Granulation device for production of high-filling wood-plastic composite material

A technology of wood-plastic composite materials and granulation equipment, which is applied in the direction of coating, etc., can solve problems such as affecting quality, long residence time, and wood powder is not resistant to temperature, so as to improve production efficiency, reduce moisture content, and reduce moisture content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

[0024] Example.

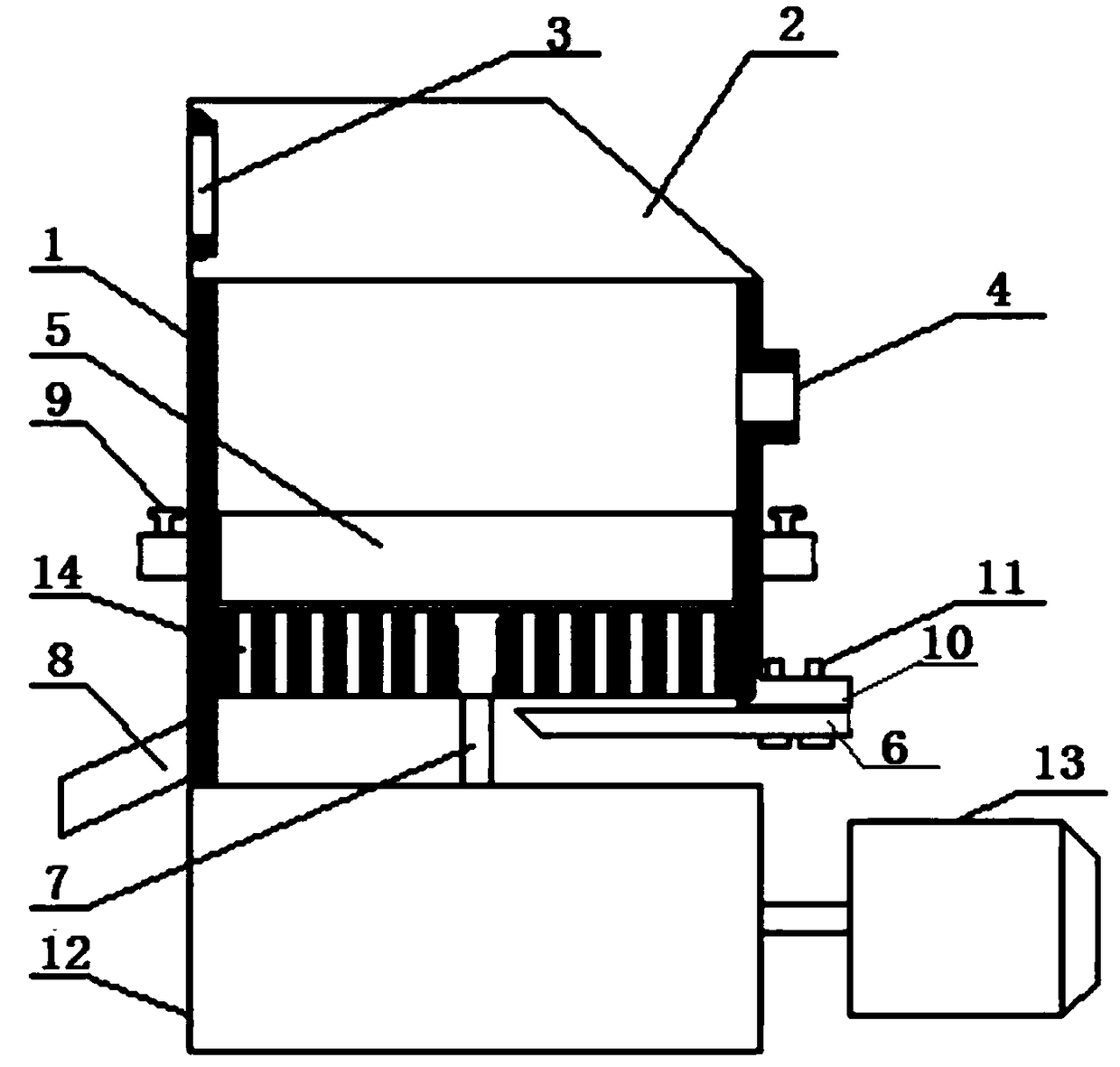

[0025] A kind of granulation device for the production of highly filled wood-plastic composite material of the present embodiment, such as figure 1 As shown, there is a barrel body 1, one end of the barrel body 1 is sealed with a sealing cover 2, and there is a head interface 3 on the sealing cover, and the head of the parallel twin-screw extruder is connected in the head interface 3 , the composite material is discharged to the barrel 1 through the nozzle interface 3 after high-temperature mixing in the co-rotating parallel twin-screw extruder, and the vacuum interface 4 draws away the moisture of the composite material, and the other end of the barrel 1 is provided with a porous plate, The hole of perforated plate 14 is through plate surface, and perforated plate 14 is connected with rotating shaft 7, and one side of perforat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com