Patents

Literature

31results about How to "Uniform and dense texture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

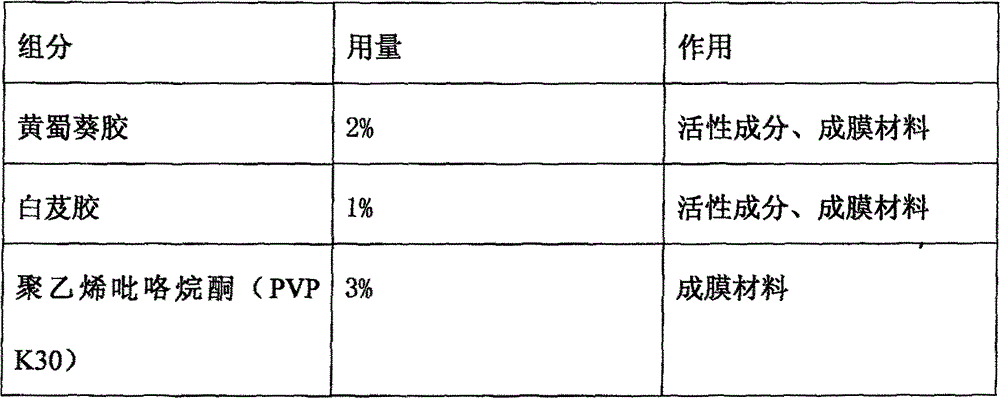

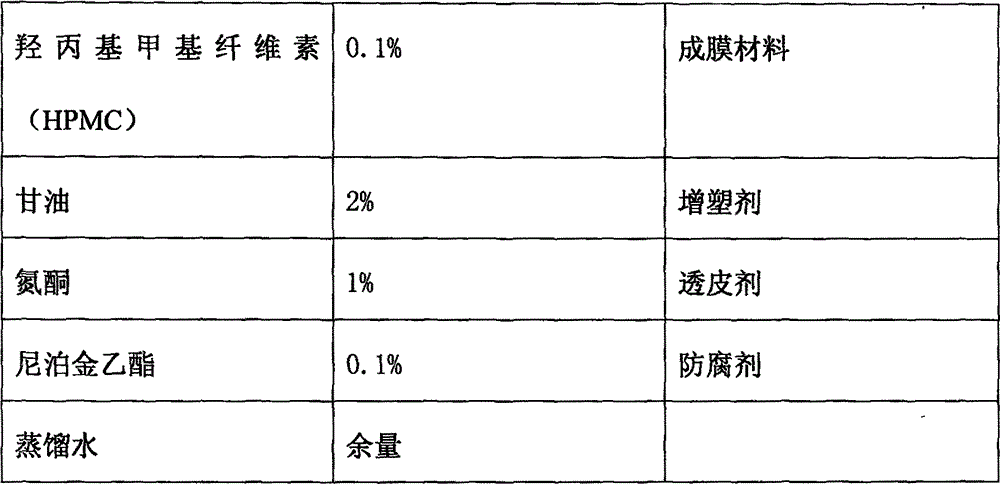

Abelmoschus manihot gum and bletilla hyacinthine gum film spraying agent and preparation method thereof

InactiveCN106266597AIncrease profitLow costPharmaceutical non-active ingredientsDermatological disorderPlasticizerPreservative

The invention discloses an abelmoschus manihot gum and bletilla hyacinthine gum film spraying agent and a preparation method thereof. The abelmoschus manihot gum and bletilla hyacinthine gum film spraying agent is prepared from the following components in percentage by weight: 1 percent to 3 percent of abelmoschus manihot gum, 1 percent to 3 percent of bletilla hyacinthine gum, 3 percent to 5 percent of polyvinylpyrrolidone, 0.1 percent to 1 percent of hydroxypropylmethyl cellulose, 2 percent to 5 percent of a plasticizer, 1 percent to 3 percent of a transdermal agent, 0.1 percent to 0.5 percent of a preservative and the balance of distilled water. According to the abelmoschus manihot gum and bletilla hyacinthine gum film spraying agent, the abelmoschus manihot gum and the bletilla hyacinthine gum are matched to prepare the film spraying agent and the film spraying agent is used for treating burns and scalds, sore ulcers, wounds, traumatic bleeding and the like; the abelmoschus manihot gum and the bletilla hyacinthine gum are reasonably matched so that the curative effect is greatly enhanced; the cost is reduced and the prepared film spraying agent avoids affected part pains caused by coating.

Owner:时维静

Nutrient soil for growing seedlings of guangxi green plum in nutrient cup and preparation method of nutrient soil

InactiveCN104086315AUniform and dense textureGood water and fat retentionFertilizer mixturesHoneycombPhosphate fertilizer

The invention discloses nutrient soil for growing seedlings of guangxi green plum in a nutrient cup. The nutrient soil comprises 57% of yellow earth subsoil, 30% of burned turf sludge, 10% of honeycomb coal ash and 3% of phosphatic fertilizer. The invention also discloses a preparation method for the nutrient soil. The preparation method comprises the following specific steps: preparing the yellow earth subsoil, preparing the burned turf sludge, preparing the nutrient soil and sterilizing the nutrient soil. The nutrient soil belongs to the field of seedling raising technology. The problem of the nutrient soil for growing a strong seedling of the precious guangxi green plum is solved. The nutrient soil has the characteristics of being compact and uniform, good in water and fertilizer retention, good in permeation, and having no diseases and pests and weed seeds, and can be used for providing various nutrients and moisture for growing of guangxi green plum seedlings, guaranteeing that the seedlings of the guangxi green plum are strong, and providing good seedlings for creating a fast-growing and high-yield plantation of guangxi green plum.

Owner:黄振忠

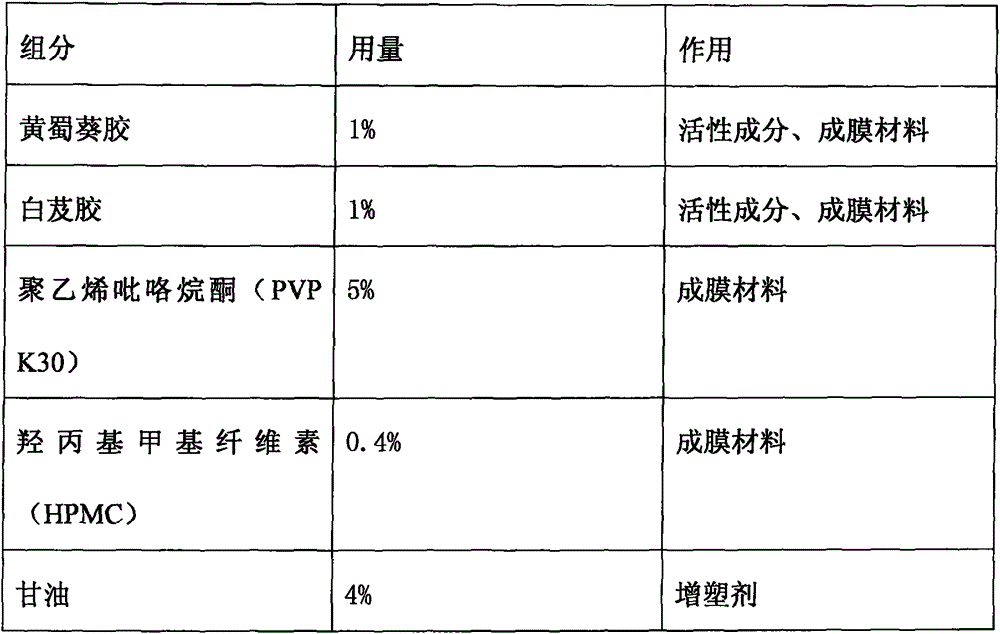

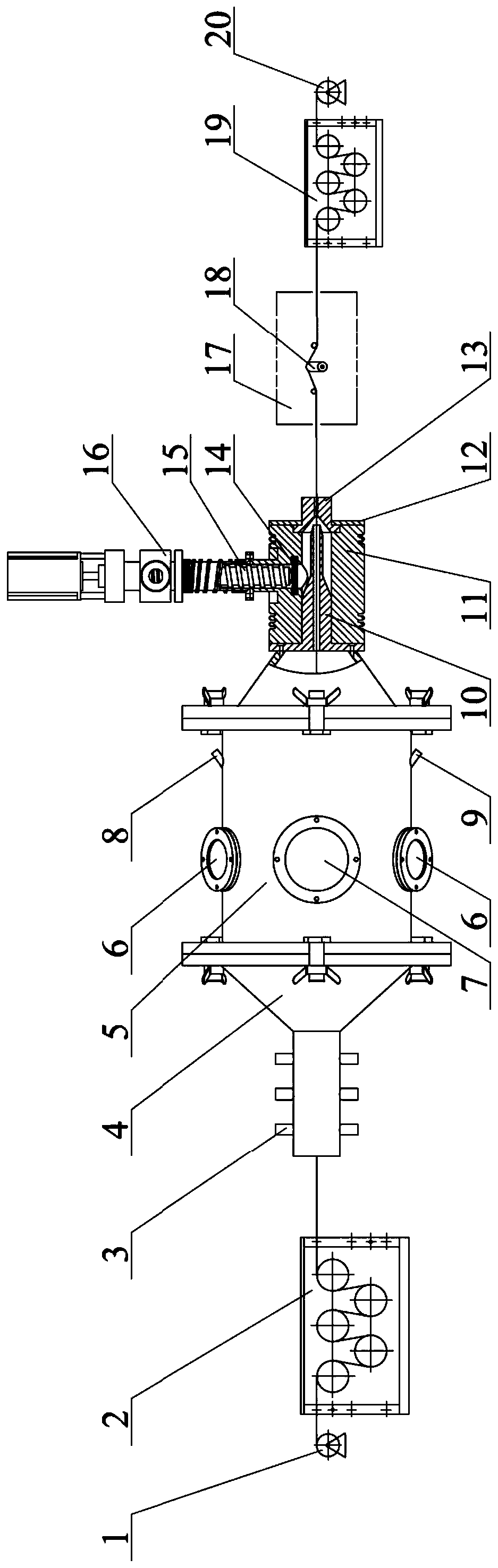

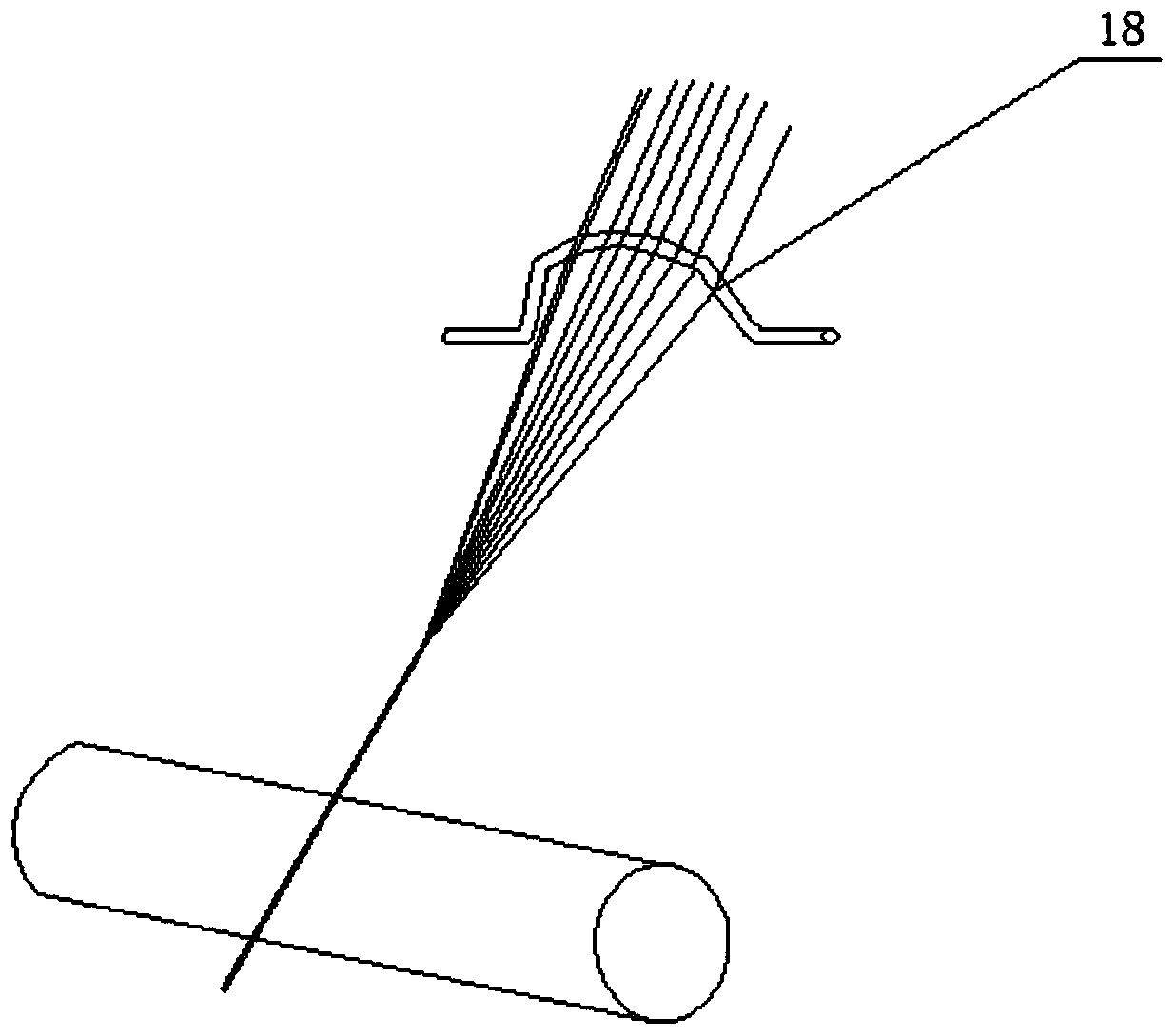

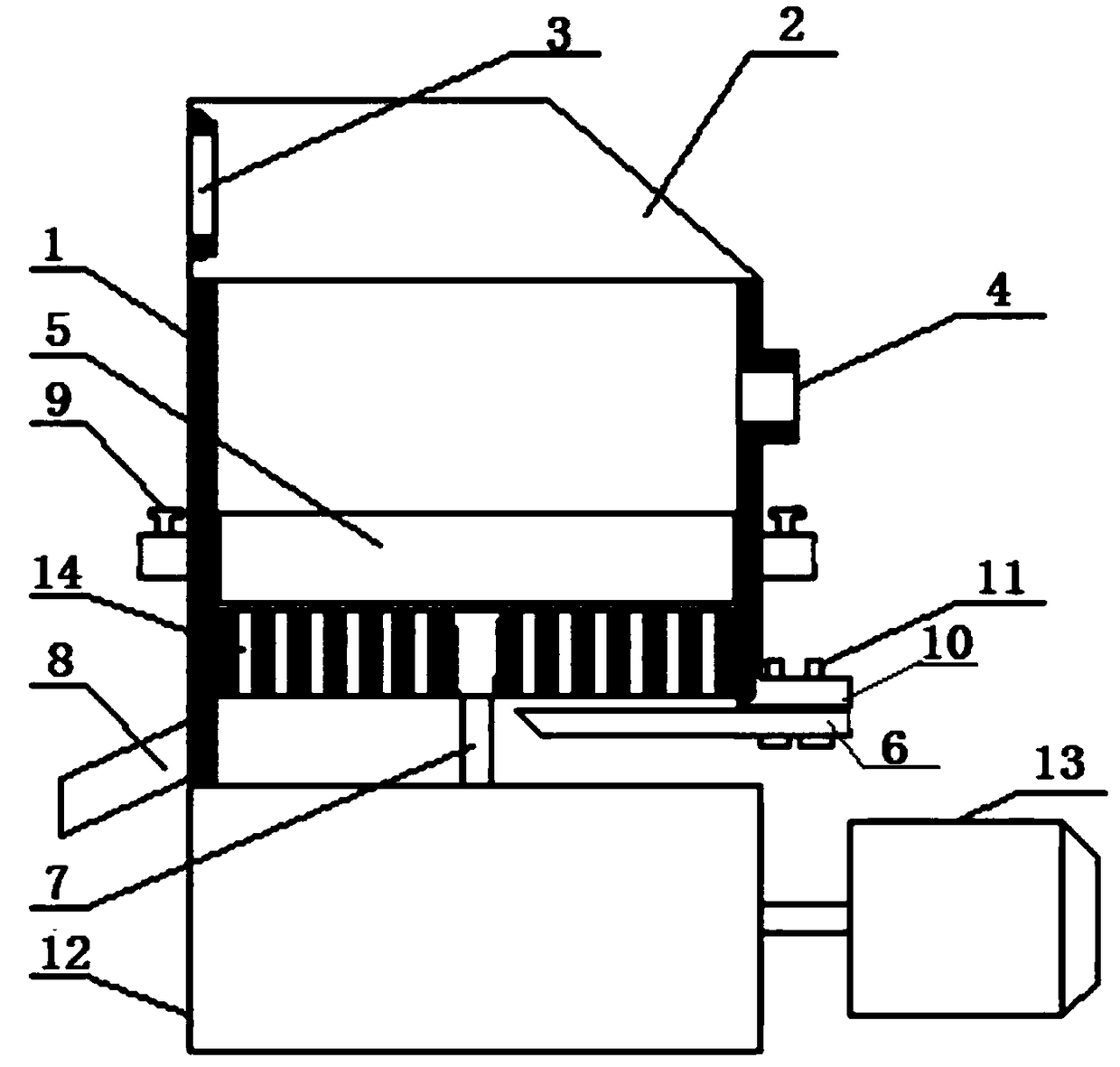

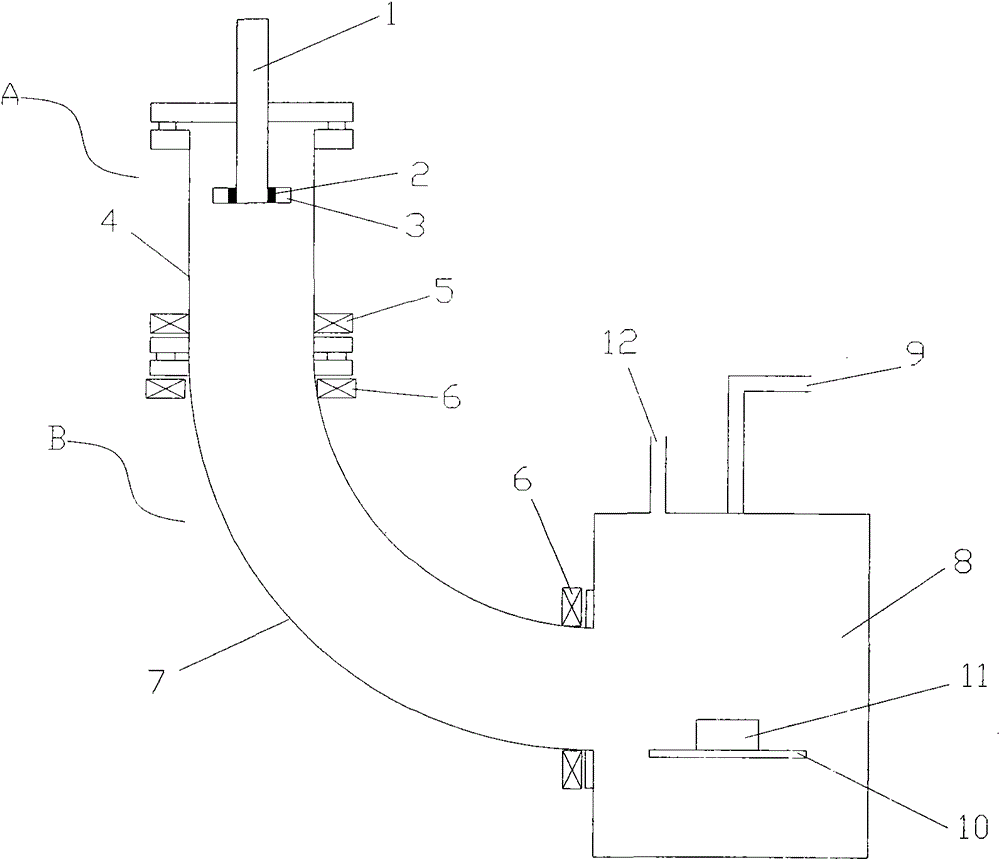

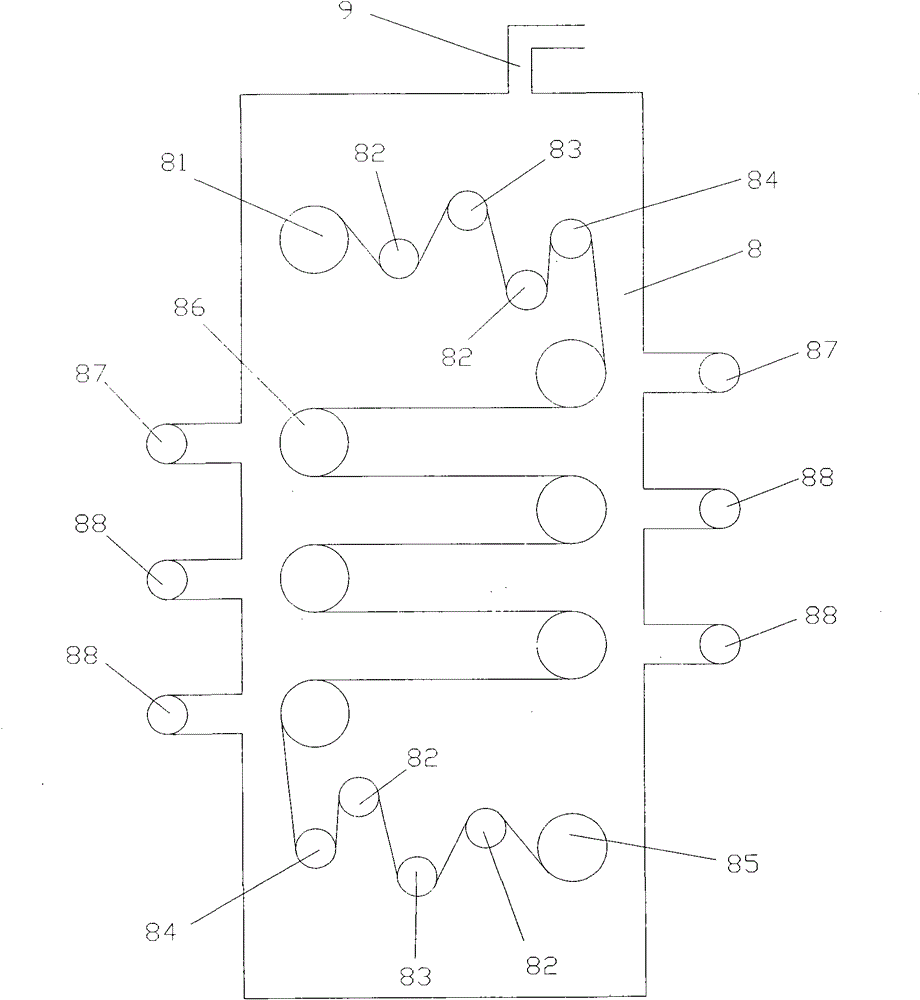

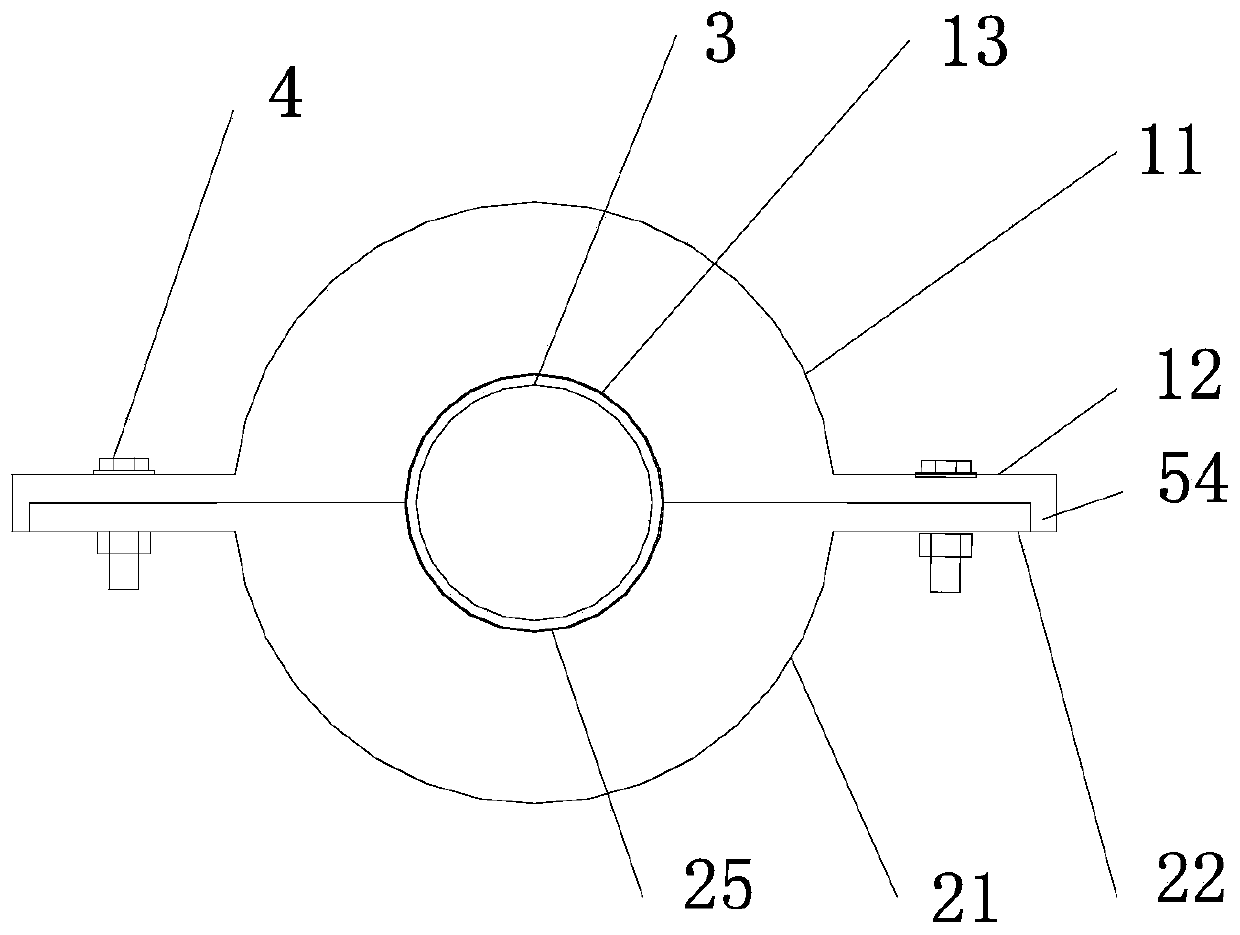

Carbon fiber laser graphitizing sizing equipment and method

ActiveCN110042583AGood fiber opening effectImprove wear resistancePhysical treatmentCarbon fibresCarbon fibersEngineering

The invention discloses carbon fiber laser graphitizing sizing equipment and method. The equipment is mainly composed of a silk releasing device, a drafting device A, a gas seal end cover, a graphitizing furnace body, a coating machine head, an extruder, a drying device, a drafting device B and a silk collecting device. The devices are sequentially arranged, the gas seal end cover is fixed to theleft end of the graphitizing furnace body through a bolt, the right end of the graphitizing furnace body is connected with the sizing coating machine head, the side face of the coating machine head isconnected with the small extruder, and the drying device, the drafting device B and the silk collecting device are sequentially mounted on the right side of the coating machine head. An outlet of a graphitizing furnace is directly connected with the coating machine head, inert gas sealing on the outlet is omitted, and the use amount of argon is saved. An extruded sizing agent has uniform and dense texture and is tightly attached to the surfaces of fibers, due to sizing in the pressure environment, the skinning performance of the sizing agent is better than the soaking effect in a sizing agenttank, skin films on the surfaces of the fibers are denser, and the performance of a prepared composite is improved.

Owner:BEIJING UNIV OF CHEM TECH +1

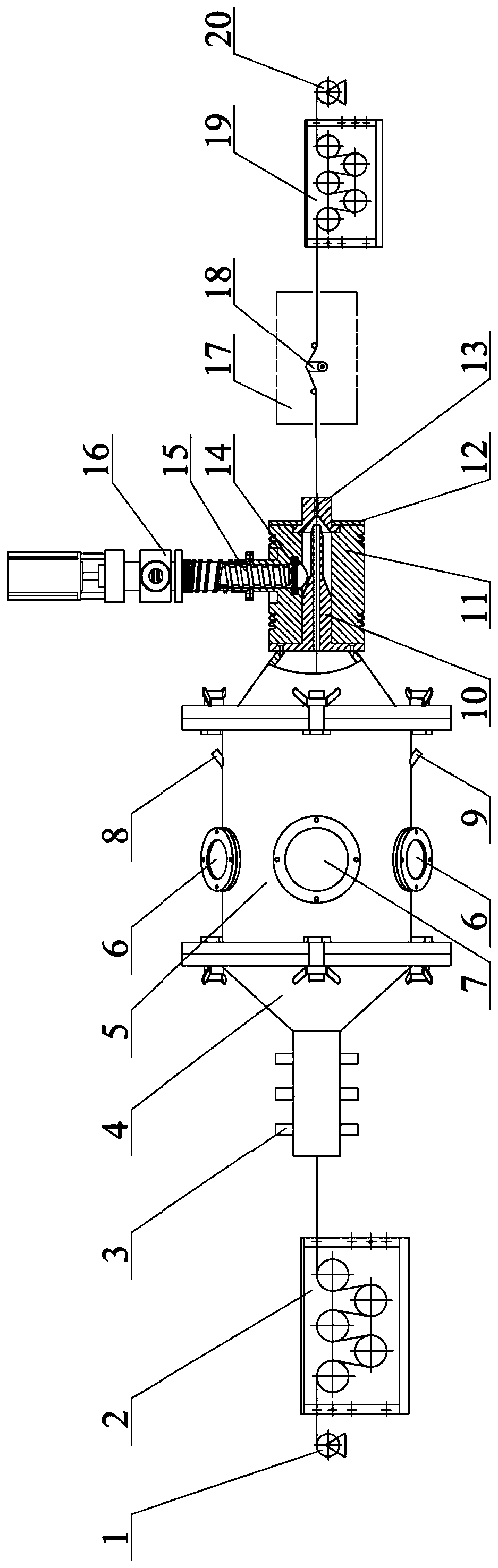

Making method of pickled Chinese cabbage ham sausage

ActiveCN103919164AExtended shelf lifeUniform and dense textureFood freezingFood dryingBiotechnologyNutritive values

The invention relates to a making method of a pickled Chinese cabbage ham sausage. The making method includes the following processing steps of pickled Chinese cabbage ham sausage formula material preparation, pickled Chinese cabbage preprocessing, primary stirring, pickling, secondary stirring, casing filling, sterilization and normal-temperature cooling. In the pickled Chinese cabbage ham sausage formula preparation step, prepared formula materials are composed of raw meat, pickling materials and auxiliary materials, and the raw meat is selected, unfreezed and minced. In the making method, pickled Chinese cabbages are processed by using the microwave vacuum drying and low-temperature liquid-nitrogen refrigeration technology, original color, aroma and taste of the pickled Chinese cabbages and nutritive value of the pickled Chinese cabbages are kept to the maximum limit, therefore, the made ham sausage has the peculiar flavor of the pickled Chinese cabbages, and the eating quality of the ham sausage is improved. The making method is simple and easy to implement; on the basis of the functions of a traditional ham sausage, nutritional ingredients and functional characteristics of the pickled Chinese cabbages are added, and the defects that existing ham sausages are greasy, high in fat, high in calorific value and low in nutrition are overcome, and the processed ham sausage benefits the stomach, reinforces intestines and is better in nutrition and flavor.

Owner:湖南唐人神肉制品有限公司

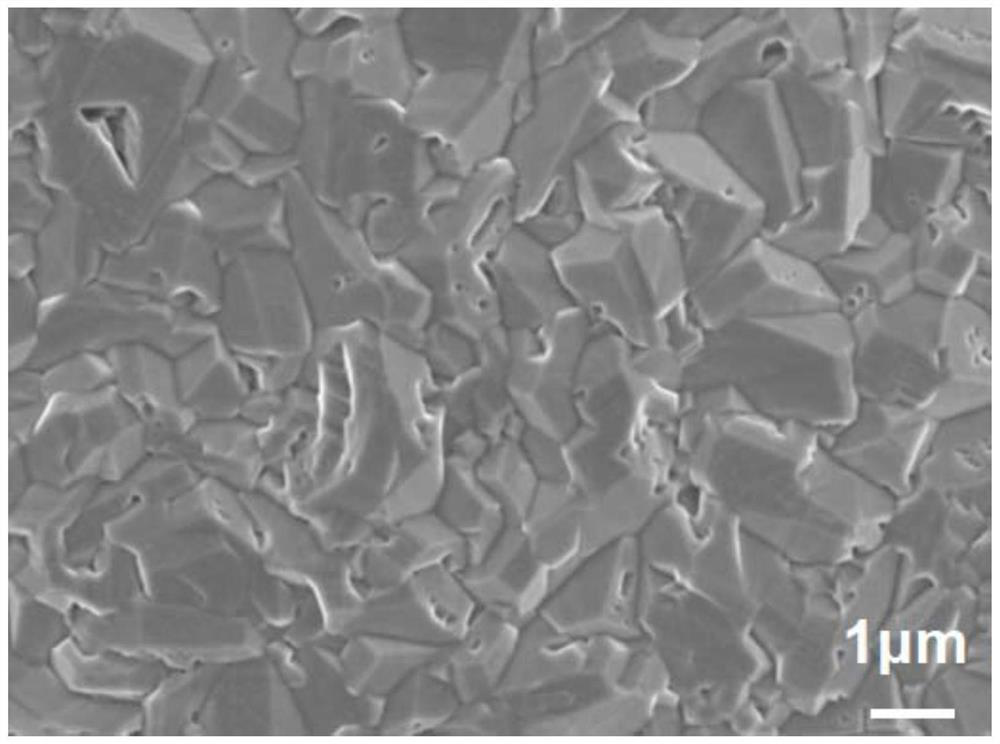

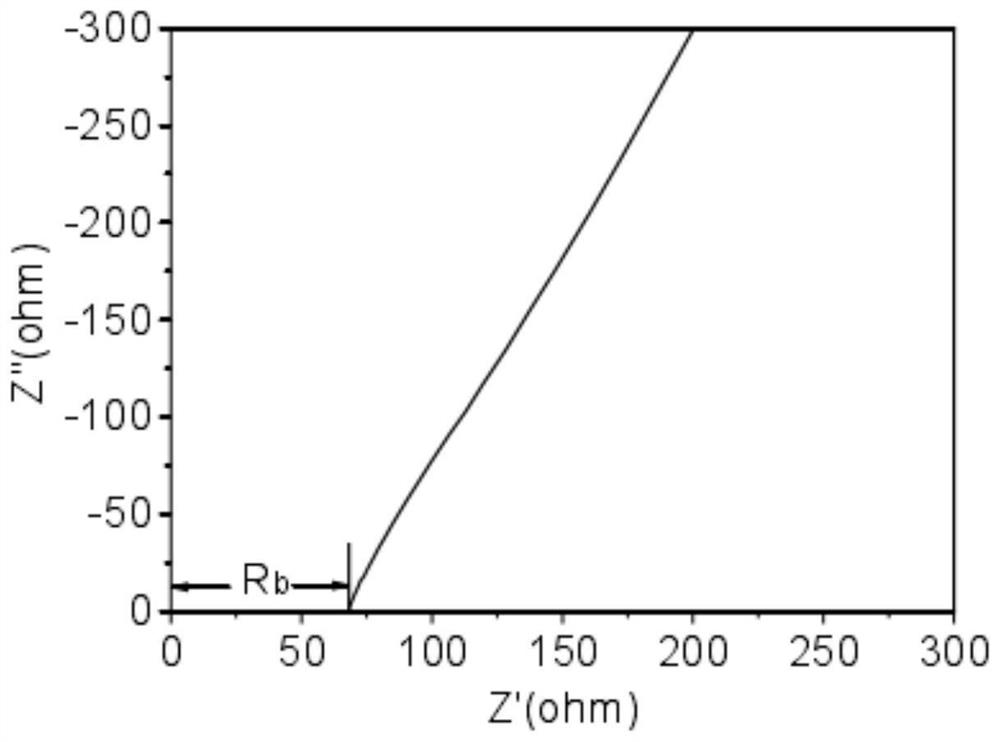

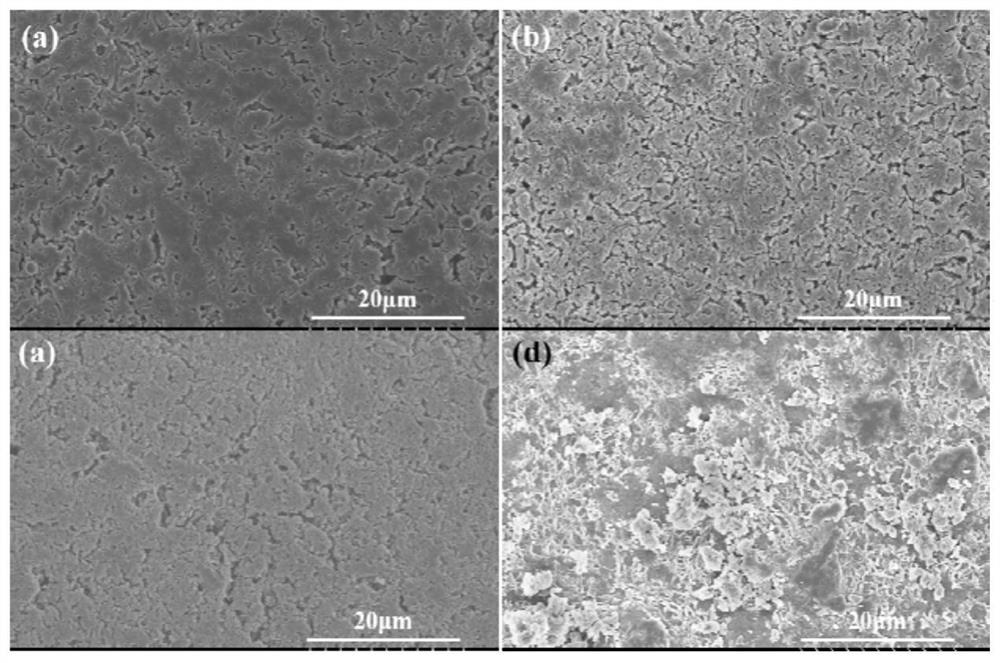

Preparation method of manganese-cobalt spinel coating and application of preparation method

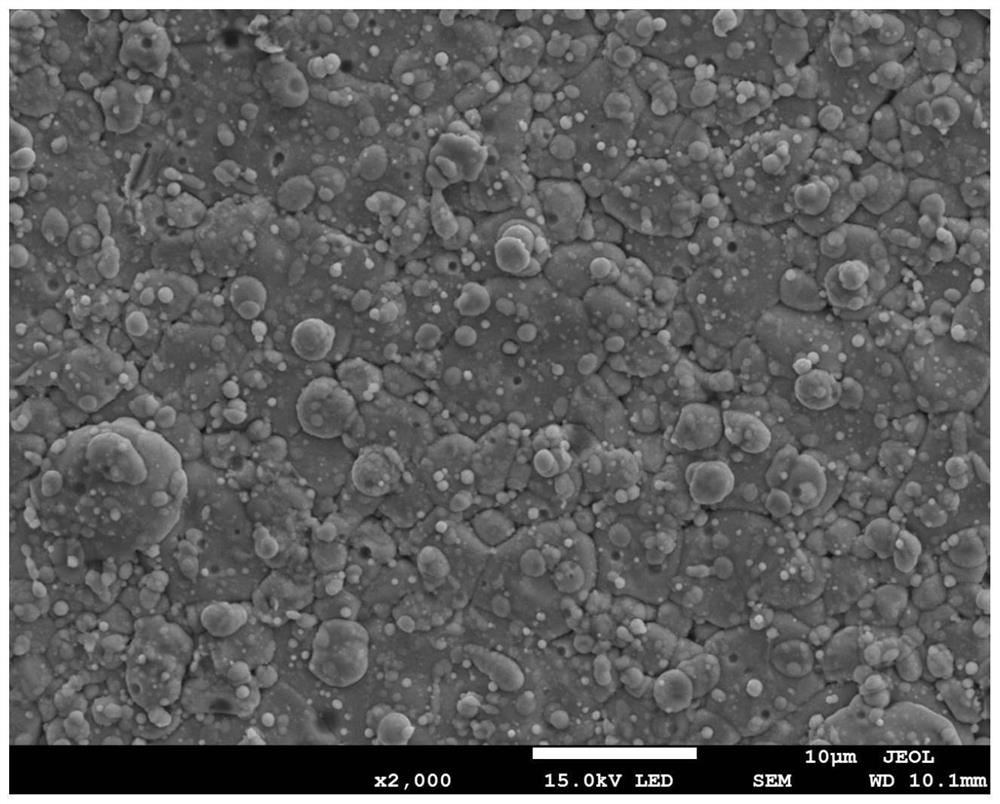

ActiveCN113265655AUniform and dense textureSimple preparation processSolid electrolyte fuel cellsHeat inorganic powder coatingPhysical chemistryManganese

The invention provides a preparation method of a manganese-cobalt spinel coating and application of the preparation method, and relates to the technical field of coating materials. The preparation method of the manganese-cobalt spinel coating comprises the following steps: firstly, mixing manganese-cobalt mixed powder with a solution to obtain mixed slurry; later, coating the surface of a ferritic stainless steel connector with the mixed slurry, and drying to obtain an intermediate coating A; and then, sintering the ferritic stainless steel connector with the intermediate coating A on the surface in a reducing atmosphere, introducing air, and oxidizing at a high temperature to obtain the manganese-cobalt spinel coating. The preparation method has the advantages of being simple in preparation process, easy to operate and high in economical efficiency, and the spinel coating uniform and compact in texture can be generated. Experiments prove that the manganese-cobalt spinel coating prepared by the preparation method is good in conductivity at high temperature, the surface specific resistance of the manganese-cobalt spinel coating can reach 10 m omega.cm < 2 > or below, meanwhile, the coating has good stability, and the resistance does not obviously rise within the range of 500 hours.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Granulation device for production of high-filling wood-plastic composite material

The invention relates to the technical field of granulation equipment, in particular to a granulation device for production of a high-filling wood-plastic composite material. The device structurally comprises a cylinder body, a sealing cover is installed at one end of the cylinder body in a sealing mode, a porous plate is inlaid in the other end of the cylinder body, the sealing cover is providedwith a machine head connector, the cylinder body is provided with a vacuum connector, the two side plate faces of the porous plate are provided with a pressing roller and a cutter correspondingly, thepressing roller is located between the sealing cover and the porous plate, a gap is reserved between the pressing roller and the porous plate, the cutter edge of the cutter faces the porous plate, agap is reserved between the cutter edge of the cutter and the plate face of the porous plate, the porous plate is connected with a rotating shaft for driving the porous plate to rotate, and a discharging opening is formed in the end part, where the cutter is located, of the cylinder body. According to the device, the high-filling wood-plastic composite material particles which are uniform and dense, consistent in size and low in particle moisture content can be produced, no dust is generated in the production process of the granulation device, and the granulation device has the advantage of being high in production efficiency.

Owner:DONGGUAN MINGFENG PACKAGING CO LTD +1

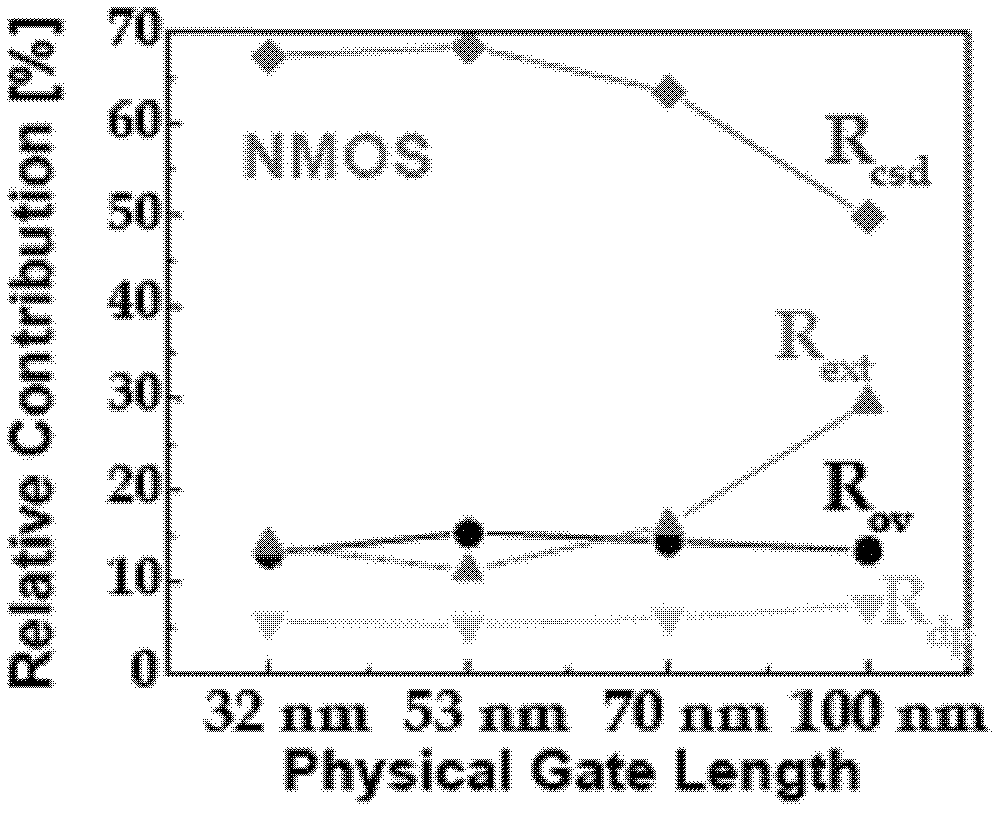

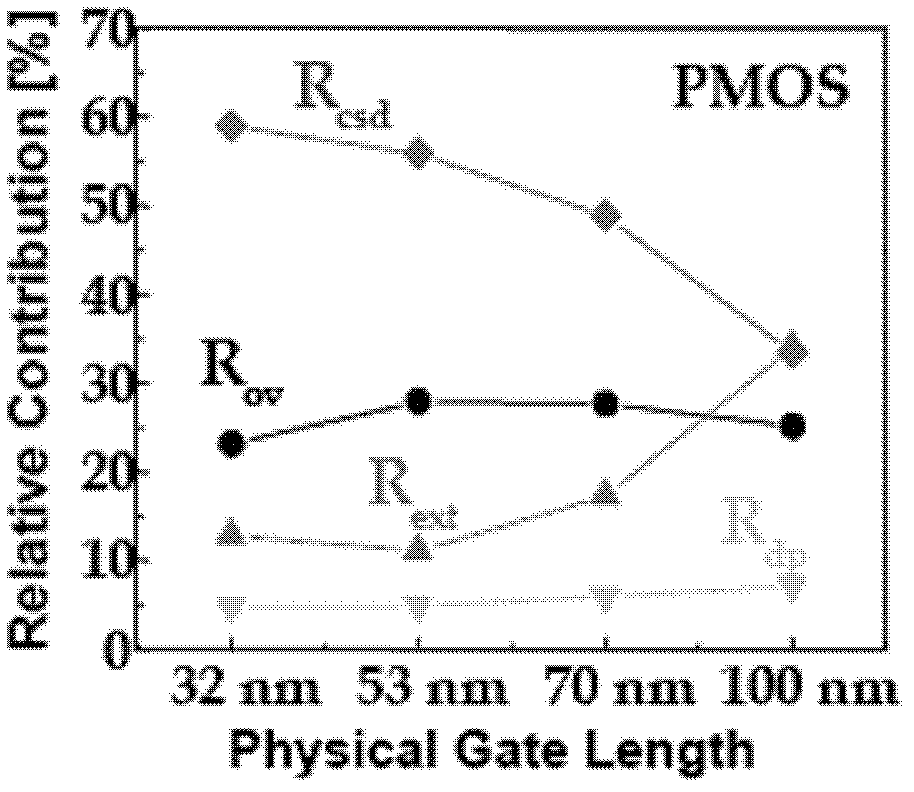

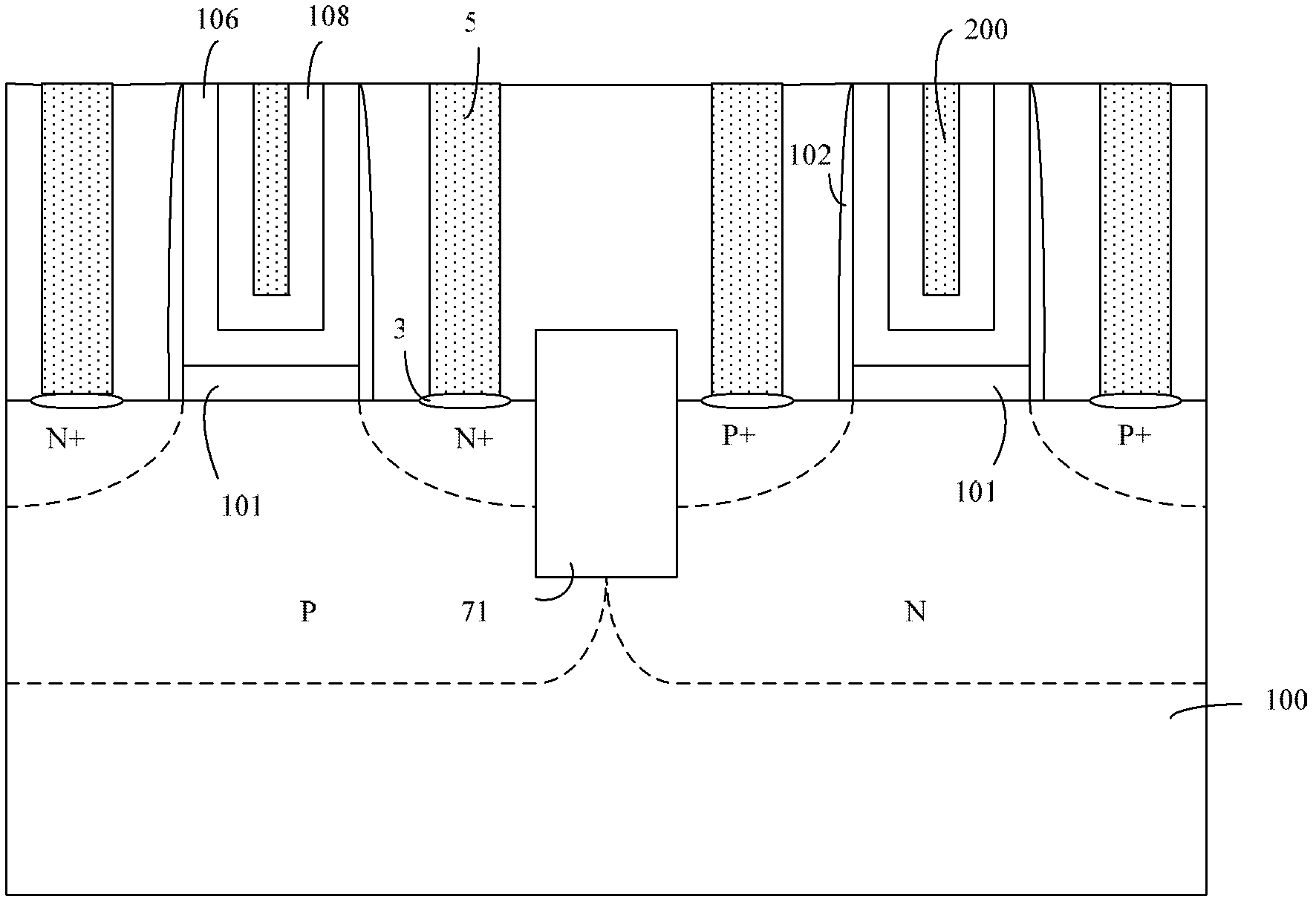

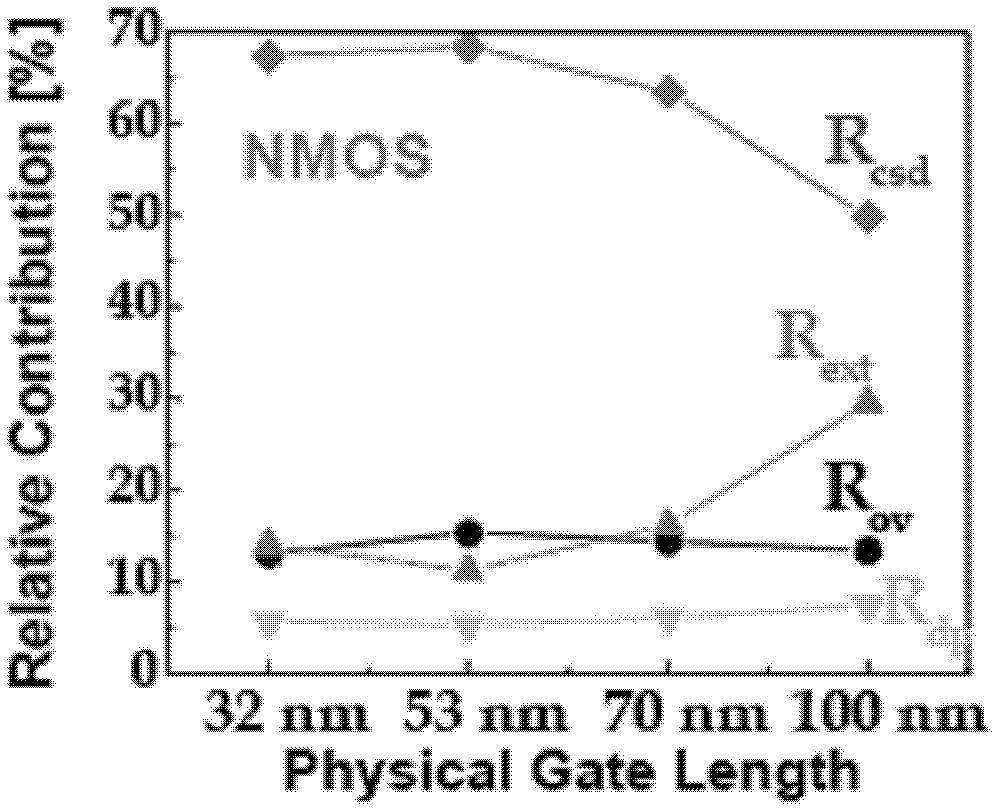

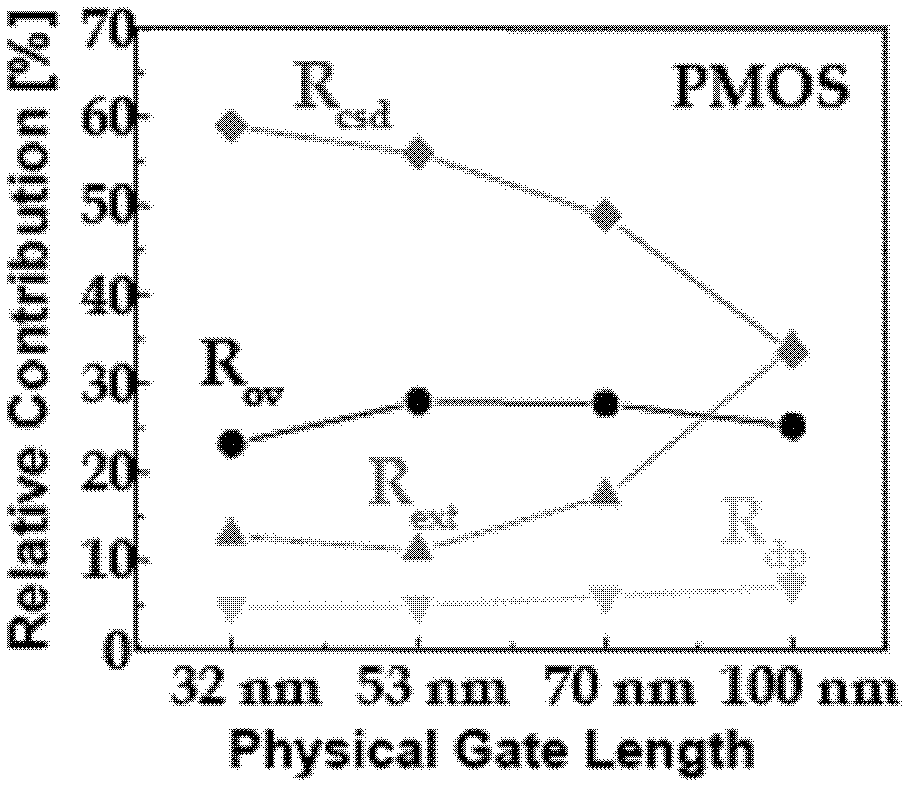

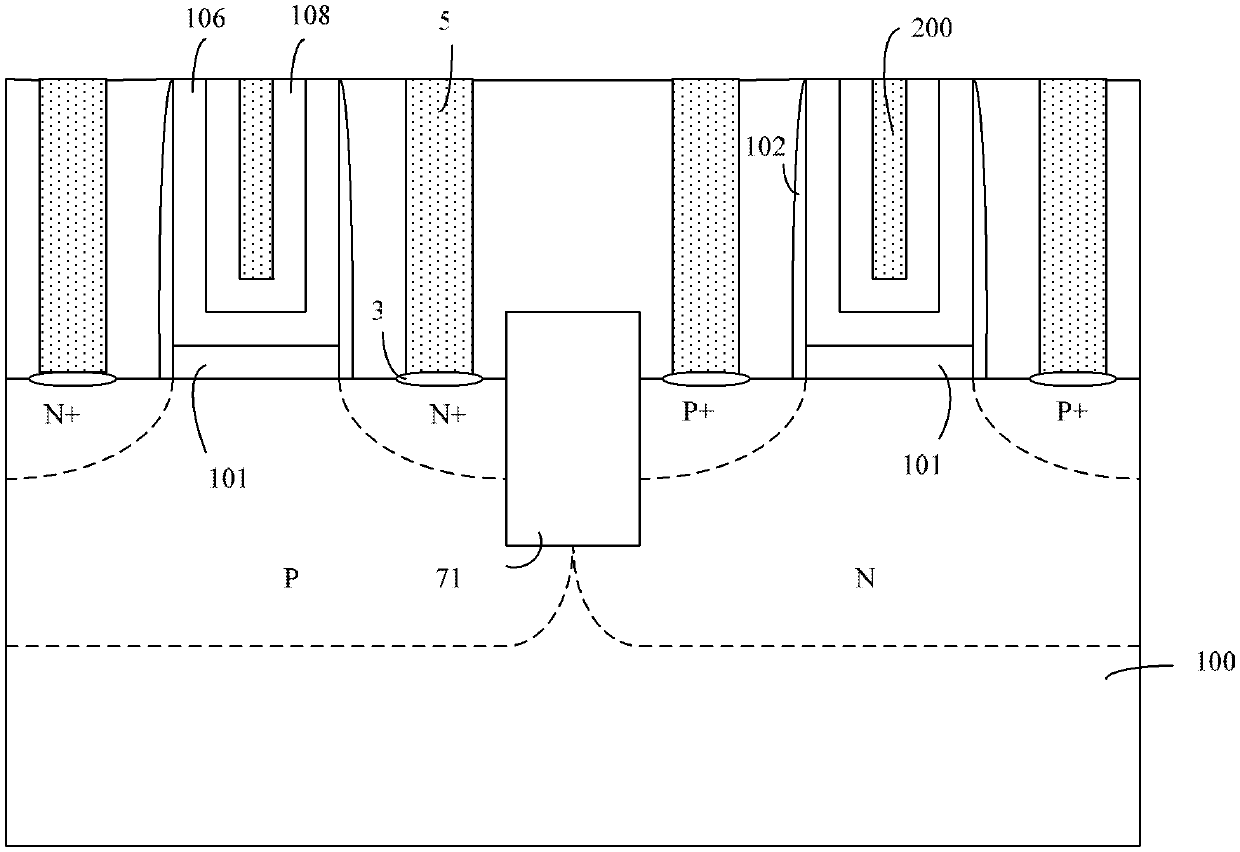

Metal gate field effect transistor and manufacturing method thereof

ActiveCN103187298AUniform and dense textureReduce process stepsSemiconductor/solid-state device manufacturingSemiconductor devicesWork functionProcess efficiency

Provided is a metal gate field effect transistor and a manufacturing method thereof. The manufacturing method of the metal gate field effect transistor comprises the following steps: forming dummy gates by applying a gate-last approach; removing the dummy gates to form openings; sequentially forming work function metal material layers and metal barrier layers on the lateral walls and the bottoms of the openings, wherein the work function metal material layers and the metal barrier layers are not fully filled with the openings; forming through holes of contact holes above a source electrode and a drain electrode; and forming filler metal layers in an electrodeless electroplating mode, wherein the filler metal layers are filled with the openings and the through holes in the contact holes. By utilizing the electrodeless electroplating metal mode to form a last layer of metal gates and the contact holes of a source region and a drain region, metal texture of metal in the metal gates and the through holes of which a high aspect ratio is same as the contact holes is compact and even, and is free of cavities and gaps. Process steps are saved, process efficiency is improved, and process cost is saved. In the meanwhile, by selecting the metal filled in the contact holes, the metal gate field effect transistor and the manufacturing method thereof can reduce parasitic resistance of the contact holes and the drain electrode.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Nutritional soil for nutritious cup nursery of parashorea chinensis and preparation method of nutritional soil

InactiveCN104119144AUniform and dense textureGood water and fertilizer retentionFertilizer mixturesWeedNutrition

The invention discloses nutritional soil for nutritious cup nursery of parashorea chinensis and a preparation method of the nutritional soil, belonging to the technical field of forestry seedling culture and solving the problem of the nutritional soil needed for strong seedling culture of the rare parashorea chinensis. The nutritional soil comprises the following components by weight percent: 68% of yellow subsoil, 30% of fired turf mud and 2% of calcium superphosphate. The preparation method comprises the following concrete steps: taking the yellow subsoil, preparing the fired turf mud, preparing the nutritional soil and disinfecting the nutritional soil. The nutritional soil has the characteristics of dense and uniform texture, good moisture and fertility preserving properties and permeability, light weight and no diseases and pests and weed seeds; various nutrients and moisture needed for growth and development of parashorea chinensis seedlings can be ensured, strong parashorea chinensis seedlings can be cultured, and a nursery stock guarantee is provided for creating fast-growing and high-yield plantation of the parashorea chinensis.

Owner:黄振忠

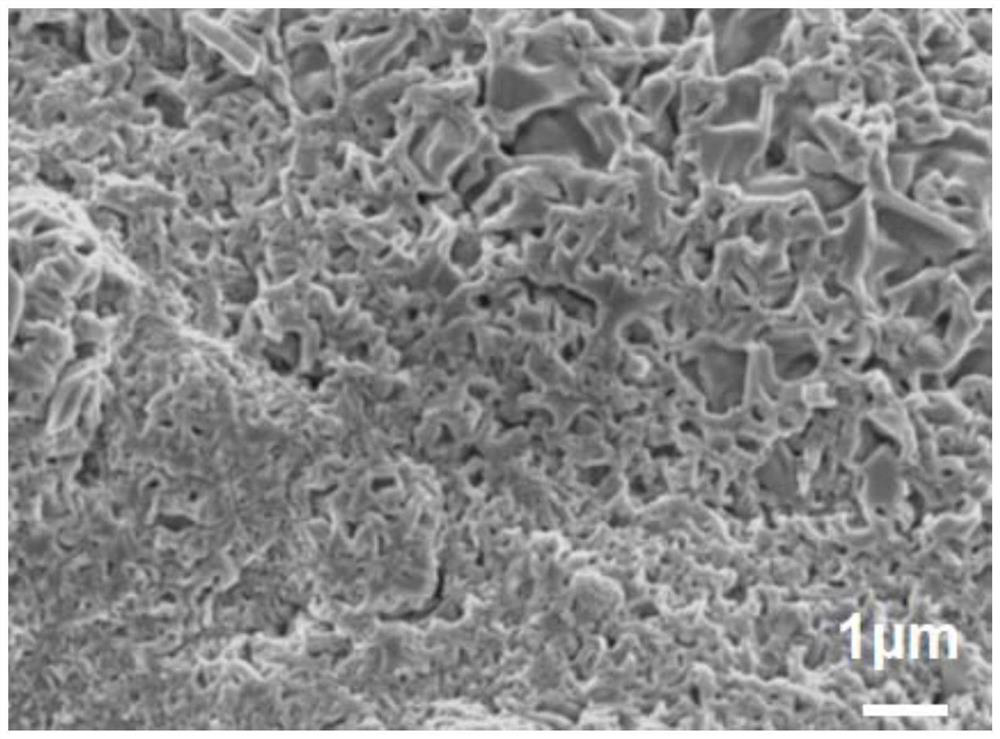

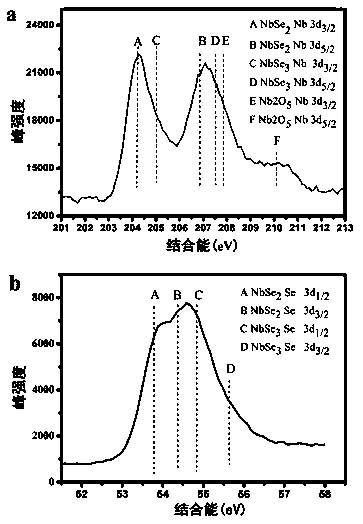

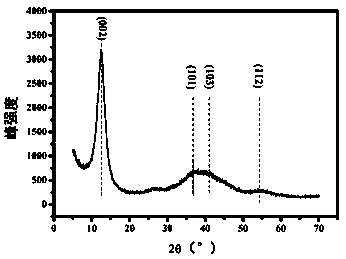

Low-temperature preparation method of lubricating/conducting dual-function NbSe2 thin film

ActiveCN108517499AUniform and dense textureHigh bonding strengthVacuum evaporation coatingSputtering coatingOptoelectronicsRadio frequency

The invention discloses a low-temperature preparation method of a lubricating / conducting dual-function NbSe2 thin film. The method takes argon gas (with the purity of 99.99 percent) as sputtering gasand NbSe2 (with the purity of 99.99 percent) as a sputtering target, and takes a radio frequency power supply used as a sputtering source to prepare the lubricating / conducting dual-function NbSe2 thinfilm. By adopting the method disclosed by the invention, low-temperature rapid deposition of the thin film is realized. The solid thin film has a uniform and dense structure, relatively good film-base bonding strength and good preferred orientation; under an atmospheric environment (with 30 percent RH and the temperature of 20 DEG C), the solid thin film has excellent tribological performance (the friction coefficient is about 0.033) and good conducting performance (the static contact resistance is about 1.76*10<-3>ohm*cm); under a dynamic contact sliding mode, the solid thin film still has excellent lubricating / conducting dual-function. The NbSe2 thin film has a wide application prospect in the field of surface treatment of an electric contact sliding part.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

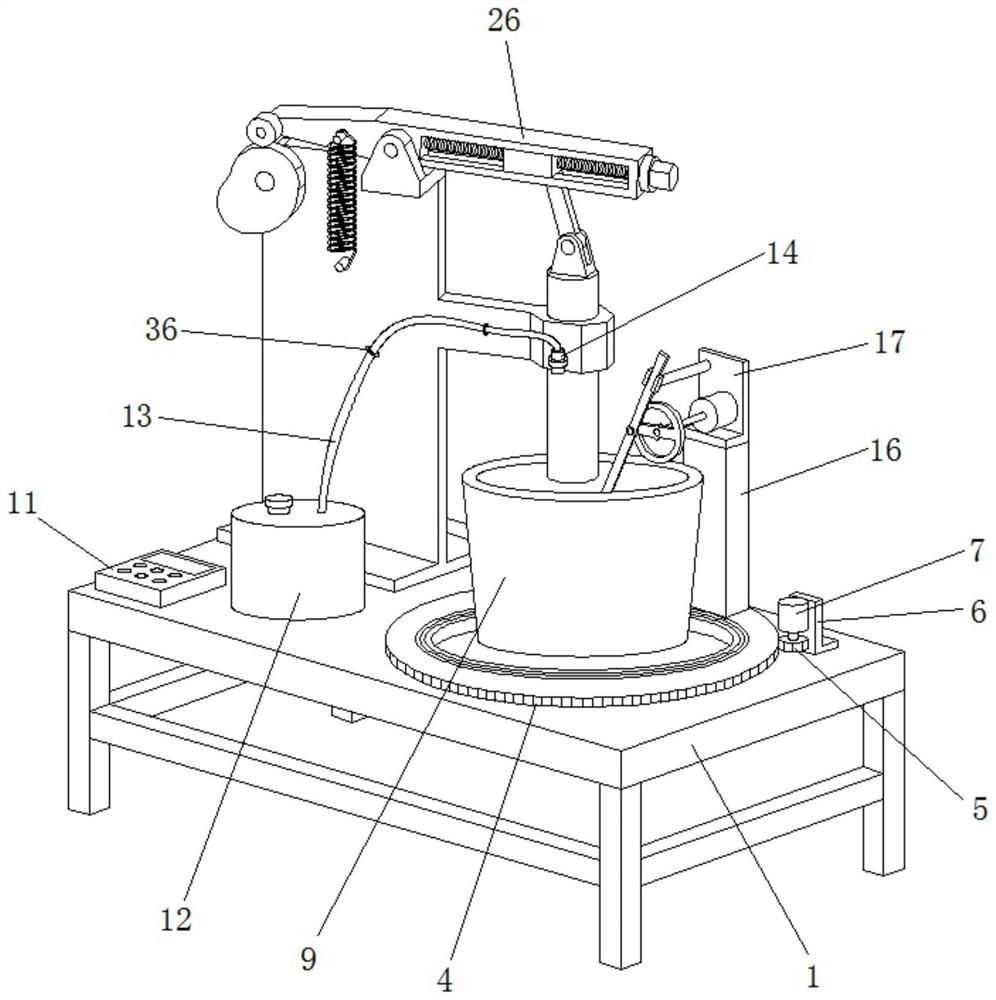

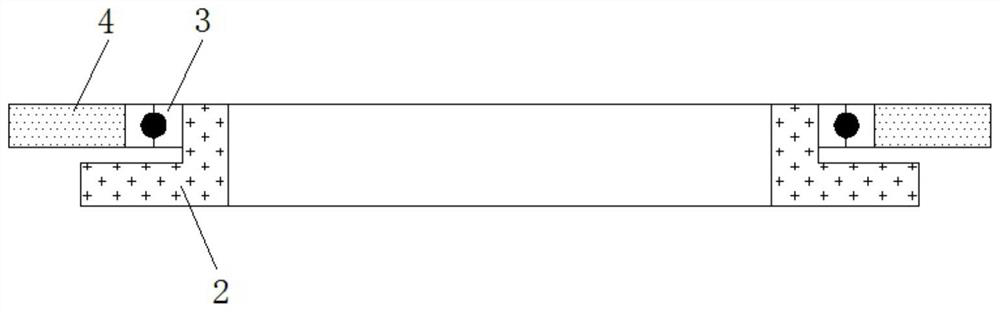

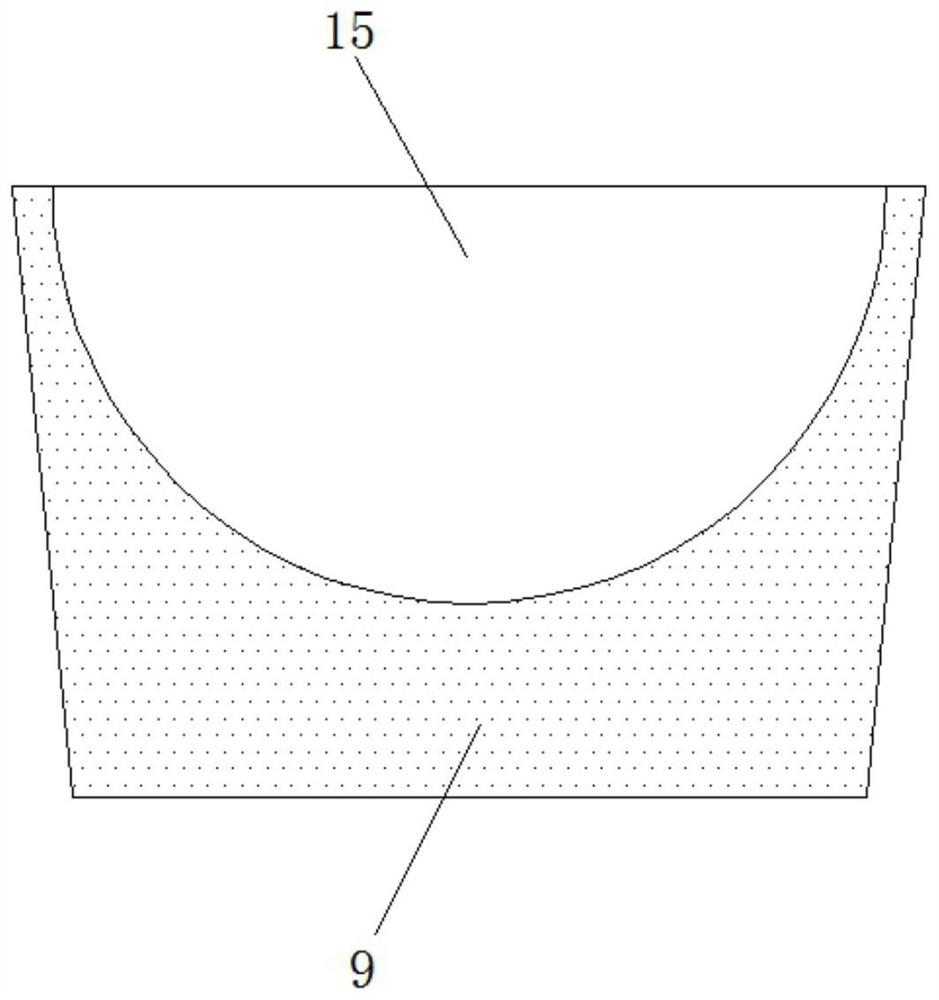

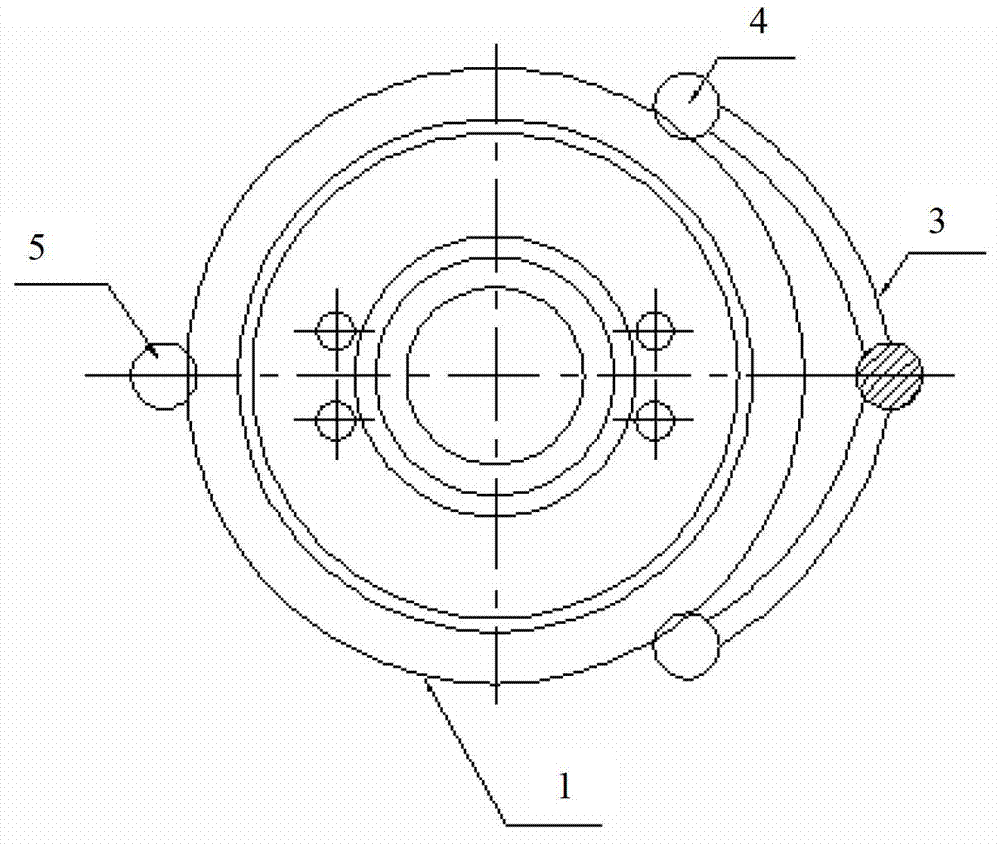

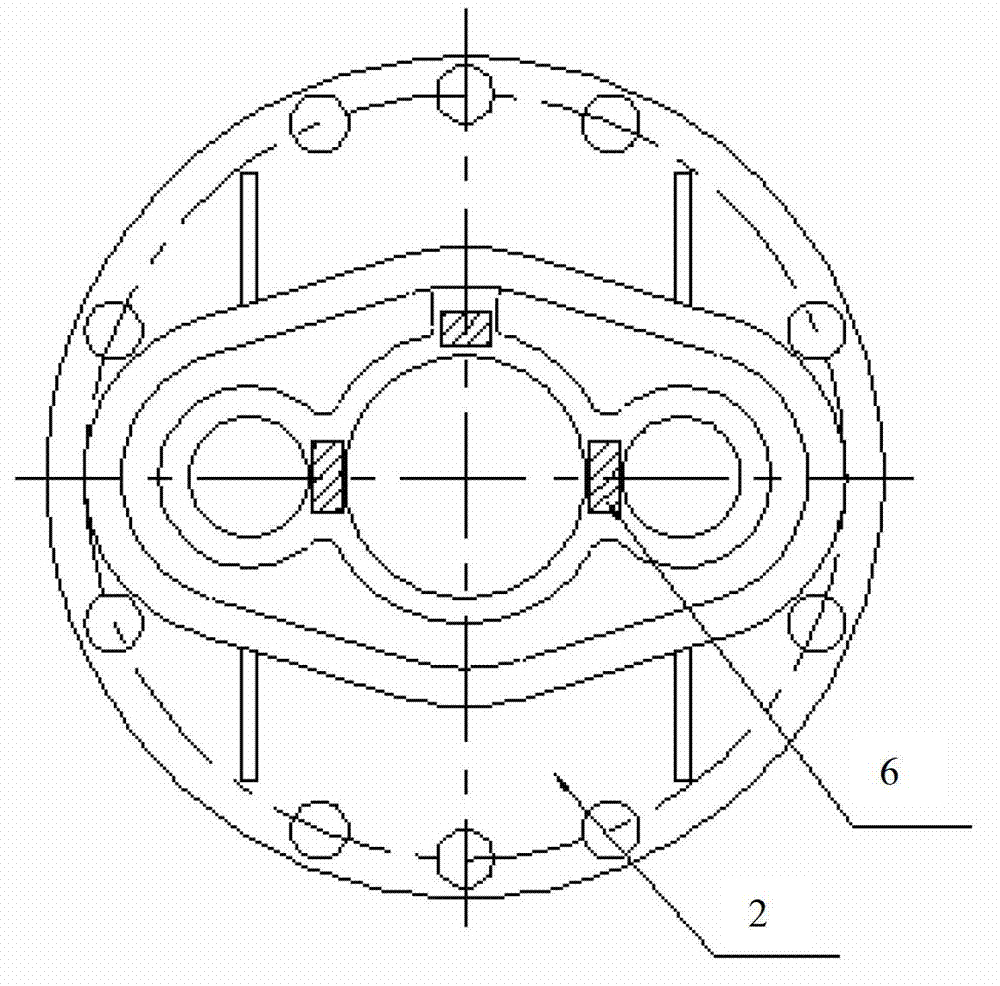

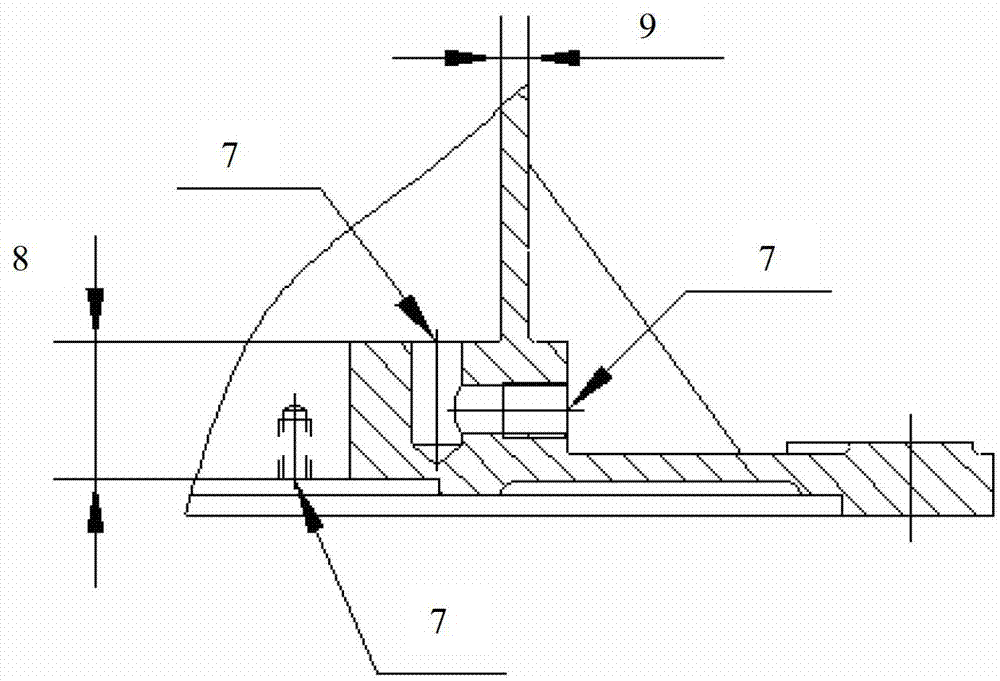

Rice cake processing device simulating mortar beating and turning actions

InactiveCN112956718AUniform and dense textureGreat tasteFood shapingGear wheelAgricultural engineering

The invention discloses a rice cake processing device simulating mortar beating and turning actions. The rice cake processing device comprises a base; a flange plate is fixedly installed at one end of the upper surface of the base; the outer surface of the upper end of the flange plate is fixedly sleeved with a bearing; the outer side of the bearing is fixedly sleeved with a gear ring; the outer side of the gear ring is in meshed connection with a driving gear; the driving gear is driven by a first servo motor installed on the base through a first L-shaped installation plate; a stirring mechanism is fixedly installed at one end of the upper surface of the gear ring; a pounding mortar installed on the upper surface of the base is arranged in the middle of the flange plate; a pounding and hammering mechanism is fixedly installed at the other end of the upper surface of the base; and a control switch and a water tank are fixedly mounted on one side of the pounding and hammering mechanism. The pounding and hammering mechanism simulates the mortar beating and pounding and hammering actions of traditional rice cake making, the pounding and hammering mechanism is matched with the stirring mechanism rotating around the pounding mortar to turn over rice cake raw materials, and therefore, the processed rice cakes are more uniform and compact in texture and better in taste.

Owner:杨廷

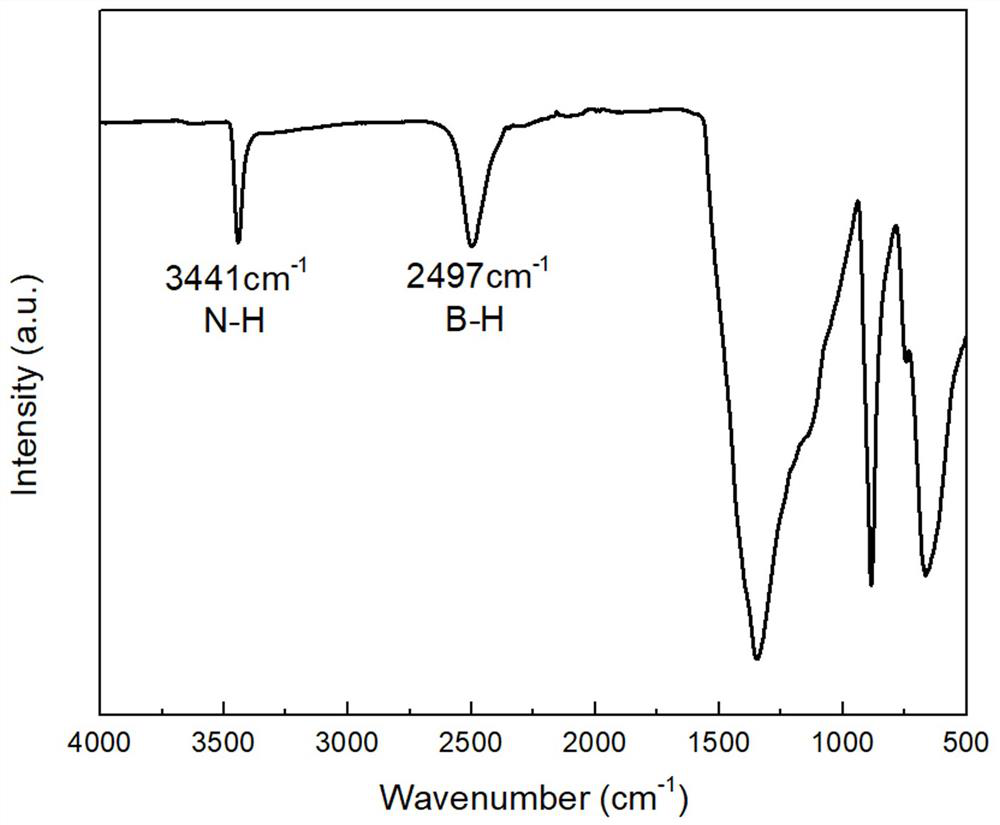

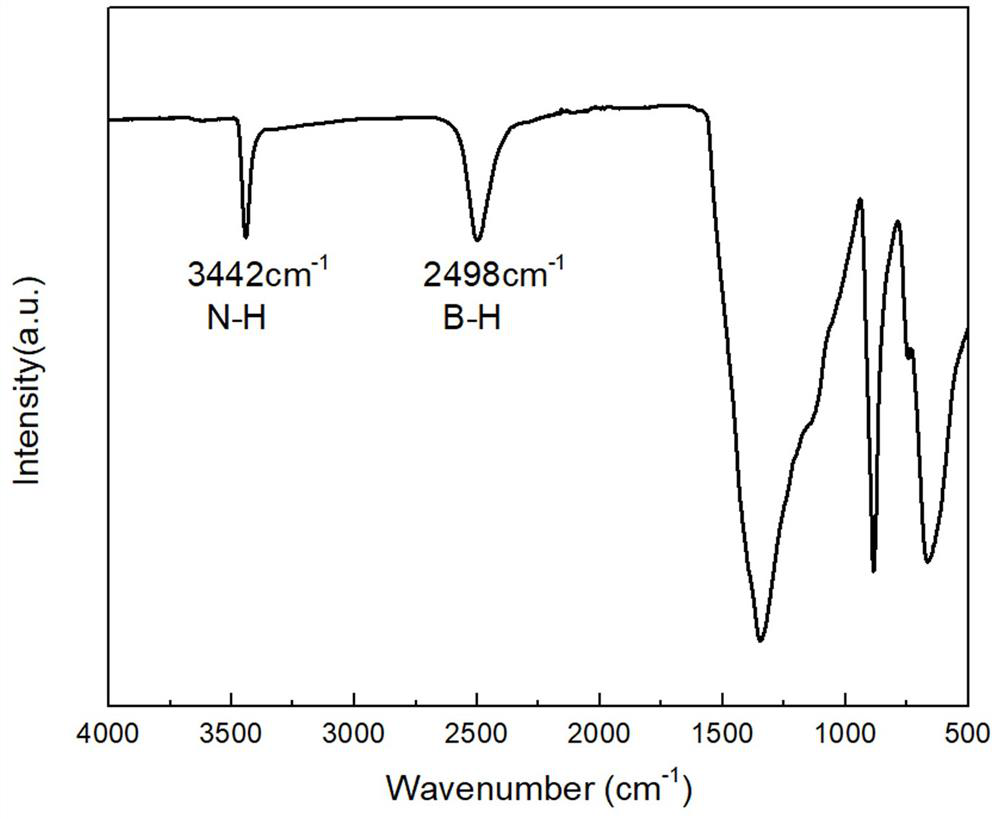

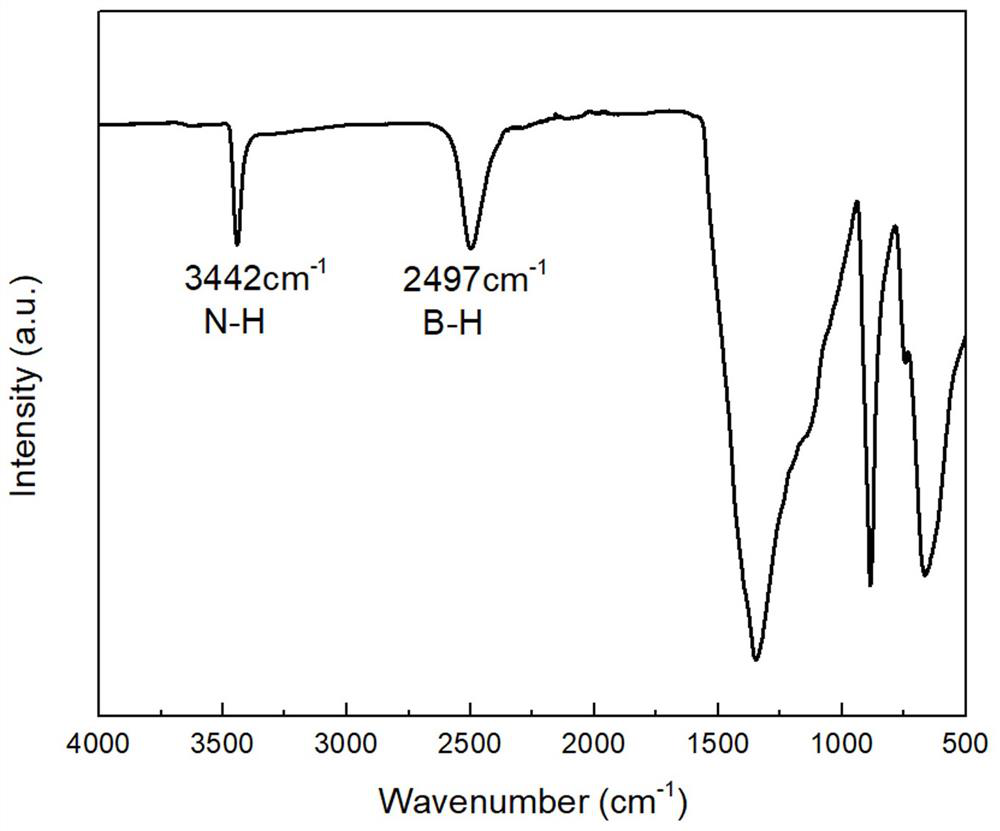

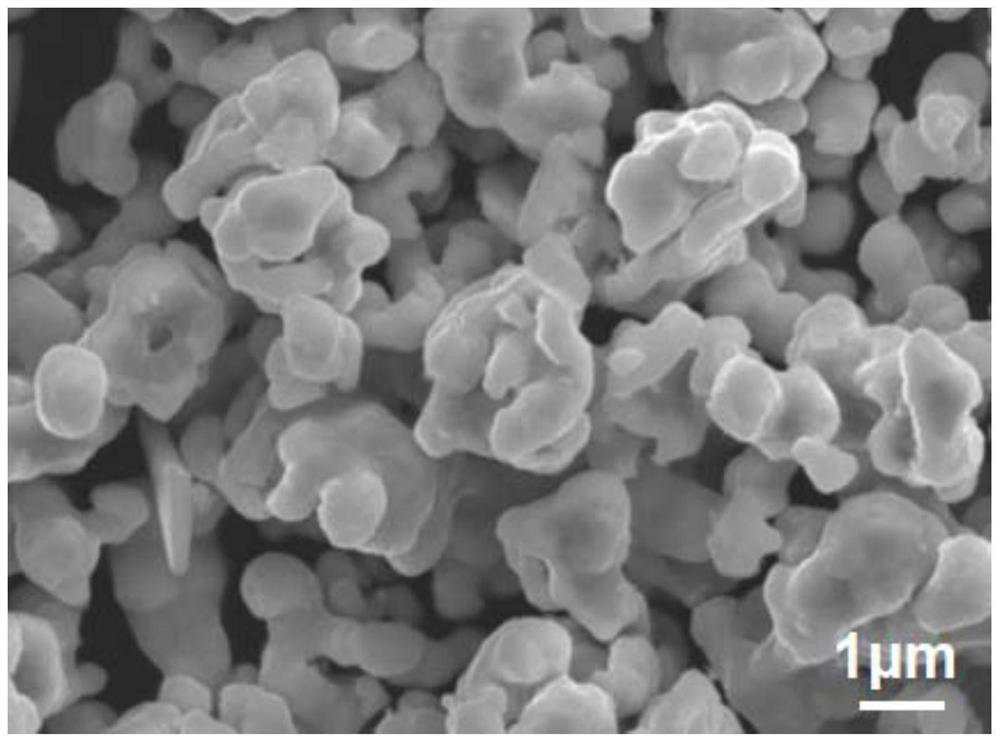

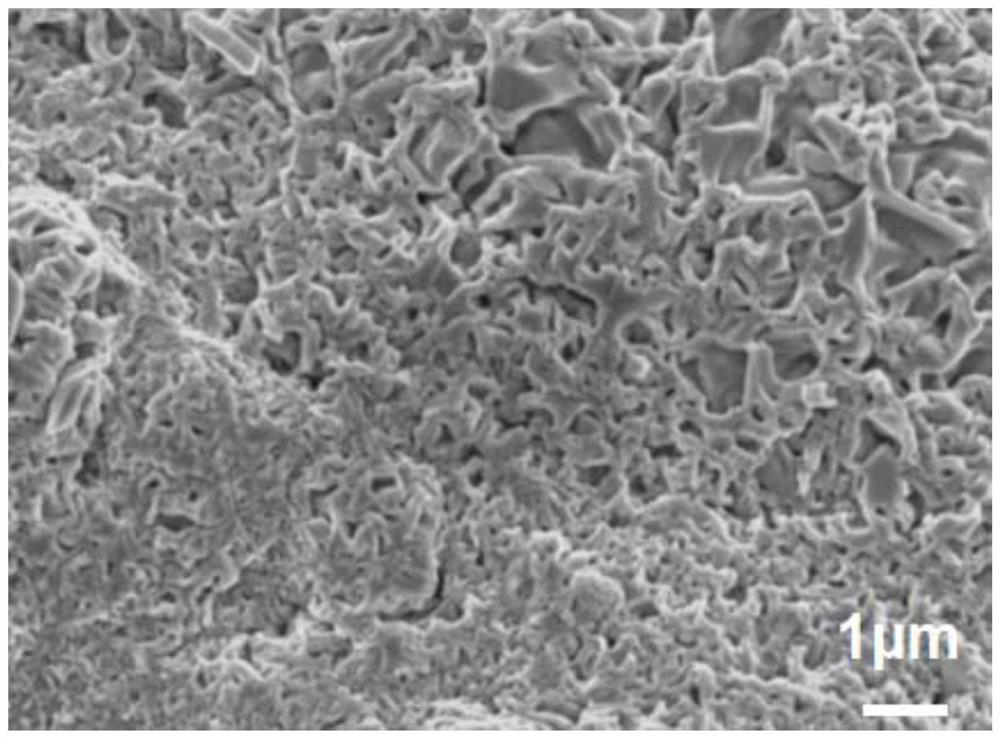

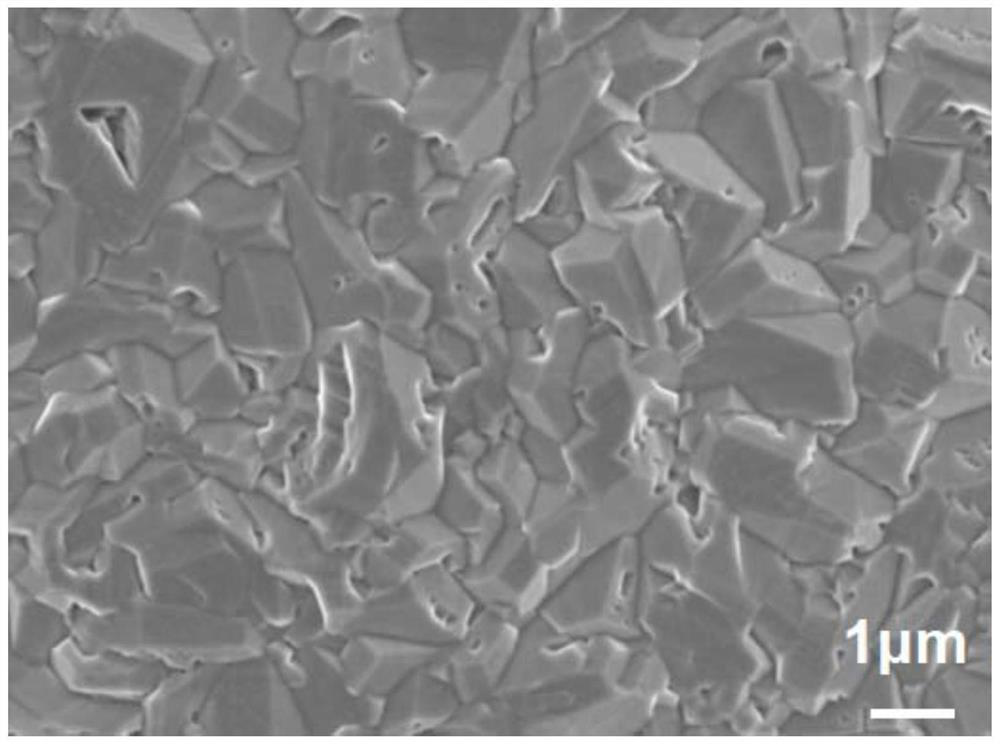

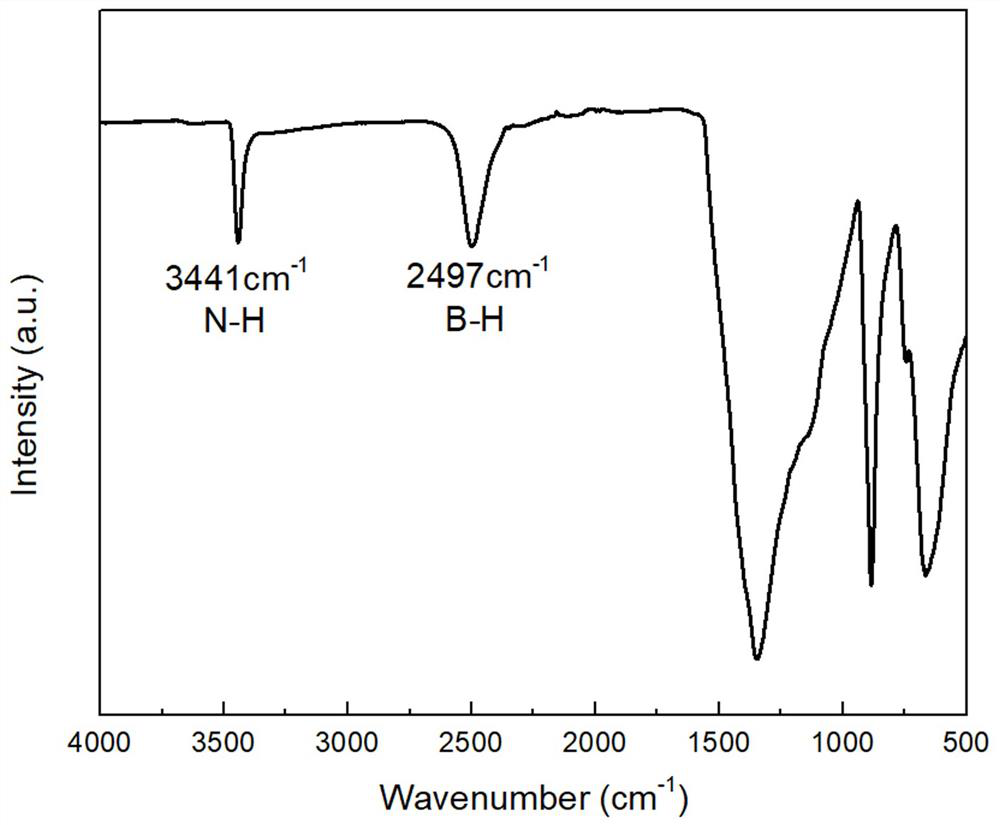

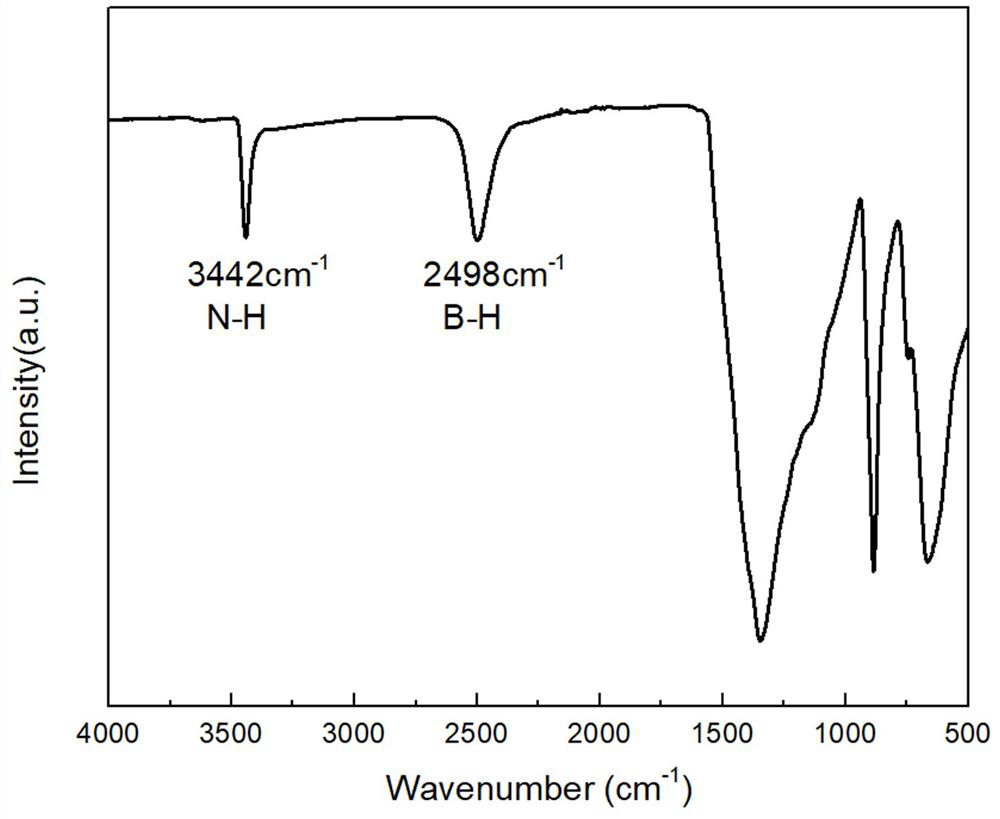

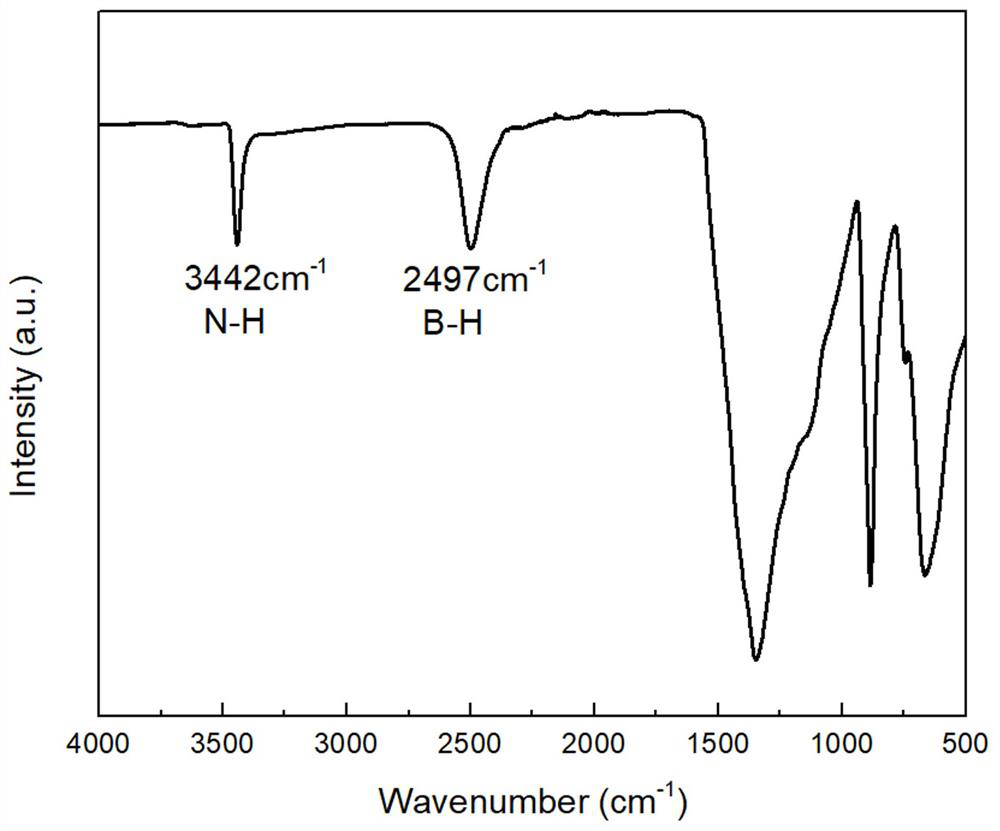

Low-reactivity inorganic boron nitride powder and preparation method thereof

The invention relates to the technical field of inorganic materials, in particular to low-reactivity inorganic boron nitride powder and a preparation method thereof. The preparation method comprises the following steps: adding borazine into a high-pressure kettle, introducing inert gas, and raising the pressure to 1-5 MPa; after boosting, raising the temperature to 100-150 DEG C for the first time, and keeping the temperature for 0.5-6 hours; raising the temperature to 150-200 DEG C for the second time, and keeping the temperature for 0.5-3 hours to obtain a solid product; crushing and refining the solid product to obtain the low-reactivity inorganic boron nitride powder. Through the design of the preparation method of the low-reactivity inorganic boron nitride powder, the technical problems that in the prior art, the inorganic boron nitride powder needs to be obtained under a high-temperature condition and has high requirements on equipment and the like, and meanwhile, the obtained inorganic boron nitride powder is low in porosity and moderate in looseness degree and reaction activity are solved.

Owner:北京玻钢院复合材料有限公司 +1

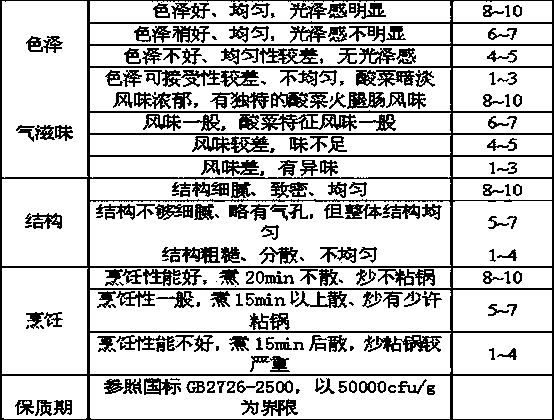

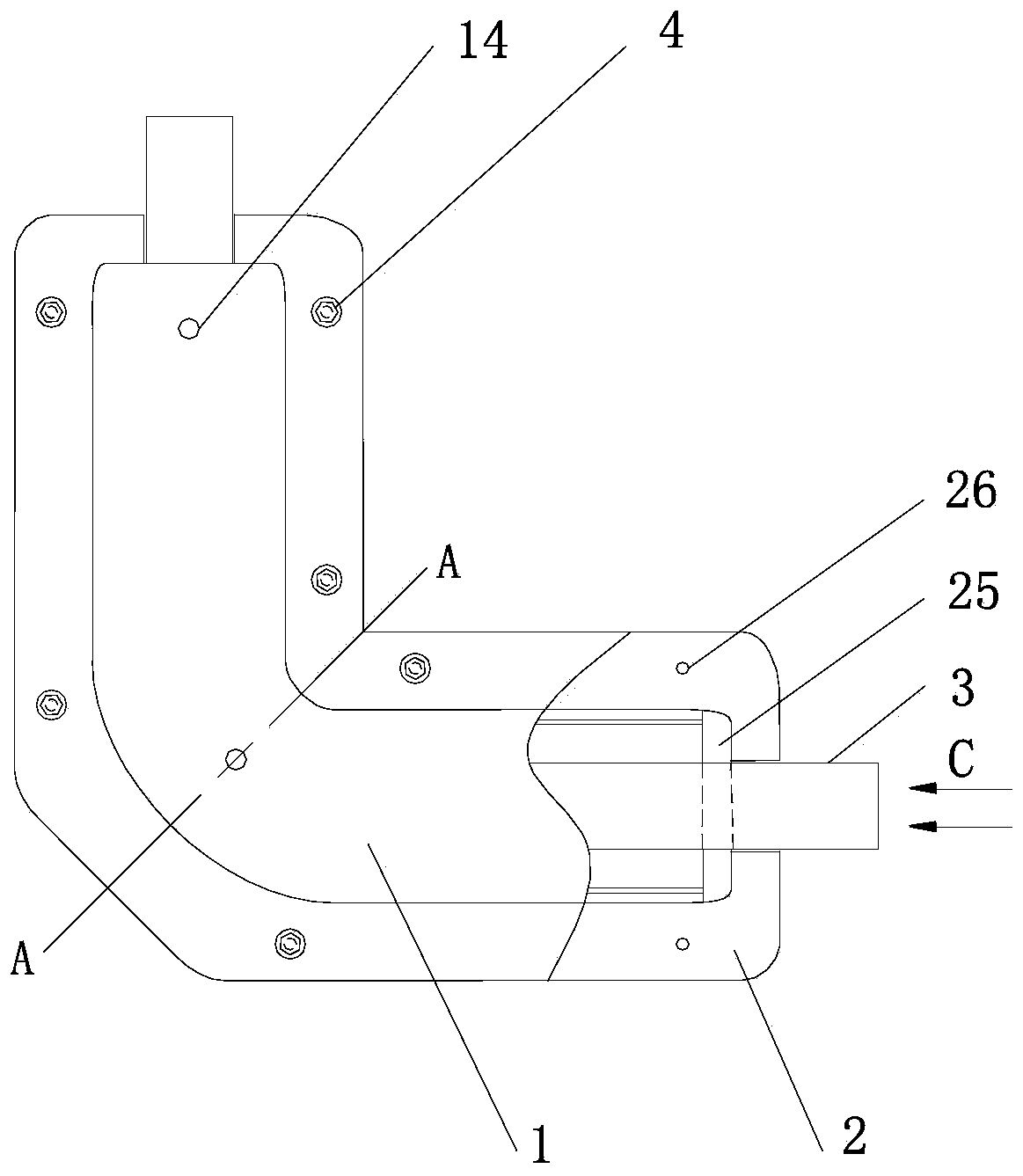

Ion injection and plasma deposition equipment and method for processing films by using plasmas

ActiveCN101956171BUniform and dense textureImprove bindingVacuum evaporation coatingSputtering coatingMetallurgyPlasma deposition

The invention provides ion injection and plasma deposition equipment, which comprises an ion source and a vacuum chamber, wherein the wall of the vacuum chamber is provided with a vacuumizing port and at least one opening for communicating with the ion source; the vacuum chamber is internally provided with an unreeling roller, a cooling part and a reeling roller; the cooling part comprises at least one cooling roller; the cooling roller, the unreeling roller and the reeling roller are mutually parallel, and the axial direction of the cooling roller is perpendicular to the direction in which the plasmas enter the vacuum chamber; the cooling roller is in one-to-one correspondence to the opening in a horizontal height, or the opening is in one-to-one correspondence to the cooling roller in the left to right direction or in the front to back direction; or the cooling roller is positioned just below or just above the opening correspondingly. The invention also provides a method for processing films by using the plasmas. The equipment provided by the invention can be used for carrying out a continuous plasma deposition and / or ion injection operation to the films.

Owner:SUMITOMO ELECTRIC INTERCONNECT PROD SHENZHEN LTD

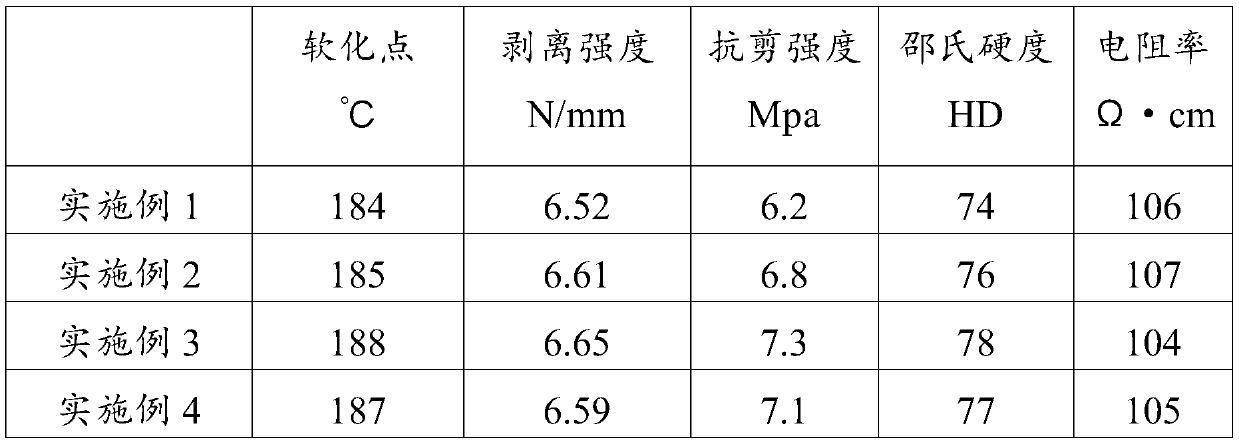

LED packaging conductive polyamide hot melt adhesive and preparation method thereof

InactiveCN110982479AImprove heat resistanceImprove cooling effectNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer sciencePolyamide

The invention discloses an LED packaging conductive polyamide hot melt adhesive and a preparation method thereof. The conductive polyamide hot melt adhesive comprises 55-100 parts of an unsaturated fatty acid dimer, 10-20 parts of ethylenediamine, 10-20 parts of hexamethylene diamine, 15-20 parts of sebacic acid, 5-12 parts of dimethyl silicone oil, 1-2 parts of alkyl modified organosiloxane, 5-12parts of a waterproof filler, 5-10 parts of a conductive agent, 3-5 parts of a tackifier, 1-4 parts of a viscosity regulator, 2-4 parts of an anti-aging agent, 3-8 parts of a transparent agent and 2-5 parts of phosphor. The prepared conductive polyamide hot melt adhesive has the advantages of good heat resistance, good heat dissipation property, waterproof and impermeable performance, chemical erosion resistance, abrasion resistance and high binding power, and also has excellent conductivity, excellent dispersity and stable conductivity due to the conductive mica powder used as the conductiveagent.

Owner:湖南省和祥润新材料有限公司

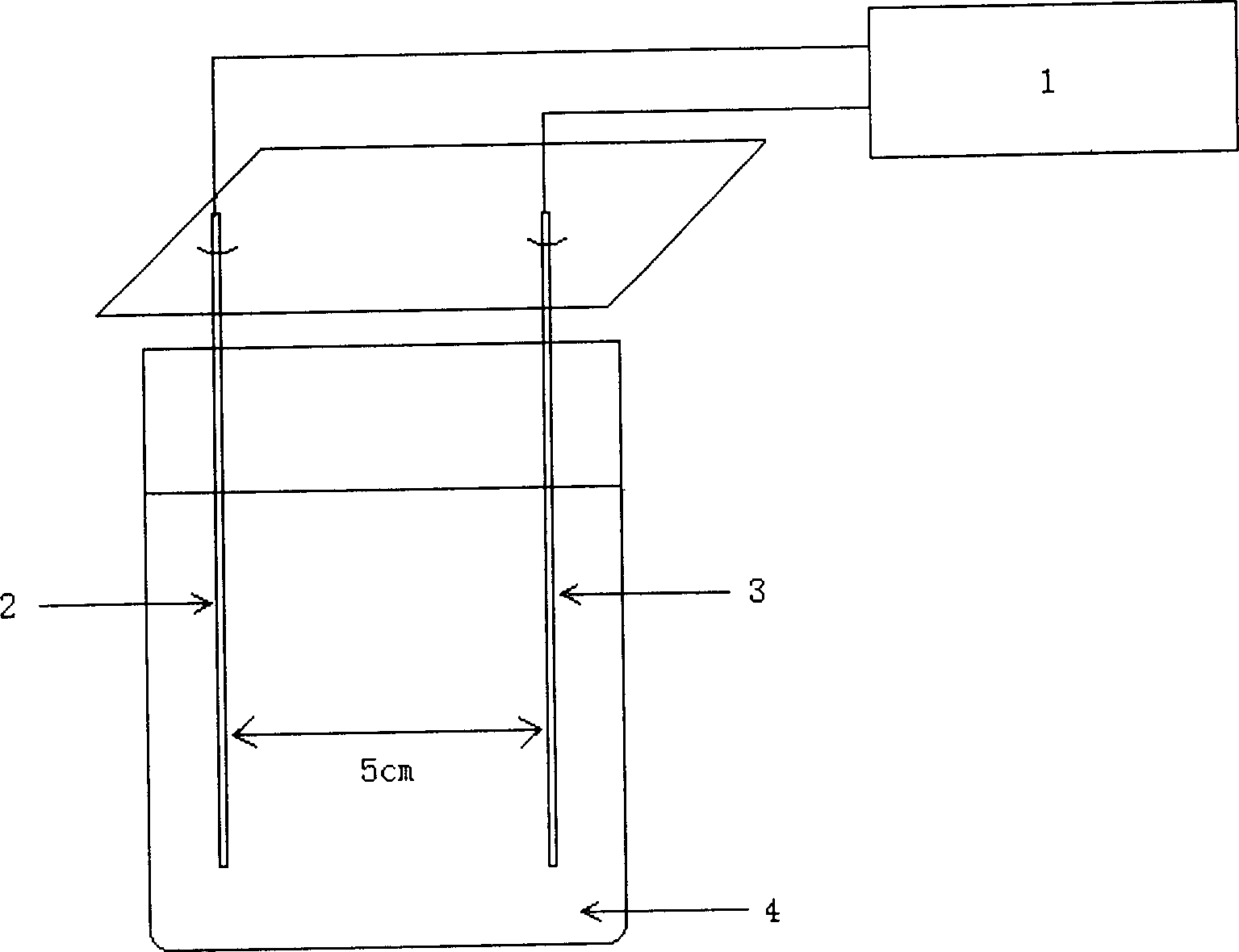

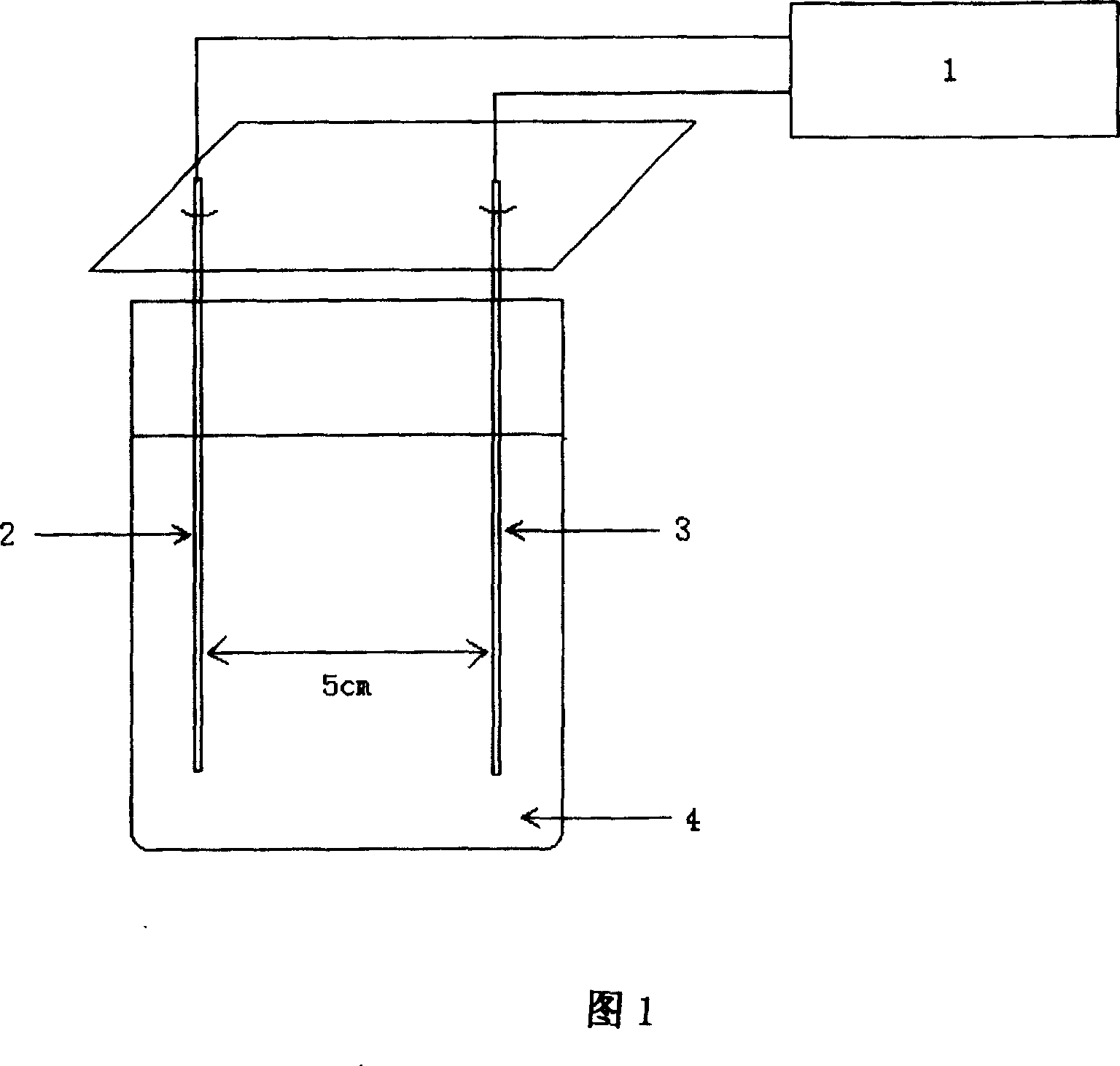

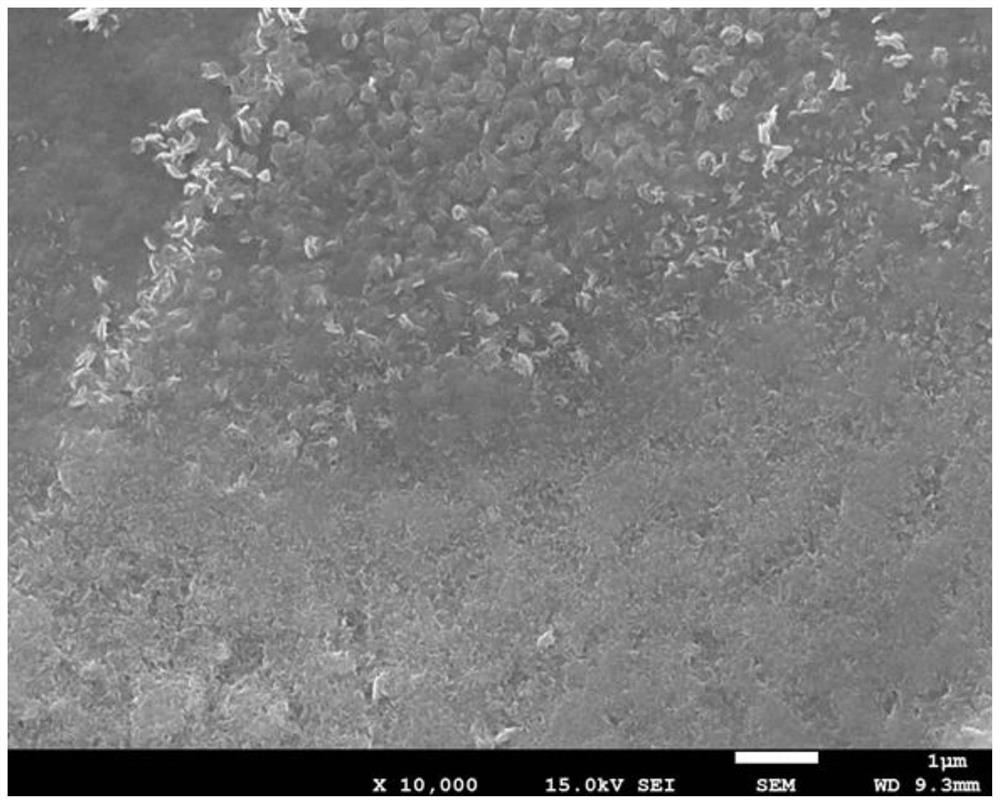

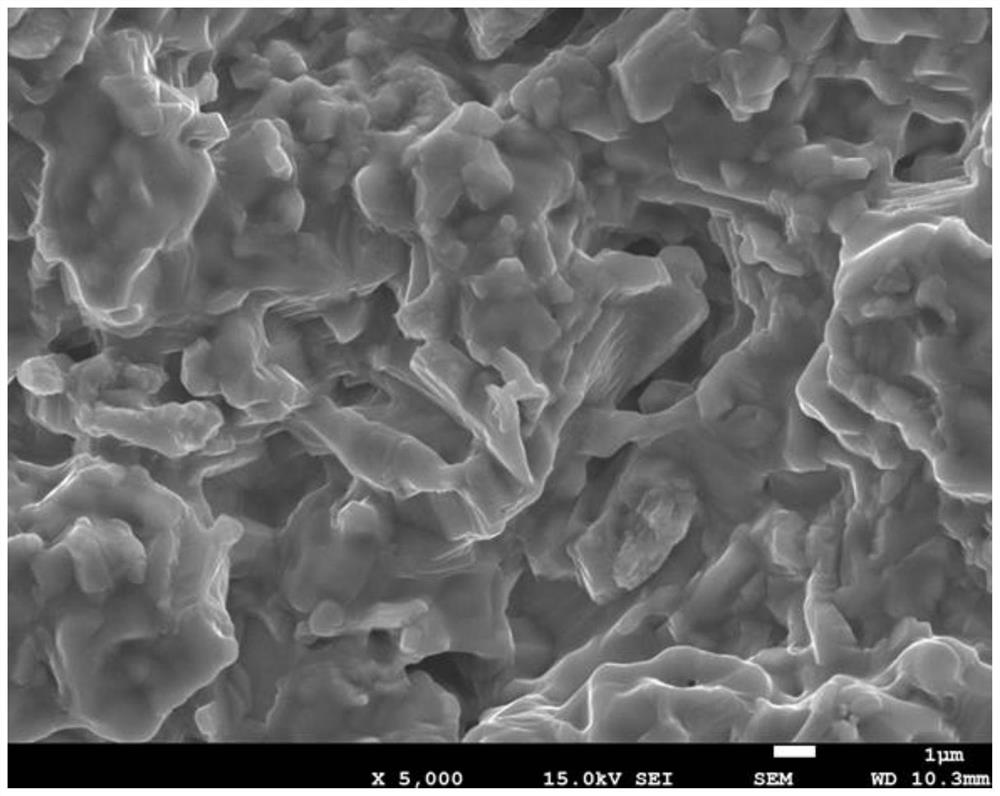

Method for preparing high temperature superconductor thick film of Ba/YCu with large area by using electrophoresis technique

InactiveCN1447451AControllable growthSimple textureElectrophoretic coatingsSuperconductor device manufacture/treatmentOrganic solventGranularity

A method includes following steps. (1) A metal layer is vaporized on the MgO monocrystal substrate. Then, the substrate is fixed on the negative electrode for stand by application. (2) YBa2Cu3O7-delta sintered is ground till the granularity of the powder is less than 0.1-10 micros. The powder is mixed with organic solvent in mixing ratio being as 20g / liter. The YBa2Cu3O7 delta electrophoresis fluid is prepared by stirring up the organic solvent making the fluid disperse evenly. (3) The YBa2Cu3O7-delta electrophoresis fluid and the electrode with the motorcrystal substrate are put to the cleaned electrophoresis pool. The even YBa2Cu3O7-delta film is obtained after 20-900V DC current being add to electrodes and 5-1600 seconds deposit time being kept.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

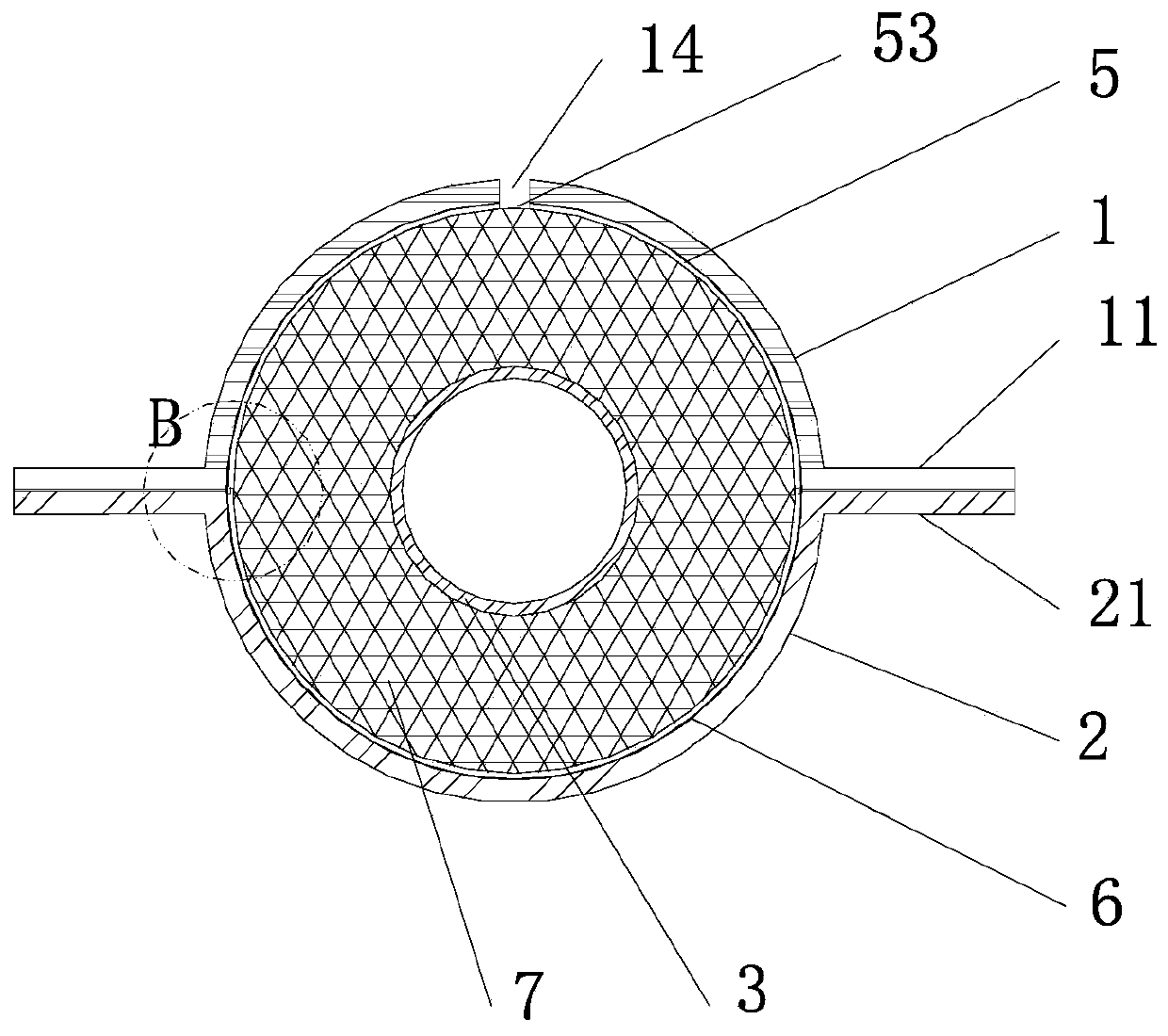

Production mold and production process of special-shaped prefabricated heat insulating pipe member

PendingCN110394937AHigh densityIncrease productivityTubular articlesEngineeringMechanical engineering

The invention relates to a production mold of a special-shaped prefabricated heat insulating pipe member. The production mold comprises an upper mold, a lower mold and an outer protective pipe; an upper foaming cavity is formed in the lower portion of the upper mold, a lower foaming cavity is formed in the upper portion of the lower mold, upper side plates are arranged at the two ends of the upperfoaming cavity, upper semicircular holes are formed in the centers of the lower positions of the upper side plates, lower side plates are arranged at the two ends of the lower foaming cavity, and lower semicircular holes are formed in the centers of the lower positions of the lower portions of the lower side plates; and a foaming mold cavity with a round cross section is formed by the upper foaming cavity and the lower foaming cavity when the upper mold and the lower mold are closed, inner pipe perforation holes with round cross sections are formed by the upper semicircular holes and the lower semicircular holes, and the foaming mold cavity and the inner pipe perforation holes are concentric; and the outer protective pipe comprises an upper protective shell and a lower protective shell which are buckled into a barrel. By means of the production mold, the density of a polyurethane layer can be improved, the production efficiency of the special-shaped prefabricated heat insulating pipeis improved, and the production mold is easy to learn and easy to use.

Owner:HENAN SANJIE THERMOELECTRIC TECH

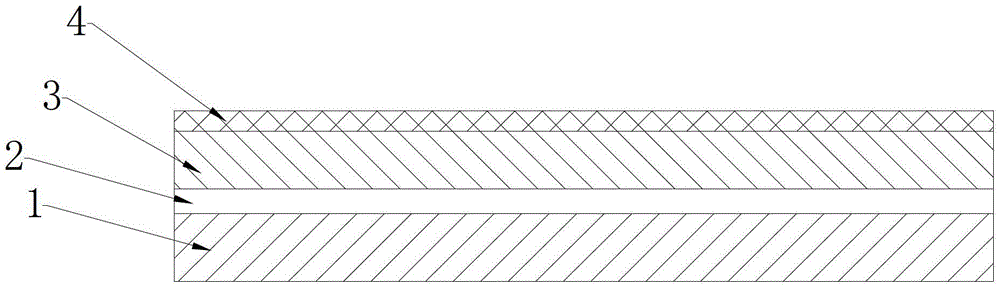

A metal-based conductive circuit board and its manufacturing method

InactiveCN103313509BImprove cooling effectImprove heat resistancePrinted circuit manufactureCircuit susbtrate materialsHeat resistanceHemt circuits

The invention relates to a printed circuit board, in particular to a metal-based conductive circuit board used in high-power electronic devices, and belongs to the technical field of electronic circuits. The printed circuit board includes a bottom layer, an insulating layer and a conductive layer. The material of the bottom layer is metal; an insulating layer is arranged on the bottom layer, and the material of the insulating layer is silicon oxide; a conductive layer is arranged on the insulating layer. In the metal-based conductive circuit board provided by the invention, the silicon oxide insulating layer has good heat resistance and corrosion resistance, is dense and uniform, and is firmly combined with the substrate, which can effectively overcome the differences between the circuit layer, the insulating heat-conducting layer and the metal base layer. The expansion coefficient causes problems such as low mechanical strength and difficult processing. The thermal conductivity of the silicon oxide insulating layer is higher than that of ordinary fibers and resins, and the texture of the film is dense and uniform, so that the heat dissipation performance of the metal-based conductive circuit board is better.

Owner:上舜电子科技(中国)有限公司

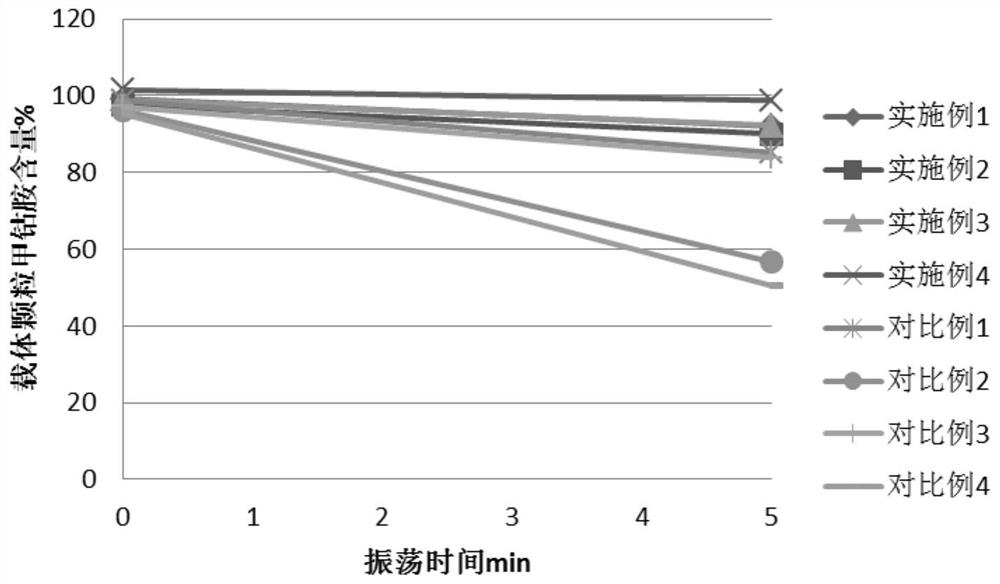

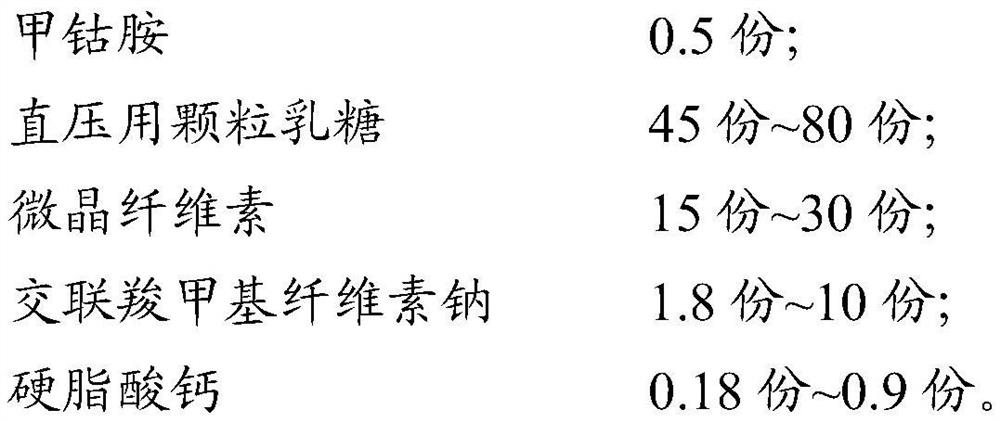

A kind of methylcobalamin tablet and preparation method thereof

ActiveCN110251477BImprove stabilityReasonable choiceOrganic active ingredientsPharmaceutical non-active ingredientsMethylcobalaminLactose

Owner:北京斯利安药业有限公司

Preparation method and application of manganese-cobalt spinel coating

ActiveCN113265655BUniform and dense textureSimple preparation processSolid electrolyte fuel cellsHeat inorganic powder coatingElectrical resistance and conductanceManganese

The invention provides a preparation method and application of a manganese-cobalt spinel coating, and relates to the technical field of coating materials. The preparation method of the manganese-cobalt spinel coating firstly mixes the manganese-cobalt mixed powder with the solution to obtain a mixed slurry; then applies the mixed slurry to the surface of a ferritic stainless steel connector and dries to obtain an intermediate coating A; Then sinter the ferritic stainless steel connecting body with the intermediate coating A on the surface under a reducing atmosphere, and then pass it into air to oxidize at a high temperature to obtain a manganese-cobalt spinel coating. The above preparation method has the advantages of simple preparation process, easy operation and strong economy, and can generate a spinel coating with uniform and dense texture. It has been verified by experiments that the manganese-cobalt spinel coating prepared by the above preparation method has good electrical conductivity at high temperature, and its surface specific resistance can reach 10mΩ·cm 2 At the same time, the coating has good stability, and there is no obvious resistance increase in the range of 500 hours.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

A kind of preparation method of hydrotalcite-based magneto-optic film material

ActiveCN107541718BSimple preparation processUniform and dense textureLiquid/solution decomposition chemical coatingHydrotalciteThin membrane

The invention discloses a preparation method of a hydrotalcite-based magneto-optical thin film material. The process utilizes metal ion adsorption deposition, obtains a hydrotalcite-based magneto-optical thin film precursor under vacuum conditions, and then uses inert gas washing, ultraviolet curing and other processes A finished film material is obtained. The prepared hydrotalcite-based magneto-optical thin film material has the advantages of simple manufacturing process, uniform and compact texture of the thin film material, superior electrical properties, and good application prospects.

Owner:SUZHOU YUNSHU NEW MATERIAL TECH

A kind of inorganic boron nitride powder with low reactivity and preparation method thereof

The invention relates to the technical field of inorganic materials, in particular to a low-reactivity inorganic boron nitride powder and a preparation method thereof. The method includes the following steps: adding borazine into the autoclave, feeding an inert gas, and increasing the pressure to 1-5MPa; after increasing the pressure, the temperature is raised to 100-150°C for the first time, and the temperature is kept for 0.5-6h; the temperature is raised for the second time To 150-200°C, keep warm for 0.5-3h to obtain a solid product; pulverize the solid product and obtain a low-reactivity inorganic boron nitride powder after refinement; through the preparation method of the low-reactivity inorganic boron nitride powder It is designed to solve the problem of preparing inorganic boron nitride powder in the prior art, which needs to be obtained under high temperature conditions and has high requirements for equipment. At the same time, the obtained inorganic boron nitride powder has low porosity, moderate porosity and moderate reactivity. technical problem.

Owner:北京玻钢院复合材料有限公司 +1

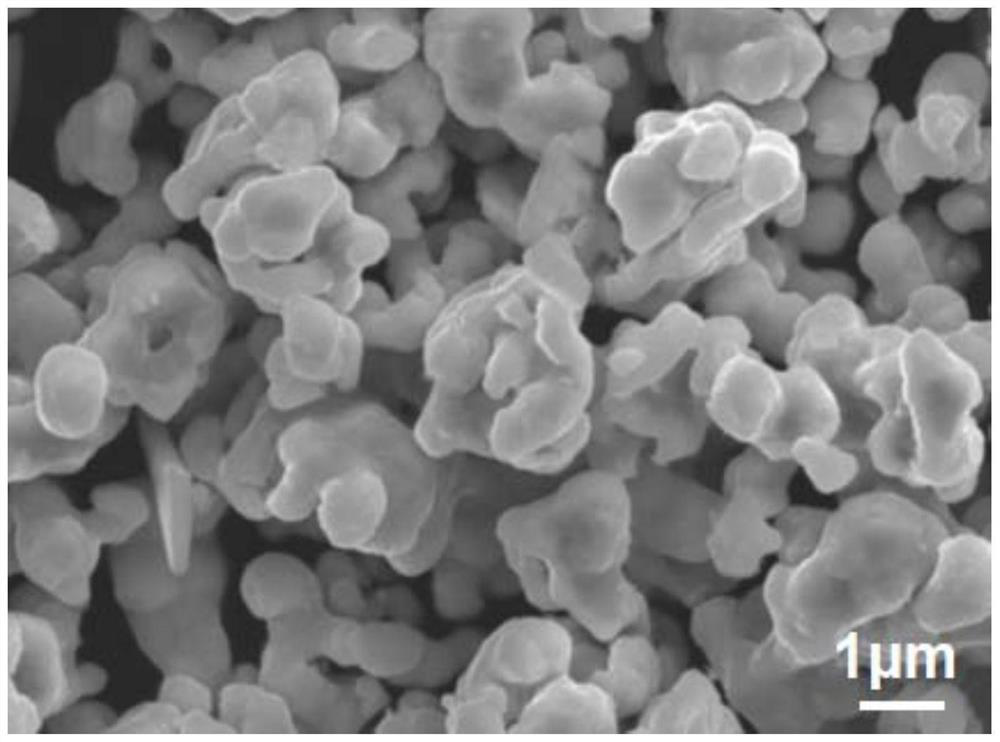

Method for preparing high temperature superconductor thick film of Ba/YCu with large area by using electrophoresis technique

InactiveCN100373649CSimple textureUniform and dense textureElectrophoretic coatingsSuperconductor device manufacture/treatmentOrganic solventGranularity

A method includes following steps. (1) A metal layer is vaporized on the MgO monocrystal substrate. Then, the substrate is fixed on the negative electrode for stand by application. (2) YBa2Cu3O7-delta sintered is ground till the granularity of the powder is less than 0.1-10 micros. The powder is mixed with organic solvent in mixing ratio being as 20g / liter. The YBa2Cu3O7 delta electrophoresis fluid is prepared by stirring up the organic solvent making the fluid disperse evenly. (3) The YBa2Cu3O7-delta electrophoresis fluid and the electrode with the motorcrystal substrate are put to the cleaned electrophoresis pool. The even YBa2Cu3O7-delta film is obtained after 20-900V DC current being add to electrodes and 5-1600 seconds deposit time being kept.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

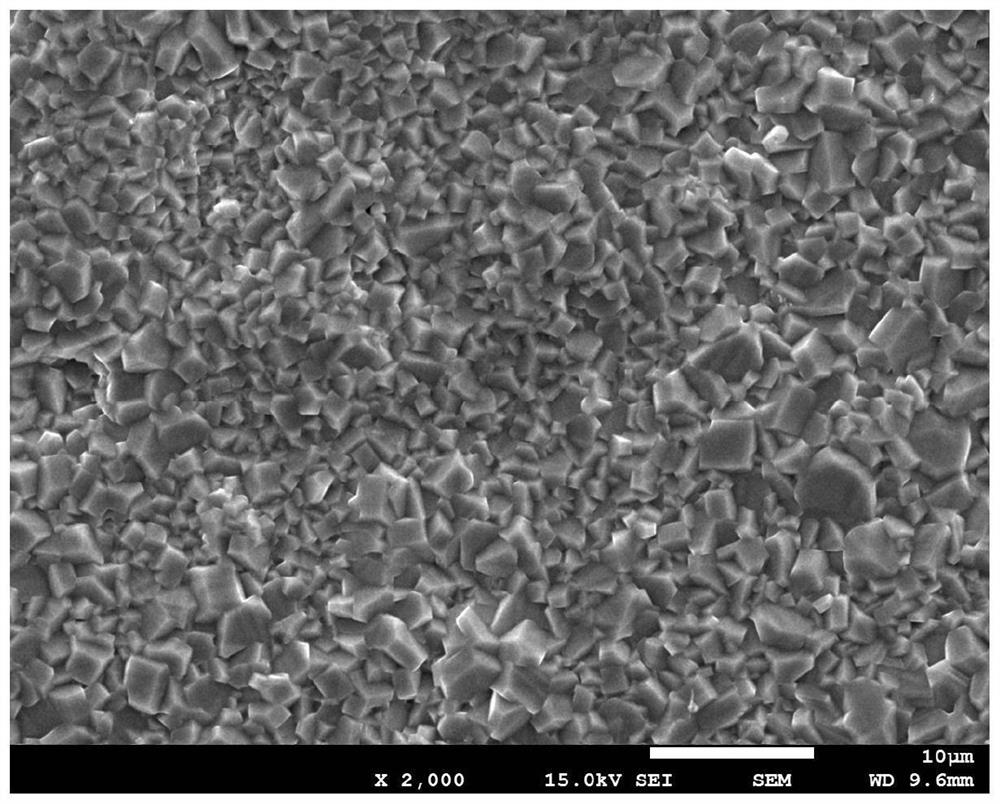

Preparation method of spinel coating and its application in preparation of solid oxide fuel cells

ActiveCN113584466BUniform and dense textureIncrease profitLiquid/solution decomposition chemical coatingFuel cellsFuel cellsMetallurgy

The invention provides a method for preparing a spinel coating and its application in preparing solid oxide fuel cells, and relates to the technical field of coating materials. The preparation method of the spinel coating is to first provide a nitrate solution, and then spray the nitrate solution on the surface of the ferritic stainless steel by means of ultrasonic atomization spraying to form a spinel oxide layer attached to the surface of the ferritic stainless steel. The nitrate solution contains the metal required for the formation of the spinel coating; repeat the above steps of spraying until a 5-50 μm thick spinel oxide film is formed on the surface of the ferritic stainless steel, and sintered to prepare a spinel oxide film. Spar coating. The above preparation method has the characteristics of simple preparation process and easy operation, and can generate a spinel coating with uniform and dense texture. At the same time, the method for preparing the spinel coating by ultrasonic atomization spraying in the present application has the advantages of low energy consumption, high material utilization rate and environmental friendliness compared with the existing spinel coating preparation method.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Stone maintenance agent

PendingCN114015302AAvoid erosionExtended service lifeAntifouling/underwater paintsPaints with biocidesAdhesivePyrrolidinones

The invention discloses a stone maintenance agent which comprises the following components in percentage by mass: 30%-45% of a maintenance agent, 5%-10% of an isolating agent, 3%-5% of an antioxidant, 5%-10% of a waterproof agent, 1%-3% of an adhesive, 3%-5% of a rust remover, 1%-3% of a preservative and the balance of oily emulsion. The stone maintenance agent provided by the invention is mainly characterized in that the preparation process is simple, the raw material cost is low, an antioxidant is adopted to form an anti-oxidation layer on the surface of stone, and polyvinylpyrrolidone and polyvinyl alcohol are matched for use, so that a formed film is flat in edge and uniform and compact in texture, and the stone maintenance agent is short in film forming time, and meanwhile, the waterproof agent is added, corrosion of water to the stone is avoided, the service life of the stone is prolonged, meanwhile, the preservative is added, breeding of bacteria can be effectively inhibited, and rusty spots on the surface of the stone are avoided.

Owner:深圳市思创力石材护理有限公司

Metal gate field effect transistor and method of making the same

ActiveCN103187298BUniform and dense textureReduce process stepsSemiconductor/solid-state device manufacturingSemiconductor devicesWork functionProcess efficiency

Provided is a metal gate field effect transistor and a manufacturing method thereof. The manufacturing method of the metal gate field effect transistor comprises the following steps: forming dummy gates by applying a gate-last approach; removing the dummy gates to form openings; sequentially forming work function metal material layers and metal barrier layers on the lateral walls and the bottoms of the openings, wherein the work function metal material layers and the metal barrier layers are not fully filled with the openings; forming through holes of contact holes above a source electrode and a drain electrode; and forming filler metal layers in an electrodeless electroplating mode, wherein the filler metal layers are filled with the openings and the through holes in the contact holes. By utilizing the electrodeless electroplating metal mode to form a last layer of metal gates and the contact holes of a source region and a drain region, metal texture of metal in the metal gates and the through holes of which a high aspect ratio is same as the contact holes is compact and even, and is free of cavities and gaps. Process steps are saved, process efficiency is improved, and process cost is saved. In the meanwhile, by selecting the metal filled in the contact holes, the metal gate field effect transistor and the manufacturing method thereof can reduce parasitic resistance of the contact holes and the drain electrode.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Vacuum lost foam casting process

The invention discloses a vacuum lost foam casting process which includes the following steps: bonding and combining foam sand to form a cavity membrane with the same size and shape with a casting part; placing deslagging sheets made of foam materials at the wall thickness position of the cavity membrane at intervals; inserting internal chill at the corresponding positions of the cavity membrane according to the hole positions on the casting part needing processing; arranging drainage sheets at the corresponding positions of the cavity membrane according to the position of a runner port; brushing fireproof coatings on the cavity membrane, drying the cavity membrane and burying the cavity membrane in quartz sand for vibration molding; performing bottom injecting type pouring under vacuum negative pressure, simultaneously filling in oxygen to lead the cavity membrane to burn and gasify, and leading liquid metal to occupy the space position of the cavity membrane; and solidifying and cooling the cavity membrane to form the casting part. The vacuum lost foam casting process enables the casting part to be compact in texture and accurate in size, and can improve rate of finished products.

Owner:湖南三星机床有限公司

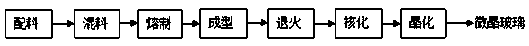

A method for preparing glass-ceramic by using yellow phosphorus slag and chromium slag

The invention discloses a method for preparing microcrystalline glass by using yellow-phosphorus slag and chromium slag and belongs to the field of resource converting of wastes. The microcrystalline glass contains the raw materials in parts by weight: 45-55 parts of yellow-phosphorus slag, 25-35 parts of chromium slag, 10-20 parts of quartz sand, 3-6 parts of reducer and 1-3 parts of fluorite and is obtained through crushing the raw materials and carrying out batching, founding, molding, annealing, nucleating and crystallizing. According to the method, the effective utilization of both the yellow-phosphorus slag and the chromium slag is achieved simultaneously, the problem, i.e., pollution to environment caused by the yellow-phosphorus slag and the chromium slag is directly eliminated, the preparation process is simple, and the product quality is stable, so that the method is applicable to large-scale industrial production.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method and application of manganese-cobalt spinel coating

PendingCN114318248AUniform and dense textureImprove conductivityVacuum evaporation coatingSputtering coatingCobalt metalFuel cells

The invention provides a preparation method and application of a manganese-cobalt spinel coating. The method comprises the following steps: placing a to-be-sprayed substrate and a manganese-cobalt target material in a vacuum oxygen-free environment, heating the manganese-cobalt target material by using a high-temperature electric arc, gasifying the manganese-cobalt target material, and filling the whole cavity with manganese-cobalt steam; keeping the sample at a low temperature such as 300 DEG C, and desublimating the manganese-cobalt steam on the surface of the to-be-sprayed substrate to form a manganese-cobalt metal pre-coating layer; and then oxidizing the to-be-sprayed substrate with the manganese-cobalt metal pre-coating on the surface in high-temperature air to obtain the manganese-cobalt spinel coating. The obtained manganese-cobalt spinel coating is uniform and compact in texture and good in electrical conductivity at the high temperature, the surface specific resistance of the coating can reach 10 m omega.cm < 2 > or below, the coating has good stability, and no obvious resistance rise exists within the range of 500 hours; the material can be widely applied to solid oxide fuel cells.

Owner:SHENHUA NEW ENERGY CO LTD +1

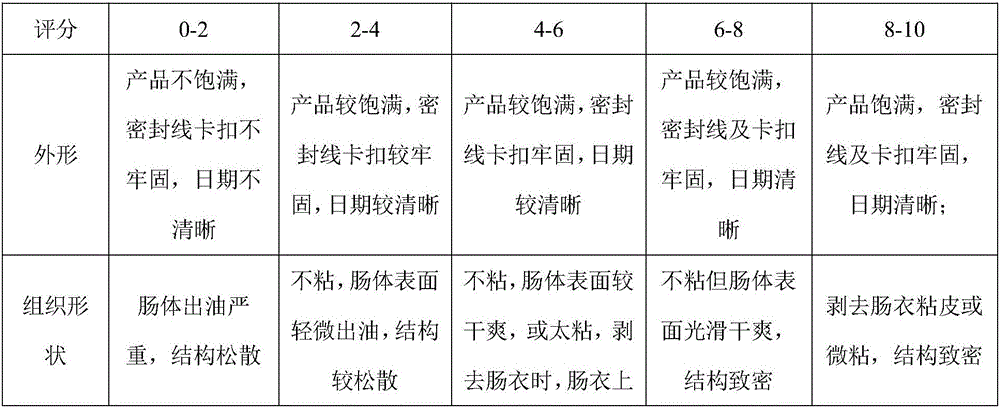

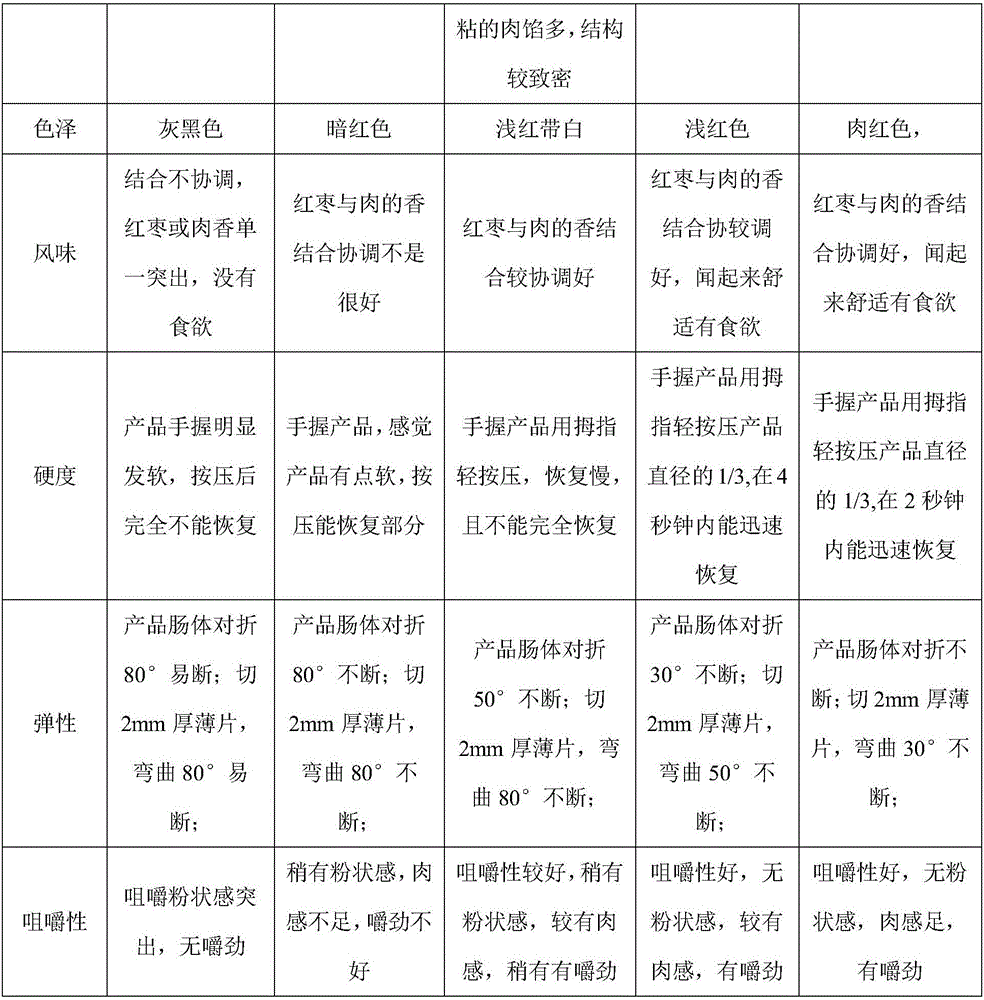

Red date sausage and production method thereof

InactiveCN106174110AIncrease added valueNutritional balanceFood ingredient as mouthfeel improving agentHealthy dietFreeze-drying

The invention relates to the technical field of food producing and processing and discloses a red date sausage and a production method thereof. The invention, based on an idea of healthy diet and thinking of matching of meat and vegetarian dishes, provides a production method of a healthy nutrition red date sausage mainly made of animal lean meat, animal fat and red date vegetable diet; a vacuum freeze drying technology is adopted, and by virtue of a low temperature freeze drying and recombination granulation technologies, the original flavour and nutrition of the red date raw material are reserved to the utmost extent; and a medium temperature gradient sterilization technology is adopted, and an application technology of an enzymic preparation in a meat product is utilized. The obtained red date sausage is balanced in nutrition, uniform and compact in texture, perfectly combines red date flavour and meat flavour, tastes elastic and crisp, tender, smooth, refreshing but not greasy in taste and strong in meat particle sense. The production method of the red date sausage is relatively low in cost and strong in operability, mass production can be easily realized, and a healthy food which is full of nutrients and high in cost performance is provided for most people while additional value of red dates is improved, so that the production method provided by the invention has good popularization and market values.

Owner:湖南唐人神肉制品有限公司

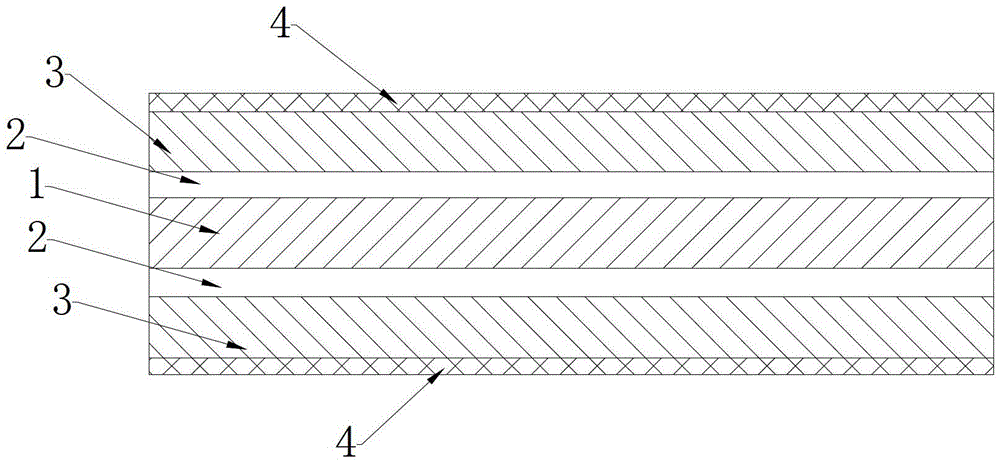

A kind of multi-layer solid electrolyte and its preparation method and lithium battery formed therefrom

ActiveCN111261934BStay flexiblePrevent intrusionSolid electrolytesLi-accumulatorsSolid state electrolyteChemical physics

The invention relates to a multilayer solid electrolyte in the technical field of new energy materials, a preparation method thereof and a lithium battery formed therefrom. The multilayer solid electrolyte includes sequentially arranged 1×10 ‑6 Lithium ion uniform deposition layer, lithium dendrite suppression layer and support layer with ion conductivity above S / cm. The uniform deposition layer of lithium ions can well protect the surface of lithium metal and induce Li + The uniform distribution of lithium dendrites; the lithium dendrite suppression layer provides mechanical support for the electrolyte as a whole, while preventing lithium dendrites from piercing the separator and inhibiting the growth of lithium dendrites; The supporting characteristics and mechanical strength are not high enough to completely prevent the problem of lithium dendrite piercing. On the other hand, it is beneficial to reduce the interface impedance. The multilayer solid electrolyte of the present invention has the advantages of high electrical conductivity, high mechanical strength, low electrolyte / positive electrode interface resistance and high temperature resistance, and can simultaneously realize the protection of lithium metal and the suppression of lithium dendrites.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

A kind of ceramic handicraft and preparation method thereof

Owner:福建省春秋陶瓷实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com