Preparation method of spinel coating and its application in preparation of solid oxide fuel cells

A technology of spinel oxide and spinel coating, which is applied in fuel cells, coatings, metal material coating processes, etc., can solve the problems of SOFC battery stack cathode performance degradation, SOFC battery stack failure, etc., and achieve material High utilization rate, easy operation, uniform and dense texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] According to one aspect of the present invention, a preparation method of spinel coating, the preparation method comprises the following steps:

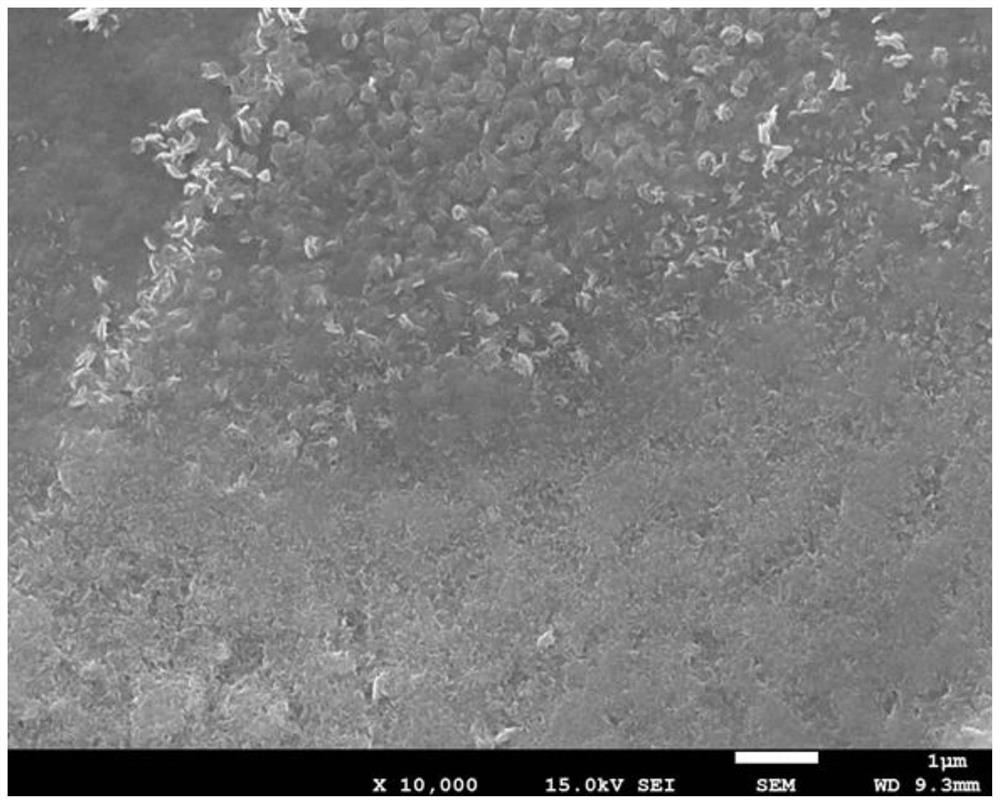

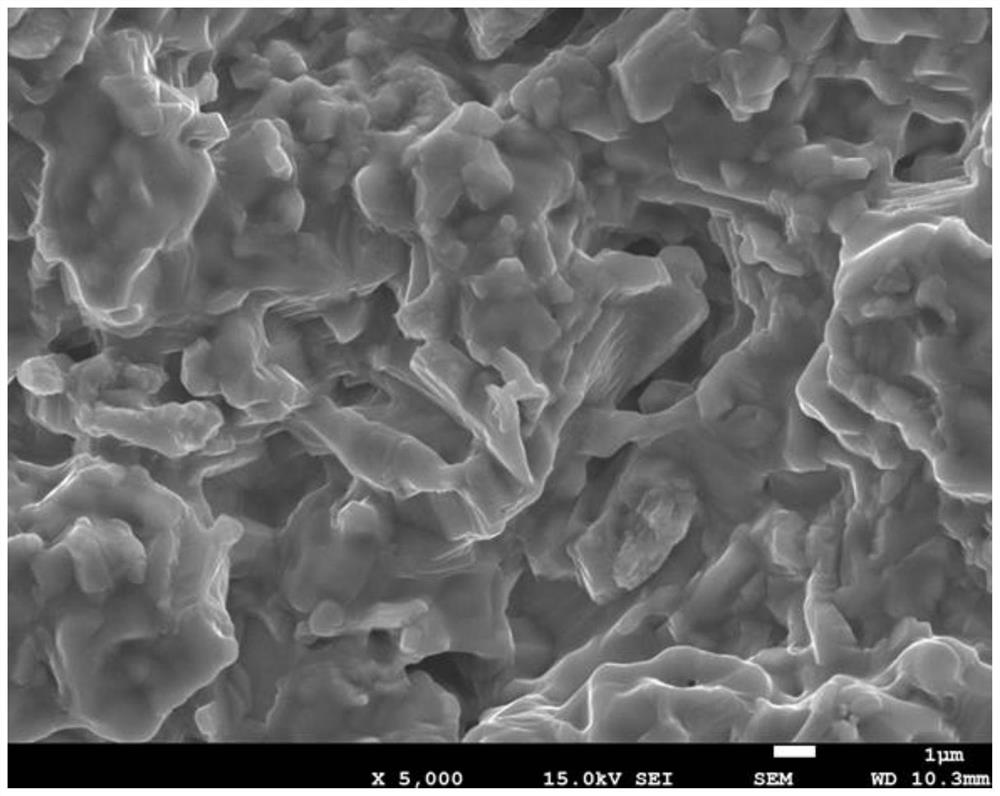

[0052] (a), provide a nitrate solution, then spray the nitrate solution on the surface of the ferritic stainless steel by means of ultrasonic atomization spraying, and then heat the ferritic stainless steel to the decomposition temperature of the nitrate solution to form an attached ferritic stainless steel Spinel oxide film on the surface;

[0053] The nitrate solution contains the metal required for the formation of the spinel coating;

[0054] (b), repeating step (a) until a spinel oxide film with a thickness of 5-50 μm is formed on the surface of the ferritic stainless steel, and sintering to prepare a spinel coating.

[0055] The preparation method of the spinel coating provided by the present invention comprises the following steps: firstly providing a nitrate solution, then spraying the nitrate solution on the surface ...

Embodiment 1

[0087] A preparation method of spinel coating, the preparation method comprises the following steps:

[0088] (1) Provide SUS430 ferritic stainless steel, use 800-mesh sandpaper to polish the stainless steel surface to a roughness of 0.9 microns on the surface of the ferritic stainless steel to remove the oxide layer on the surface and ensure that the solution can adhere to the stainless steel surface.

[0089] (2), configure copper nitrate (Cu(NO) with deionized water as solvent 3 ) 2 ) and cobalt nitrate (Co(NO) 3 ) 2 ) mixed solution, wherein the concentration range of copper nitrate is 0.1mol / L, and the concentration range of cobalt nitrate is 0.2mol / L. To ensure the copper-cobalt ratio in the final coating, the molar ratio of copper nitrate to cobalt nitrate was kept at 1:2.

[0090] (3), placing the ferritic stainless steel polished in step (1) on a hot stage, and setting the temperature of the hot stage to 270°C. At the same time, use inert gases such as nitrogen, ...

Embodiment 2

[0099] A preparation method of spinel coating, the preparation method comprises the following steps:

[0100] (1) Provide SUS430 ferritic stainless steel, use 800-grit sandpaper to polish the stainless steel surface to a roughness of 0.8 microns on the surface of the ferritic stainless steel to remove the oxide layer on the surface and ensure that the solution can adhere to the stainless steel surface.

[0101] (2), configure copper nitrate (Cu(NO) with deionized water as solvent 3 ) 2 ) and cobalt nitrate (Co(NO) 3 ) 2 ) mixed solution, wherein the concentration range of copper nitrate is 0.01mol / L, and the concentration range of cobalt nitrate is 0.02mol / L. To ensure the copper-cobalt ratio in the final coating, the molar ratio of copper nitrate to cobalt nitrate was kept at 1:2.

[0102] (3), placing the polished ferritic stainless steel in step (1) on a hot stage, and setting the temperature of the hot stage to 250°C. At the same time, use inert gas such as nitrogen, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com