Low-temperature preparation method of lubricating/conducting dual-function NbSe2 thin film

A dual-function, thin-film technology, applied in the direction of ion implantation plating, metal material coating process, coating, etc., can solve the problems that cannot meet the needs of industrial applications, low material deposition rate, high preparation temperature requirements, etc., to achieve excellent lubrication/ Conductive dual function, dense and uniform structure, good bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

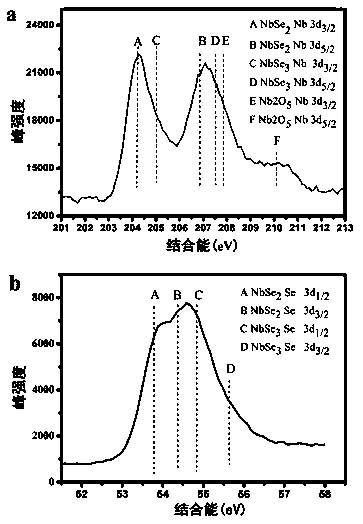

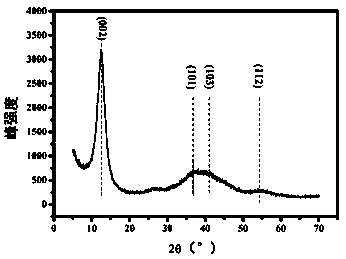

Method used

Image

Examples

Embodiment 1

[0034] NbSe 2 The target material and the Ti target material were respectively installed on the corresponding target positions of the radio frequency magnetron sputtering coating chamber; single crystal silicon, soda lime glass or steel was used as the substrate, and ultrasonically cleaned in absolute ethanol and acetone reagent solutions for 15 min respectively, After natural drying, it is placed on the rotating workpiece plate in the chamber. During the entire sputtering coating process, the rotating speed of the rotating workpiece disk was kept at 1.0 r / min. The substrate temperature is at room temperature; turn on the vacuum system and evacuate to 7×10 -4 Pa, argon gas was introduced, under the conditions of pressure of 1.5 Pa, duty cycle of 80%, and pulse bias of -600 V, the substrate was cleaned by plasma sputtering for 15 min to remove the oxide layer on the surface of the substrate and impurities; then, Ti transition layer deposition. Introduce argon gas, use a DC ...

Embodiment 2

[0037] The target material and installation process are the same as in Example 1; the substrate surface is cleaned, the plasma sputtering cleaning process and the rotation speed of the rotating workpiece disk are the same as in Example 1; then, the Ti transition layer is deposited. Introduce argon gas, use a DC power supply, and deposit a Ti transition layer for 4 min under the conditions of a pressure of 0.8 Pa, a pulse bias of -50 V, and a Ti target current of 0.3 A. The thickness of the Ti transition layer is about 30 nm; , for NbSe 2 thin film deposition. Turn off the DC power supply and turn on the RF power supply at the same time, when the RF power density is 0.068 W / mm 2 , the working pressure is 0.5 Pa, the initial temperature is 28 ℃, the substrate bias is -150 V, and the duty cycle is 80%, the deposition of NbSe 2 film for 1.8 h; finally, after the deposition, the chamber temperature was 40°C, and the film was naturally cooled to room temperature.

[0038] image...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com