Rice cake processing device simulating mortar beating and turning actions

A processing device and action technology, which is applied in food forming, food science, application, etc., can solve the problems of bruising, time-consuming and laborious, and insufficient coordination, and achieve the effect of uniform and tight texture, uniform texture, and better taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

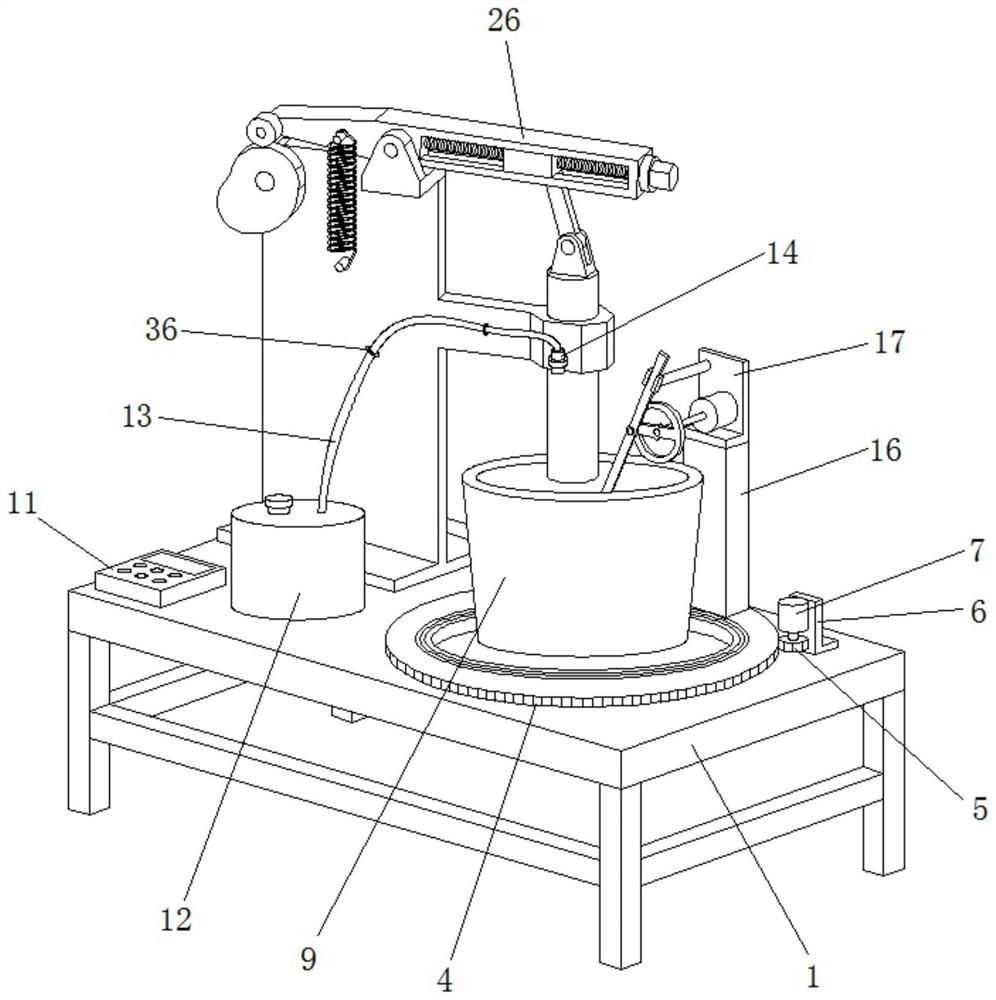

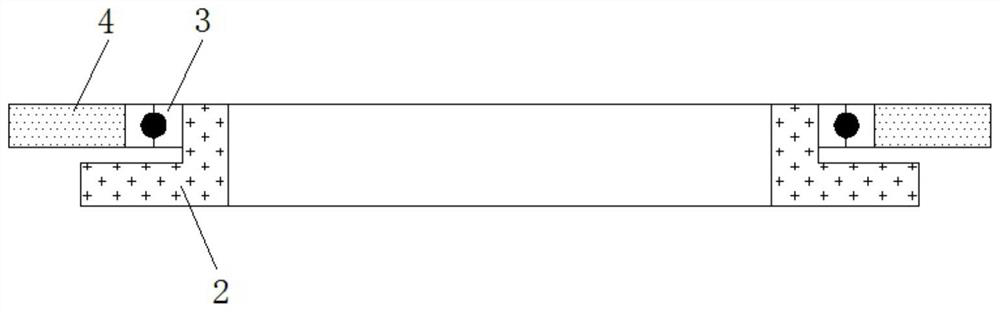

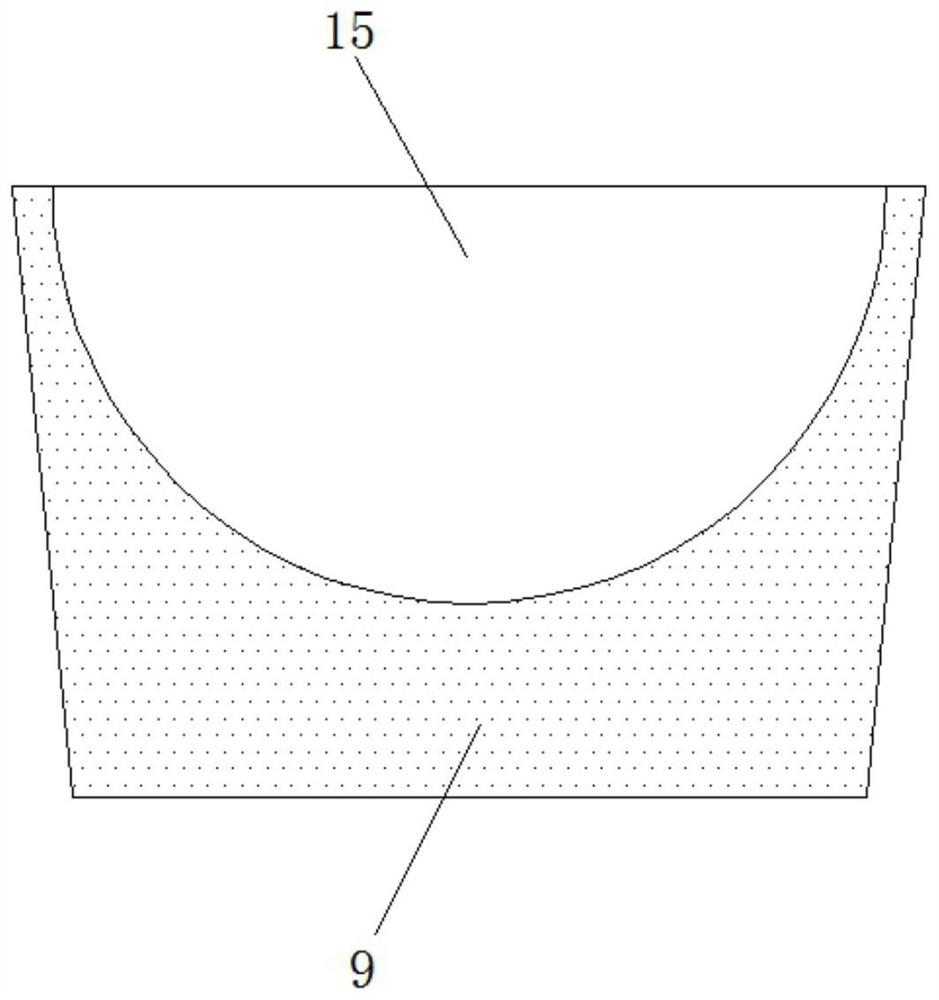

[0029] see Figure 1-2 A rice cake processing device for simulating mortar beating and flipping actions, comprising a base 1, a flange 2 is fixedly mounted on one end of the upper surface of the base 1, and a bearing 3 is fixedly sleeved on the outer surface of the upper end of the flange 2 The outer side of the bearing 3 is fixedly sleeved with a gear ring 4, and the outer side of the gear ring is meshed with a driving gear 5, and the driving gear 5 is mounted on the base 1 through the first L-shaped mounting plate 6. Driven by a servo motor 7, one end of the upper surface of the gear ring 4 is fixedly equipped with a toggle mechanism 8, and the middle position of the flange 2 is provided with a pounding bowl 9 installed on the upper surface of the base 1, and the upper surface of the base 1 The other end of the surface is fixedly equipped with a tampering mechanism 10, one side of the tampering mechanism 10 is fixedly equipped with a control switch 11 and a water tank 12, an...

Embodiment example 2

[0033] see Figure 4 , the toggle mechanism 8 includes a support rod 16 vertically fixedly installed on the gear ring 4, the top of the support rod 16 is fixedly installed with a second L-shaped mounting plate 17, the second L-shaped mounting plate 17 The outer lower end is fixedly installed with a second servo motor 18 perpendicular to the direction of the second L-shaped mounting plate 17. The output shaft of the second servo motor 18 is equipped with a turntable 19, and one end of the outer surface of the turntable 19 is rotated. Rod 20, the outer surface of the upper end of the connecting rod 20 is slidingly sleeved with a chute 21, and the chute 21 is rotatably arranged on the connecting column 22 installed on the outer upper end of the second L-shaped mounting plate 17. The connecting rod 20 The bottom end is provided with a scraper 23.

[0034]The second servo motor 18 of the toggle mechanism 8 drives the turntable 19 to rotate, thereby driving the scraper 23 at the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com