LED packaging conductive polyamide hot melt adhesive and preparation method thereof

A polyamide hot-melt adhesive and LED packaging technology, which is applied in the directions of adhesives, adhesive additives, non-polymer adhesive additives, etc. and other problems, to achieve the effect of reducing surface dust adsorption, improving adhesion and stable electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a conductive polyamide hot-melt adhesive for LED packaging and a preparation method thereof. The hot-melt adhesive components include by weight: 75 parts of unsaturated fatty acid dimer, 19 parts of ethylenediamine, 18 parts of hexamethylenediamine, 16 parts of sebacic acid, 6 parts of dimethyl silicone oil, 1 part of alkyl modified organosiloxane, 7 parts of waterproof filler, 8 parts of conductive agent, 3 parts of tackifier, 2 parts of viscosity regulator, 2 parts of anti-aging agent 4 parts, 4 parts of transparent agent and 2 parts of fluorescent powder;

[0025] Described waterproof filler is made up of silicon micropowder and sodium bentonite, and the ratio of described silicon micropowder and sodium bentonite is set to 2:1;

[0026] Further, the tackifier is set to hydrophobic water-soluble polyelectrolyte, and the viscosity modifier is set to cyclohexanol;

[0027] Further, the conductive agent is set to conductive mica powder, and the an...

Embodiment 2

[0038] The invention provides a conductive polyamide hot-melt adhesive for LED packaging and a preparation method thereof. The hot-melt adhesive components include by weight: 76 parts of unsaturated fatty acid dimer, 20 parts of ethylenediamine, 19 parts of hexamethylenediamine, 17 parts of sebacic acid, 7 parts of dimethyl silicone oil, 1.5 parts of alkyl modified organosiloxane, 8 parts of waterproof filler, 9 parts of conductive agent, 4 parts of tackifier, 3 parts of viscosity regulator, 3 parts of anti-aging agent 5 parts, 5 parts of transparent agent and 3 parts of fluorescent powder;

[0039] Described waterproof filler is made up of silicon micropowder and sodium bentonite, and the ratio of described silicon micropowder and sodium bentonite is set to 3:1;

[0040] Further, the tackifier is set to hydrophobic water-soluble polyelectrolyte, and the viscosity modifier is set to cyclohexanol;

[0041] Further, the conductive agent is set to conductive mica powder, and the...

Embodiment 3

[0052] The invention provides a conductive polyamide hot-melt adhesive for LED packaging and a preparation method thereof. The hot-melt adhesive components include by weight: 77 parts of unsaturated fatty acid dimer, 21 parts of ethylenediamine, 20 parts of hexamethylenediamine, 18 parts of sebacic acid, 8 parts of dimethyl silicone oil, 1.5 parts of alkyl modified organosiloxane, 9 parts of waterproof filler, 9 parts of conductive agent, 4 parts of tackifier, 4 parts of viscosity regulator, 3 parts of anti-aging agent 5 parts, 5 parts of transparent agent and 4 parts of fluorescent powder;

[0053] Described waterproof filler is made up of silicon micropowder and sodium bentonite, and the ratio of described silicon micropowder and sodium bentonite is set to 4:1;

[0054] Further, the tackifier is set to hydrophobic water-soluble polyelectrolyte, and the viscosity modifier is set to cyclohexanol;

[0055] Further, the conductive agent is set to conductive mica powder, and the...

PUM

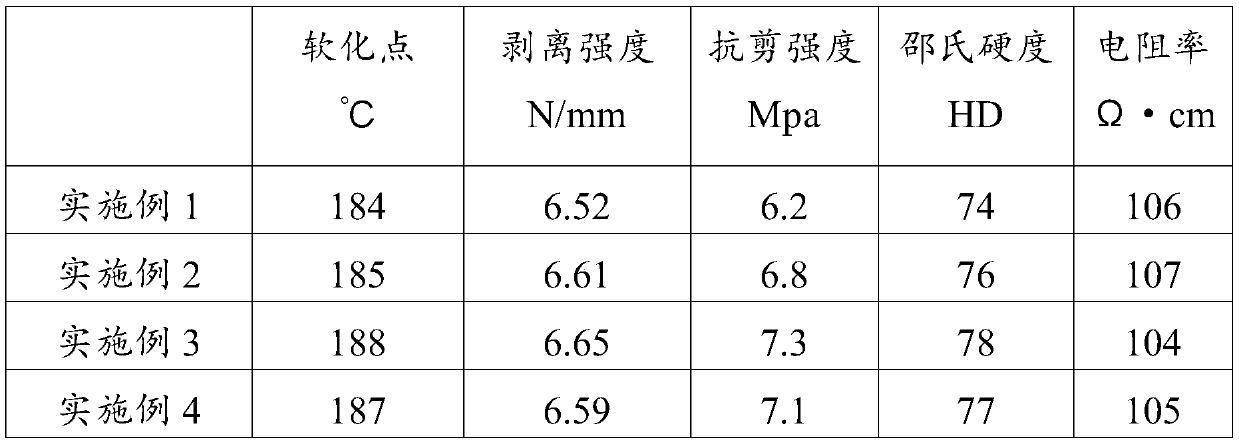

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com