Durable elastic floating body and preparation method thereof

A durable and elastic technology, which is applied in the field of durable elastic floating body and its preparation, can solve the problems of poor compatibility and limitation of inorganic effects, and achieve the effects of enhanced binding force, high quality and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

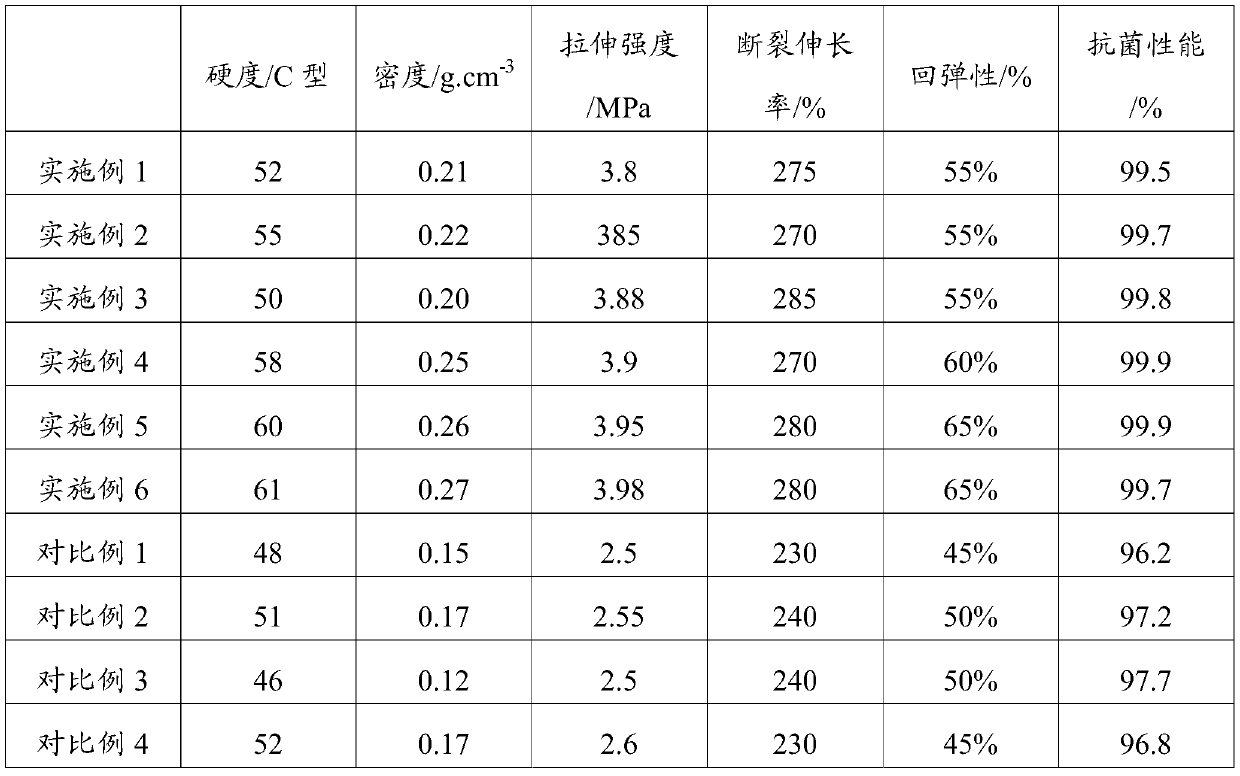

Examples

preparation example Construction

[0016] The preparation method of above-mentioned durable elastic floating body, comprises the following steps:

[0017] Step 1, mix ethylene-vinyl acetate copolymer, thermoplastic elastomer TPE, filler, foaming aid, lubricant and pigment, then add coupling agent modified anti-ultraviolet agent, coupling agent modified antioxidant and coupling agent The mixture of the modified antibacterial agent by the joint agent is blended, banburyed and granulated to obtain the first granulated material, wherein the temperature of banburying is 50-80°C, and the time is 10-15min;

[0018] Step 2, blending and injecting the first granulation material, foaming agent and crosslinking agent to obtain mother embryo, wherein the injection temperature is 80-100°C;

[0019] Step 3. Molding and foaming the mother embryo to obtain a durable elastic floating body. The foaming temperature is 165-180° C. and the time is 30-60 minutes.

[0020] It can be seen from the above description that the beneficia...

Embodiment 1

[0034] A durable elastic floating body is made of the following components by weight:

[0035] 60kg ethylene-vinyl acetate copolymer, 10kg thermoplastic elastomer TPE, 10kg calcium carbonate, 4kg foaming agent, 2kgAC foaming aid, 2kgHSt, 1kg coupling agent modified anti-ultraviolet agent, 0.5kg coupling agent modified antioxidant , 1kg coupling agent modified antibacterial agent, 0.6kgDCP and 8kg pigment;

[0036] The anti-ultraviolet agent modified by the coupling agent is UV-531 modified by titanate coupling agent NDZ-201;

[0037] The coupling agent modified antioxidant is antioxidant 1010 modified by titanate coupling agent NDZ-201;

[0038] The antibacterial agent modified by the coupling agent is the antibacterial agent JDTKS-005 modified by the titanate coupling agent NDZ-201;

[0039] The preparation method of described coupling agent modified anti-ultraviolet agent, coupling agent modified antioxidant and coupling agent modified antibacterial agent is:

[0040] The...

Embodiment 2

[0046] A durable elastic floating body is made of the following components by weight:

[0047]80kg ethylene-vinyl acetate copolymer, 10kg calcium carbonate, 6kg AC foaming agent, 3kg zinc oxide, 3kg silicone oil, 2kg coupling agent modified anti-ultraviolet agent, 0.8kg coupling agent modified antioxidant, 2kg coupling agent modified Antibacterial agent, 1.2kg DCP and 9kg pigment;

[0048] The anti-ultraviolet agent modified by the coupling agent is UV-531 modified by titanate coupling agent NDZ-201;

[0049] The coupling agent modified antioxidant is antioxidant 1010 modified by titanate coupling agent NDZ-201;

[0050] The antibacterial agent modified by the coupling agent is the antibacterial agent JDTKS-005 modified by the titanate coupling agent NDZ-201;

[0051] The preparation method of the coupling agent modified anti-ultraviolet agent, coupling agent modified antioxidant and coupling agent modified antibacterial agent is the same as that in Example 1.

[0052] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com