Production process of colar glaze guartz paint

A manufacturing method and color glaze technology, applied in the direction of coating, etc., can solve the problems of not meeting the requirements of market diversity, single performance of imitation stone coating, and affecting popularization and application, and achieve bright colors, simple process methods, and reduced production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

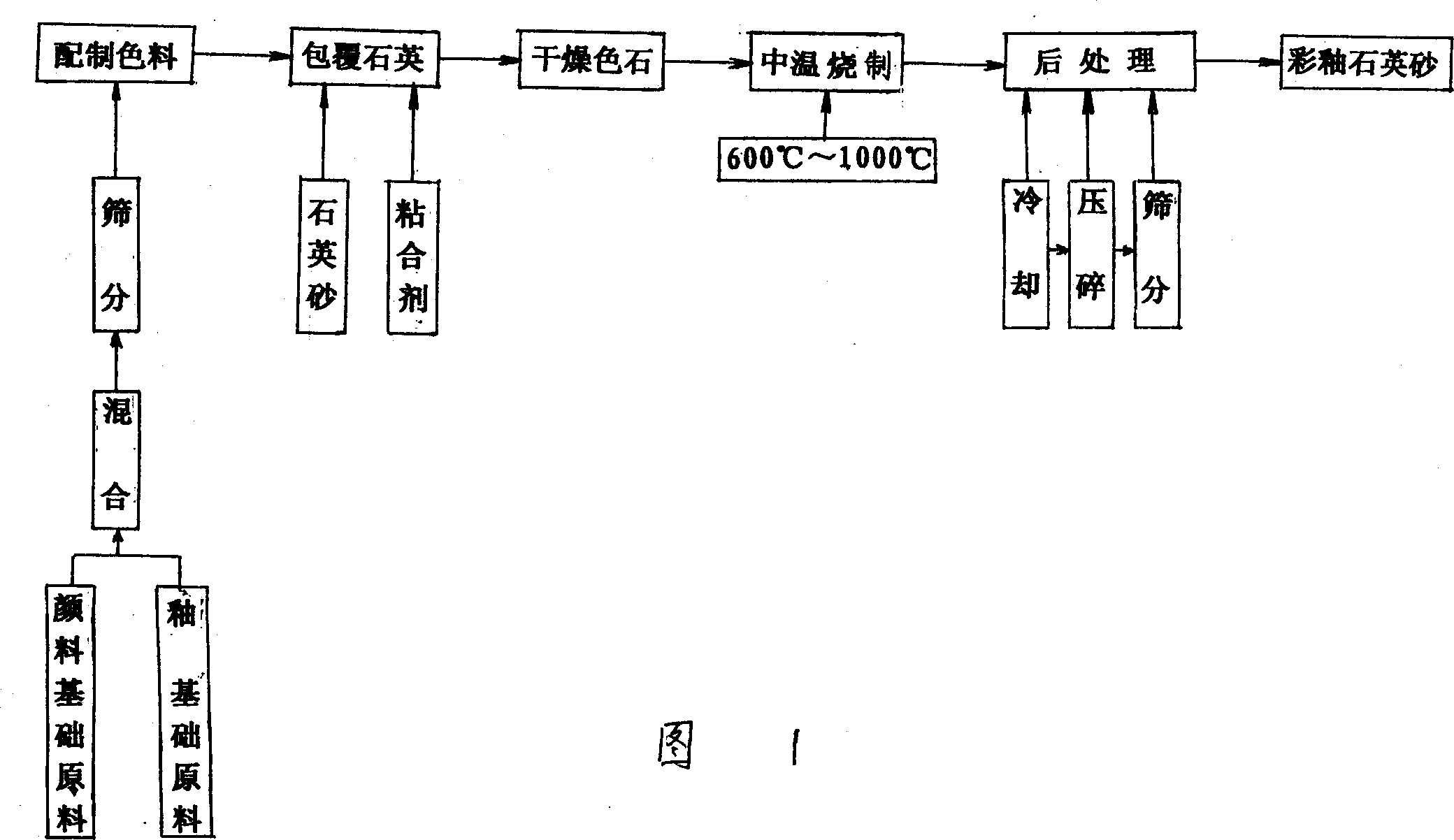

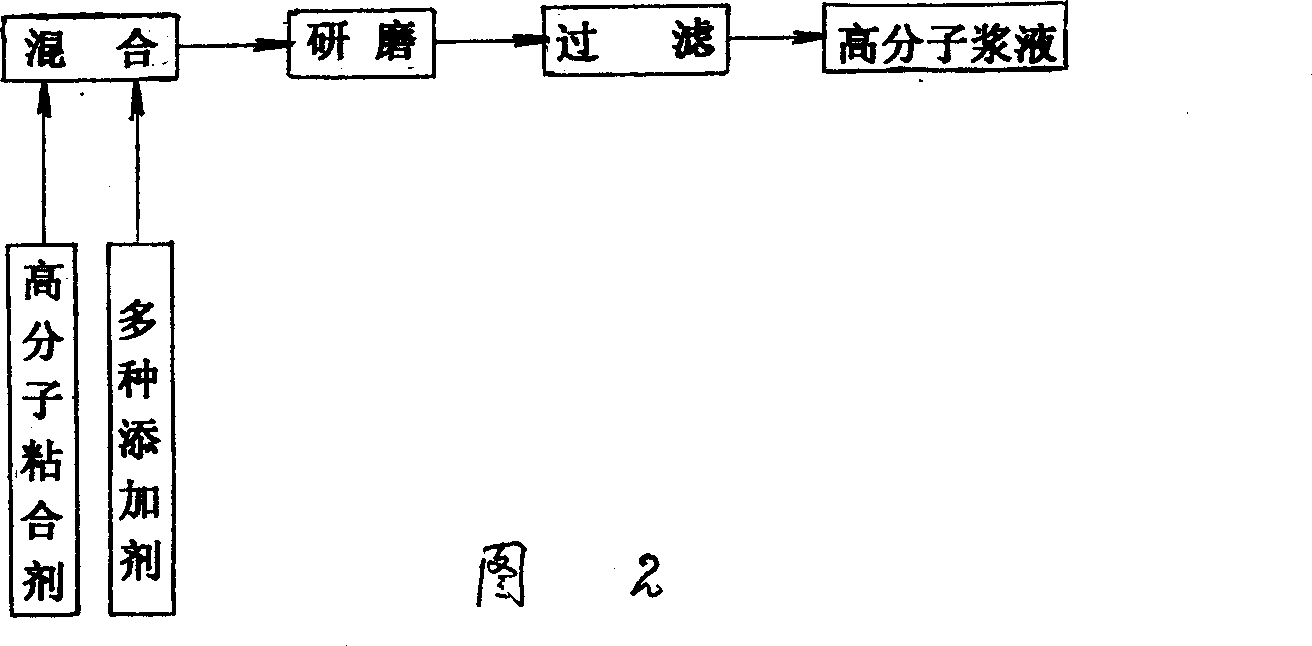

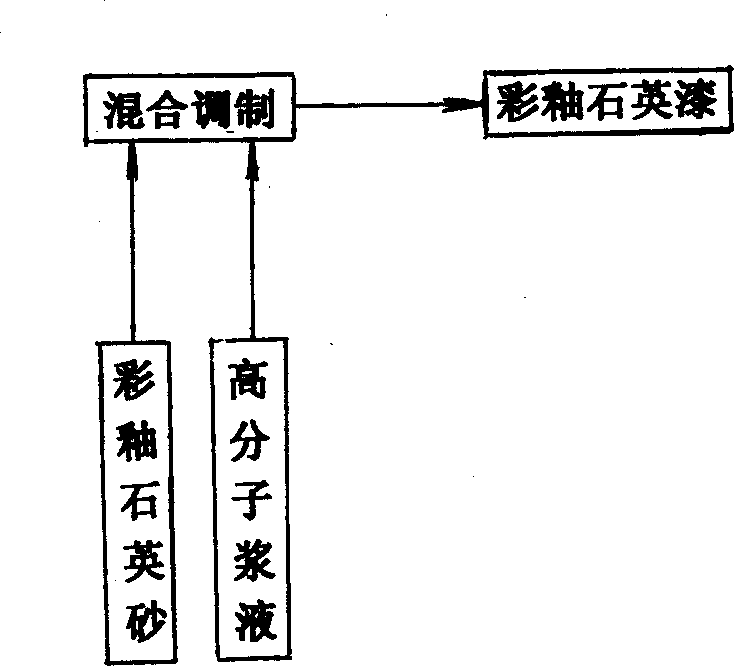

Method used

Image

Examples

Embodiment 2

[0019] Boric acid 8-2% Silica 25-3% The raw materials for producing glazes in the composition of pigments are: red lead, boric acid, silicon dioxide, and the rest are raw materials for producing pigments. Preheat the quartz sand first, weigh, grind, mix and sieve the various components in the color material according to the proportion. In the case of uniform stirring, first add the adhesive to the preheated quartz sand and stir evenly, then add the color material, stir evenly, so that the surface of the quartz sand particles is covered with a layer of color material, and dry. Then send the quartz sand wrapped with pigment into an electric furnace, and burn it in an oxidizing atmosphere at a furnace temperature of 600°C to 1000°C, then cool, crush, and sieve to obtain golden colored glazed quartz sand. Embodiment 2 Formula of sky blue colored glaze quartz sand: quartz sand (18~140 mesh) 60~95%

[0020] Pigment (>325 mesh) 5-40% of which the pigment is composed of...

Embodiment 3

[0022] Aluminum oxide 15-30% Cobalt trioxide 15-0.2% The raw materials for producing glazes in the composition of pigments are: red lead, boric acid, silicon dioxide, and the rest are raw materials for producing pigments. Carry out the operation as described in Example 1 and calcinate at 1000°C to obtain sky blue glazed quartz sand with uniform and bright color. Example 3 Formula of yellow colored glaze quartz sand: quartz sand (18-140 mesh) 55-95%

[0023] Pigment (>325 mesh) 5-45% of which the composition of the pigment is: ferric oxide 1.5-12% zinc oxide 0.5-5%

[0024] Potassium nitrate 10-1% lead red 20-49%

[0025] Antimony trioxide 8~20% Boric acid 35~10%

[0026] Silicon dioxide 25-3% Iron sulfate 0-7% The raw materials for producing glazes in the composition of pigments are: red lead, boric acid, silicon dioxide, and the rest are raw materials for producing pigments. Operate as described in Example 1, fire below 900°C...

Embodiment 4

[0026] Silicon dioxide 25-3% Iron sulfate 0-7% The raw materials for producing glazes in the composition of pigments are: red lead, boric acid, silicon dioxide, and the rest are raw materials for producing pigments. Operate as described in Example 1, fire below 900°C, and obtain ivory-yellow glazed quartz sand after cooling. Example 4 Orange-red colored glaze quartz sand formula: quartz sand (18-140 mesh) 65-95%

[0027] Pigment (>325 mesh) 5-35% of which the pigment is composed of: calcium carbonate 0.5-8% potassium carbonate 1-11%

[0028] Cadmium carbonate 5-25% Boric acid 3-10%

[0029] Red lead 15-25% Zinc oxide 0.1-5%

[0030] Silicon dioxide 20-30% Lead oxide 0.5-10%

[0031] Borax 3-10% Selenium 0.1-2%

[0032] The raw materials for producing glazes in the composition of sulfur 2-12% pigments are: zinc oxide, red lead, boric acid, silicon dioxide, borax, lead oxide, potassium carbonate, calci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com