A metal-based conductive circuit board and its manufacturing method

A conductive circuit and metal-based technology, which is applied in printed circuit manufacturing, printed circuit, circuit substrate materials, etc., can solve the problems of poor heat dissipation of metal-based conductive circuit boards, and achieve good heat resistance and corrosion resistance, heat dissipation Excellent performance and strong combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

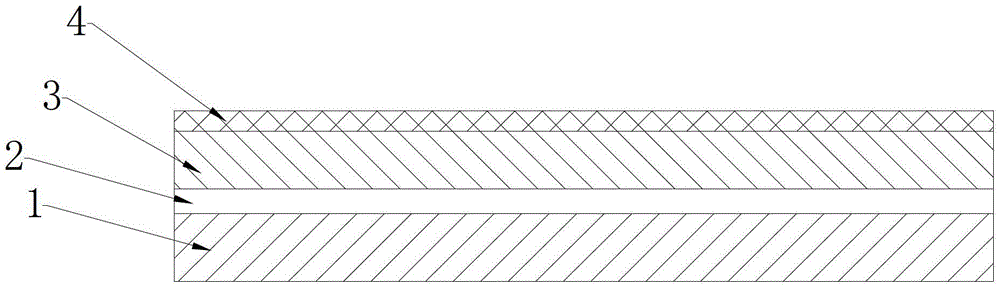

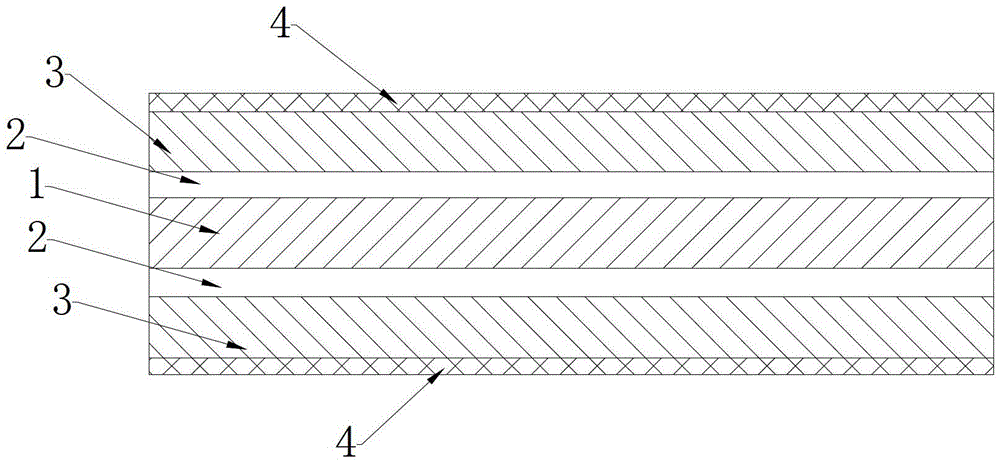

[0026] Such as figure 1 and figure 2 As shown, a metal-based conductive circuit board includes a bottom layer 1, an insulating layer 2 and a conductive layer 3, and the material of the bottom layer 1 is metal; an insulating layer 2 is arranged on the bottom layer 1, and the insulating layer 2 The material is silicon oxide; a conductive layer 3 is provided on the insulating layer 2 .

[0027] The metal-based conductive circuit board in this embodiment is manufactured by the following method:

[0028] Firstly, take the aluminum bottom layer 1 and polish it, then use a surfactant solution and water to clean the surface of the bottom layer 1 respectively, remove stains, dust, etc. on the surface of the bottom layer 1, and make the bottom layer 1 smooth and flat.

[0029] Next, silicon oxide particles with an average particle size of 250 μm are used to form a silicon oxide film on the bottom layer 1 by vacuum evaporation, and then sintered at 1200° C. for 1 hour to vitrify the ...

Embodiment 2

[0035] Such as figure 1 and figure 2 As shown, a metal-based conductive circuit board includes a bottom layer 1, an insulating layer 2 and a conductive layer 3, and the material of the bottom layer 1 is metal; an insulating layer 2 is arranged on the bottom layer 1, and the insulating layer 2 The material is silicon oxide; a conductive layer 3 is provided on the insulating layer 2 .

[0036] The metal-based conductive circuit board in this embodiment is manufactured by the following method:

[0037] Firstly, take the aluminum bottom layer 1 and polish it, then use a surfactant solution and water to clean the surface of the bottom layer 1 respectively, remove stains, dust, etc. on the surface of the bottom layer 1, and make the bottom layer 1 smooth and flat.

[0038] Next, a silicon oxide film is formed on the bottom layer 1 by vacuum spraying, and then sintered to obtain an aluminum plate 1 with a silicon oxide insulating layer 2 .

[0039] Next, the conductive layer 3 i...

Embodiment 3

[0044] Manufacturing steps of a metal-based conductive circuit board:

[0045] Firstly, take the aluminum bottom layer 1 and polish it, then use a surfactant solution and water to clean the surface of the bottom layer 1 respectively, remove stains, dust, etc. on the surface of the bottom layer 1, and make the bottom layer smooth and flat.

[0046] Next, take a sodium silicate solution (concentration is 0.25mol / L), adjust the pH to 4-8 with acid, and stir to obtain a sol; put the bottom layer 1 obtained above in the sol, and pull it out after immersing for 6 hours. Drying; heat treatment at 500°C for 4 hours.

[0047] Next, the conductive circuit layer 3 is directly fabricated on the aluminum plate 1 with the silicon oxide insulating layer by means of sputtering or vapor deposition. In this embodiment, silver is used as the material of the conductive layer 3 .

[0048] Finally, it is enough to form the solder resist layer 4 on the conductive layer 3, and white oil is selected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com