Fabricated fast wall (inner partition wall) structure and installation method

A prefabricated and internal partition wall technology, applied in the direction of walls, building components, building structures, etc., can solve problems such as the inability to realize 100% dry construction methods, the pollution of the environment by waste solids, and the difficulty in solving common quality problems. The effect of avoiding surface cracking, rich and varied textures, and reliable connection methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

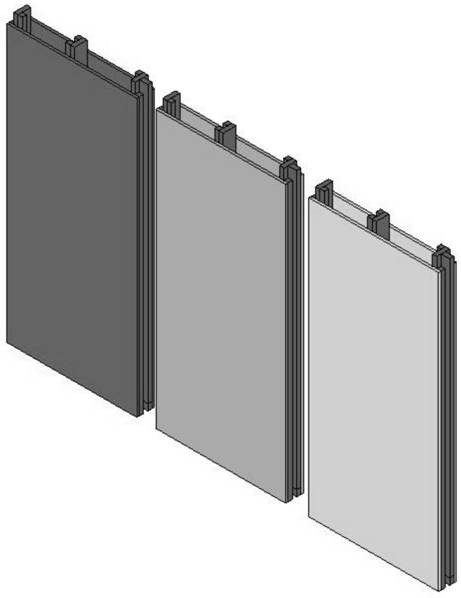

[0021] 1. Take the glass magnesium board, calcium silicate board or fiber cement board purchased on the market that meets the requirements of Class A fire protection. The commonly used large board is 1220×2440. into 608×2440 dimensions. The thickness of the plate can be customized according to the needs. In this case, a 12mm thick plate is used.

[0022] 2. Put the above panels into the coating production line or veneer production line to produce the decorative surface, and then get the originally set high-quality hardcover panel after going off the production line.

[0023] 3. Use a thicker blank plate. In this case, use a 20mm thick plate and cut it into three pieces of 60×20×2440mm; eight pieces of 20×20×2440mm for use as keels.

[0024] 4. On the back of the hardcover panel, press the Figure 7 In the position shown, use carpentry gun nails or glue to nail the two together, and the connection is reliable to form a whole.

[0025] 5. attach Figure 7 The right side pane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com