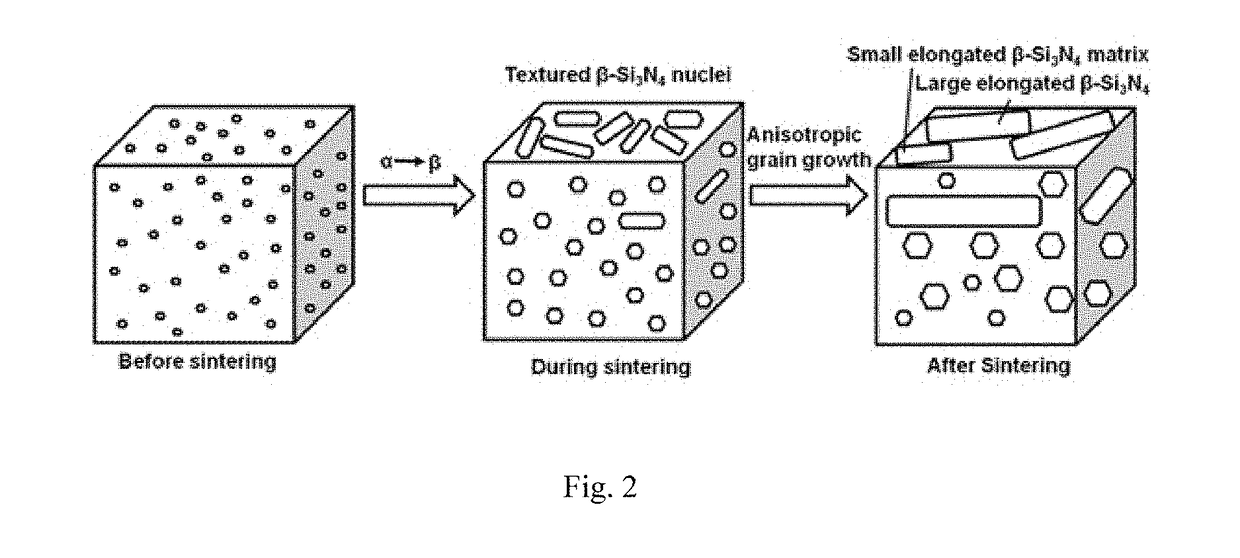

Method of making textured ceramics

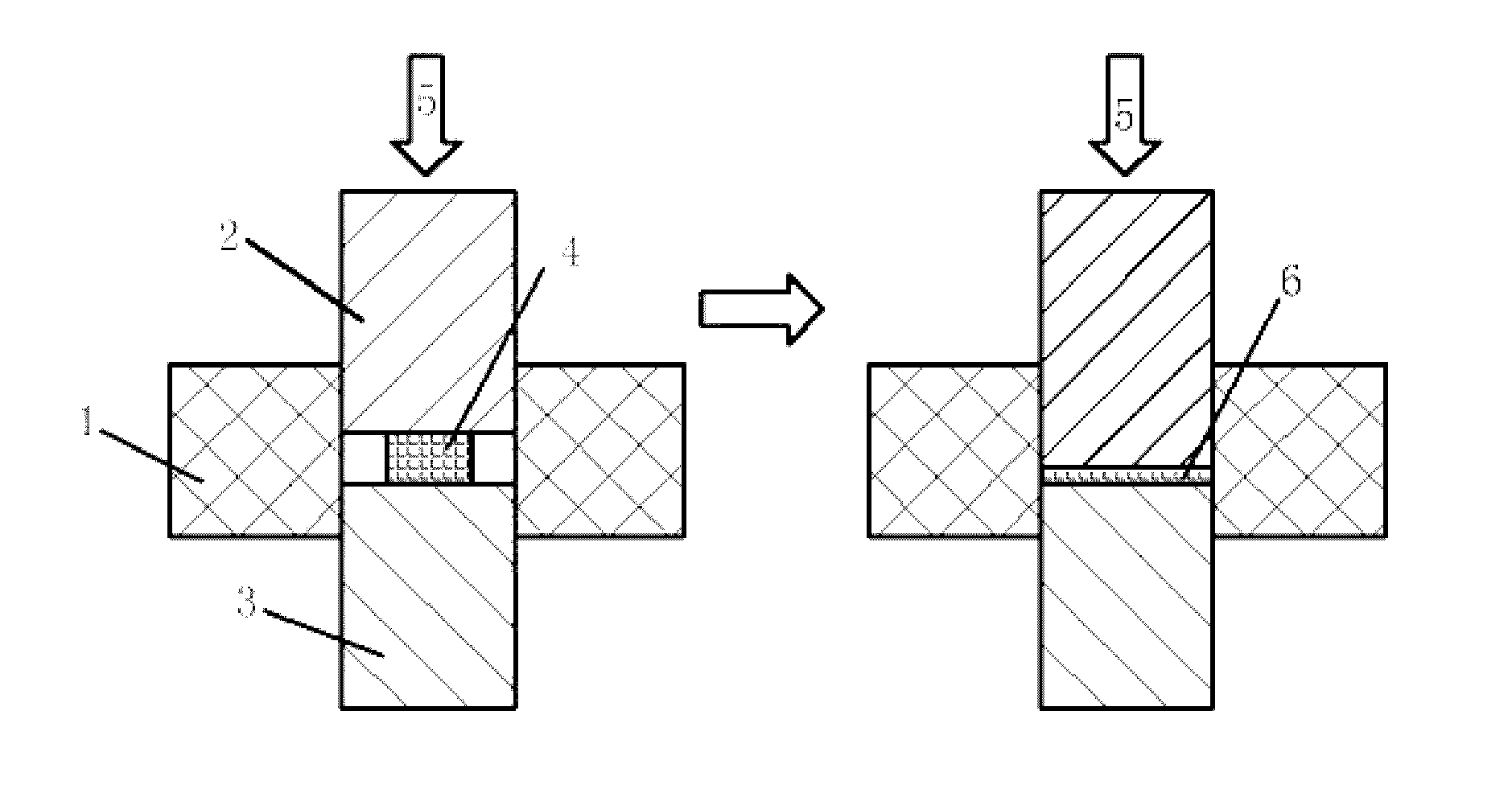

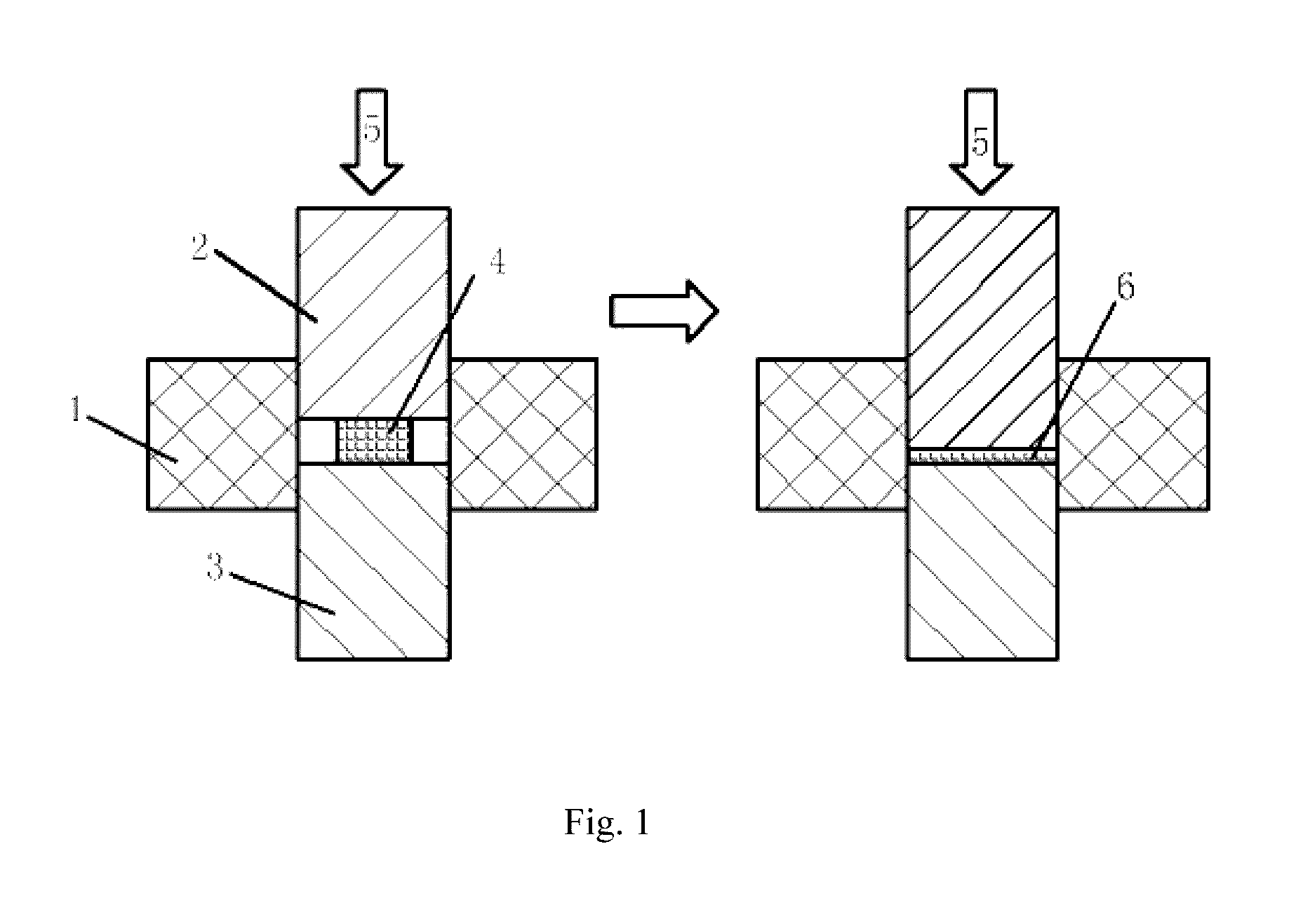

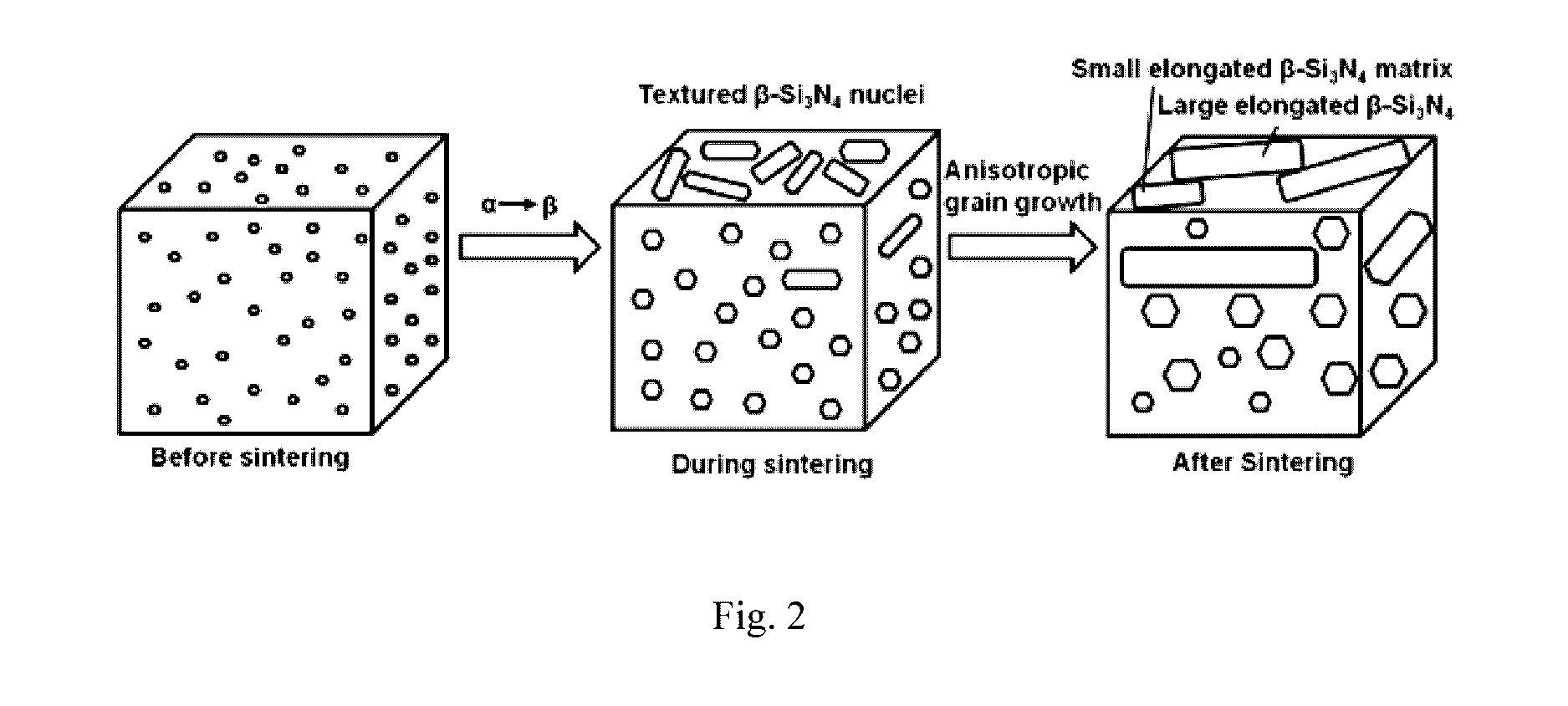

The invention proposed a novel hot pressing flowing sintering method to fabricate textured ceramics. The perfectly 2-dimensional textured Si3N4 ceramics (Lotgering orientation factor fL 0.9975) were fabricated by this method. During the initial sintering stage, the specimen flowed along the plane which is perpendicular to the hot pressing direction under pressure, through the controlling of the graphite die movement. The rod-like β-Si3N4 nuclei was easily to texture during the flowing process, due to the small size of the β-Si3N4 nuclei and the high porosity of the flowing specimen. After aligned, the β-Si3N4 grains grew along the materials flowing direction with little constraint. textured Si3N4 ceramics fabricated by this invention also showed high aspect ratio. Compared to the conventional hot-forging technique which contained the sintering and forging processes, hot pressing flowing sintering proposed is simpler and lower cost to fabricate textured Si3N4.

Owner:DONGGUAN SOUTH CHINA DESIGN INNOVATION INST +1

Leaf material and its making method and use

InactiveCN1775559ANo pollution in the processSimple textureNatural patternsSpecial ornamental structuresEngineeringPutty

The invention provides a leaf material and the making method and use, and the leaf material includes leaf vein attached with an additive layer, where the additive layer is made by being dried in the shade after the mixed glue composed of putty glue and opal glue is coated on the leaf vein. The leaf material has flexible quality and good elasticity, and excellent quality, uneasy to break, and the making process is simple and low-cost, and has excellent effect as used in manual drawing, computer color spraying or broidering.

Owner:汤家禄 +1

Archaized solid wood composite floor and production process thereof

PendingCN111749425ANo pollution in the processSave resourcesNatural patternsWood veneer joiningSolid woodAdhesive

The invention belongs to the technical field of building materials, and relates to an archaized solid wood floor, in particular to an archaized solid wood composite floor. A crisscross multilayer board base material layer is taken as a main body, the surface of the multilayer board base material layer is coated with adhesive to form a bonding layer, a surface layer is attached, a special archaizedprocessing layer is further arranged on the surface layer, and the uppermost layer is a UV paint layer. The special archaized layer is located between the surface layer and the surface UV paint layer, the thickness of the special archaized layer is between 0.1 mm and 1 mm, and the special archaized layer comprises a hand scraping archaized layer, a wire drawing process layer, a sawtooth grain treatment layer, a color coating process layer, a sand mark treatment layer and a color wiping treatment layer from top to bottom. The present invention also discloses a production process. According tothe archaized solid wood composite floor, the natural texture and the natural color of the wood are retained, the production process is simple, no distortion is lost in the texture pattern, the floorhas good visual characteristics through post-processing, and has relatively high paint adhesion and the like, and the physical and mechanical properties of the produced archaized floor meet the requirements of various indexes.

Owner:圣象地板(句容)有限公司

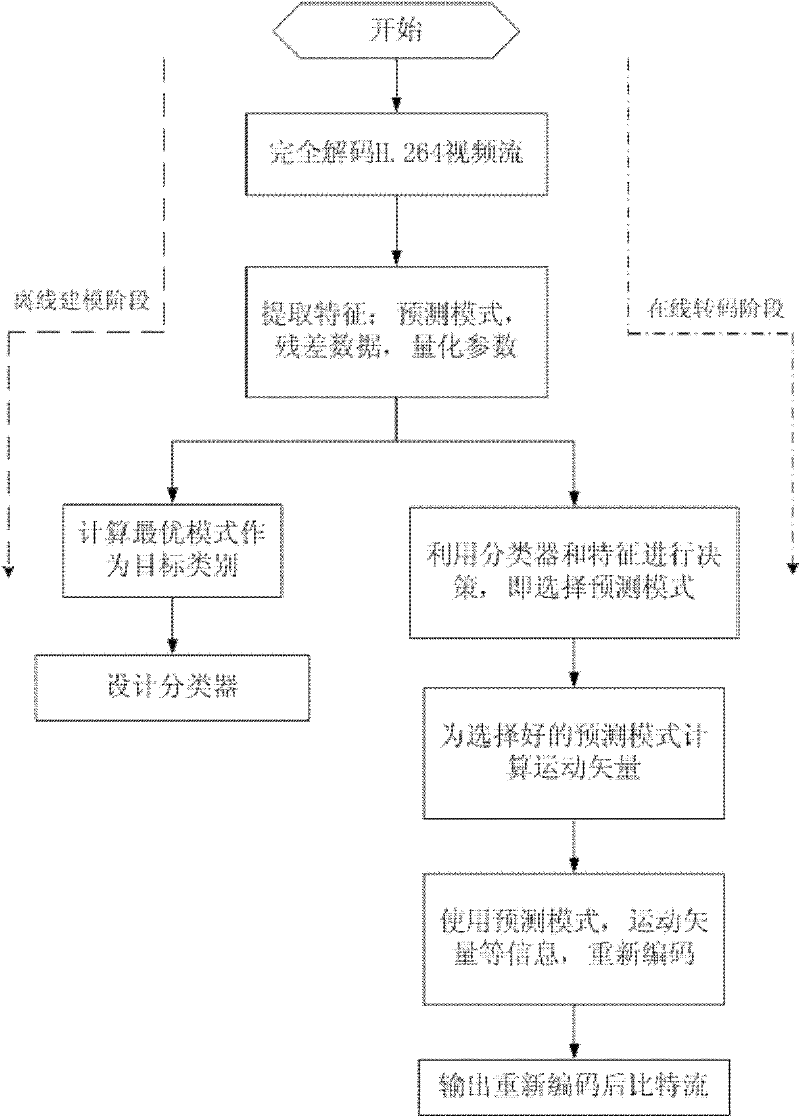

Real-time low-bit rate video transcoding method based on H.264

InactiveCN101924943BFast transcoding speedGuaranteed correctnessTelevision systemsDigital video signal modificationModel selectionAlgorithm

The invention relates to a real-time low-bit rate video transcoding method based on H.264, belonging to the field of multi-media signal processing and mainly solving the problem that the transcoding speed is demanded to be high at low bit rate. Video transcoding in the invention is divided into an off-line modeling stage and an online transcoding stage; a model identification technology is utilized to select a macrolbock prediction model; the macrolbock prediction model selection process is a category decision-making process in model identification; and extracted characteristics are input into a classifier to obtain a classification result, i.e. a macroblock prediction model. The classifier is obtained through offline training. The method not only can remarkably accelerate the transcodingspeed but also ensures the quality of a recoded image to meet the demand of real-time performance. The invention is suitable for the fields of wireless video monitoring, internet video monitoring andwireless video on demand.

Owner:郭敏

Preparation method of natural antibacterial latex liner for underwear

The invention relates to the technical field of natural rubber materials, and concretely relates to a preparation method of a natural antibacterial latex liner for underwear. The preparation method comprises the following steps: mixing natural rubber with water, adding a supramolecular solvent to the mixed solution, removing proteins, and performing freeze drying to obtain a natural latex; dissolving chitosan in an acetic acid-water mixed solution, adding natural latex, nano-cellulose, an inorganic filler, glutaraldehyde and a silane modifier, carrying out a reaction, filtering the obtained solution, and performing freeze drying to obtain a natural latex master batch; and performing high-speed stirring and mixing on the natural latex master batch, a natural antibacterial agent, an oxidant,nano-silica and a punching agent, heating and melting the obtained mixture at 100-150 DEG C, injecting the melted mixture into a grinding tool, carrying out curing molding, keeping the temperature at60-75 DEG C for 2-4 h, and cooling, washing and drying the cured mixture to obtain the natural antibacterial latex liner for underwear. The method of the invention is simple to operate, and the prepared latex liner has the advantages of soft texture, excellent mechanical properties, good air permeability and good antibacterial and anti-oxidation properties.

Owner:唐卫兵

Wood product antiquing treatment agent and application method thereof

InactiveCN106426469AEasy to useSimple textureWood treatment detailsWood impregnation detailsBletilla striataIron(II) chloride

The invention discloses a wood product antiquing treatment agent and an application method thereof. The antiquing treatment agent consists of copper slag, carbon black, ferrous chloride, bletilla striata glue, vanillin, manganese chloride and water. The application method comprises the following steps: after the treatment agent is coated on a wood product, mixed solution of aluminum trichloride and ethanol is coated on the wood product after drying. The method homogenizes and lasts the antiquing effect, is free of damaging internal structure of the wood product, and is free of influencing normal use of the wood product; and the treated wood product is plain in texture, dose not decolor and fade in the use process, is green and environment-friendly in the use process, and generates no harm to human bodies and environments.

Owner:FUNAN XINGGUANG ARTS & CRAFTS CO LTD

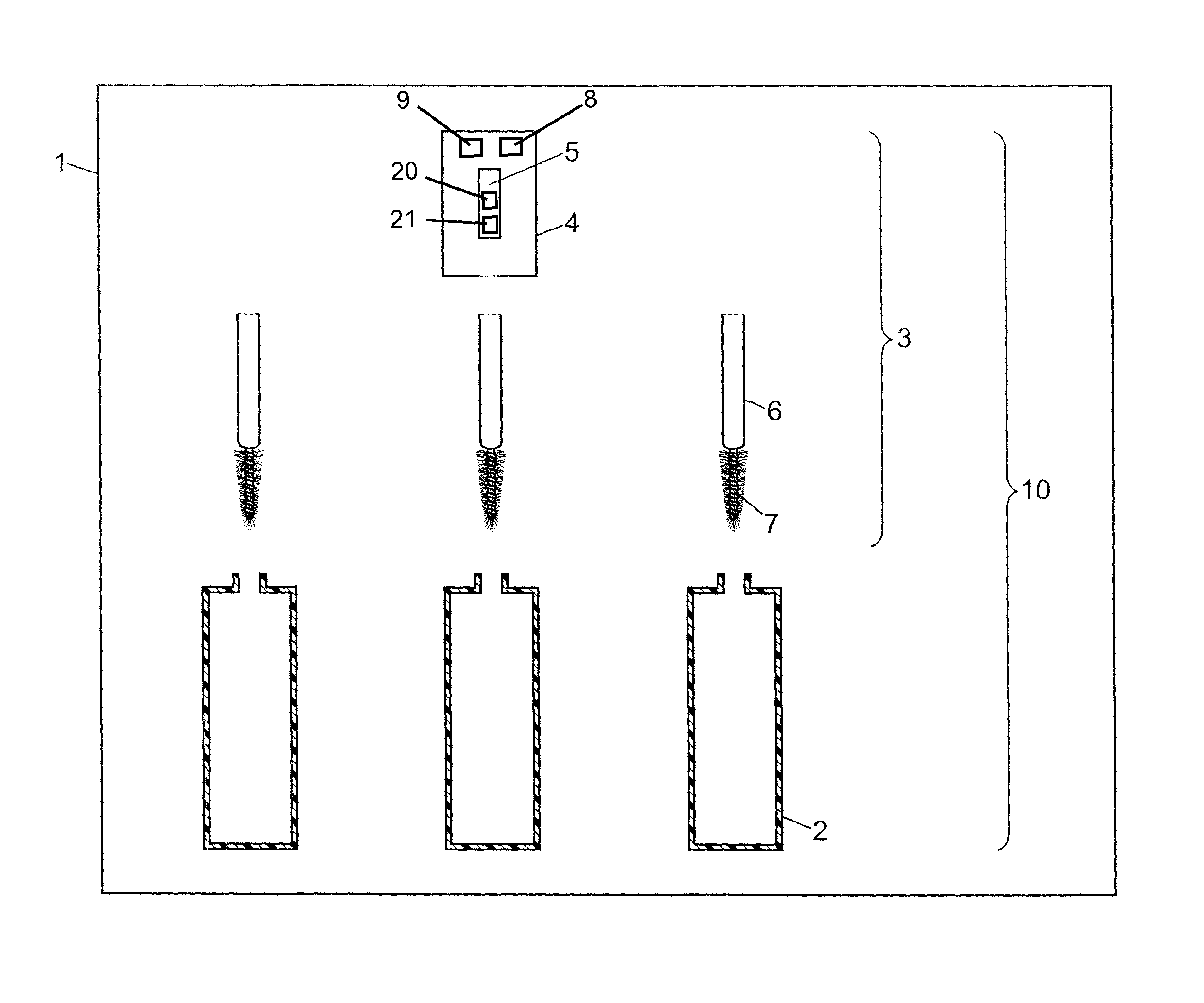

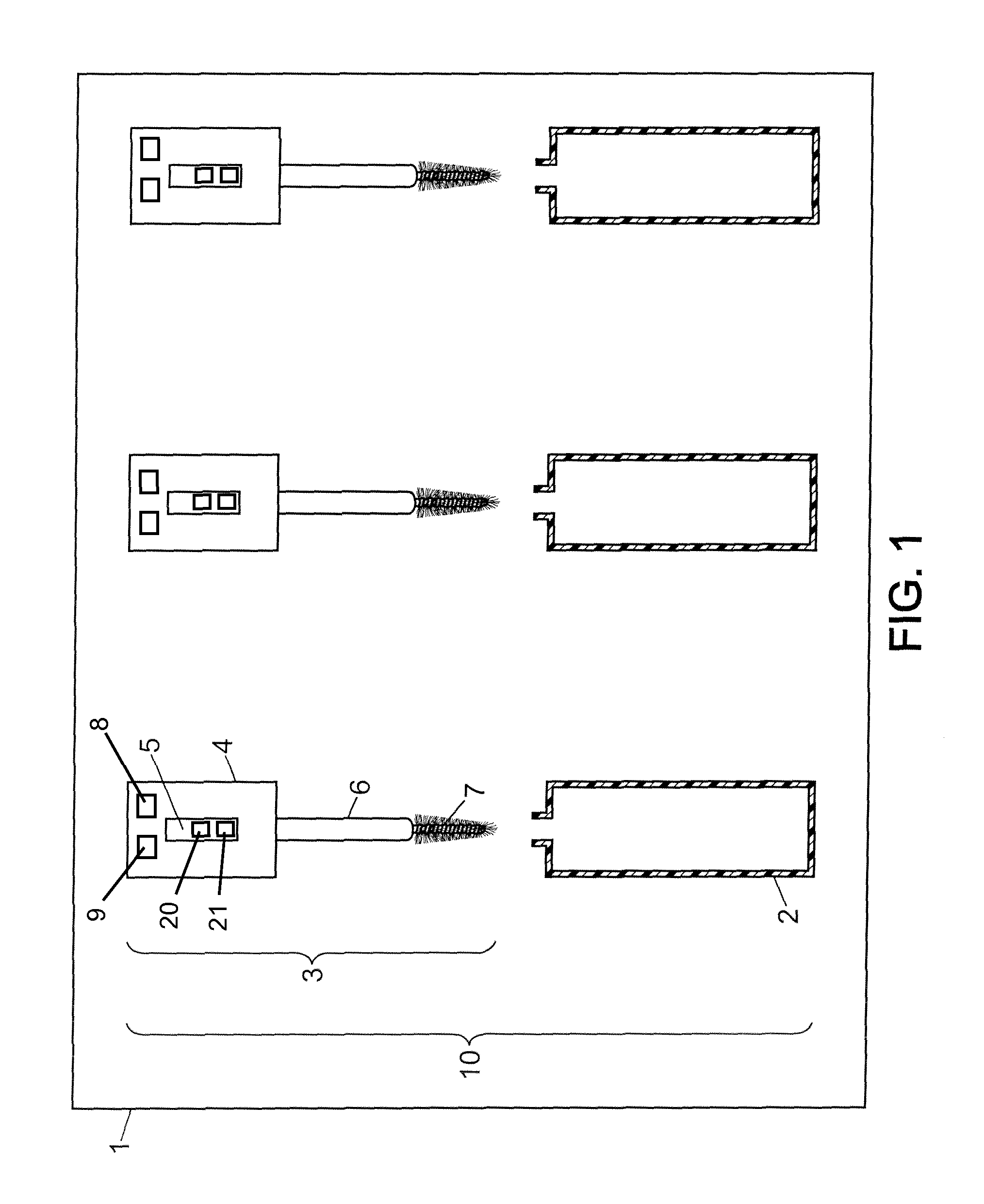

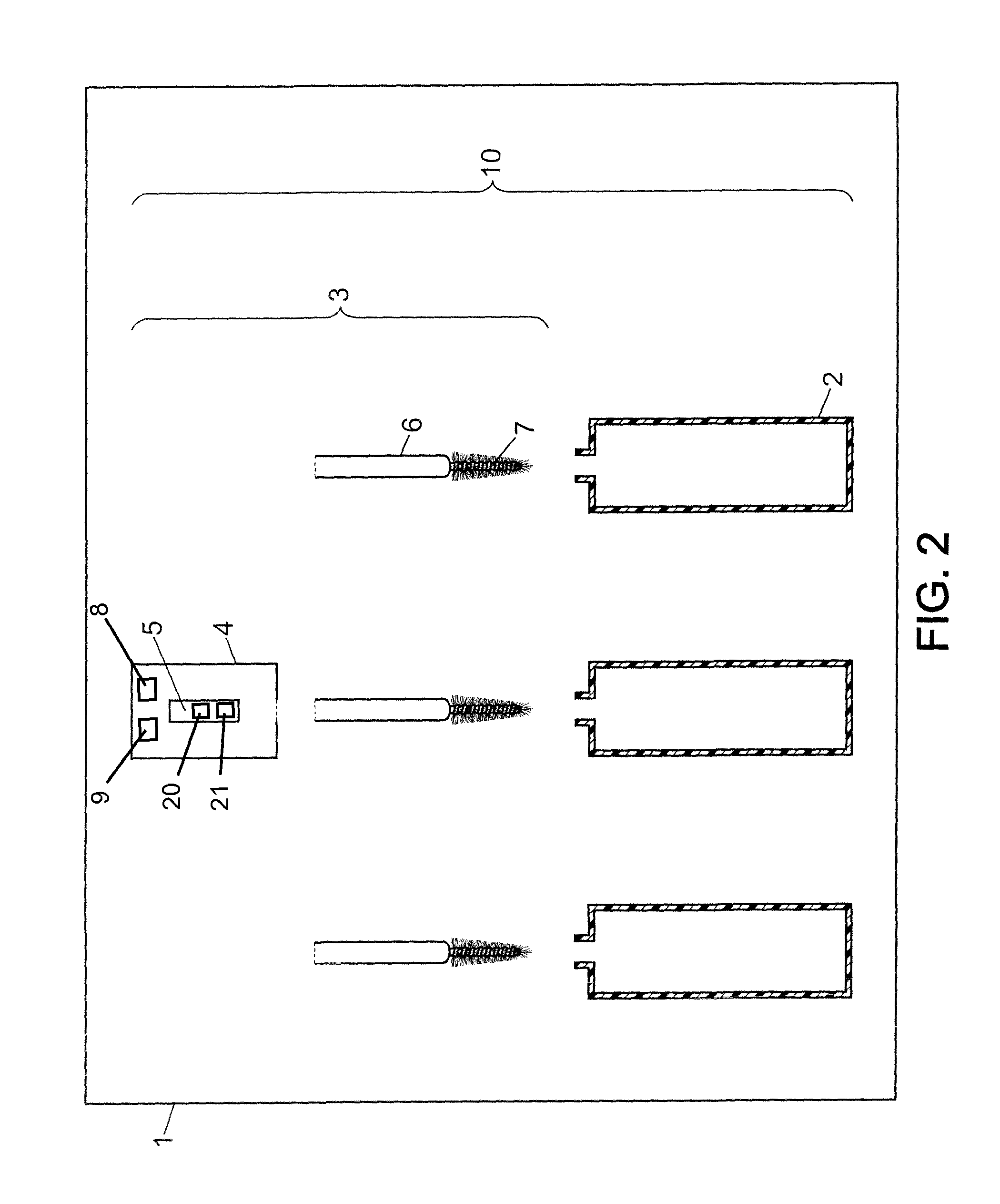

Kit for applying a cosmetic composition

ActiveUS8443816B2Deep dense colour effectGood effectCarpet cleanersFloor cleanersBiomedical engineering

Owner:LVMH RECH

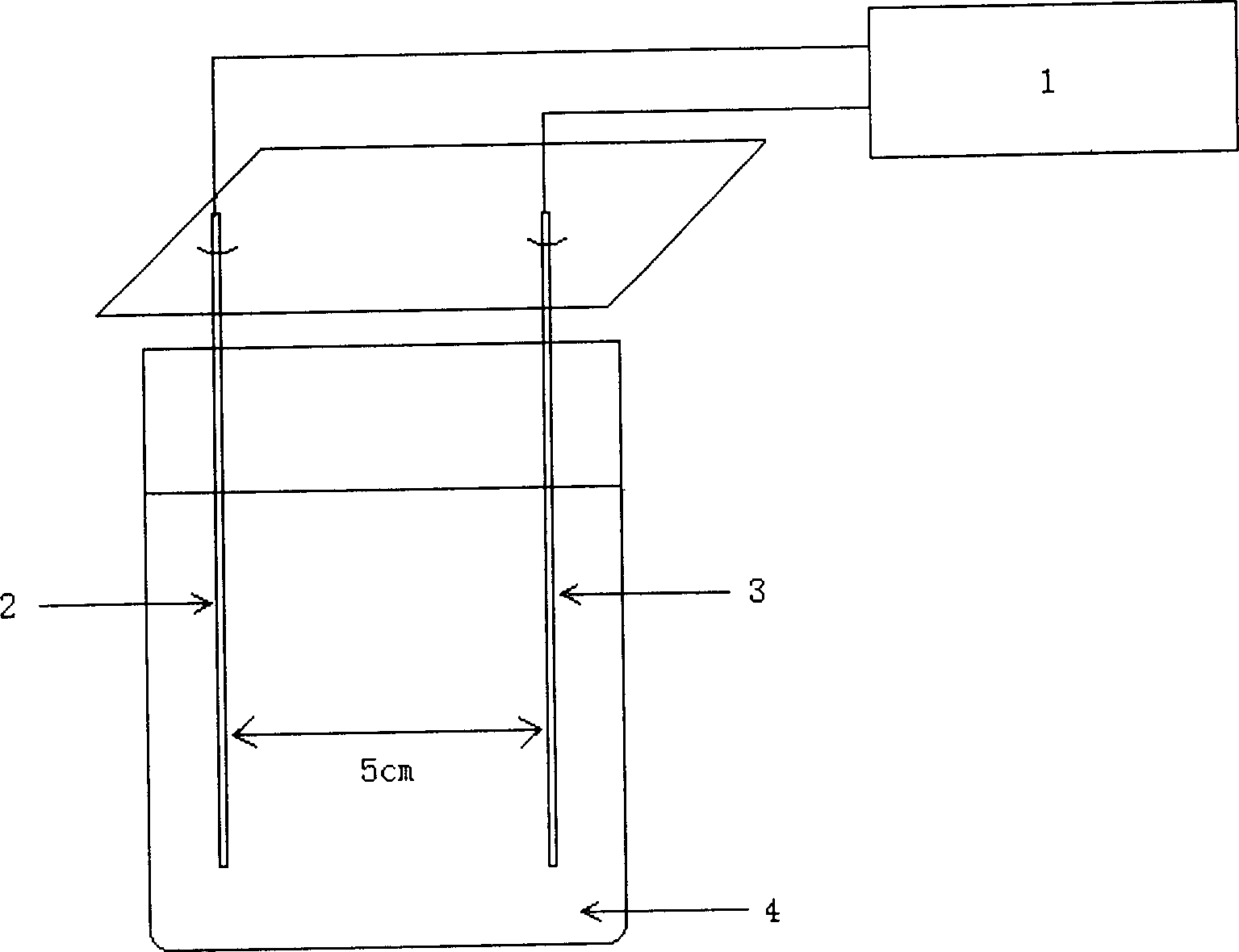

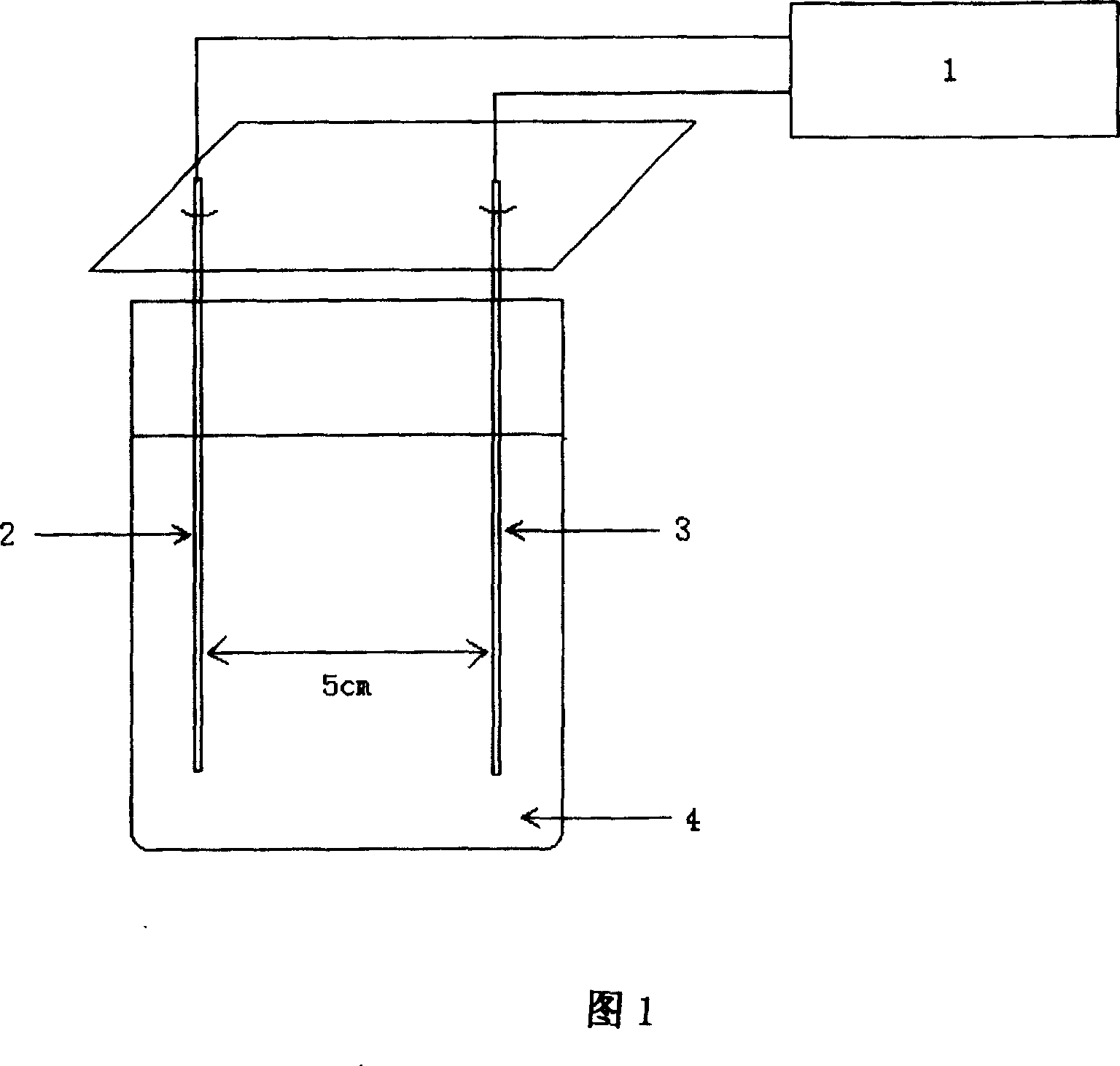

Method for preparing high temperature superconductor thick film of Ba/YCu with large area by using electrophoresis technique

InactiveCN1447451AControllable growthSimple textureElectrophoretic coatingsSuperconductor device manufacture/treatmentOrganic solventGranularity

A method includes following steps. (1) A metal layer is vaporized on the MgO monocrystal substrate. Then, the substrate is fixed on the negative electrode for stand by application. (2) YBa2Cu3O7-delta sintered is ground till the granularity of the powder is less than 0.1-10 micros. The powder is mixed with organic solvent in mixing ratio being as 20g / liter. The YBa2Cu3O7 delta electrophoresis fluid is prepared by stirring up the organic solvent making the fluid disperse evenly. (3) The YBa2Cu3O7-delta electrophoresis fluid and the electrode with the motorcrystal substrate are put to the cleaned electrophoresis pool. The even YBa2Cu3O7-delta film is obtained after 20-900V DC current being add to electrodes and 5-1600 seconds deposit time being kept.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Non-paint capillary crystalline wooden door

InactiveCN111331702ACushion the shockEnsure safety and stabilityImpregnation spraying apparatusDoor leavesCrazingPhysical chemistry

The invention relates to the field of wooden doors, in particular to a non-paint capillary crystalline wooden door. The non-paint capillary crystalline wooden door is prepared by adopting the following steps that raw wood, pine gum, peach gum, apricot gum, stillingia oi, a silanol group and silicate are mixed and then stirred evenly through a wall breaking technology until the water-based temperature ranges from 12 DEG C to 20 DEG C, the mixture permeates into the raw wood through nanoscale spraying permeation mechanical equipment, and the raw wood is placed in the environment with the temperature ranging from 16 DEG C to 36 DEG C to be dried for 4 h to obtain the non-paint permeable crystallization wooden door. The preparation process can be widely applied to production and manufacturingof wooden doors, and can overcome the defects that existing wooden doors produced at home and abroad have formaldehyde, benzene, heavy metals and other substances exceeding the standard, most of usedpaint is made of chemical materials and is prone to damp deformation, cracks and poor stability due to the influence of the environment, manufacturing and production are strenuous, environment friendliness is not achieved, and environmental pollution is generated.

Owner:张治

PCV antiskid floor

The invention discloses a method for preparing a PCV antiskid floor. The PCV antiskid floor comprises the following components in parts by weight: 100-150 parts of polyvinyl chloride, 5-10 parts of an additive, 10-15 parts of dye and 5-10 parts of waterproof glue. The PCV antiskid floor has the advantages that the PCV antiskid floor is produced by environmentally-friendly renewable materials, is non-toxic, odorless, free of parasitic bacteria, environmentally-friendly, simple in construction and rapid to install, and can be recycled and reutilized, and can be laid after glue (special environmentally-friendly waterproof glue) is applied to a flat cement or asphalt pavement; the PCV antiskid floor is simple to maintain, free of waxing and low in maintenance cost, and just needs to be washed or cleaned with a mop; and the PCV antiskid floor has strong resistance to bactericides and chemical medicines, which are frequently used at the periphery of a swimming pool have strong and does not deform or change color and is not corroded after being soaked by chlorine water for a long period of time. Due to good drainage property and adoption of a concave and convex texture design on the surface, the skid resistance of the edge of the swimming pool is greatly improved; the occurrence rate of an accidental slip fall accident is effectively lowered; meanwhile, the concave and convex particles can play a role in massaging acupuncture points of feet; by adopting the latest wear-resisting layer design, the feet are tightly attached to the ground constantly; and strong motion power can be arbitrarily transmitted.

Owner:RUGAO BINJIANG URBAN CONSTR INVESTMENT

Preparation method of goat milk synthetic soap

InactiveCN107828561ATight textureSimple textureSkin careAlkali/ammonium soap compositionsHydrolysisMachining

A preparation method of goat milk synthetic soap is disclosed. The invention provides a preparation technology for preparing goat milk synthetic soap by using goat milk as the main raw material. goatmilk, caustic soda powder and mixed plant oils which are used as raw materials successively undergo steps of goat milk concentration, goat milk hydrolysis, plant oils mixing, oil-milk mixing, productmoulding and the like, so as to prepare the goat milk synthetic soap product. The technology is simple and easy to realize; machining production efficiency is high; production cost is low; and the prepared product has beautiful appearance, uniform texture, long preservation time and long service time.

Owner:XIXIA JIANYANG ANIMAL HUSBANDRY

Mushroom mooncake and making method thereof

InactiveCN108703186AImprove the coagulation effectPromote recoveryPreservation by coatingBakery productsCooking & bakingTaurine

The invention discloses mushroom mooncake and a making method thereof. The mushroom mooncake is made with mushrooms, glutinous rice, salt, corn oil, maltol, lye, low-gluten flour, beaten egg, maltodextrin, dietary fiber powder, citric acid, and chitosan. The dietary fiber powder is made by enzymatically hydrolyzing soybean residue via a composite enzyme containing hypericin and taurine; syrup is made by boiling; skin is made; stuffing is made; shaping is performed after filling with the stuffing; baking is carried out before cooling and packaging to obtain the mushroom mooncake. The mushroom mooncake is a novel mooncake type having novel flavor, rich dietary fiber, low sugar and fat, and thin skin and bright stuffing, is oily and sweet, and has the advantages of high safety, good palatability, rich sensory experience, naturalness, zero additives, and greenness and health; the making method is simple to perform and has high production efficiency and good processing convenience, is environmentally friendly since waste is turned into wealth, allows industrial production to be easily implemented, can provide improved economic benefit for enterprises and good social benefit.

Owner:兰溪市捷喜食品加工技术有限公司

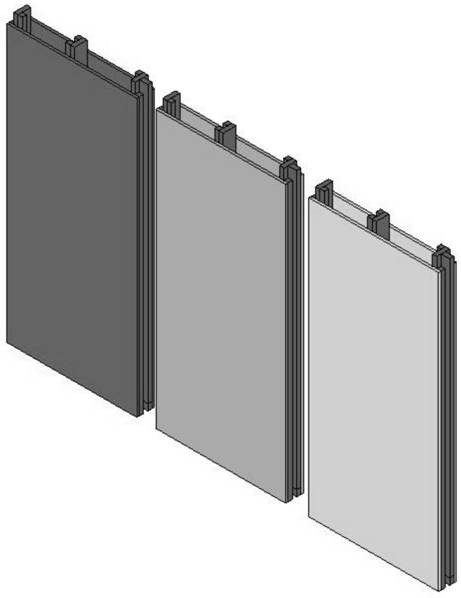

Fabricated fast wall (inner partition wall) structure and installation method

PendingCN111894175AImprove sound insulation performanceSimple and reliable connectionWallsPhysicsViscose

The invention discloses a pipeline and decoration integrated fabricated fast wall (inner partition wall) structure combination and an installation mode thereof. The product is produced and assembled by using a modern industrial assembly line in a factory to complete an inner partition wall hardcover integrated finished product, the finished product is transported to a construction site, 100% dry-type construction method installation is achieved, scientific joint installation between standard module walls is achieved, internal stress release are realized, and thus the problem of surface cracking caused by thermal expansion and cold contraction is avoided. According to the technical scheme, 1, a blank plate is produced in a factory, and the surface is polished and sanded and flatted for standby application; 2, the prepared plate is placed on a coating production line or a veneering production line to produce a decorative surface so as to realize fine decoration of a panel; 3, the plate is cut according to the design size for later use, and a thicker blank plate is cut into small square strips to be used as keels; 4, the two hardcover panels and the keel strips are connected and combined into a wall body through nailing or viscose glue, and convex-concave connectors are formed in the four side surfaces of the integrated wall by adjusting the positions of the keels, so that up-downand left-right splicing and installation are facilitated (as shown in figures 1-6); and 5, a cavity of the integrated wall can penetrate a pipe and can also be filled with sound insulation cotton. Bymeans of the steps, the fabricated fast wall (inner partition wall) integrating pipeline and decoration can be manufactured.

Owner:广西装配式建筑科技有限公司

Color enhancement method of remote sensing image based on multi-scale image segmentation and color transfer

InactiveCN103136733BImprove legibilityReduce color transfer errorsImage enhancementWavelet denoisingLightness

Owner:NO 61 INST OF GENERAL STAFF +1

A real-time selection method of inter-frame macroblock type in AVS-based video frame rate transcoding

ActiveCN103596012BShort timeFast transcodingDigital video signal modificationWireless videoTranscoding

The invention discloses an interframe macro block type selecting method used in real-time AVS-based video frame rate transcoding and belongs to the field of multimedia signal processing. The method is mainly used for achieving fast macro block type selection in frame rate transcoding. The method is characterized in that macro block type selection is achieved by means of a model established with four parameters, and macro block type selection comprises the steps of parameter calculation, threshold selection and determination of the macro block type according to a threshold. According to the interframe macro block type selecting method used in real-time AVS-based video frame rate transcoding, transcoding speed can be increased remarkably, the superior macro block type in recoding is fully guaranteed, and then a quite low bit rate is obtained. The interframe macro block type selecting method used in real-time AVS-based video frame rate transcoding is suitable for fields such as wireless video monitoring, Internet video monitoring and wireless video on demand.

Owner:山东电子职业技术学院

Processing method of instant seasoning scallop

The invention relates to a processing method of instant seasoning scallop, and the method comprises the following steps that fresh and pollution-free scallop is adopted as a raw material, cleaned, soaked in salt water, stewed, shelled and cored; the internal organs and intestinal gland are removed from scallop meat, and the scallop meat is cleaned, cured and dried until the water content of the scallop meat is controlled to be 20 percent + / -2 percent; and the dried scallop meat is detected by metal and packaged, and a seasoning scallop finished product is obtained. The processing method has reasonable procedures and is simple in preparation. The seasoning for curing is mixed scientifically, so that the flavor of the product is improved, and the saline taste and sweetness are dainty. The slightly baked scallop food which is prepared through the method better maintains the appearance form and the nutrition ingredients of the scallop, has the special aroma of seafood, golden color, soft texture, unique taste, delicious taste and long storage life, and is convenient to eat.

Owner:RONGCHENG HONGWEI FOOD

Method for preparing high temperature superconductor thick film of Ba/YCu with large area by using electrophoresis technique

InactiveCN100373649CSimple textureUniform and dense textureElectrophoretic coatingsSuperconductor device manufacture/treatmentOrganic solventGranularity

A method includes following steps. (1) A metal layer is vaporized on the MgO monocrystal substrate. Then, the substrate is fixed on the negative electrode for stand by application. (2) YBa2Cu3O7-delta sintered is ground till the granularity of the powder is less than 0.1-10 micros. The powder is mixed with organic solvent in mixing ratio being as 20g / liter. The YBa2Cu3O7 delta electrophoresis fluid is prepared by stirring up the organic solvent making the fluid disperse evenly. (3) The YBa2Cu3O7-delta electrophoresis fluid and the electrode with the motorcrystal substrate are put to the cleaned electrophoresis pool. The even YBa2Cu3O7-delta film is obtained after 20-900V DC current being add to electrodes and 5-1600 seconds deposit time being kept.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Method of making textured ceramics

The invention proposed a novel hot pressing flowing sintering method to fabricate textured ceramics. The perfectly 2-dimensional textured Si3N4 ceramics (Lotgering orientation factor fL 0.9975) were fabricated by this method. During the initial sintering stage, the specimen flowed along the plane which is perpendicular to the hot pressing direction under pressure, through the controlling of the graphite die movement. The rod-like β-Si3N4 nuclei was easily to texture during the flowing process, due to the small size of the β-Si3N4 nuclei and the high porosity of the flowing specimen. After aligned, the β-Si3N4 grains grew along the materials flowing direction with little constraint. textured Si3N4 ceramics fabricated by this invention also showed high aspect ratio. Compared to the conventional hot-forging technique which contained the sintering and forging processes, hot pressing flowing sintering proposed is simpler and lower cost to fabricate textured Si3N4.

Owner:DONGGUAN SOUTH CHINA DESIGN INNOVATION INST +1

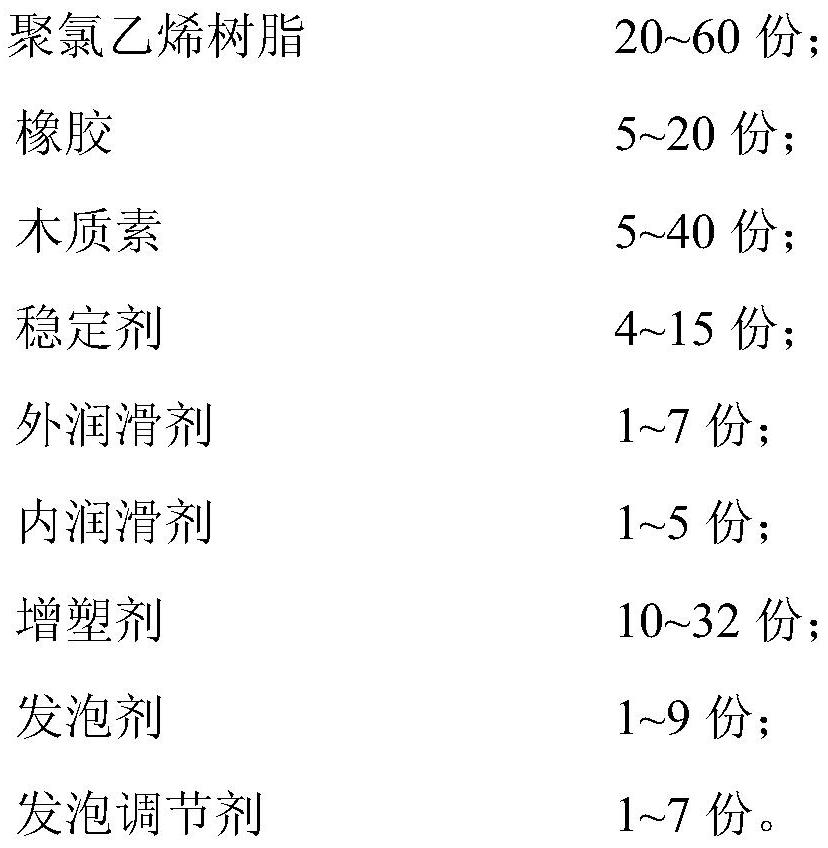

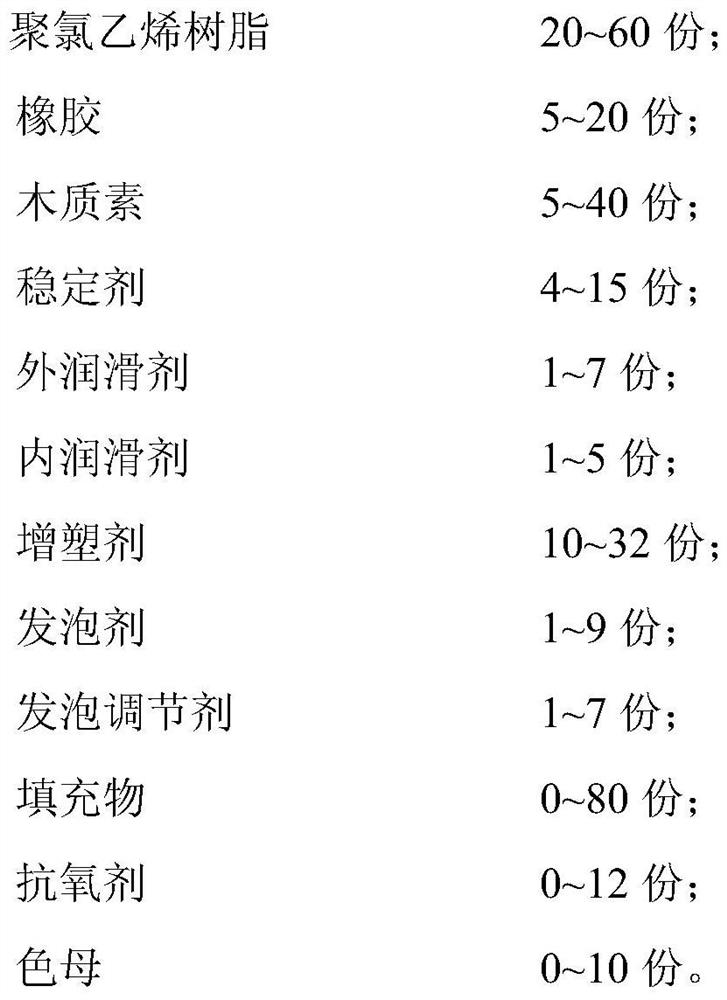

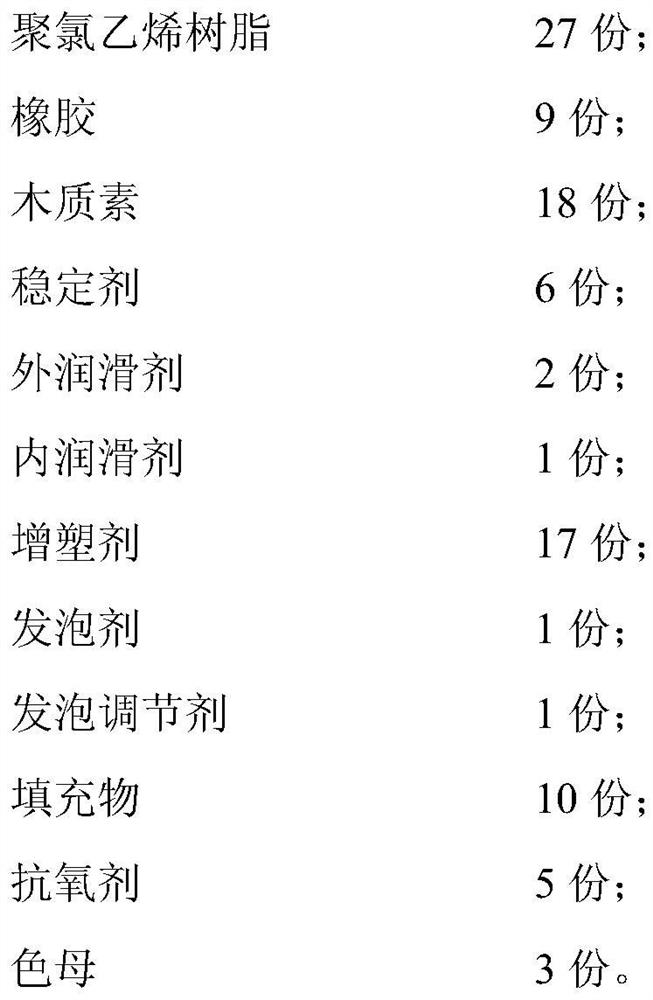

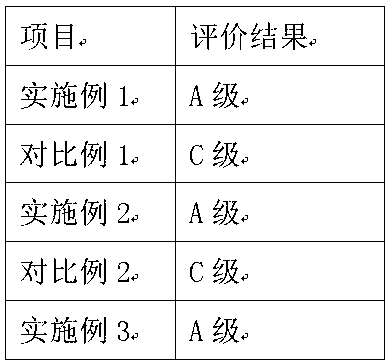

A kind of lignin-filled foam slippers and preparation method thereof

ActiveCN108503997BSimple textureSimple and soft comfortable textureFootwearMasterbatchPolymer science

The invention discloses lignin-filled foaming slippers and a producing method thereof. The slippers contain 20 to 60 parts of polyvinyl chloride resin, 5 to 20 parts of rubber, 5 to 40 parts of lignin, 4 to 15 parts of a stabilizer, 1 to 7 parts of an external lubricant, 1 to 5 parts of an internal lubricant, 10 to 32 parts of a plasticizer, 1 to 9 parts of a foaming agent, 1 to 7 parts of a foaming regulator, 0 to 80 parts of a filler, 0 to 12 parts of an antioxidant, and 0 to 10 parts of color masterbatch. Compared with the prior art, the lignin-added polyvinyl chloride is subjected to foaming treatment so as to not only effectively decrease the content of the plasticizerbut also make the product soft and comfortable in texture, and possess good resilience and wear resistance. The methodprovided by the invention has an easy producing process, has low requirements for instruments, can save cost, and has good market expectation.

Owner:NANJING TECH UNIV

Preparation method of spaghetti with compact texture

InactiveCN109123397AAttractive colorHigh nutritional valueFood ingredient as colourFood dryingVegetable oilExtrusion

The invention discloses durum wheat flour, and provides a preparation method of spaghetti with a compact texture. The preparation method comprises the following operation steps that (1) after quinoa is ground into flour, vegetable oil is added into the flour, heat preservation treatment is carried out at 70-80 DEG C, and the mixture is taken out to prepare cured quinoa flour; (2) after the cured quinoa flour, durum wheat flour, white poria dry powder, soybean isolate protein and sodium alginate are mixed uniformly, water is added, and after uniform stirring is carried out, paste is prepared; (3) the prepared paste is added into an extruder after being subjected to ultrasonic treatment, after extrusion enters a production stage and keeps stable, a treating fluid is evenly sprayed on the squeezed noodle surfaces, and then the noodles with the treating fluid on the surfaces are cut by a cutting machine; (4) after the cut noodles are dried and cooled, finished products are prepared. The spaghetti has the advantages that the nutrition is rich, the softness is moderate, the color and luster are attractive, in particular, the texture is compact, and the surface has no crack.

Owner:WUHE TONGSHIFU FOOD

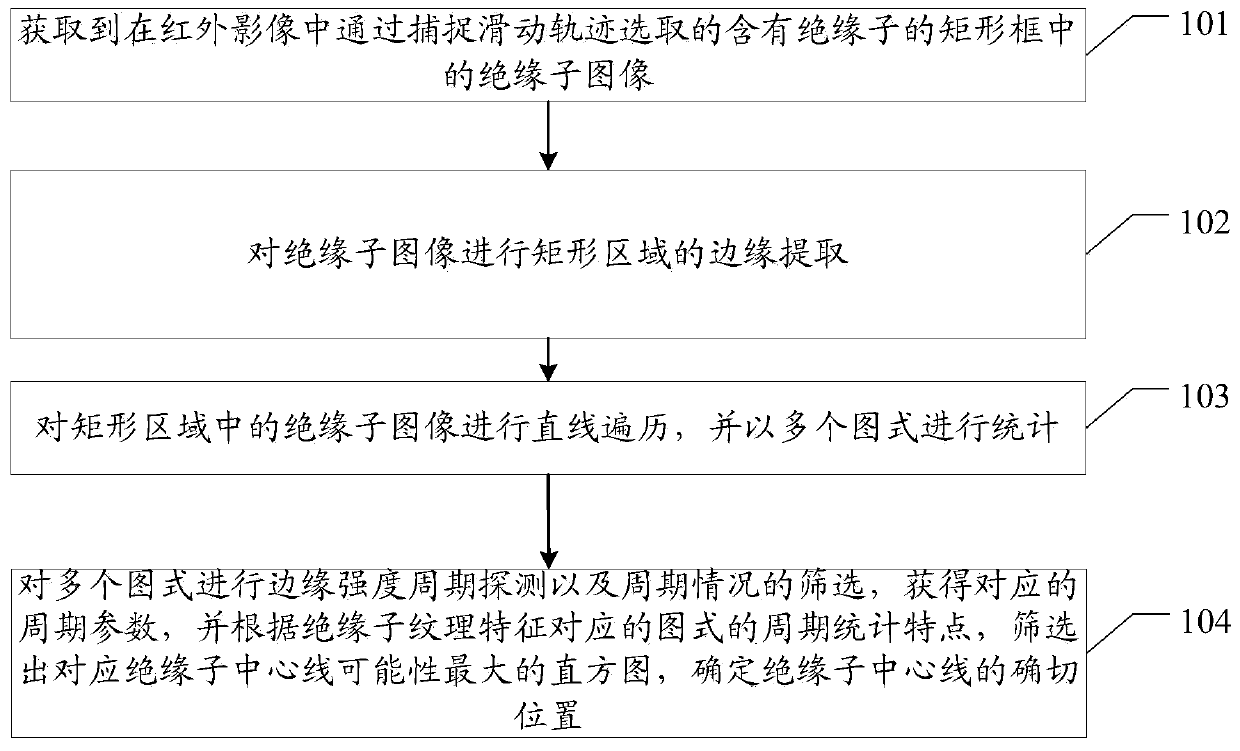

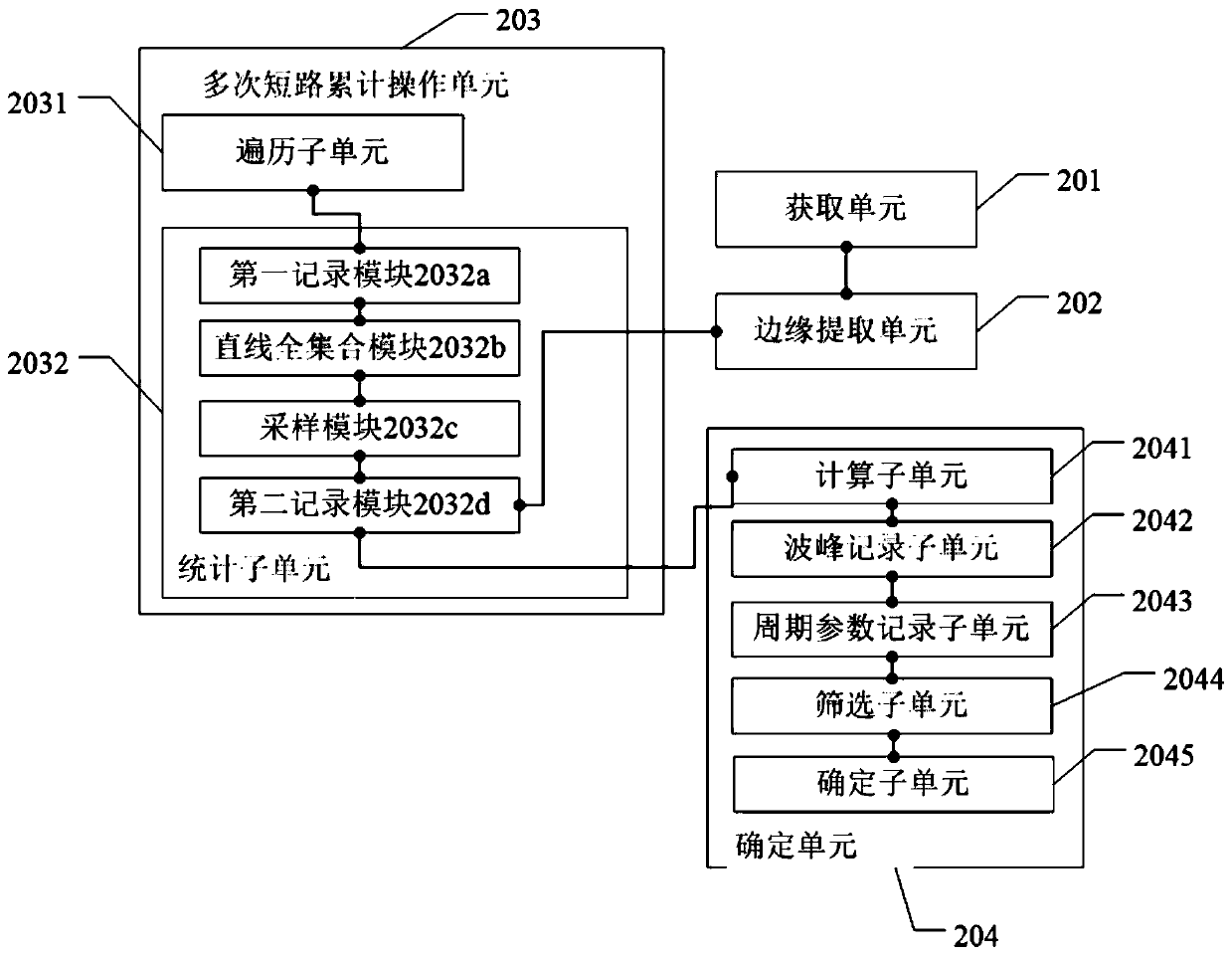

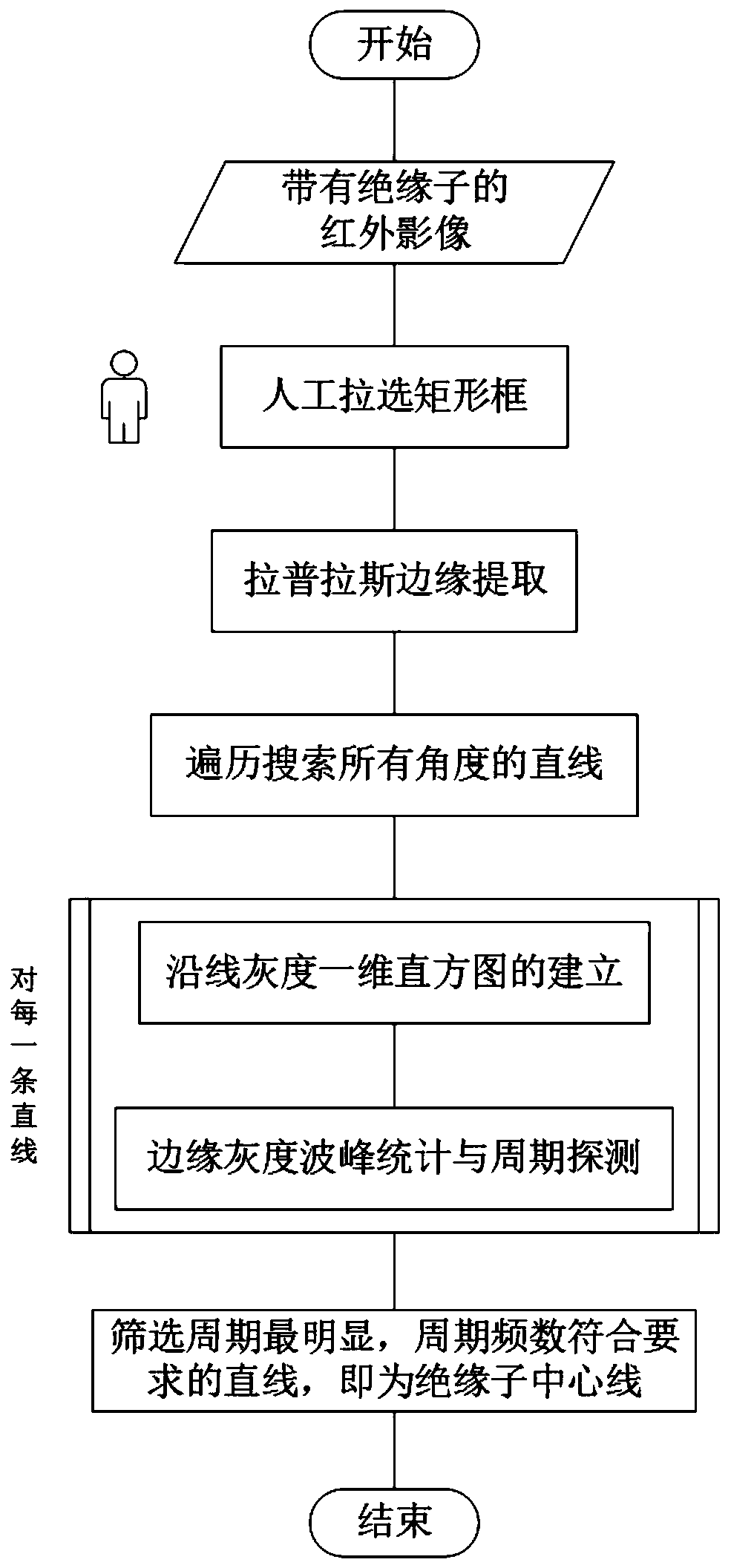

A semi-automatic extraction method and device for insulators based on infrared images

ActiveCN106529554BSolve surface temperatureReduce resolutionCharacter and pattern recognitionImage resolutionSemi automatic

The embodiment of the present invention provides a semi-automatic extraction method and device for insulators based on infrared images, which solves the problem of the current thermal infrared image recording the surface temperature of the object, which has low resolution and simple texture. It is necessary to measure the temperature of infrared insulators. , it is necessary to automatically locate the precise position of the center line of the insulator, resulting in a relatively difficult technical problem. The method in the embodiment of the present invention includes: acquiring the insulator image in the rectangular frame containing the insulator selected by capturing the sliding track in the infrared image; performing edge extraction on the insulator image in a rectangular area; The insulator image is traversed in a straight line, and statistics are performed with multiple schemas; the edge strength cycle detection and cycle situation screening are performed on multiple schemas to obtain the corresponding cycle parameters, and according to the graphs corresponding to the insulator texture characteristics According to the periodic statistical characteristics of the insulator, the histogram corresponding to the center line of the insulator with the greatest possibility is selected, and the exact position of the center line of the insulator is determined.

Owner:GUANGDONG ELECTRIC POWER SCI RES INST ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com