Preparation method of manganese-cobalt spinel coating and application of preparation method

A spinel coating, manganese-cobalt technology, applied in coating, metal material coating process, heating inorganic powder coating, etc., can solve the problems of low activity, poor conductivity, increase battery internal resistance, etc., and achieve the preparation process Simple, even and dense texture, economical results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] According to one aspect of the present invention, a kind of preparation method of manganese-cobalt spinel coating, described preparation method comprises the following steps:

[0049] (a), providing manganese-cobalt mixed powder, then mixing the manganese-cobalt mixed powder with the solution to obtain a mixed slurry;

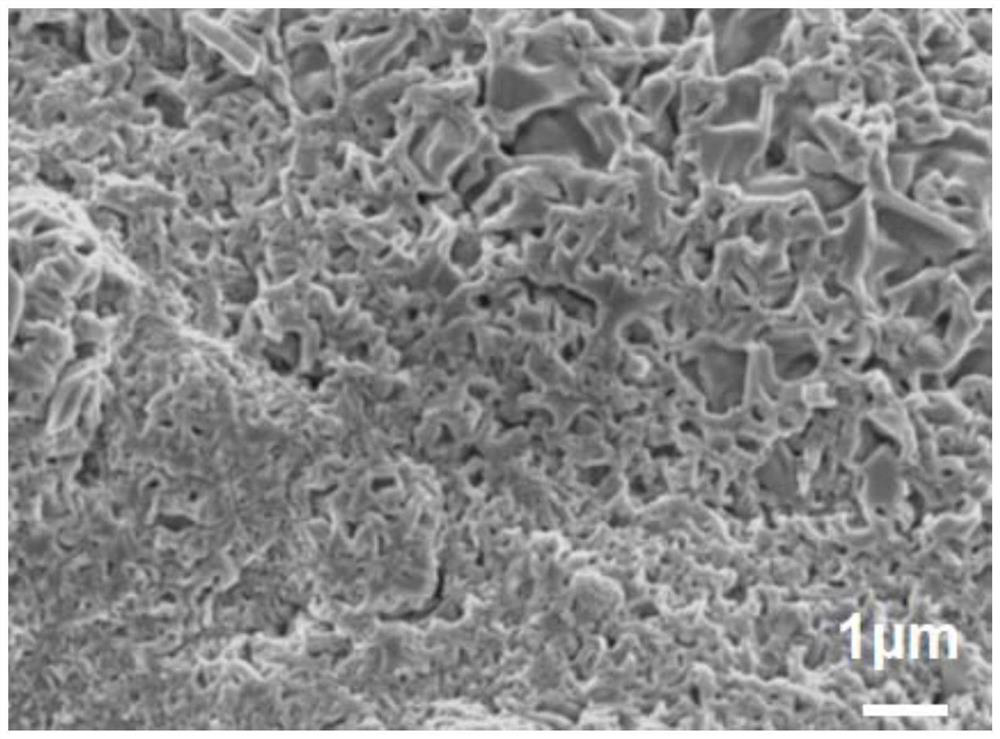

[0050] (b), the mixed slurry is coated on the surface of the ferritic stainless steel connecting body, dried, and an intermediate coating A is obtained on the surface of the ferritic stainless steel connecting body;

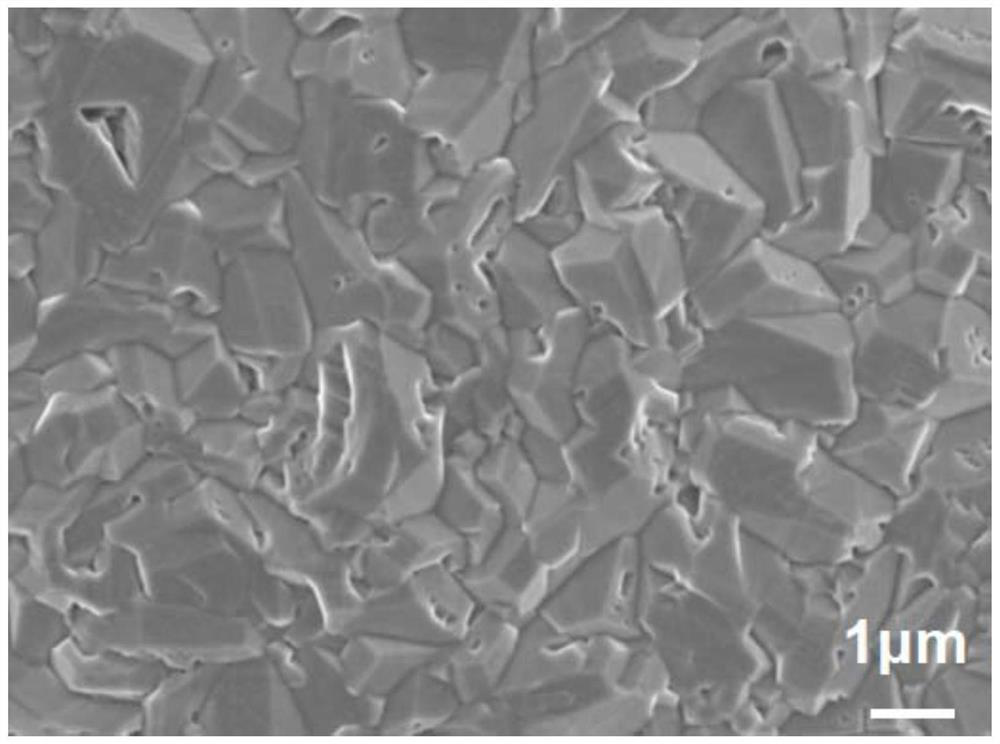

[0051] (c) Sintering the ferritic stainless steel connection body with the intermediate coating A on the surface in a reducing atmosphere, and then passing air into it to oxidize at a high temperature to obtain a manganese-cobalt spinel coating.

[0052] The preparation method of the manganese-cobalt spinel coating provided by the present invention, the preparation method first mixes the manganese-cobalt mixed powder with the solution to ob...

Embodiment 1

[0107] A kind of preparation method of manganese-cobalt spinel coating, described preparation method comprises the following steps:

[0108] (1) Cut a flat ferritic stainless steel plate of appropriate size as a connecting body, and use 240, 800, and 2000 mesh sandpaper to polish and polish the front and back sides of the steel plate on a polishing machine until the surface roughness of the steel plate is <0.3 μm; Subsequently, the polished steel plates were ultrasonically cleaned in deionized water and absolute ethanol for 10 min to remove surface impurities and left to dry to obtain ferritic stainless steel joints;

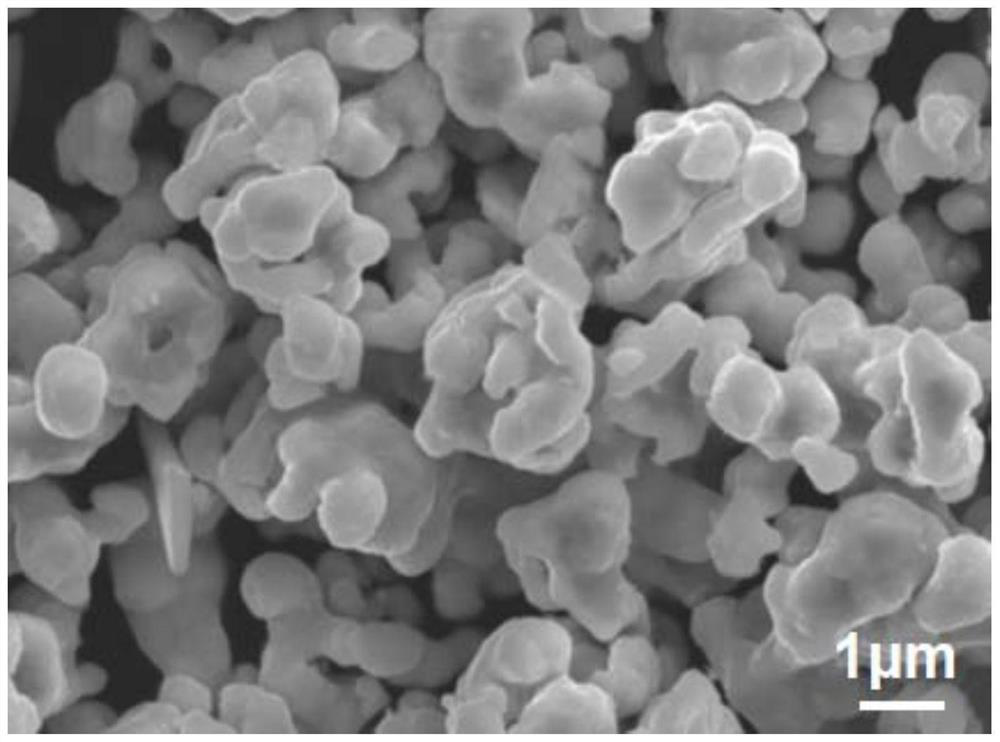

[0109] (2), mix manganese powder and cobalt powder with a mass ratio of 1.5:1.5, then add 2 times the mass of mixed powder in ethanol and mix to obtain a manganese-cobalt suspension; then mix the manganese-cobalt suspension in a ball mill Ball mill at a rate of not less than 180 rpm for more than 24 hours to prepare a suspension of manganese-cobalt powder that i...

Embodiment 2

[0119] A kind of preparation method of manganese-cobalt spinel coating, described preparation method comprises the following steps:

[0120] (1), with embodiment 1;

[0121] (2), mix manganese powder and cobalt powder with a mass ratio of 1.5:1.5, then add 2 times the mass of mixed powder in ethanol and mix to obtain a manganese-cobalt suspension; then mix the manganese-cobalt suspension in a ball mill Ball mill at a rate of not less than 100 rpm for more than 10 hours to prepare a uniformly mixed suspension of manganese-cobalt powder with a particle size of less than 2 microns. After the ball milling is completed, take out the suspension and place it at 40°C for 48 Hours of evaporation to remove the ethanol in the suspension to obtain dried and mixed manganese-cobalt mixed powder;

[0122] (3) Compound ethyl cellulose and terpineol at a mass ratio of 2:98 to obtain solution A; then mix the manganese-cobalt mixed powder in step (2) with solution A at a mass ratio of 1:1 , to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com